Multifunctional sand sieving device

A multi-functional, sand-screening technology, which can be used in sieves, solids separation, grids, etc., and can solve the problems of heavy workload, poor practicability, and inability to screen out sand that cannot be thick or fine at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

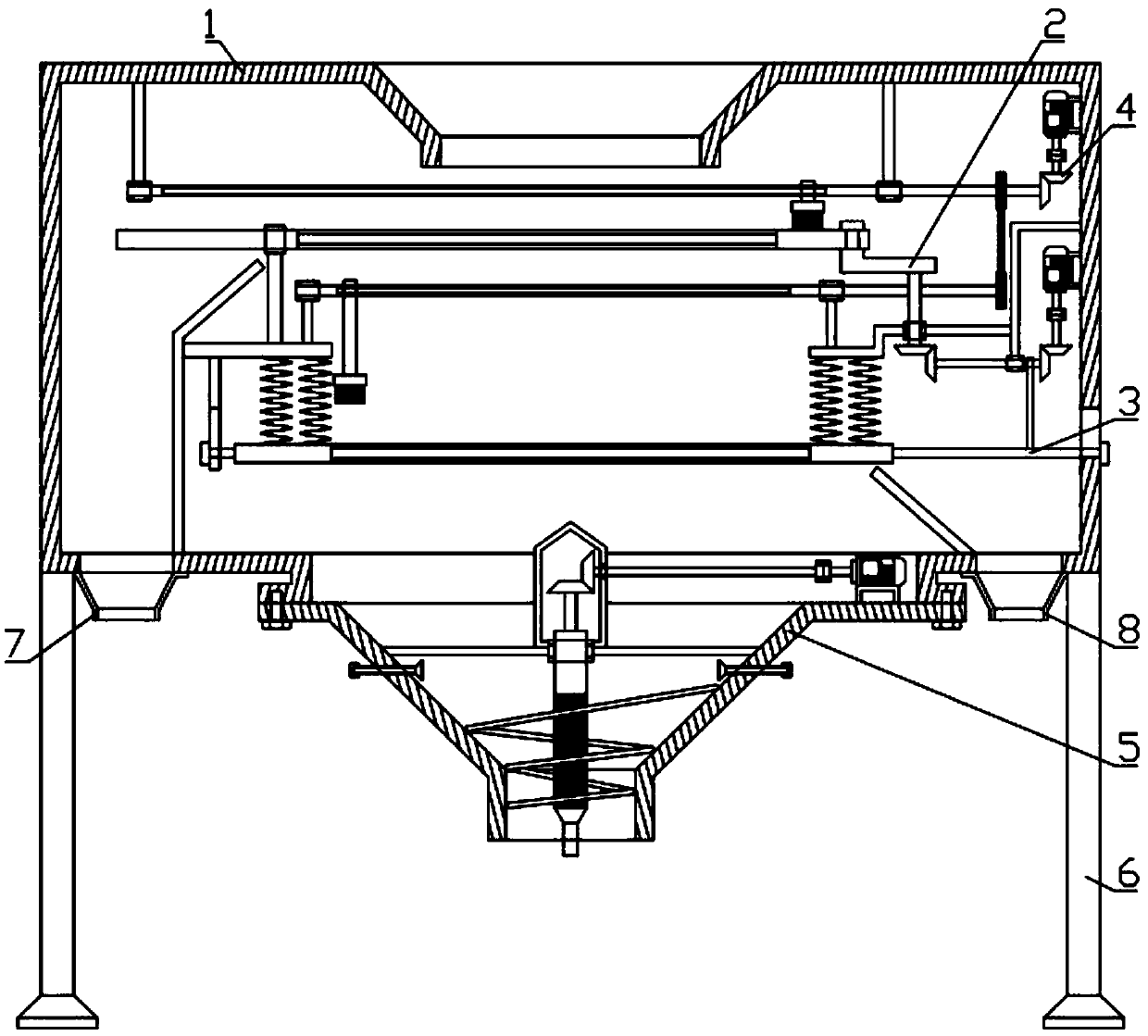

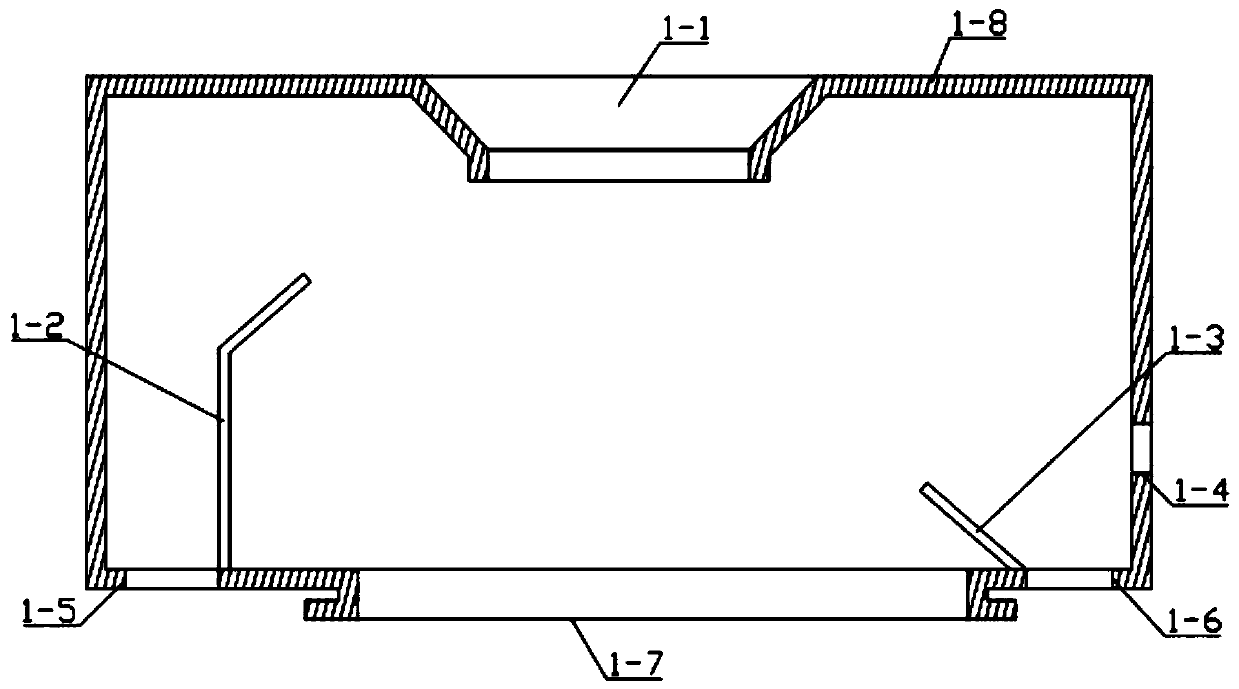

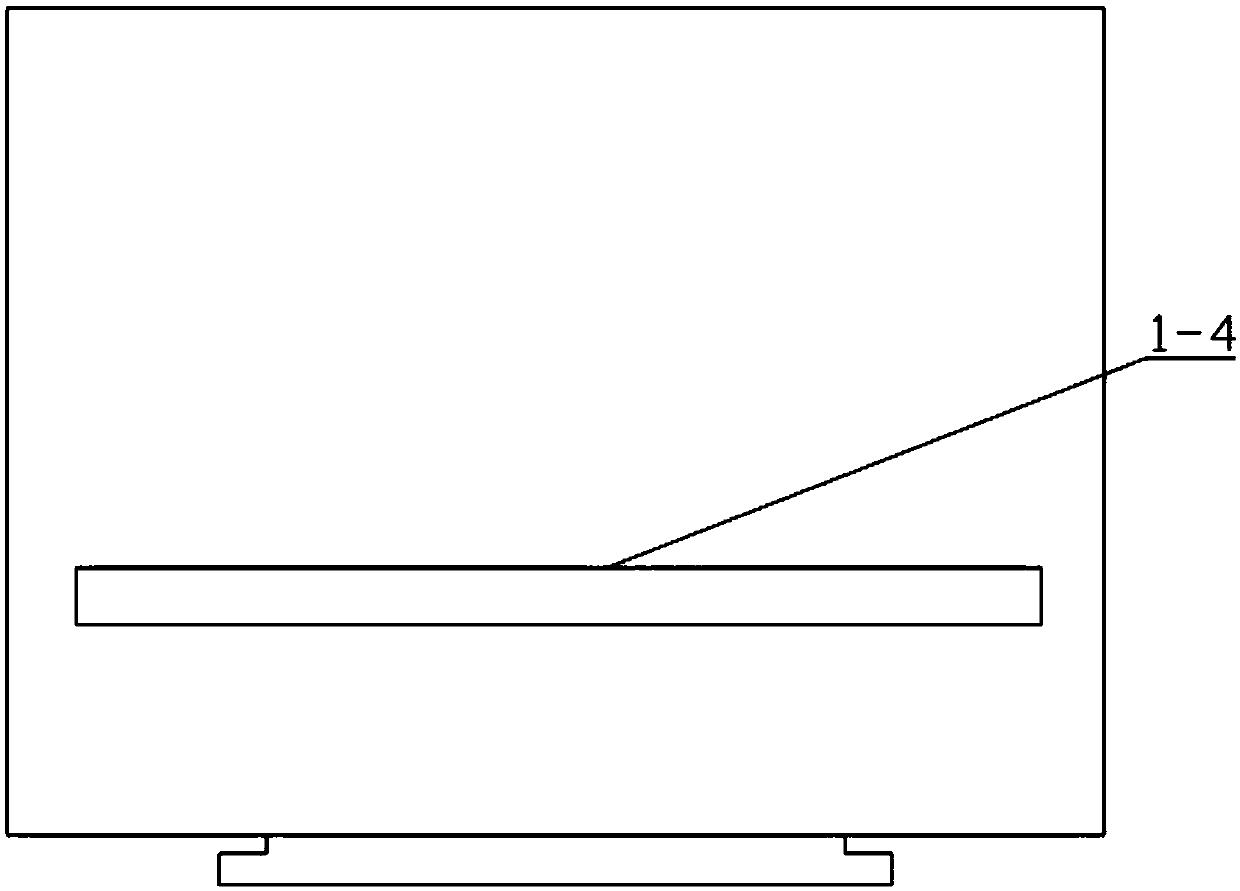

[0030] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 To illustrate this embodiment, the present invention relates to a sand screening device, more specifically a multifunctional sand screening device, including a chassis mechanism 1, a primary sand screening mechanism 2, a secondary sand screening mechanism 3, and a cleaning device 4. Multi-functional secondary sand sieving hopper mechanism 5, bracket 6, waste