Insulation cover for sealing tank mouth of torpedo car

A heat preservation cover and mixed iron car technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of not providing tank mouth closing devices, not finding mixed iron car tank mouth closing devices, etc., and achieve energy saving Remarkable effect, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

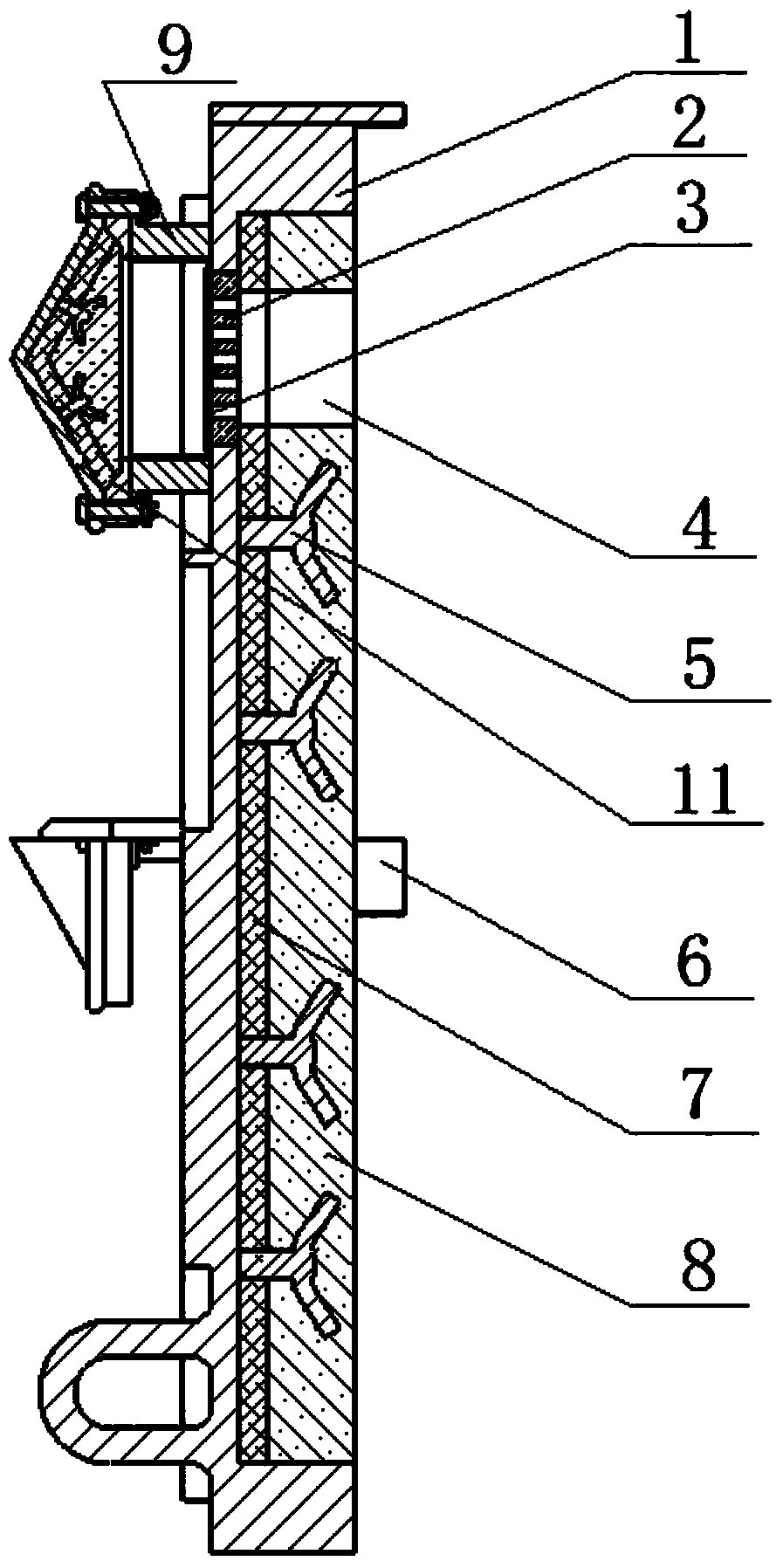

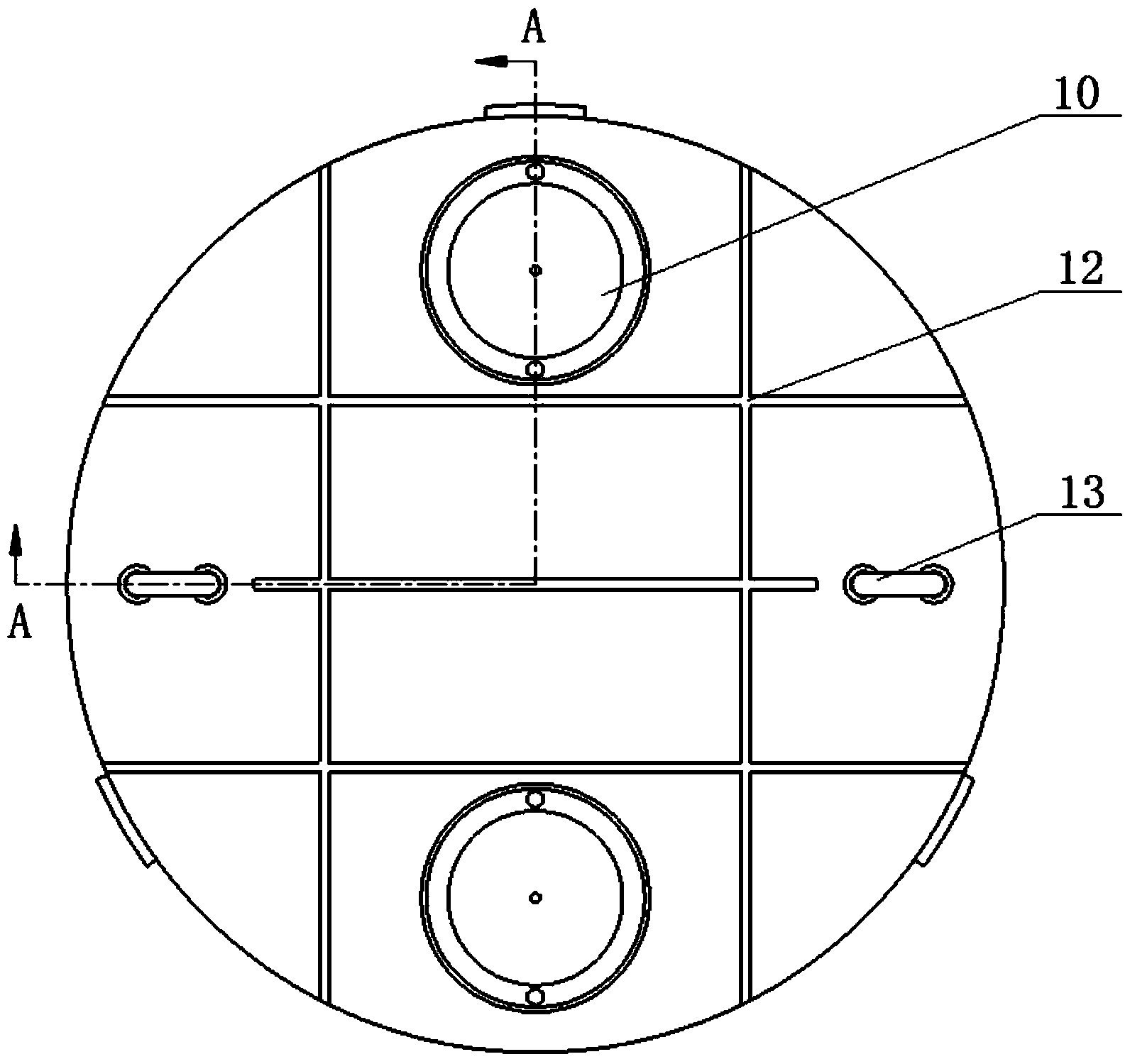

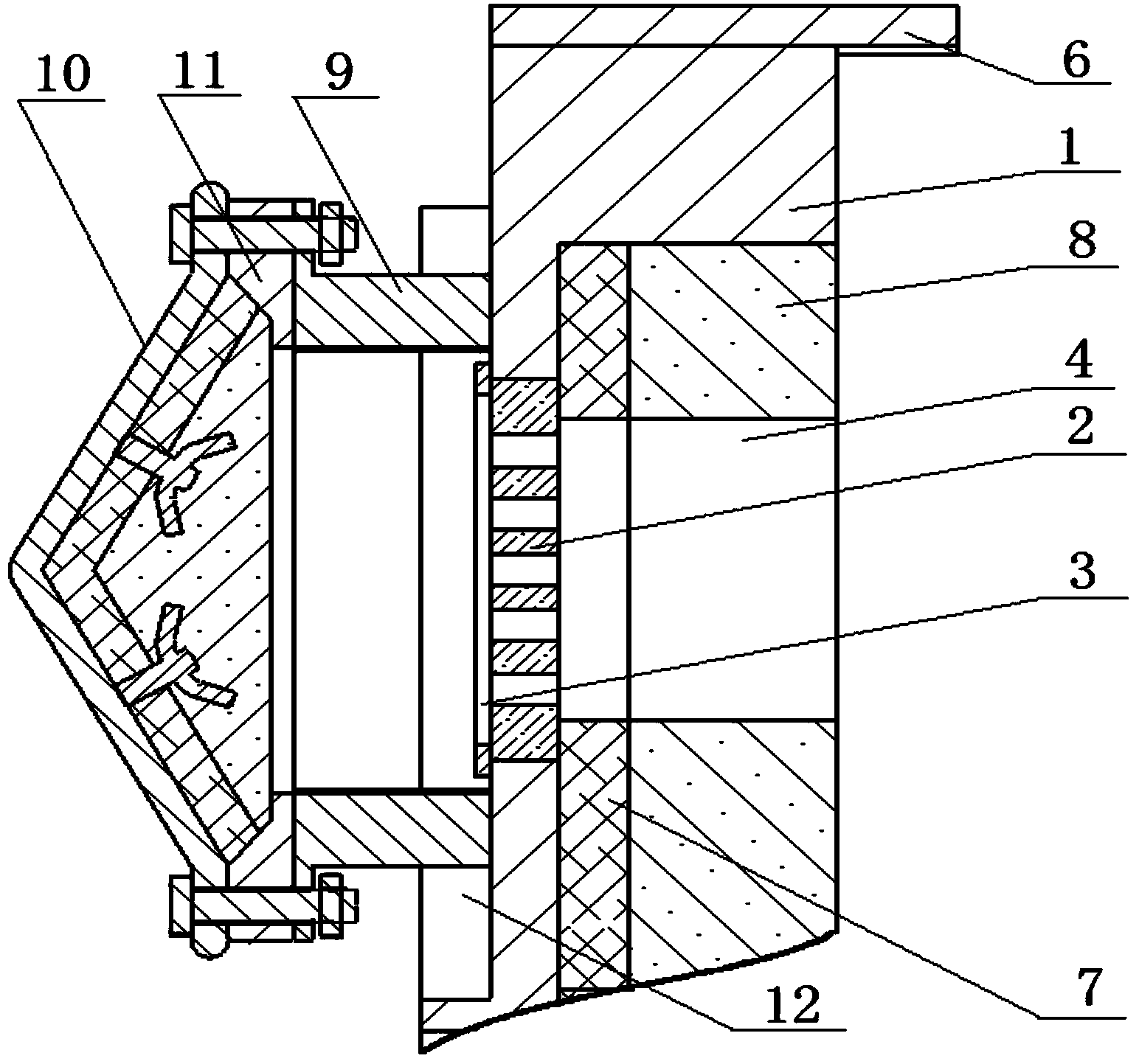

[0015] like Figure 1~5 As shown in the figure, a thermal insulation cover used for closing the tank mouth of a mixed iron vehicle is circular in shape and consists of a steel shell 1, a honeycomb refractory brick 2, a ring-shaped cover plate 3, a stepped hole 4, a riveting piece 5, and a positioning It is composed of support 6, inner layer refractory material 7, outer layer refractory material 8, column 9, rain shield 10, ring-shaped fixing piece 11, rib plate 12 and inverted U-shaped lifting lug 13. The inner layer of refractory material 7 and outer layer of refractory material 8 are laid in the steel shell 1 with a circular groove and connected by riveting. The steel shell 1 is provided with two stepped holes 4 , and the rain shield 10 is welded on the steel shell 1 and is located above the stepped holes 4 . Honeycomb refractory bricks 2 are built in the stepped hole 4 and fixed with an annular cover plate 3 welded on the steel shell 1 . The surface of the steel shell 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com