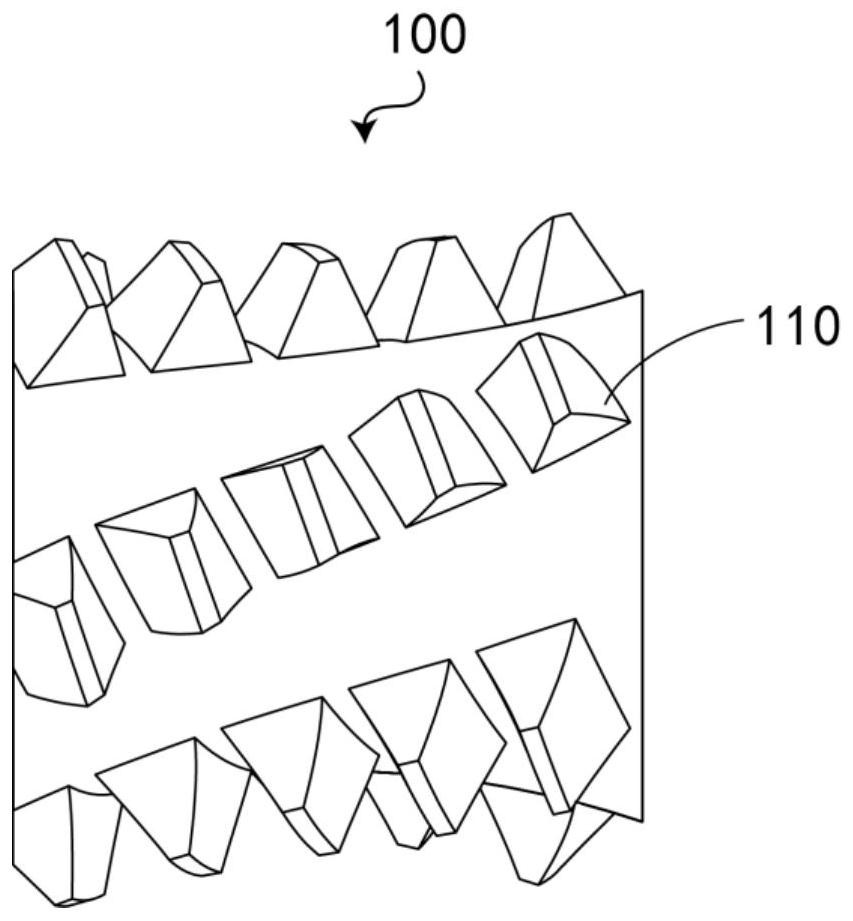

Design method of side rear angle surface of toroidal worm gear hob

A design method and technology of worm gear hobs, which are applied in the field of mechanical transmission, can solve problems such as the correctness of the blade shape of the toroidal worm gear hob, the difficulty in processing the side relief surface, and the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

