Aluminum alloy precast-forging forming technique and mold thereof

A technology of liquid forging and aluminum alloy, which is applied in the field of aluminum alloy liquid forging forming technology and its mould, can solve problems such as high cost and complicated technology, and achieve the effects of improving productivity, optimizing process parameters, and reducing solidification shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

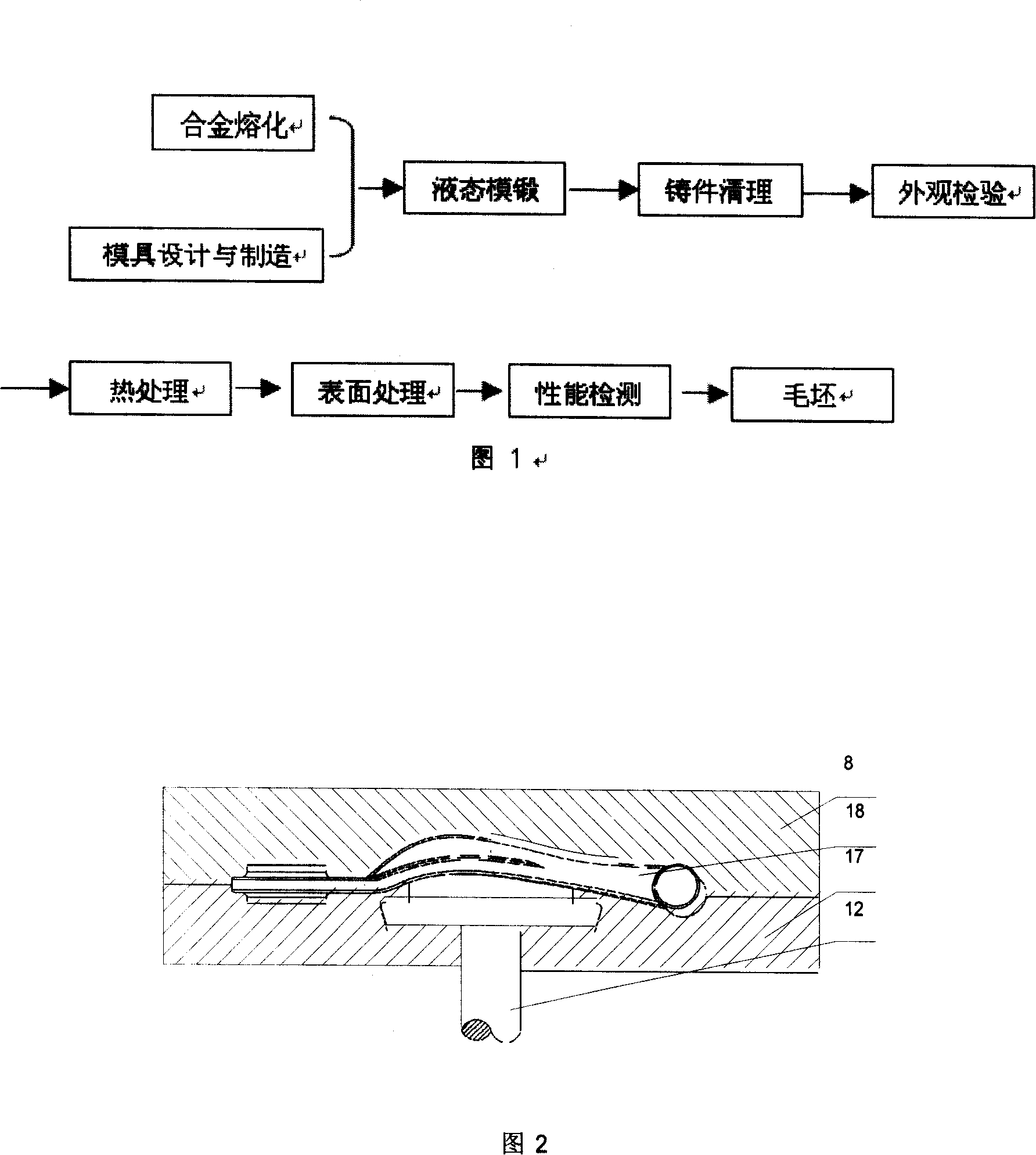

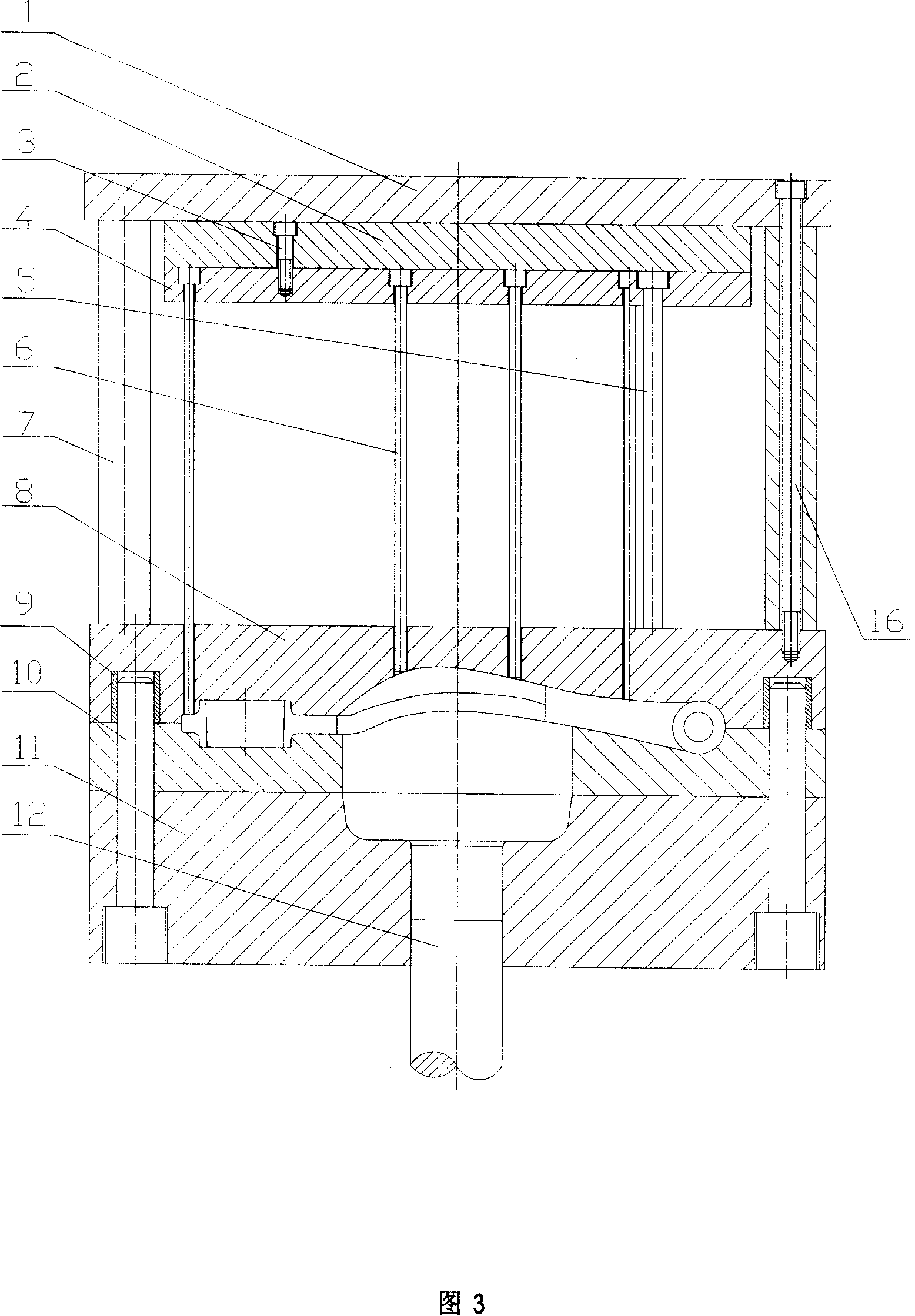

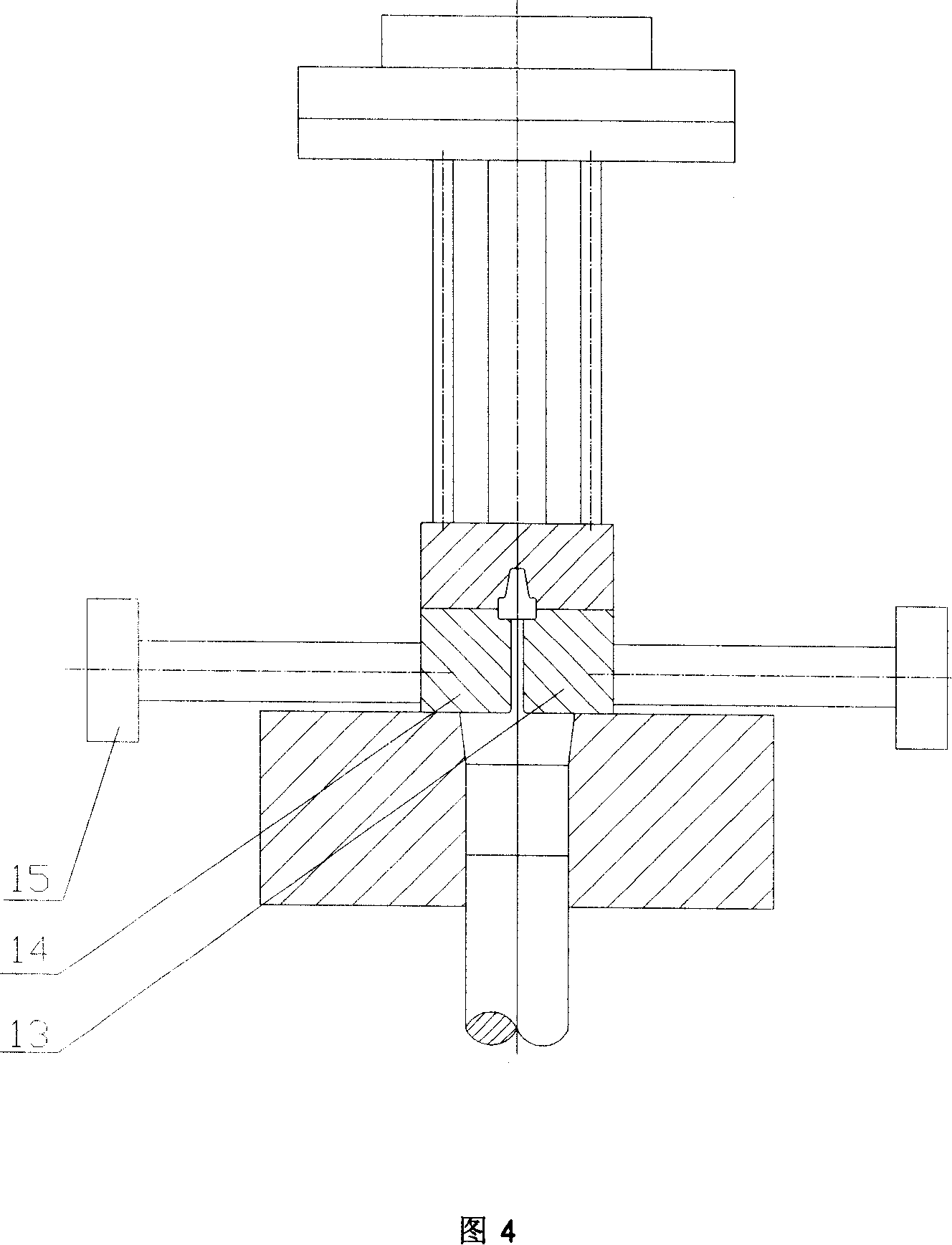

[0043] As shown in Figure 1 and Figure 2:

[0044]The lower module 17 is composed of the lower left module 14 and the lower right module 13 arranged horizontally, the cylinder bottom punch 12 is located in the opening