Rolling forming die for disposable hygiene product

A hygienic product and rolling forming technology, which is applied in metal processing and other directions, can solve the problems that the protective sleeve cannot protect the knife edge, the processing technology requirements are high, and the buffer cannot be obtained, so as to reduce the mold cost, reduce the production cost, and improve the unit cost. The effect of secondary service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

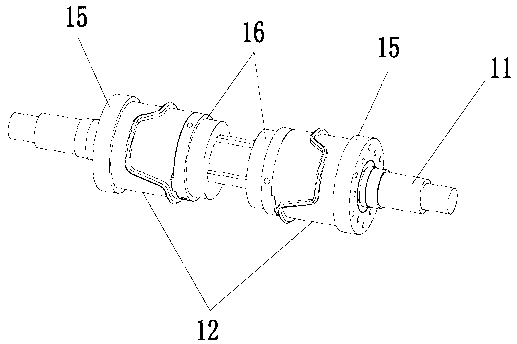

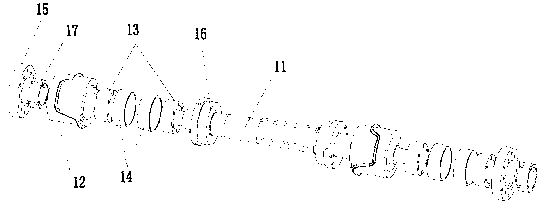

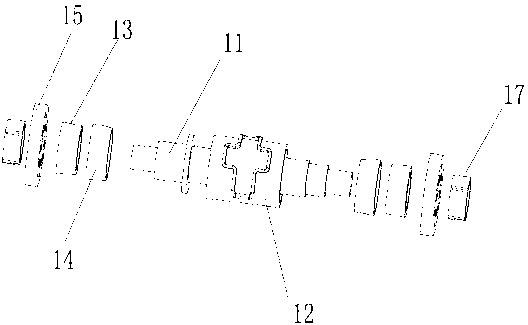

[0027] figure 1 , figure 2 The shown roller 1 includes a central axis 11, a pair of symmetrical movable dies 12, an adjustment sleeve 13, a protective sleeve 15 and a pair of transmission sleeves 16, a pair of symmetrical movable dies 12, an adjustable sleeve 13, and a protective sleeve 15 and a pair of transmission sleeves 16 are fixed on the central shaft 11, and a pair of adjustment sleeves 13 are fixed inside each movable die 12. The adjustment sleeves 13 are in the shape of a circular table, and a layer of rubber ring 14 is cast on the side of the adjustment sleeve 13. , the movable die 12 is provided with a card slot, and the corresponding position of the transmission sleeve 16 is provided with a key. The movable die 12 and the traditional sleeve 16 are connected through the slot and the key. Groove, the central shaft 11 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com