Wafer loading disc for MOCVD (metal organic chemical vapor deposition) reactor and MOCVD reactor

A technology for reactors and wafers, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of not being able to maximize the use of the loading plate and uneven temperature in the peripheral area of the surface, so as to prevent the reaction of reactants Diffuse into the area of the heating device, improve equipment performance, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

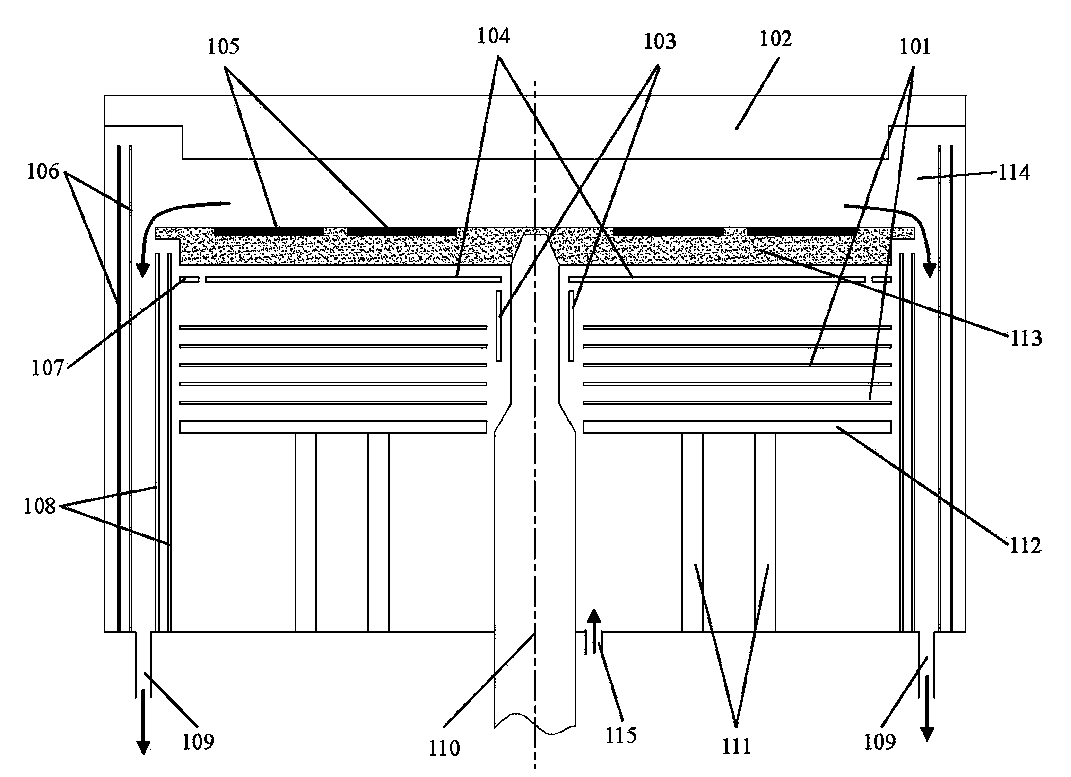

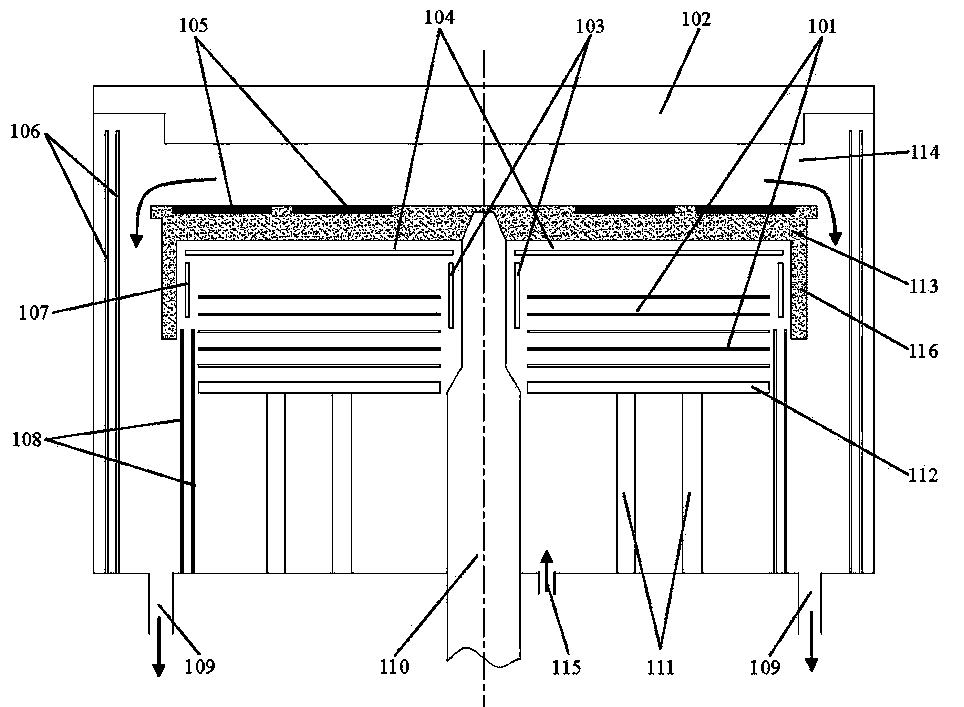

[0031] A MOCVD reactor, such as figure 2 As shown, above the reactor is a gas distribution device (shower head) 102, below 102 is a wafer carrier 113, the upper surface of 113 has a circular groove for placing the wafer 105, and the lower surface is an annular protrusion 116, surrounding the ring The protrusion 116 is provided with a heat shield 106, and the annular protrusion 116 is also provided with an outer ring 107 of a heating device. The wafer carrier 113 is coupled to the rotating shaft 110 through the cone-shaped hole, and the wafer carrier 113 can rotate at a specified speed driven by the rotating shaft. Just below the wafer carrier 113 is provided with a ring heating body 104 in the heating device. There are several horizontal heat-insulation shielding layers 101 under the heating body in the heating device, and a cooling plate 112 with a cooling device is arranged below the heat-insulation shielding layer 101, and a cylindrical heat-insulation shielding layer 108...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com