between the lower left module 14 and the lower right module 13, and the upper module 8 is installed on the lower module 17; There is a sprue at the casting port, which is located on the lower module, and the lower module is located on the lower formwork 11, and the cylinder bottom punch 12 passes through the through hole in the center of the lower formwork; the support column is divided into the ejector rod 6 and the reset rod supported on the upper module 5. Connect the guide pillars of the lower template and the upper module, the upper module 8 and the lower module 17 are connected with the guide sleeve 9 through the guide pillar 10, one end of the ejector rod and the reset rod is fixed on the ejector rod fixing plate, and the ejector rod fixing plate 4 passes t...

Embodiment 2

[0061] In the second process test, the Fe content in the chemical composition was 0.6%, the Mg content was 0.4%, and the process test was carried out at a specific pressure of 100Mpa. The mechanical properties are shown in Table 5. All the other are identical with embodiment 1.

[0062] Table 6 The mechanical properties of the third process test

[0063] Sample No

Embodiment 3

[0065] In the third process test, the Fe content in the chemical composition was 0.1%, the Mg content was 0.3%, and the process test was carried out at a specific pressure of 50Mpa. The mechanical properties are shown in Table 6. All the other are identical with embodiment 1.

[0066] Table 7 Mechanical properties of the fourth process test

[0067] Sample No

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com