Differential locking mechanism

A differential lock and differential gear technology, applied in the field of differential locking mechanism, can solve the problems of high technical and material requirements, complex locking process, slow response speed, etc., and achieve low technical and material requirements, simple structure, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

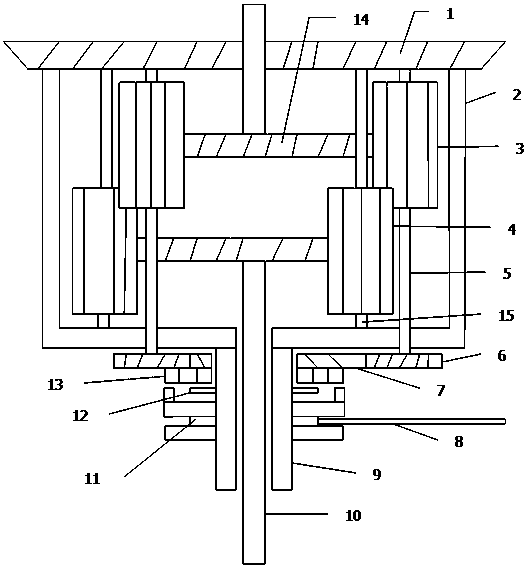

[0009] Now refer to the attached figure 1 , combined with embodiments described as follows: a differential locking mechanism, including a differential and a locking mechanism. Described differential includes driven gear 1, differential case 2, axle shaft 10, axle gear 14, planetary gear A3, planetary gear B4, planetary gear shaft 5, planetary gear shaft 15; Described differential One end of the case 2 is fixedly provided with a driven gear 1, and the two ends of the differential case 2 are respectively provided with half shafts 10 for rotation, and one end of the two half shafts 10 facing the inside of the differential case 2 is respectively fixedly provided with a half shaft Gear 14, the planetary gear A3 and the planetary gear B4 are arranged rotationally symmetrically around the side gear 14, and the planetary gear B4 is rotatably connected to the differential case 2 through the planetary gear shaft 15, and the planetary gear shaft 15 and the half shaft The shafts 10 are p...

Embodiment 2

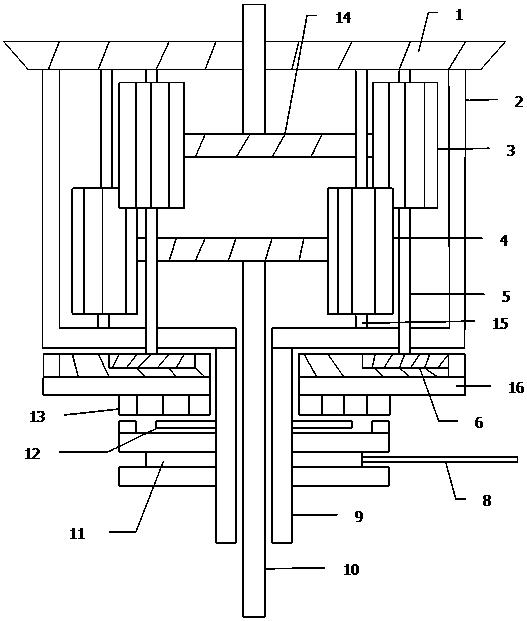

[0014] Now refer to the attached figure 2 , combined with embodiments described as follows: a differential locking mechanism, including a differential and a locking mechanism. Described differential includes driven gear 1, differential case 2, axle shaft 10, axle gear 14, planetary gear A3, planetary gear B4, planetary gear shaft 5, planetary gear shaft 15; Described differential One end of the case 2 is fixedly provided with a driven gear 1, and the two ends of the differential case 2 are respectively provided with half shafts 10 for rotation, and one end of the two half shafts 10 facing the inside of the differential case 2 is respectively fixedly provided with a half shaft Gear 14, the planetary gear A3 and the planetary gear B4 are arranged rotationally symmetrically around the side gear 14, and the planetary gear B4 is rotatably connected to the differential case 2 through the planetary gear shaft 15, and the planetary gear shaft 15 and the half shaft The shafts 10 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com