A system for continuously preparing polyoxymethylene dimethyl ether with methanol as the initial reaction raw material

A technology of polymethoxydimethyl ether and reaction raw materials, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the limitations of technological development and industrial application, the utilization rate of raw materials is less than 45%, and the catalyst activity Low and other problems, to achieve the effect of high equipment material requirements, reduced energy consumption, and strong equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

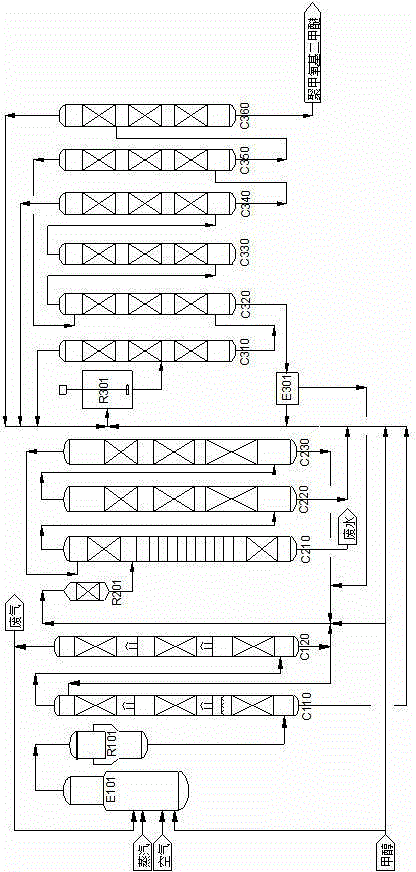

[0030] Such asfigure 1 as shown,

[0031] A. Formaldehyde preparation unit

[0032] The formaldehyde preparation unit includes a methanol evaporator E101, a formaldehyde reactor R101, a first absorption tower C110, and a second absorption tower C120. Methanol, air and water vapor enter the evaporator E101 in a certain proportion, and after being evaporated and gasified by the evaporator E101, they enter the formaldehyde reactor R101, and under the action of the silver catalyst, the reaction of methanol oxidation to formaldehyde is carried out continuously , after the reaction product is absorbed by the first absorption tower C110 and the second absorption tower C120, two strands of formaldehyde solution are obtained as intermediate products, wherein, the formaldehyde solution produced by the first absorption tower C110 tower tank is provided as a raw material to polyoxymethylene oxide The reactor R301 of the dimethyl ether preparation unit and the by-produced formaldehyde sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com