Differential locking mechanism

一种锁止机构、差速锁的技术,应用在差速传动装置、机械设备、传动装置等方向,能够解决技术和材料要求高、锁止过程复杂、反应速度慢等问题,达到技术和材料要求低、结构简单、反应灵敏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

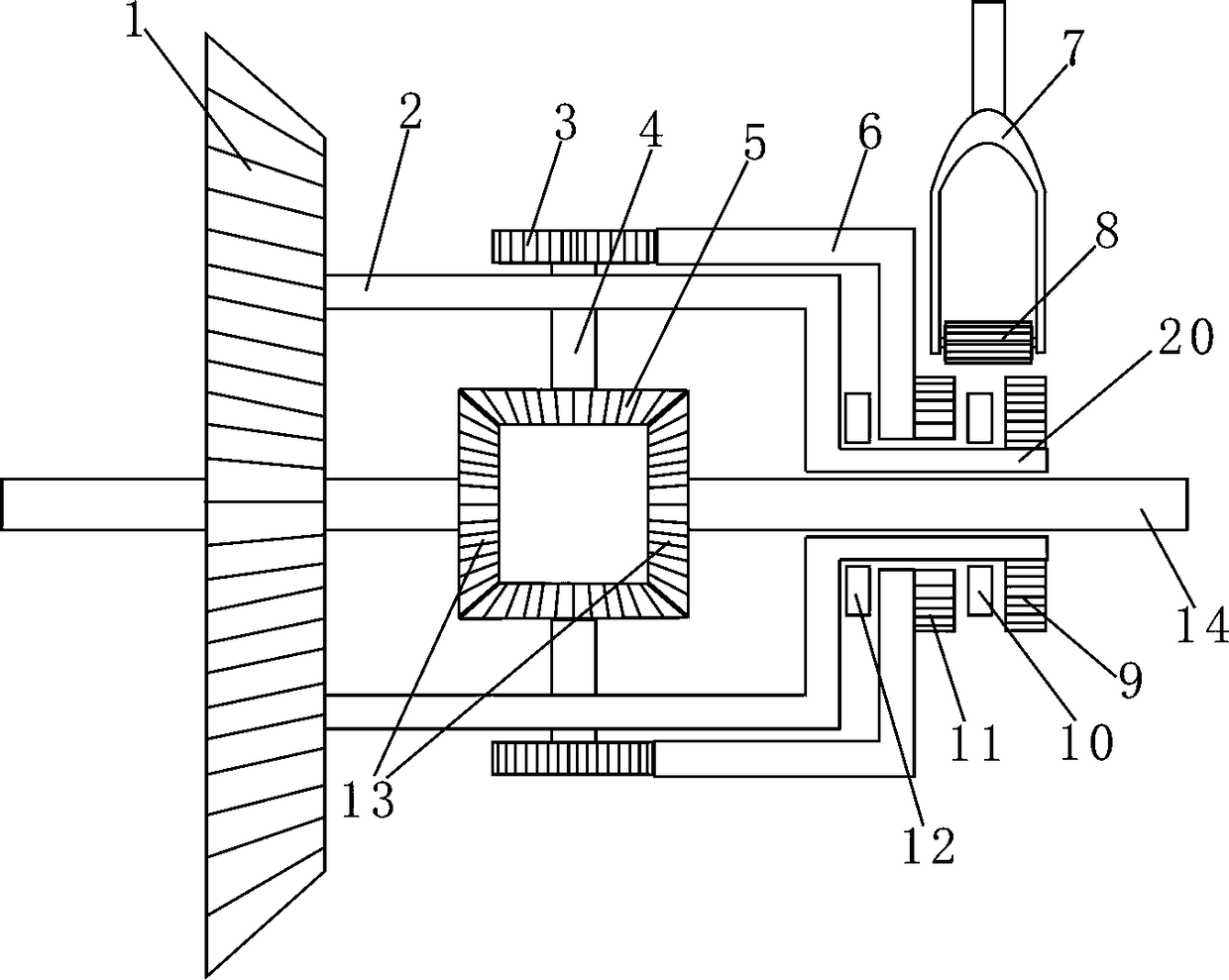

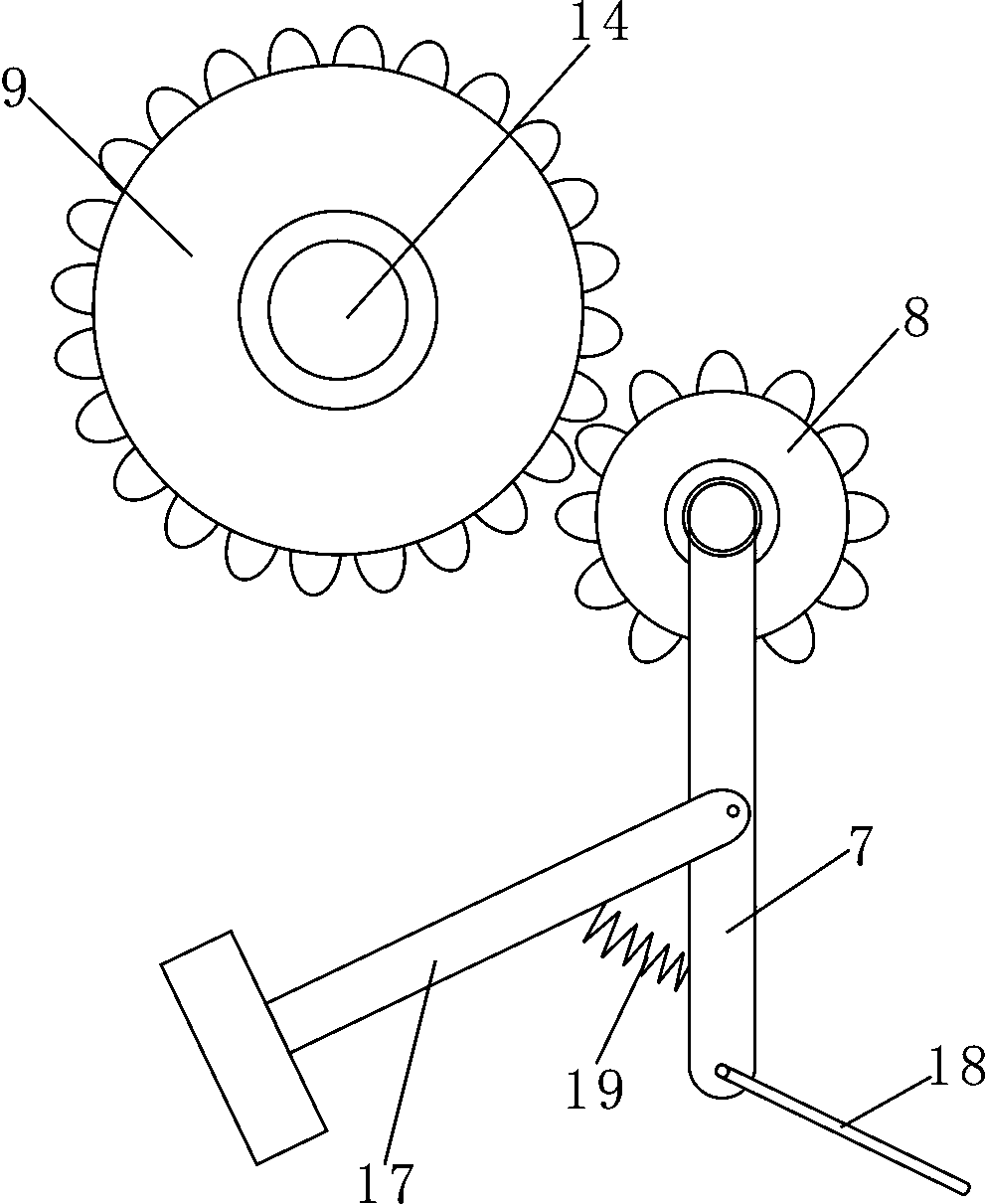

[0009] Now refer to the attached figure 1 And attached image 3 , described in conjunction with the embodiment as follows: a differential locking mechanism, including a differential and a locking mechanism, the differential includes a driven gear 1, a differential housing 2, a half shaft 14, a bevel gear, One end of the differential case 2 is fixedly provided with a driven gear 1, and two ends of the differential case 2 are respectively provided with a semi-shaft 14 for rotation, and the two semi-shafts 14 face the outside of the differential case 2 One end is rotatably connected with an axle housing, and one end of the two half shafts 14 facing the differential case 2 is respectively fixed with a bevel gear A13, and one side of the differential case 2 is rotatably arranged on the case wall. There is a rotating shaft 4, and a bevel gear B5 is fixedly arranged at one end of the rotating shaft 4 towards the inside of the differential case 2, and the bevel gear B5 meshes with tw...

