Three-stroke inner-cooling rotor engine

A rotary engine, three-stroke technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of high engine fuel consumption, gas leakage, insufficient combustion, etc., to improve thermal efficiency, reliability and durability , the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings.

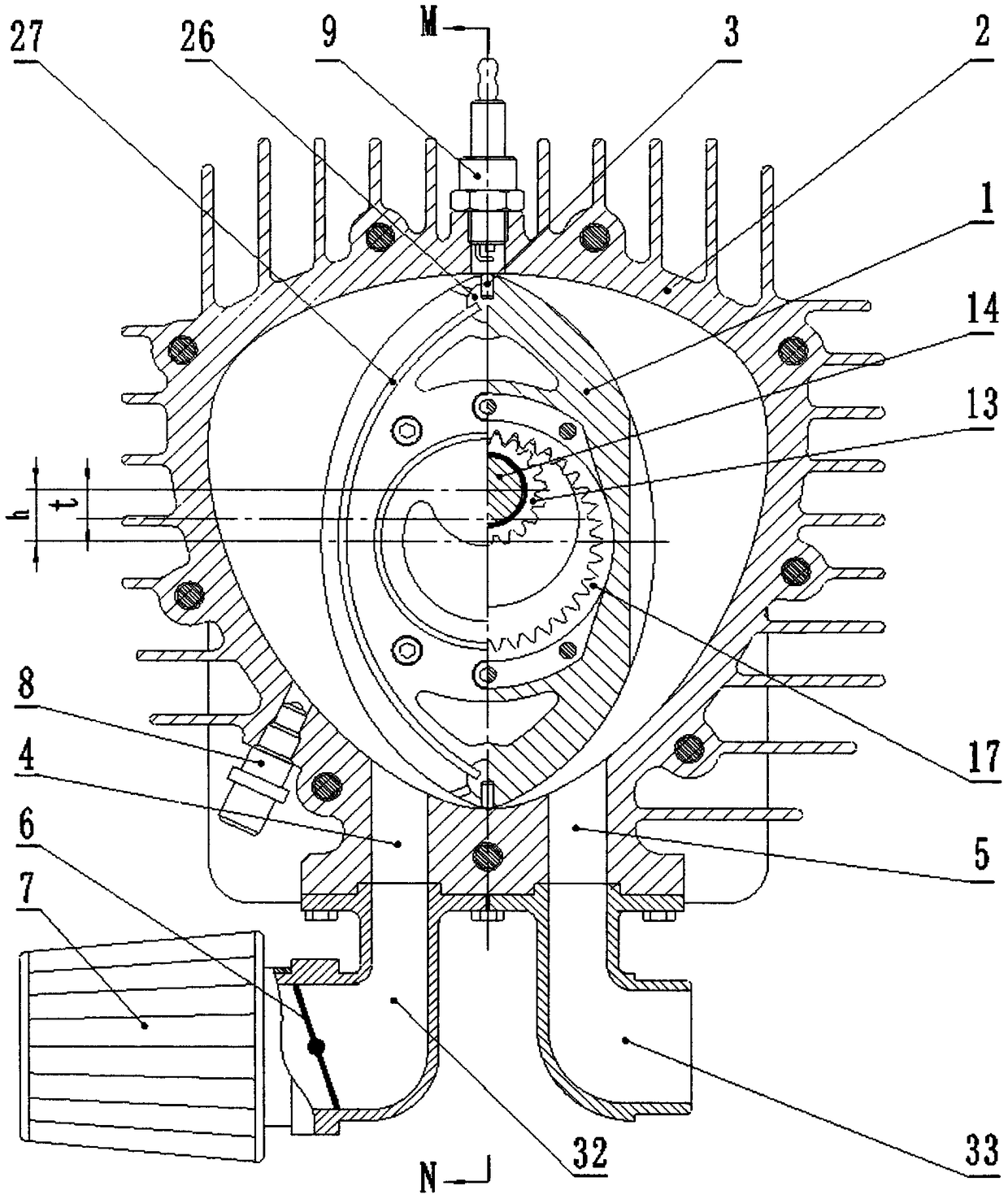

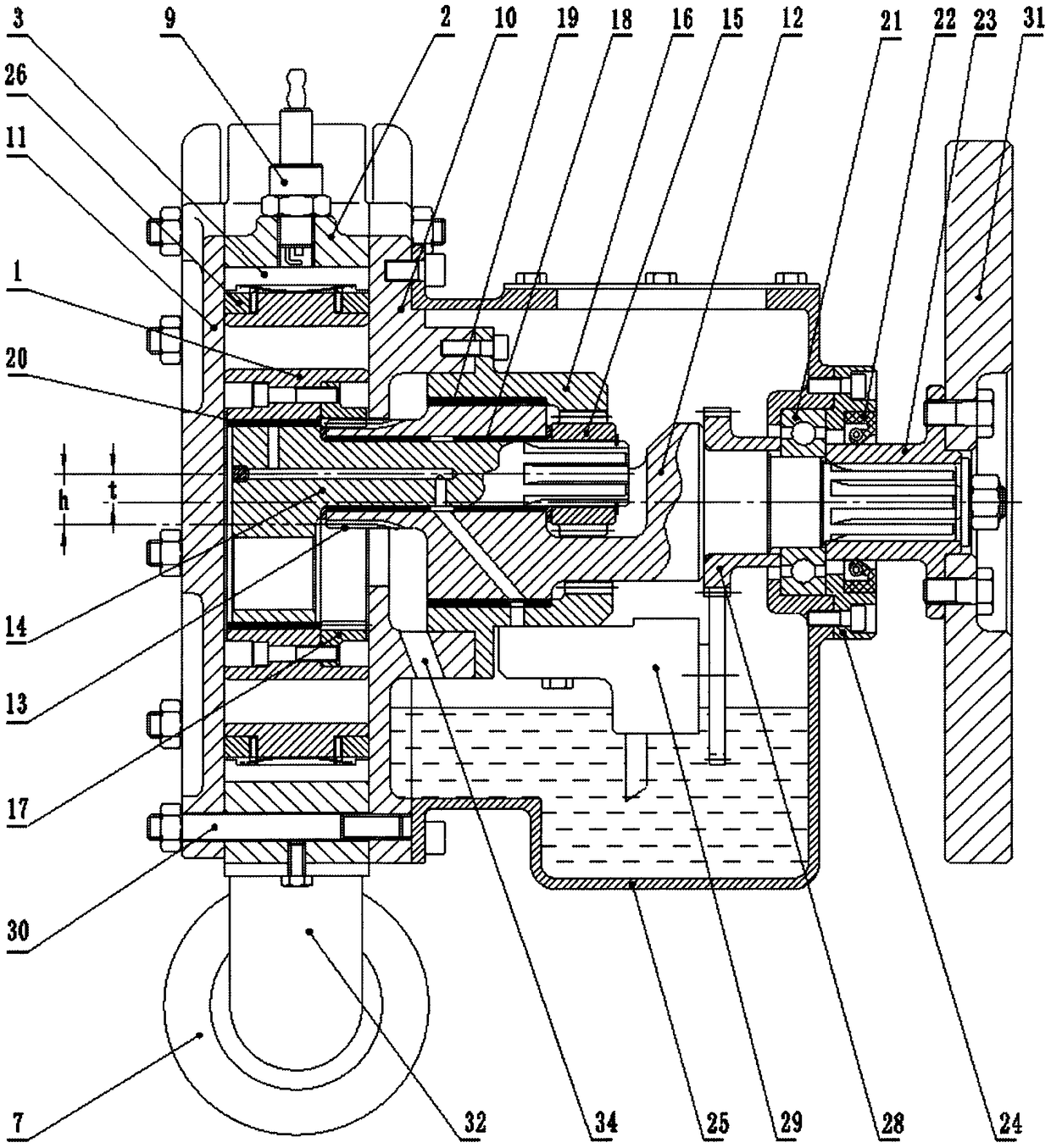

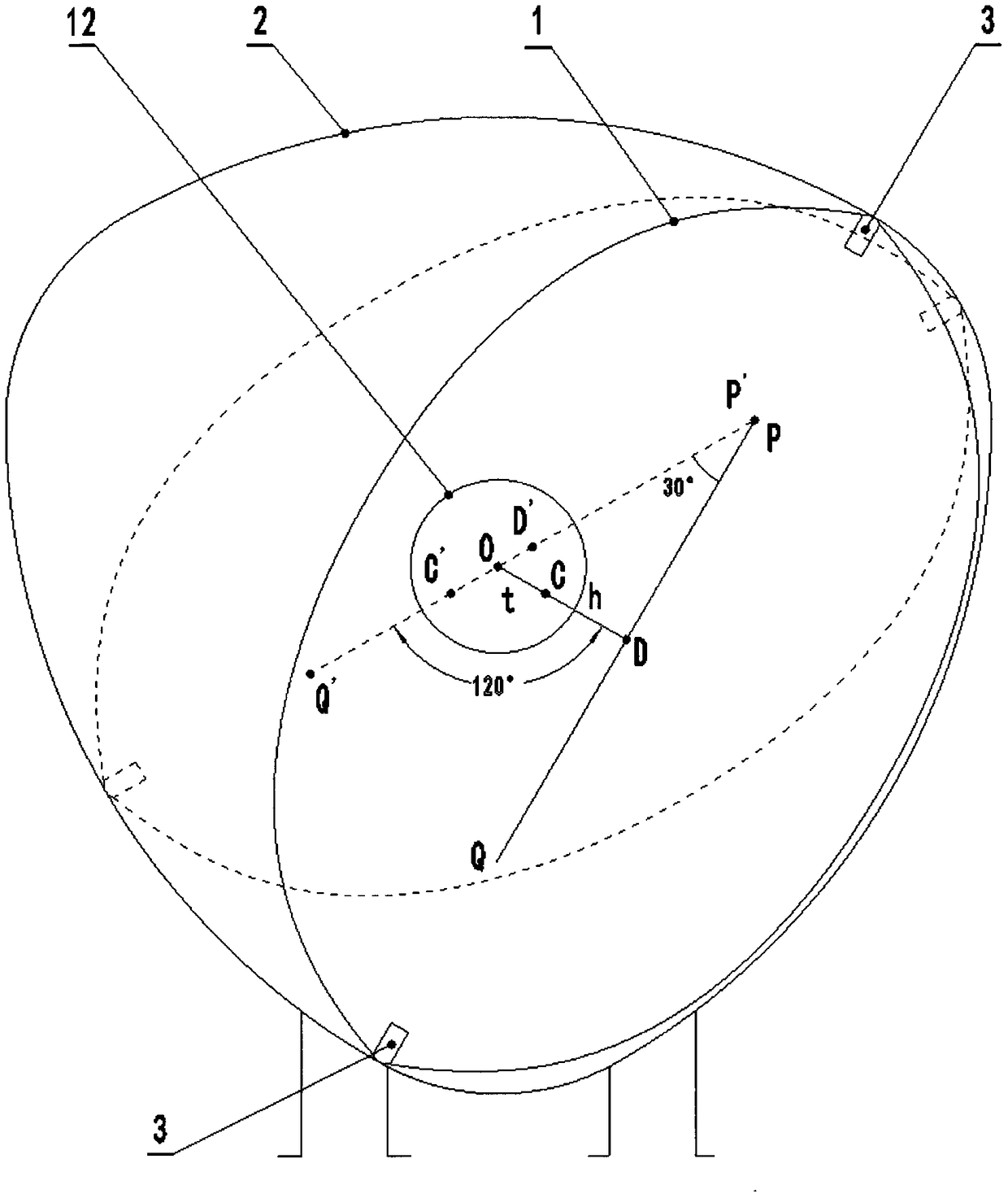

[0014] figure 1 figure 2 It is a structural diagram of the present invention. The invention contains piston 1, cylinder 2, radial seal 3, intake port 4, exhaust port 5, throttle valve 6, turbocharger 7, fuel injector 8, spark plug 9, rear cylinder head 10, and front cylinder Cover 11, main shaft 12, main shaft gear 13, planetary crank shaft 14, planetary gear 15, fixed internal gear 16, piston ring gear 17, eccentric hole bearing 18, main shaft front bearing 19, piston bearing 20, main shaft rear bearing 21, main shaft Rear oil seal 22, main shaft flange 23, rear bearing cap 24, main shaft box 25, sealing pin 26, end seal 27, oil pump drive gear 28, oil pump 29, cylinder bolt 30, flywheel 31, intake pipe 32, exhaust Pipe 33, oil return hole 34 and other parts.

[0015] The cylinder 2, the rear cylinder head 10, and the front cylinder head 11 are connected by cylinder bolts 30 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com