material hopper 7, primary sieving sand hopper 8, the device can carry out the primary screening of the sand, and the device can continue to carry out the secondary screening of the sand screened out for the first time. Secondary screening, sifting sand of different thicknesses to meet the needs of use, the device can clean and collect sand of different thicknesses, the device can transport the sand, the device can control the falling spee...

specific Embodiment approach 2

[0037] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Illustrate this embodiment, this embodiment will further explain embodiment one, described screen one 2-2, screen two 3-1, secondary sieve sand outlet hopper body 5-1, water inlet pipe 5-2 and conveying The material of conical spiral 5-14 is identical, is all stainless steel.

specific Embodiment approach 3

[0038] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 This embodiment will be described. This embodiment will further describe Embodiment 1. The material of the sealing gasket 5-18 is rubber.

[0039] The device can screen the sand for the first time. The method of use of the device: the device can screen the sand for the first time, the motor one 2-11 drives the motor shaft one 2-21 to rotate, and the motor shaft one 2-21 drives the drive shaft one 2-19 Rotation, drive shaft one 2-19 drives bevel gear four 2-18 to rotate, bevel gear four 2-18 drives gear three 2-17 to rotate, gear three 2-17 drives connecting shaft 2-15 to rotate, and connecting shaft 2-15 drives Bevel gear two 2-14 rotates, bevel gear two 2-14 drives bevel gear one 2-13 to rotate, bevel gear one 2-13 drives support shaft one 2-9 to rotate, support shaft one 2-9 drives L-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com