Fruit collecting device for auxiliary picking machine and adjusting method of fruit collecting device

A collection device and picking machine technology, applied in the direction of picking machine, application, harvester, etc., can solve the problem of relatively few research on fruit collection system, and achieve the effect of ensuring integrity and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

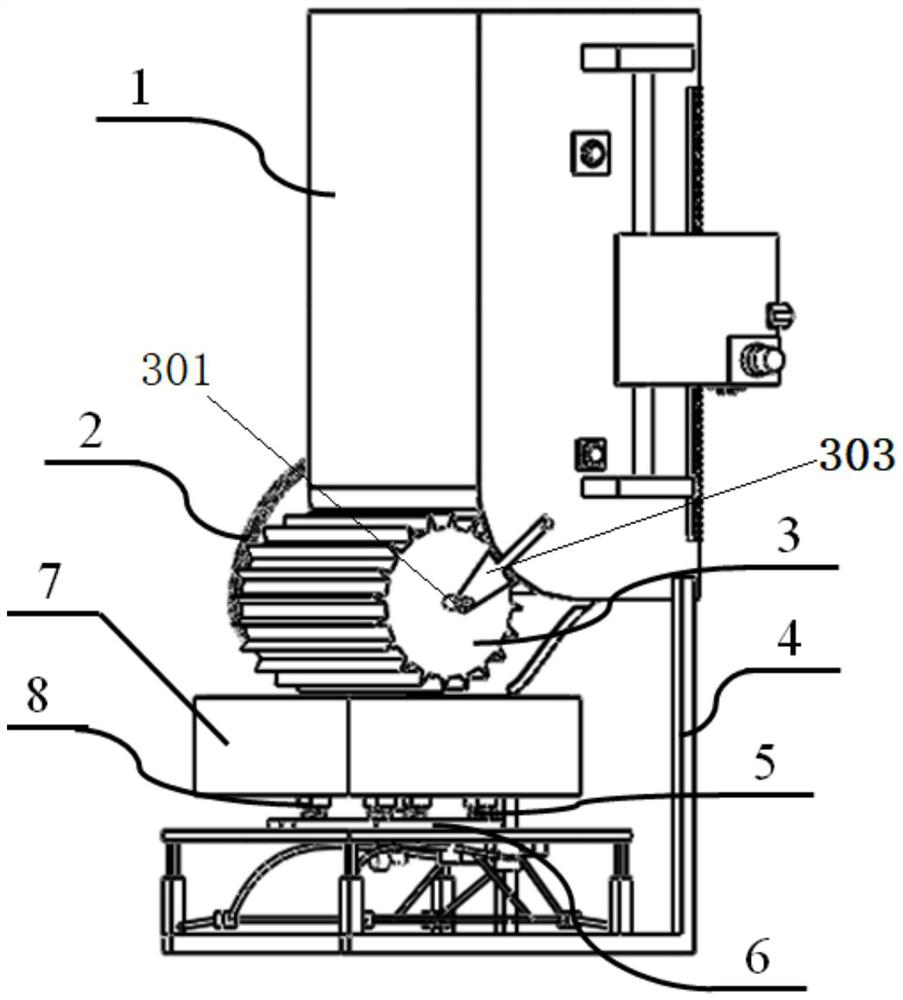

[0059] Please refer to Figure 1 to Figure 10 , this embodiment provides a dynamically adjustable fruit collection system, including a vertical conveying assembly 1, a transmission assembly 2, a buffer assembly 3, a support table assembly 4, a rotation adjustment assembly 5, a buffer and vibration reduction assembly 6, and a fruit collection box 7 , Sensing and control assembly 8, battery 9.

