Emptying system for high dam

A venting system and high dam technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of inability to realize deep water retaining and venting, increase in the amount of gate wells, and large gap between gate wells, etc. Quantity and investment, low engineering investment cost, and the effect of eliminating water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

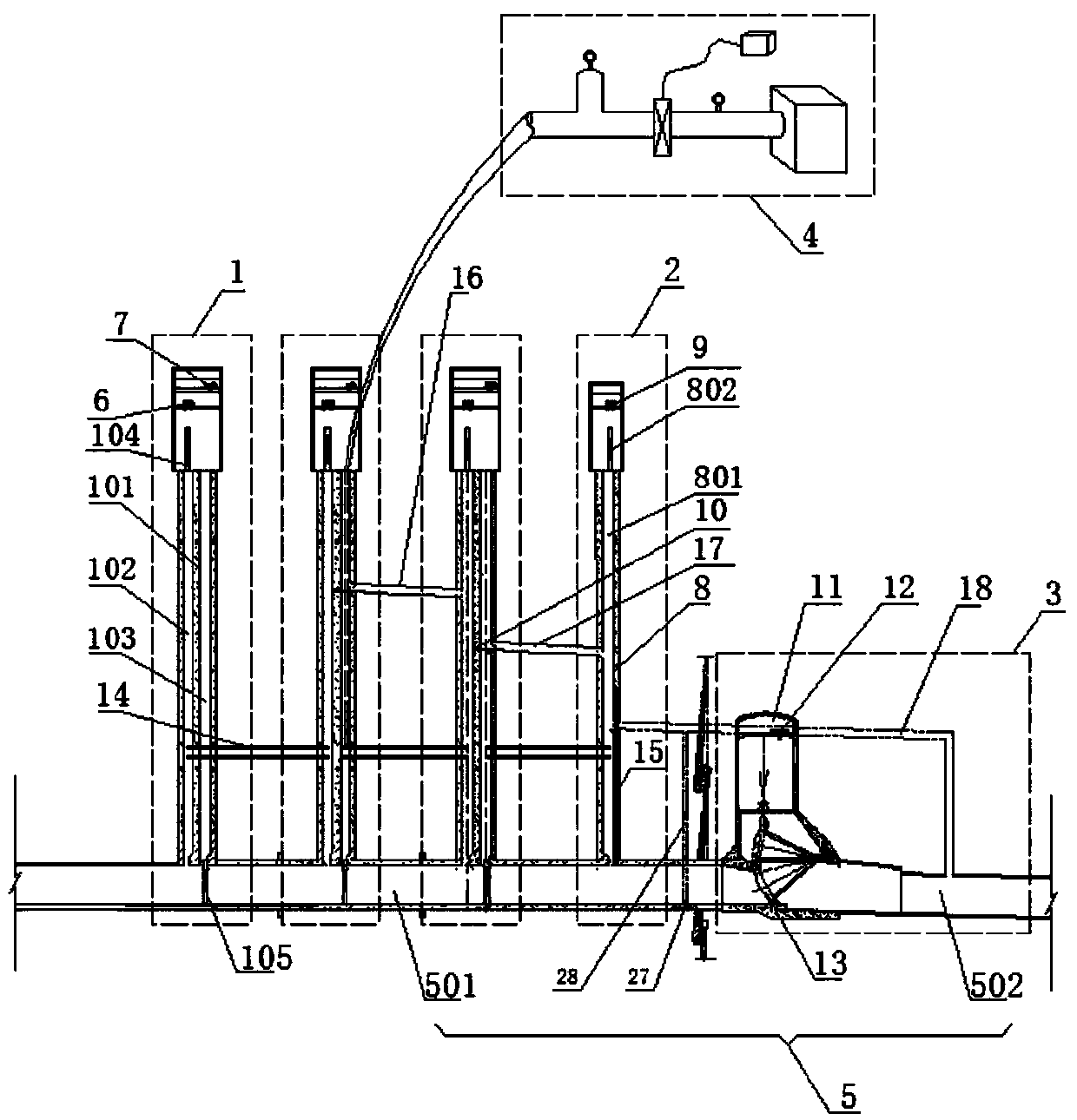

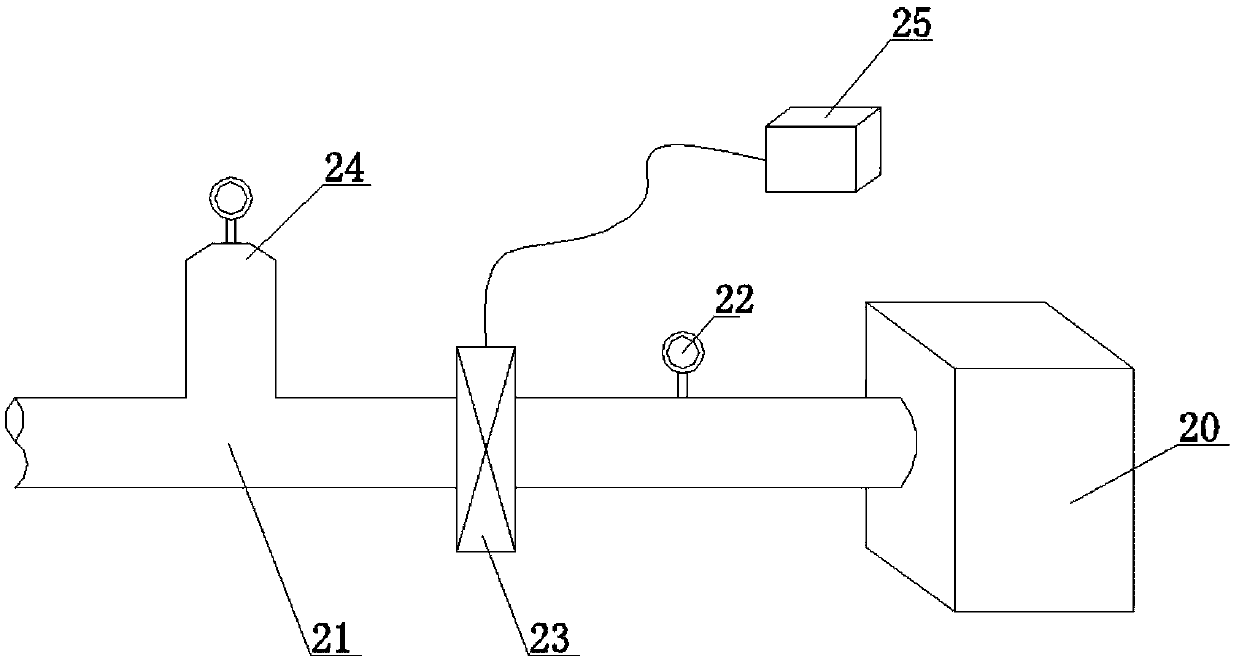

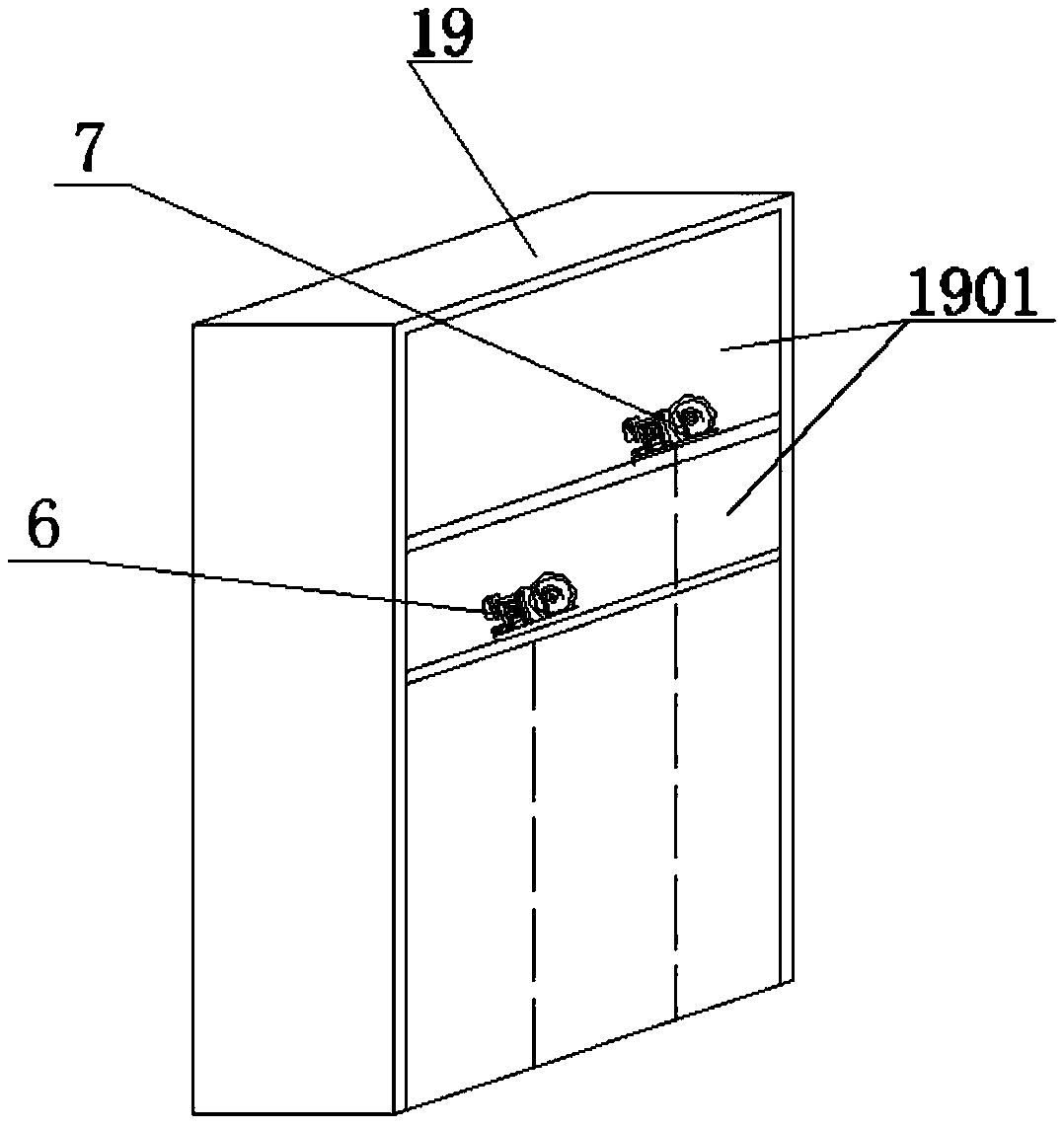

[0032] The invention provides a high dam emptying system, such as figure 1 , figure 2 , image 3 As shown, a tunnel 5 and a water replenishment unit 4 are included, and along the water flow direction inside the tunnel 5, a plurality of primary gate devices 1, at least one secondary gate device 2 and at least one emptying gate are arranged in sequence on the tunnel 5 at appropriate intervals Device 3, the tunnel 5 upstream of the emptying gate device 3 is a pressurized section 501, and the tunnel 5 downstream of the emptying gate device 3 is a non-pressure section 502. The primary gate device 1 includes a primary gate body 101, which flows along the direction of water flow in the tunnel 5 In the primary gate body 101, an inspection gate shaft 102 and a working gate shaft 103 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com