Process for synthesizing N-ethyl piperazidine

A synthesis method and technology of ethylpiperazine are applied in the synthesis field of N-ethylpiperazine, and can solve the problems of process control, difficult three-waste treatment, many by-products, and many reaction steps, etc. demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

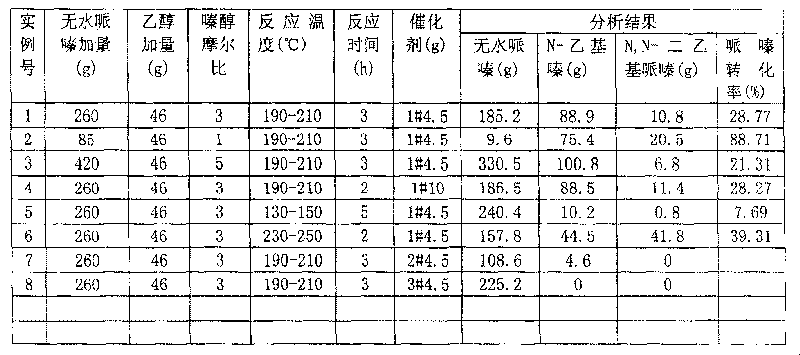

Examples

Embodiment 1

[0010] Embodiment 1: adjust the high-speed stirrer, measuring (controlling) temperature system, pressure gauge, safety valve etc. of 5L stainless steel autoclave, and replace the autoclave with nitrogen to 0 2 ≤0.5%, add 260 grams of anhydrous piperazine (purity 99.5%), 4.5 grams of 1# catalyst, and 46 grams of anhydrous alcohol at one time, wherein the composition of 1# catalyst (wt%): Cu: 1.0%, Co: 1.0 %, Mo: 2.5%, Ni: 1.0%, Mn: 0.5%, Mg: 0.1%, Cr: 0.05%, and the rest is Al 2 O 3 . After the replacement with hydrogen is qualified, the pressure in the kettle is raised to 3.0 MPa with hydrogen, and the hydrogenation valve is closed. Start stirring and heating, the temperature is controlled at 190-210 ° C, and the ammonia pressure is controlled within 6.0 MPa. During the reaction, the temperature will rise significantly, and the heat of reaction should be removed in time. The reaction was carried out for 3 hours, the temperature was lowered, the pressure was relieved, the r...

Embodiment 2

[0011] Example 2: Add 85 grams of anhydrous piperazine, and the others are the same as in Example 1.

Embodiment 3

[0012] Example 3: add 420 g of anhydrous piperazine, react for 2 hours, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com