Coconut shell carbonization material activation furnace

A technology of activation furnace and coconut shell charcoal, applied in the fields of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of insufficient carbonization of carbonized materials, low carbonization efficiency, uneven heating of materials, etc., so as to reduce the entry of flue gas Cooling section, the effect of solving surface cracks and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

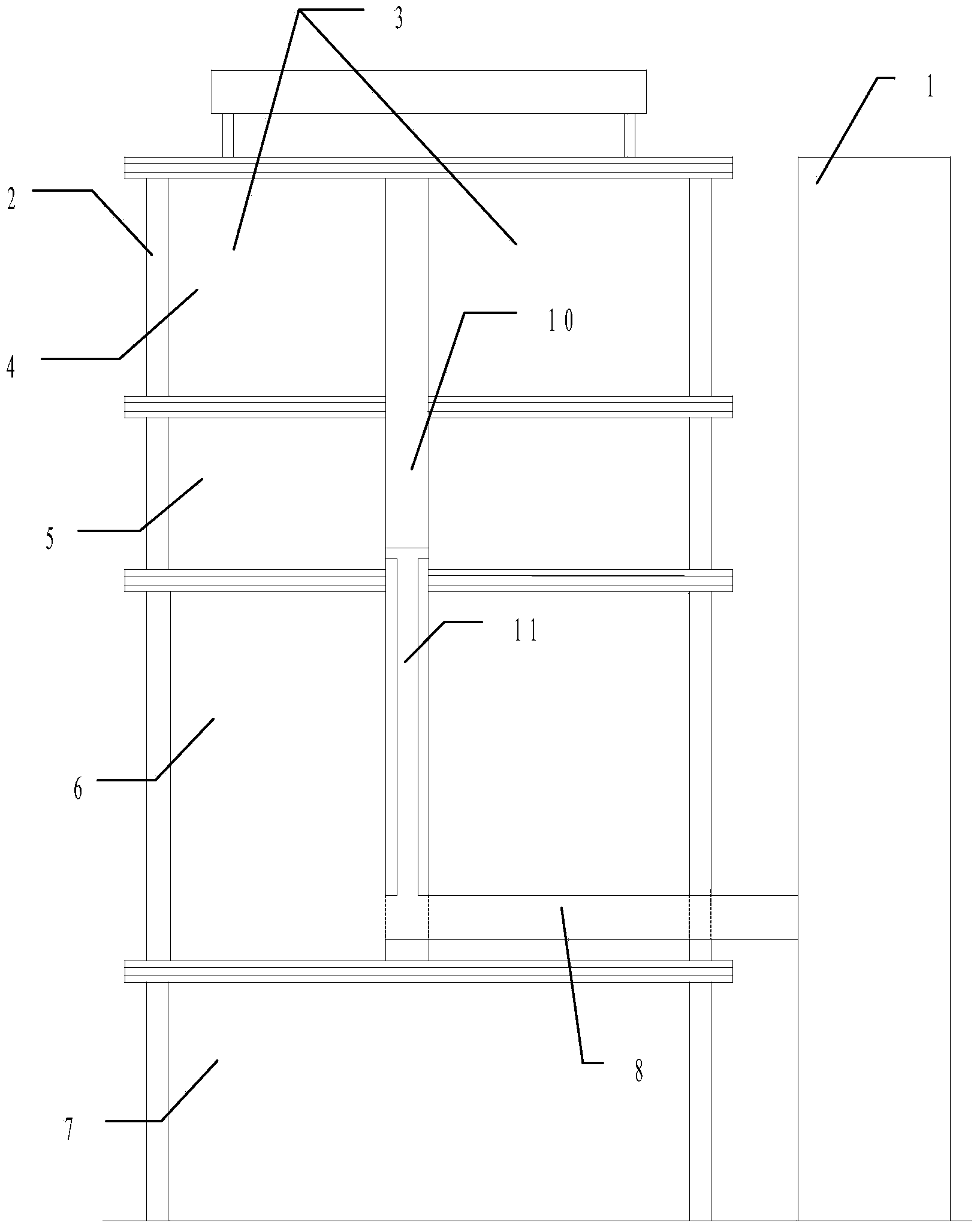

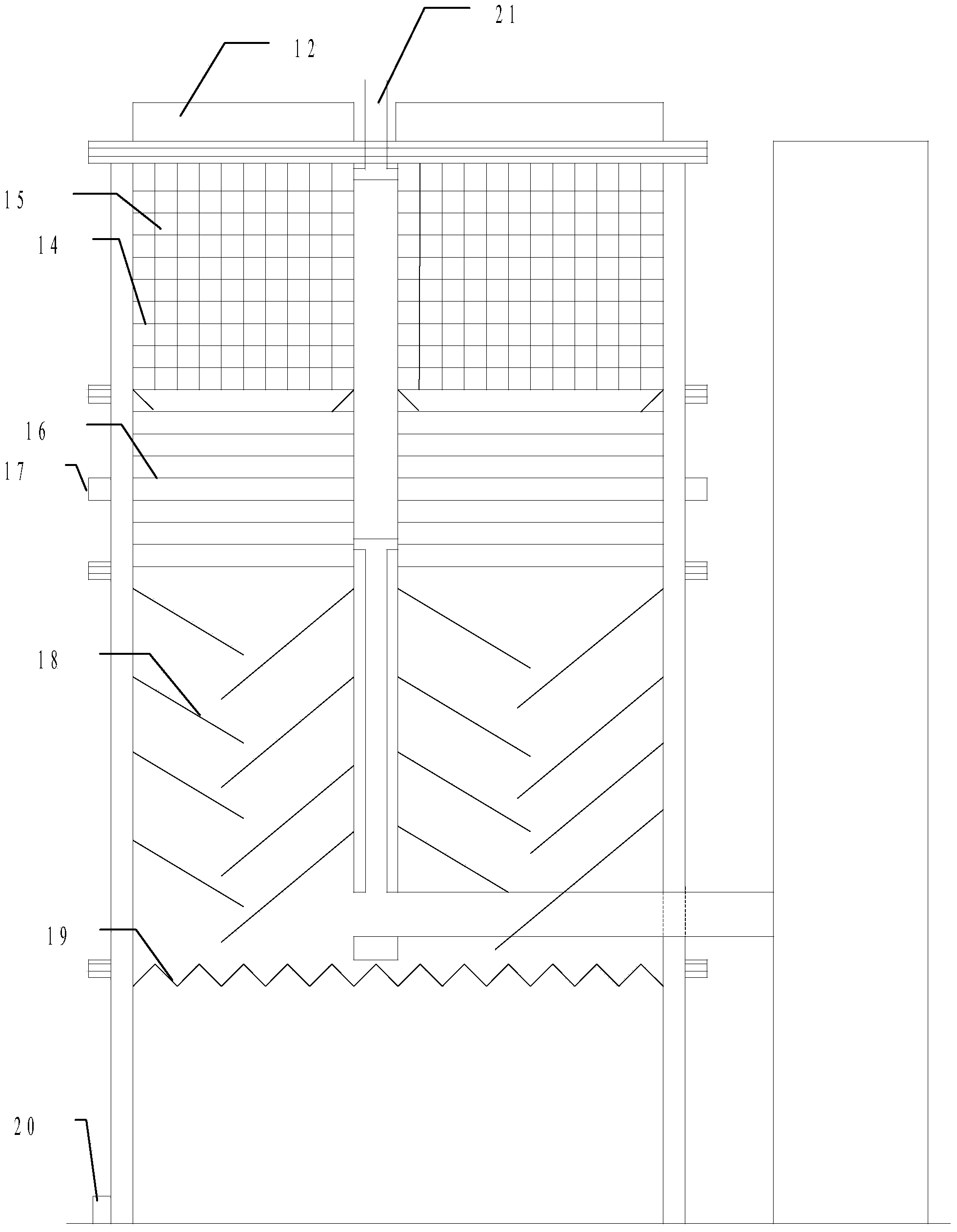

[0021] like Figure 1~2 As shown, the present invention provides a coconut shell carbonized material activation furnace, comprising: a combustion chamber 1 and a furnace body. The furnace body includes a furnace wall 2, a furnace 3 and a cooling section 7. The furnace wall 2 has four sides, and the four sides of the furnace wall 2 surround the furnace 3 and the cooling section 7. The cooling section 7 is located at the lower part of the furnace 3; inside the furnace 2, there are carbonization sections connected to each other. 4. Supplement the carbonization section 5 and the activation section 6; the carbonization section 4 is located at the top of the furnace 2, and the carbonization section 4 is connected to the feed port 12. There are multiple material channels 15 in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com