Embodiment 2

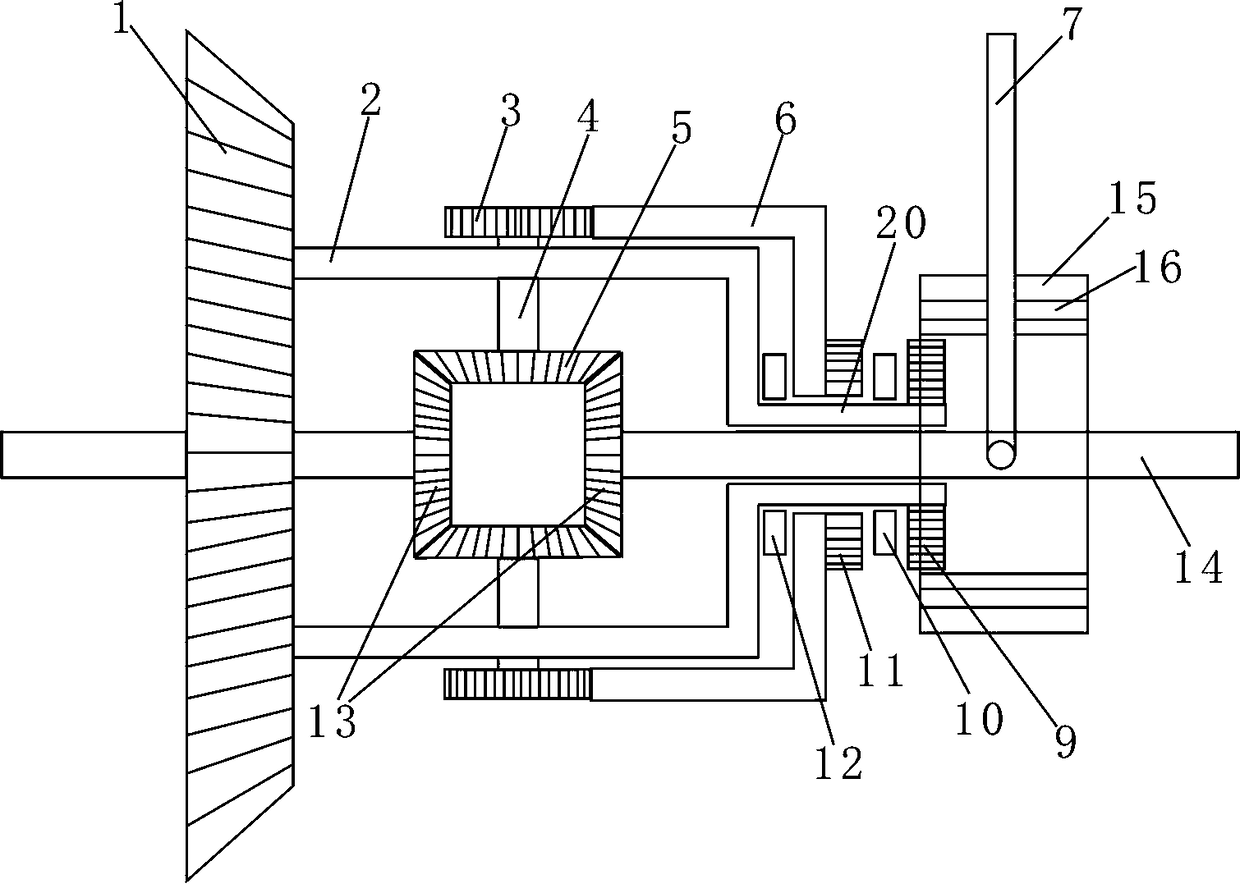

[0014] Now refer to the attached figure 2 , described in conjunction with the embodiment as follows: a differential locking mechanism, including a differential and a locking mechanism, the differential includes a driven gear 1, a differential housing 2, a half shaft 14, a bevel gear, One end of the differential case 2 is fixedly provided with a driven gear 1, and two ends of the differential case 2 are respectively provided with a semi-shaft 14 for rotation, and the two semi-shafts 14 face the outside of the differential case 2 One end is rotatably connected with an axle housing, and one end of the two half shafts 14 facing the differential case 2 is respectively fixed with a bevel gear A13, and one side of the differential case 2 is rotatably arranged on the case wall. There is a rotating shaft 4, and a bevel gear B5 is fixedly arranged at one end of the rotating shaft 4 towards the inside of the differential case 2, and the bevel gear B5 meshes with two bevel gears A13. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com