Patents

Literature

38results about How to "Prevent diffusion from entering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

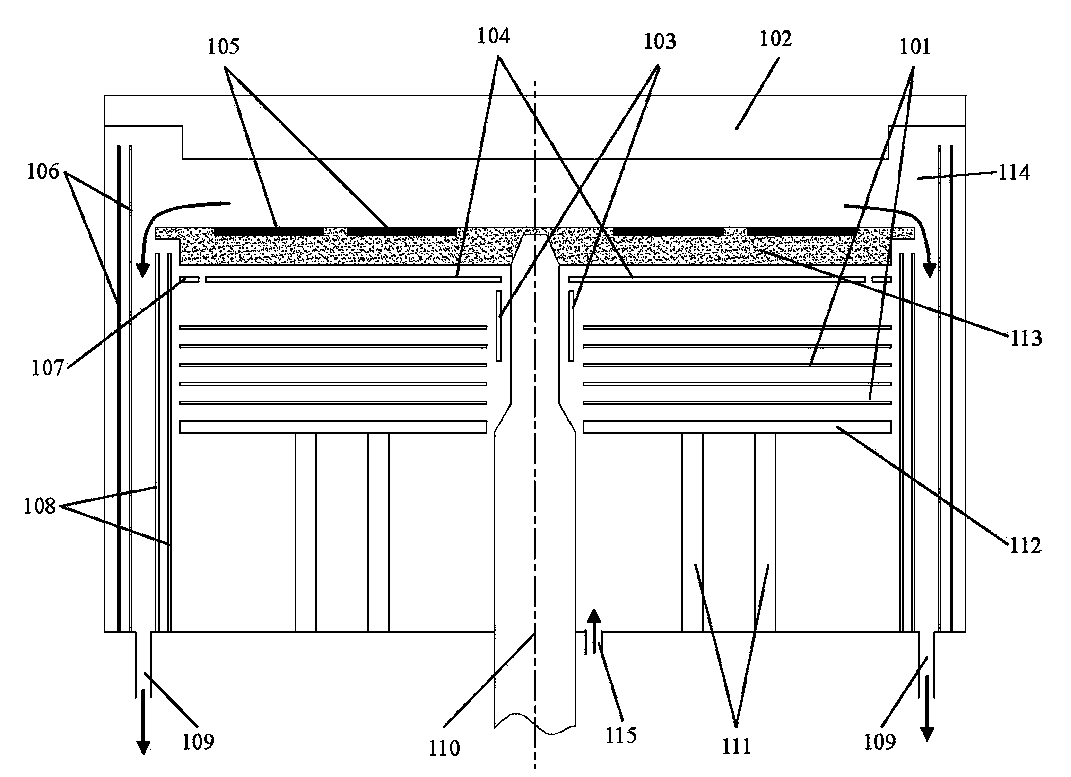

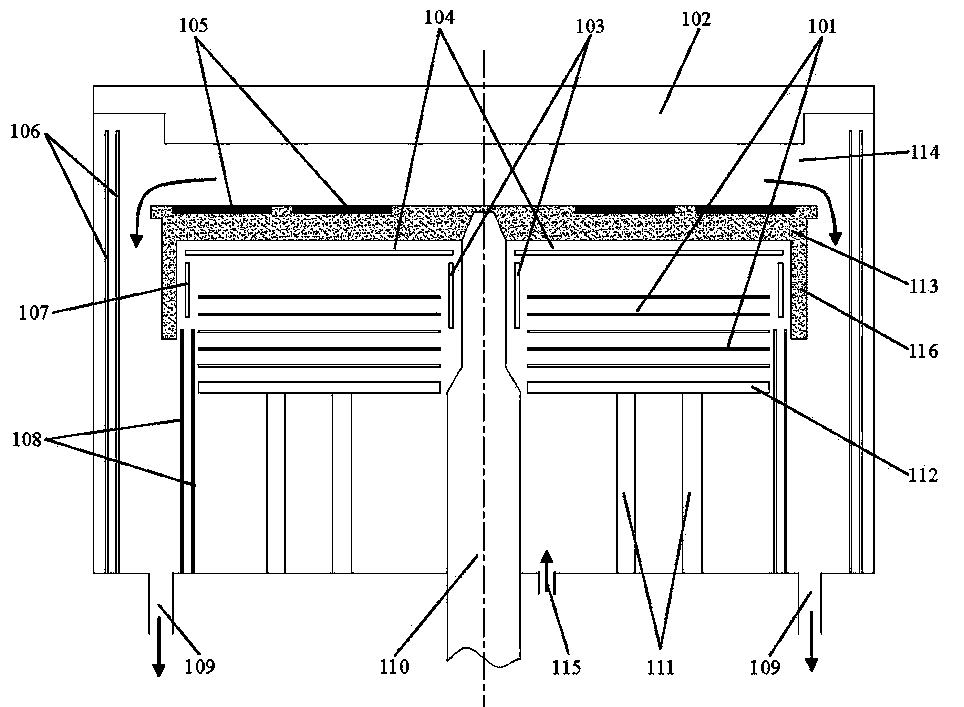

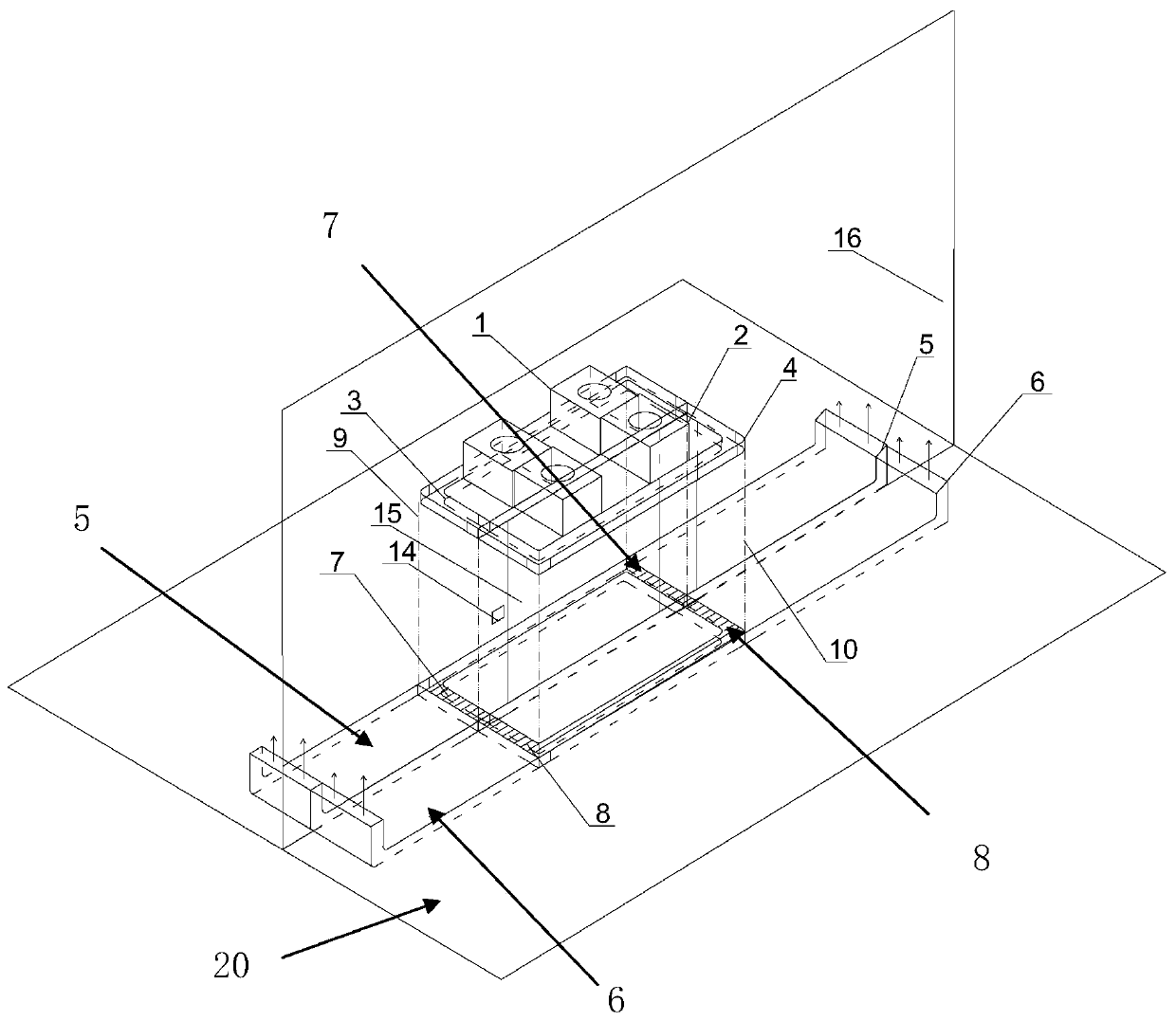

