Heat radiator perforation anchor fixing device

A technology for fixing devices and heat sinks, which is applied in the direction of circuit heating devices, printed circuit components, electrical components, etc., can solve the problems of high cost, achieve the effects of reduced manufacturing costs, low requirements for length accuracy, and reduced assembly time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 1-10 As shown, the radiator perforation anchor fixing device of this embodiment includes a radiator 50, a PCB board 60 and a radiator locking mechanism, and the radiator 50 includes a plurality of cooling fins 51, an upper surface 52 and a lower bottom surface 53 , the heat dissipation fins 51 are all fixed on the upper surface 52, at least one U-shaped groove and several cross-cut grooves are formed between adjacent heat dissipation fins 51; the PCB board includes a board surface 61, a board slot hole 62 and the lower bottom surface 63 of the plate, the plate slot hole 62 includes the short side 64 of the plate slot hole and the long side 65 of the plate slot hole;

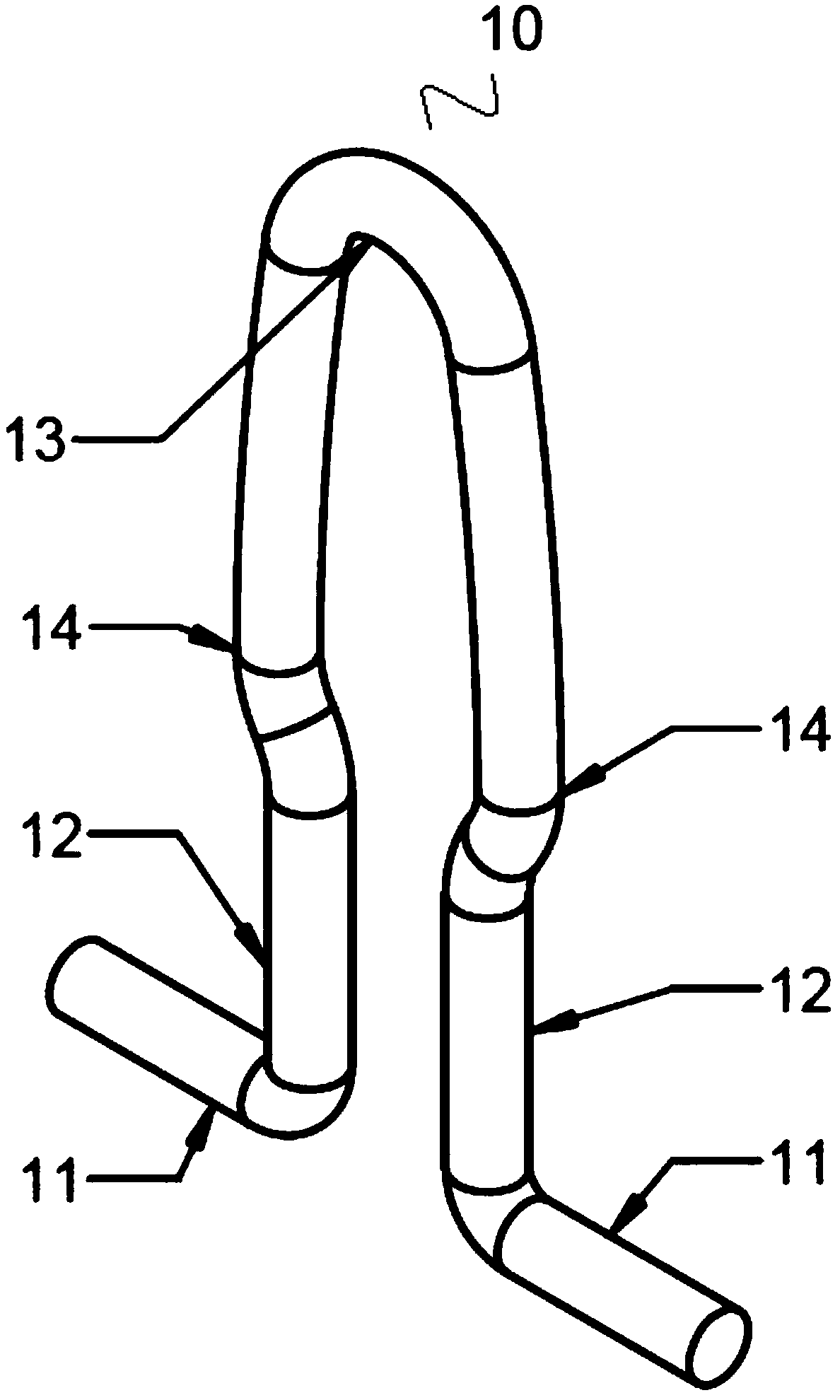

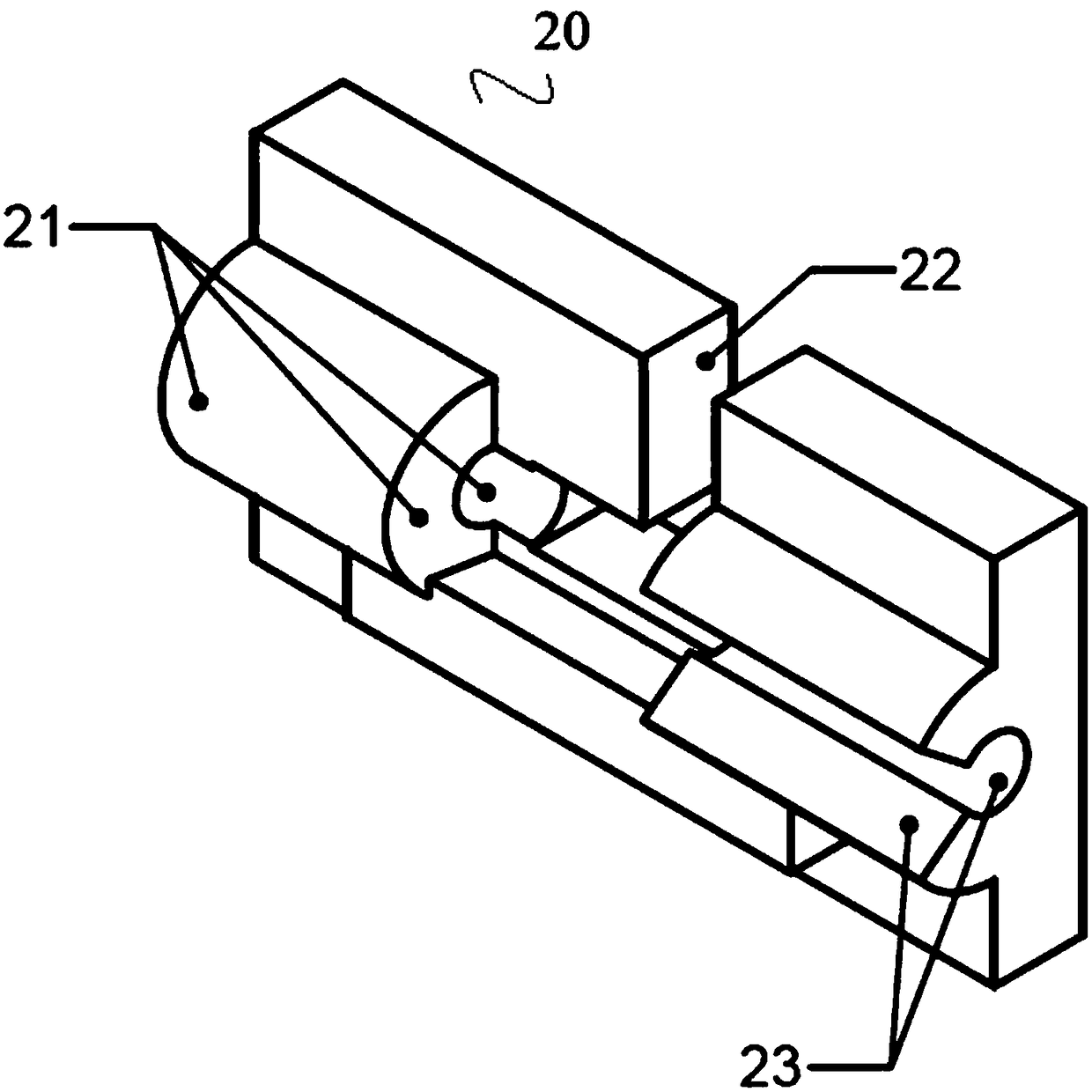

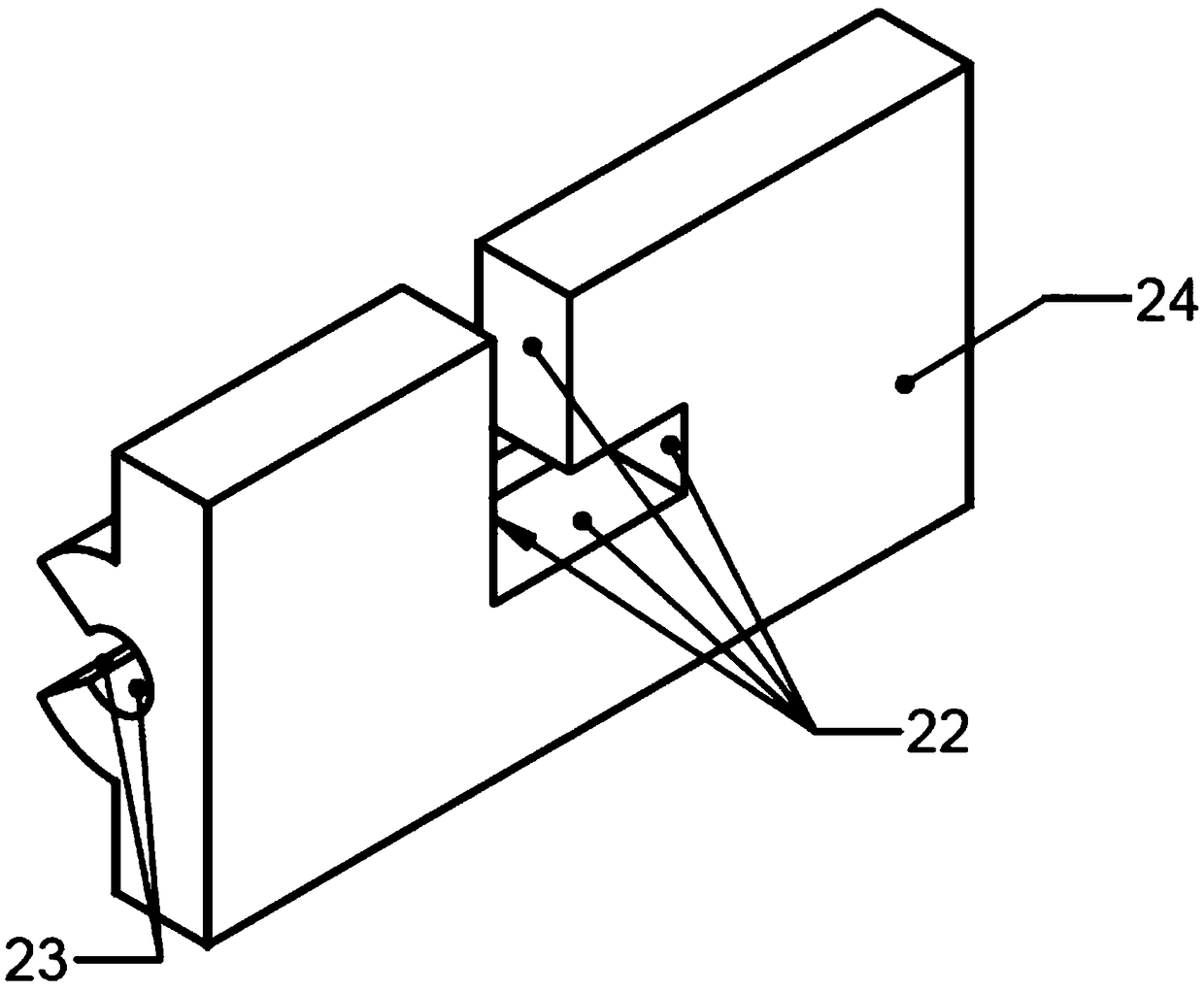

[0039] The locking mechanism includes a claw anchor 10, an anchor frame 20 and a Z-shaped spring 40. The anchor frame 20 includes an anchor frame hole 21, an anchor frame opening 22, an anchor frame V-shaped groove 23 and an anchor frame top surface 24. The Z-shaped spring 40 includes a sp...

Embodiment 2

[0044] Such as Figure 4 , 5 , 6, 7, 11, 12, 13, 14 and Figure 15 As shown, the radiator perforation anchor fixing device of this embodiment includes a radiator 50, a PCB board 60 and a radiator locking mechanism, and the radiator 50 includes a plurality of cooling fins 51, an upper surface 52 and a lower bottom surface 53 , the heat dissipation fins 51 are all fixed on the upper surface 52, at least one U-shaped groove and several cross-cut grooves are formed between adjacent heat dissipation fins 51; the PCB board includes a board surface 61, a board slot hole 62 and the lower bottom surface 63 of the plate, the plate slot hole 62 includes the short side 64 of the plate slot hole and the long side 65 of the plate slot hole;

[0045] The locking mechanism includes a pile anchor 30 and a Z-shaped spring 40, the Z-shaped spring 40 includes a spring middle part 41, a spring shoulder 42 and a spring hook 43, and the pile anchor 30 passes upward from the bottom surface 63 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com