Technique for preparing derived fuel from high-moisture domestic waste and municipal sludge

A technology of domestic garbage and municipal sludge, applied in the direction of biofuel, fuel, solid fuel, etc., can solve the problems of prolonging the production cycle, increasing the amount of flocculant input, and complex process, so as to reduce the difficulty of production process and accelerate water loss , to solve the effect of excessive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

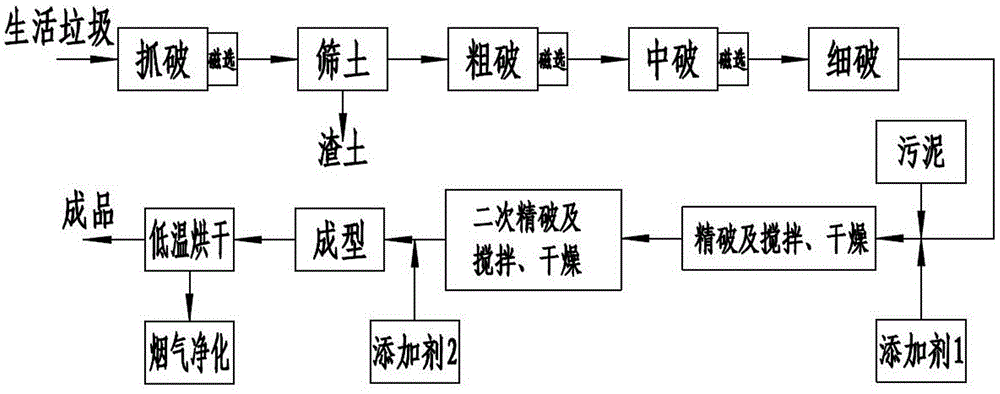

Image

Examples

Embodiment Construction

[0043] A wet molding process for preparing derived fuel based on domestic waste and municipal sludge, including the following steps:

[0044] (1) Scratching and magnetic separation process: use a crusher to break the bagged household garbage and split it; at the same time, crush and break large stones, bricks, and glass; after the metal is magnetically separated, the garbage Convey to the soil screening process.

[0045] The grabbing machine adopts the SSI-M100E type crusher from SSI Company of the United States. The rotating speed is 26r / min; the thickness of the crushing tool is 50mm. The crushing capacity is 25T / H. The magnetic separator adopts the RCYD-8 extra-strong T3 type of Shandong Weifang Hengji Magnetoelectric Machinery Co., Ltd., and its magnetic field strength is ≥ 1500 Gauss. Conveyed by the belt to the next process.

[0046] (2) Soil sieving process: the crushed stones, bricks and glass are screened out with a drum sieve, and the rest of the sieve is transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com