Acid fracturing thermal washing sledge

A technology of acid fracturing and hot washing, applied in isolation devices, cleaning equipment, mining fluids, etc., can solve the problems of a large number of equipment, unfavorable operation and use of staff, high equipment cost, etc., and achieve a high degree of automation, convenient and reliable operation, The effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

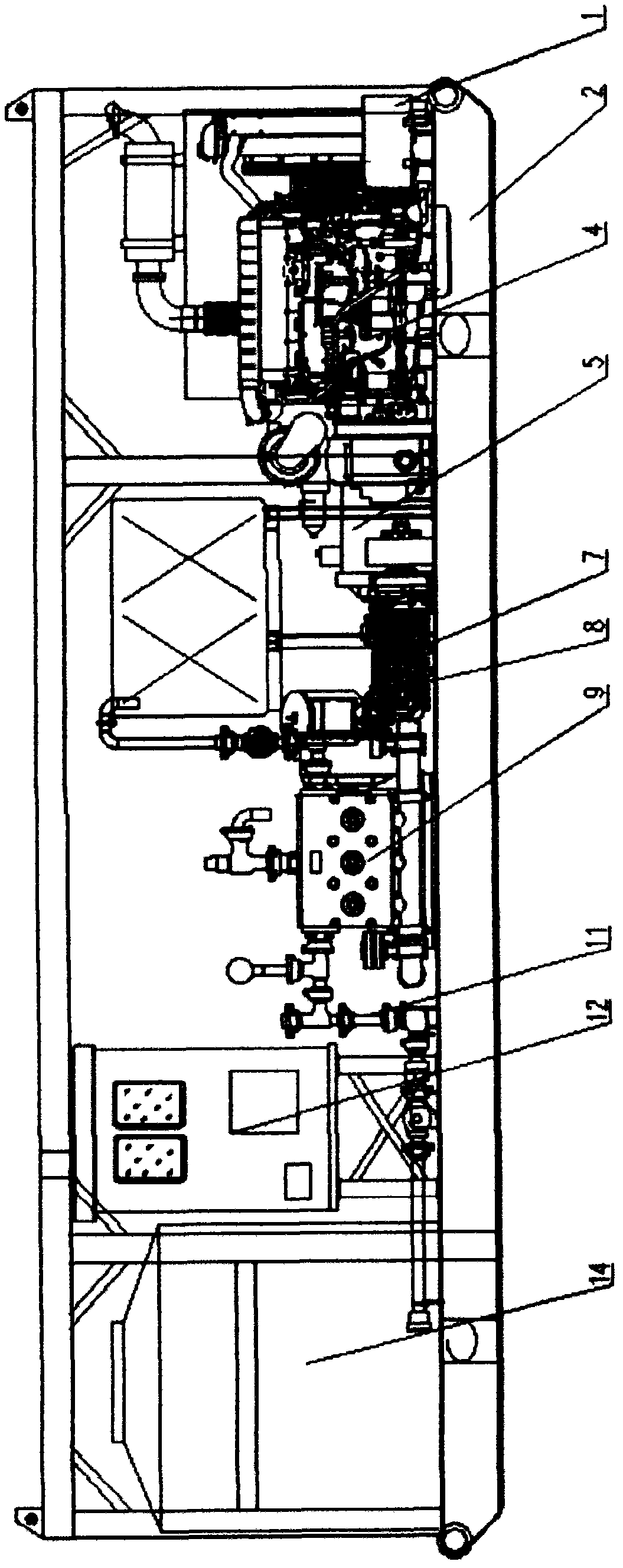

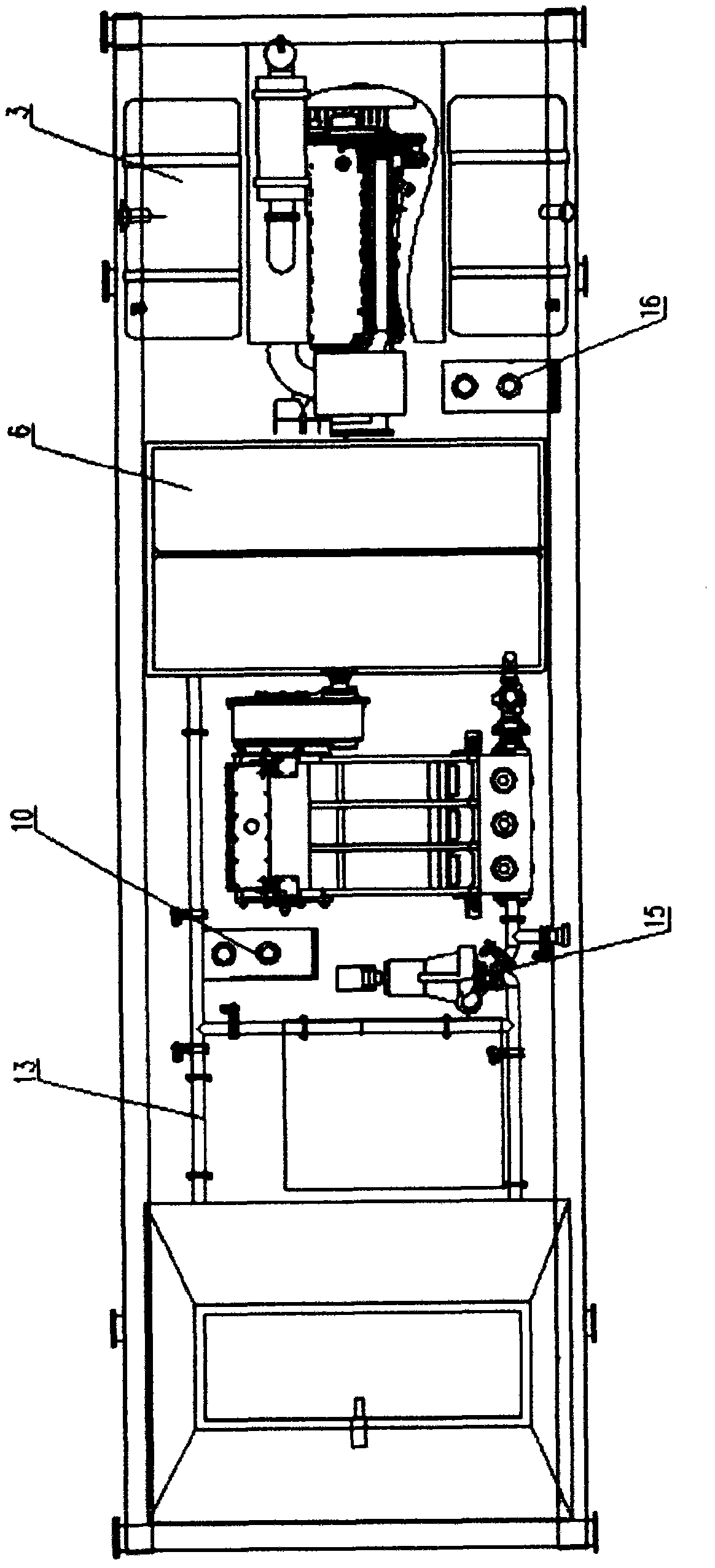

[0009] Such as figure 1 , figure 2 As shown, the acidizing and fracturing hot washing skid according to the present invention is provided with a fuel heater 1, a fuel tank 3, a diesel engine 4, a gearbox 5, a water tank 6, an air compressor system 7, and a Shaft device 8, three cylinder plunger pump 9, lubrication system 10, high pressure system 11, circuit system 12, low pressure manifold system 13, heater 14, centrifugal pump 15 and hydraulic system 16.

[0010] The fuel heater 1 is fixed beside the diesel engine 4, the gearbox 5 is connected with the diesel engine 4 through screws, the coupling 8 connects the gearbox 5 with the three-cylinder plunger pump 9, and the water tank 6 is fixed on the side of the coupling 8 Above, the air compressor system 7 is fixed below the water tank 6, and the centrifugal pump 15 is fixed in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com