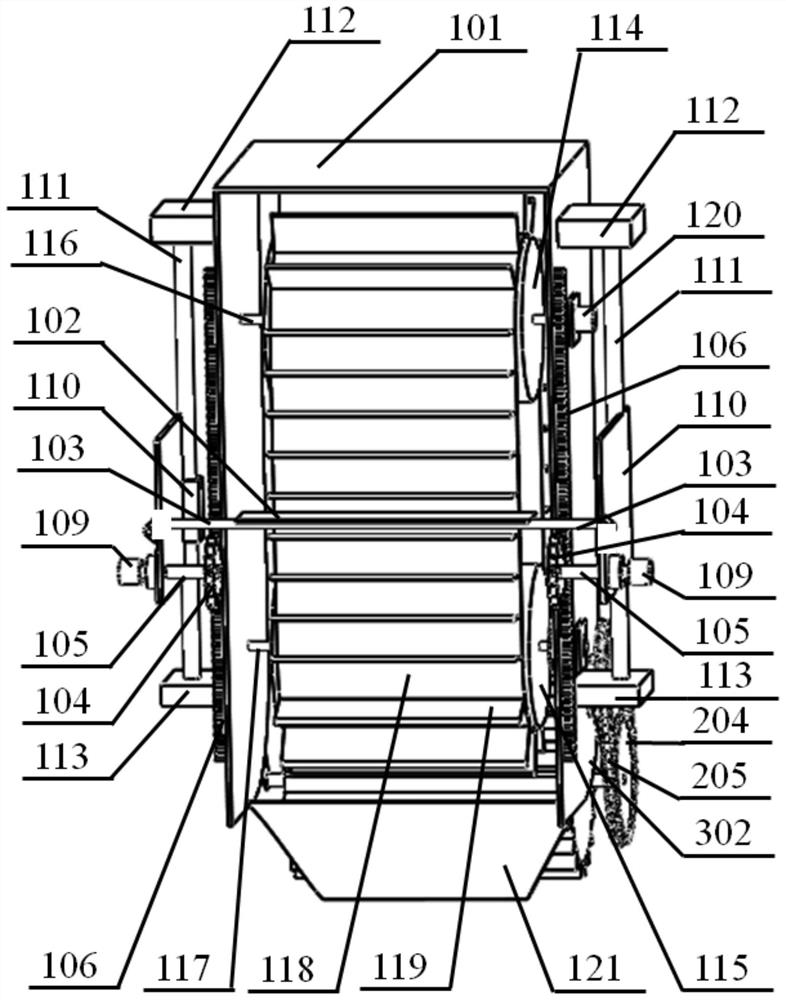

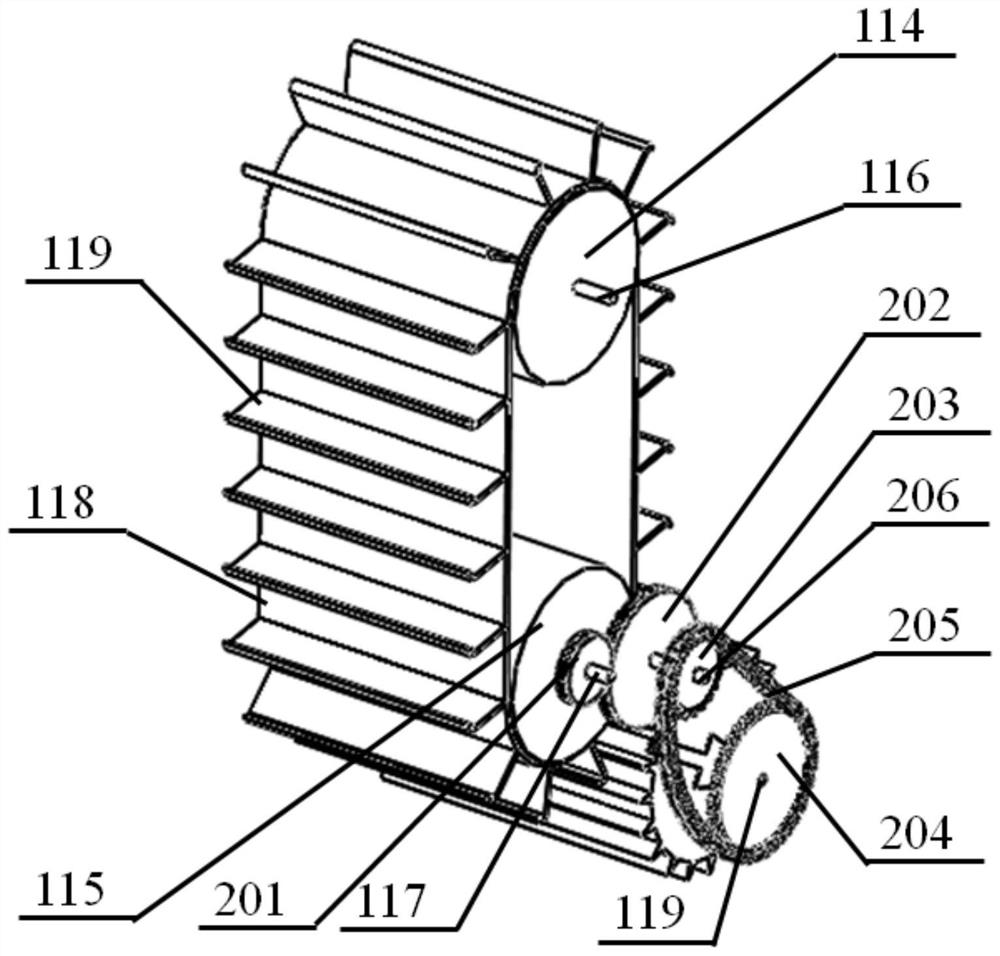

[0060] The vertical conveying assembly 1 includes a housing 101, a transition plate 102, a support shaft 103, an elevating gear 104, an elevating gear shaft 105, an elevating rack 106, a first bearing 107, a first bearing seat 108, a drive motor 109, an elevating Sliding plate 110, lifting sliding rod 111, upper limit block 112, lower limit block 113, driving roller 114, driven roller 115, driving roller connecting shaft 116, driven roller connecting shaft 117, conveyor belt 18, separation partition 119 , Drive roller drive motor 120.

[0061] The casing 101 is located outside the conv...

Embodiment 2

[0075] This embodiment is aimed at the adjustment method proposed in Embodiment 1. Specifically, this embodiment provides a dynamic adjustment method for the fruit collection system, by installing four height-adjustable hydraulic components under the support platform of the fruit collection box 7 , to realize the real-time dynamic leveling of the support platform of the fruit collection box 7; by installing the spring damping assembly under the fruit collection box 7, the spring vibration damping assembly will be vertically deformed under the action of the vertical force, so that the fruit collection box 7 is due to the fruit The inclination is caused by uneven falling, so that the real-time measurement of the fruit collection box 7 side tilt angle and pitch angle can be realized to reflect the unevenness of the fruit falling into the fruit collection box 7, and the real-time measurement of the fruit collection box 7 side tilt angle, side tilt angle acceleration, Pitch angle, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com