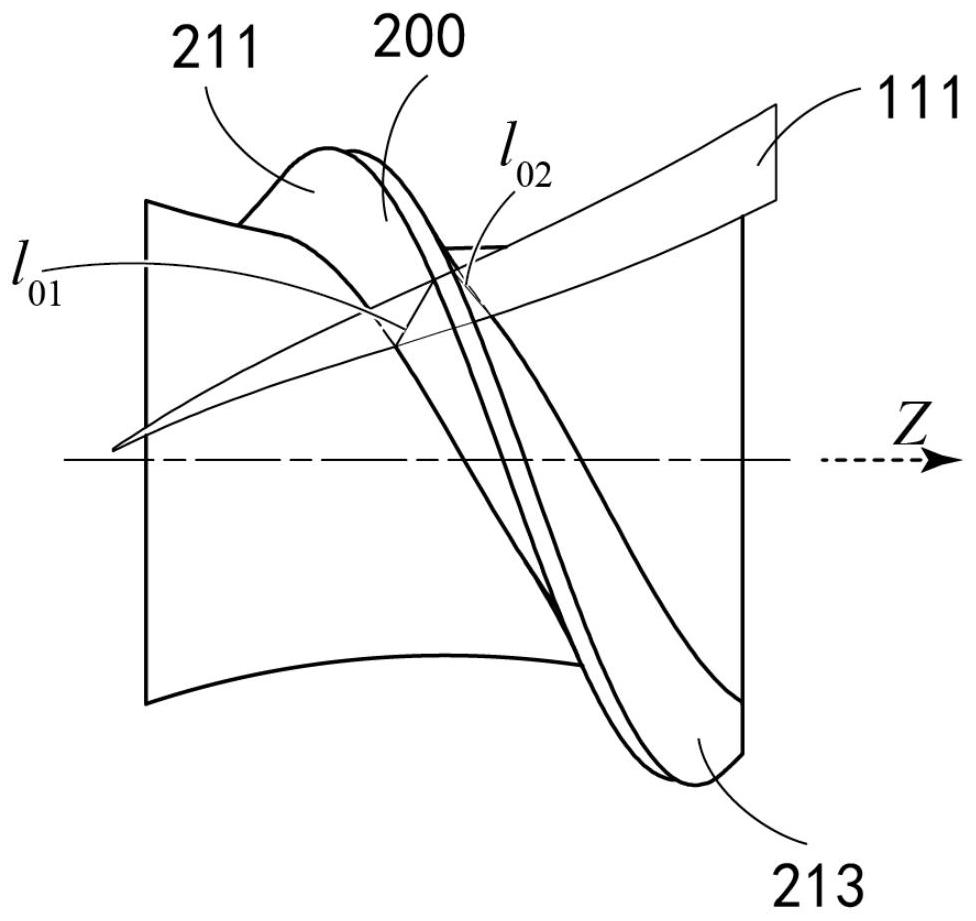

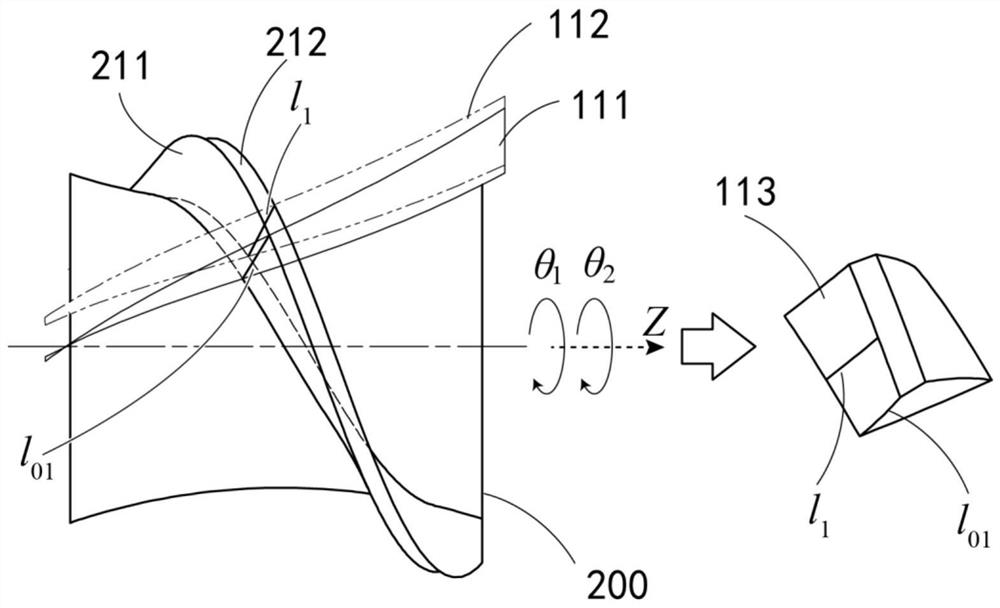

[0023] According to the general concept of the present invention, there is provided a method for designing the side relief surface of a toroidal worm gear hob, the design method comprising: constructing the left relief surface of at least one tooth of the toroidal worm gear hob, and comprising: rotating the rake face of the at least one cutter tooth by a first angle θ 1 Obtain the mapped rake face; rotate the left helicoid of the basic toric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com