Precise macromolecule adding device

A technology of adding devices and polymers, applied in transportation and packaging, mixers, applications, etc., can solve problems such as uneven mixing, uneven diversion and dispersion, and short uniform mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

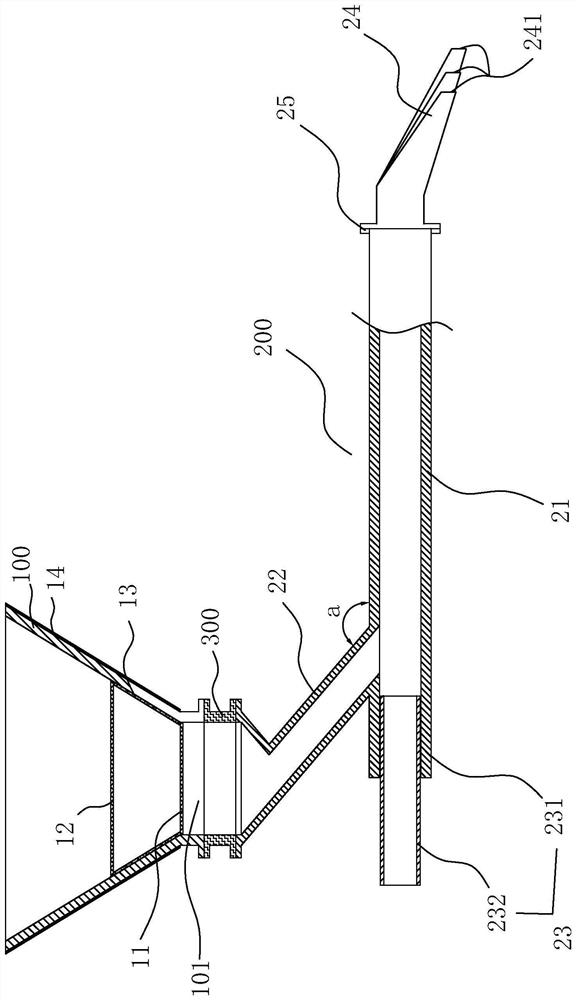

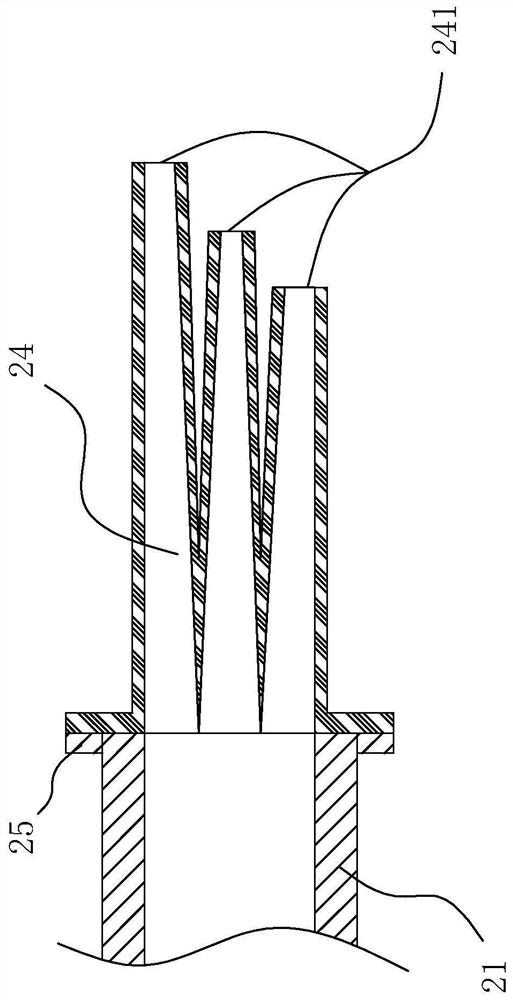

[0023] refer to figure 1 , figure 2 , the present embodiment provides a polymer precision adding device, which is located at the upper end of the mixing chamber of the wick forming device, and includes a storage hopper 100 and a blowing tube 200 communicated with the storage hopper 100 .

[0024] The storage hopper 100 is provided with a vibrating device (shown in the figure), the discharge port 101 of the storage hopper 100 is located at the bottom of the storage hopper 100, and the discharge port 101 is provided with a screen 11, by setting The vibrating device is used in conjunction with the screen 11, and the polymer material in the storage hopper 100 can be filtered through the screen 11 before spraying, which ensures that the sprayed polymer material is dispersed and not agglomerated. At the same time, the vibrating device vibrates The frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com