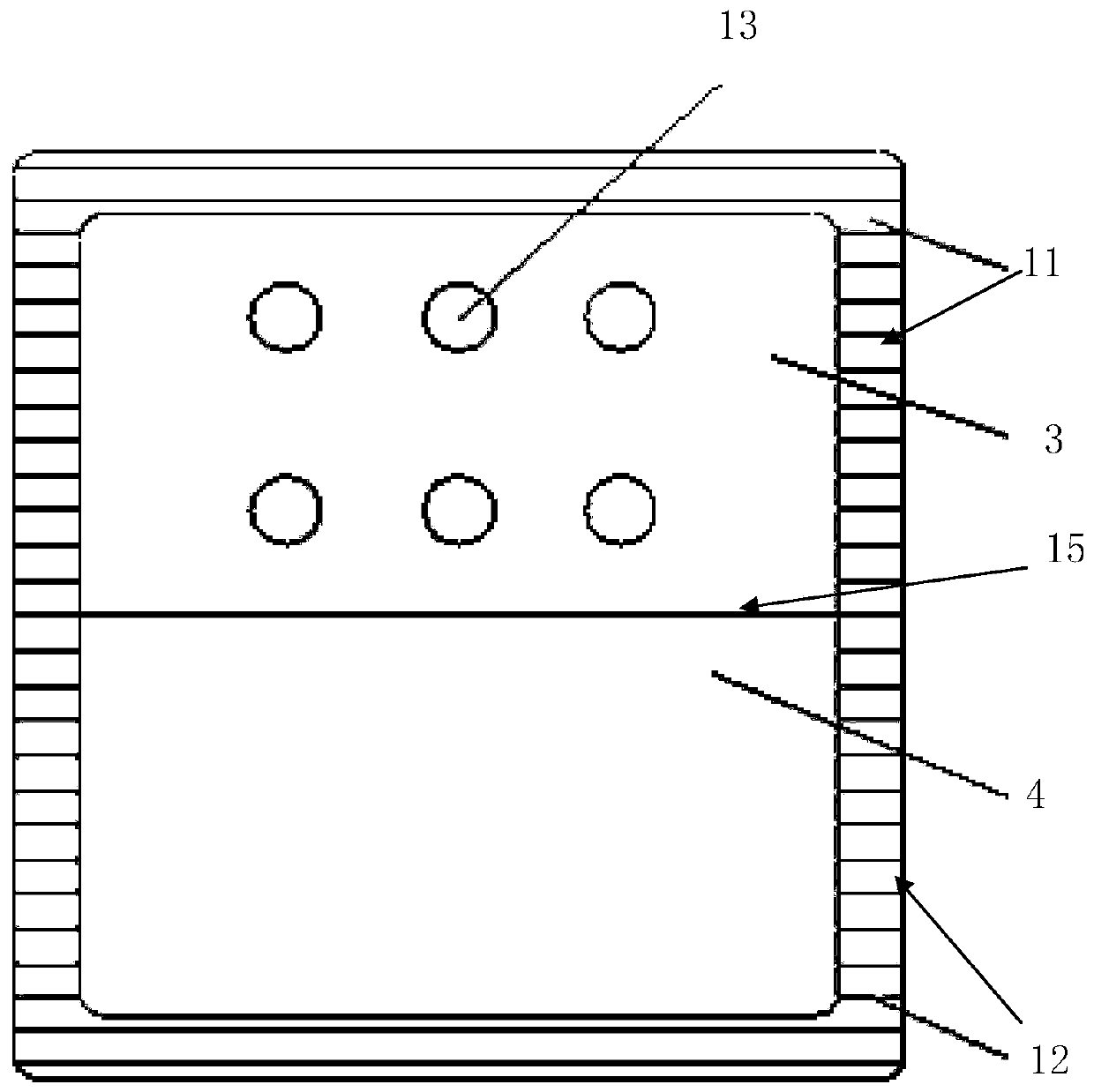

Wafer loading disc for MOCVD (metal organic chemical vapor deposition) reactor and MOCVD reactor

ActiveCN103526186AImprove protectionImprove thermal energy utilization efficiencyChemical vapor deposition coatingEngineeringHeat energy

The invention discloses a wafer loading disc for an MOCVD (metal organic chemical vapor deposition) reactor and an MOCVD reactor. In order to expand the range of a uniform-temperature field on the surface of the wafer loading disc to the greatest degree, the wafer loading disc for the MOCVD reactor comprises a wafer loading disc body, wherein a groove for placing a wafer is formed in the upper surface of the wafer loading disc body, and the periphery of the lower surface of the wafer loading disc body extends downward to form an annular bulge so that the whole wafer loading disc is of an inverted barrel shape. The MOCVD reactor is provided with the wafer loading disc with the annular bulge and a matched heater, wherein the heater is divided into an inner part, a middle part and an outer part, wherein an inner ring and an outer ring of the heater are vertically arranged in a cylindrical manner, and a middle ring is horizontally arranged in an omega shape. By adopting the wafer loading disc and the MOCVD reactor disclosed by the invention, the utilization efficiency of heat energy is improved; the heating device is separated from a reactant so as to better protect the heating device; meanwhile, the consistent-temperature area on the surface of the wafer loading disc is expanded, thereby increasing the single-batch output.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

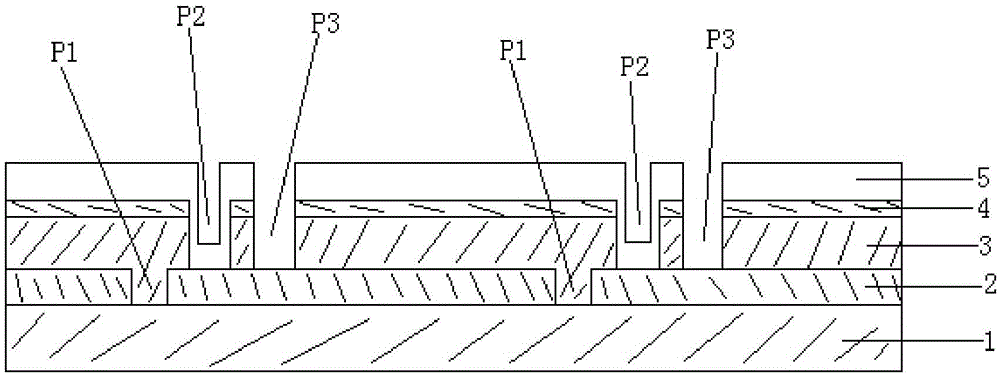

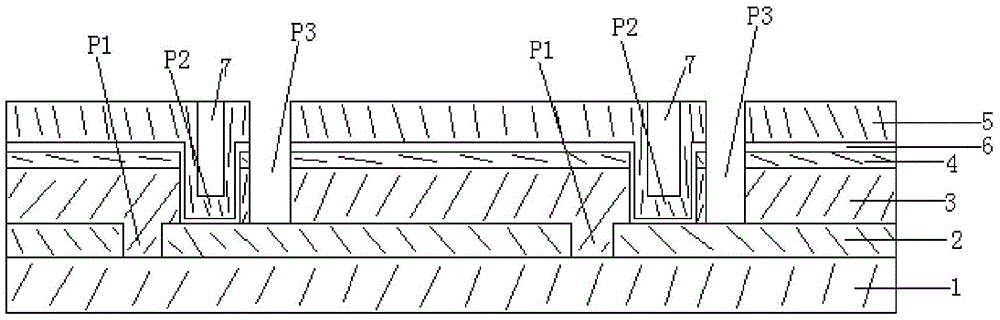

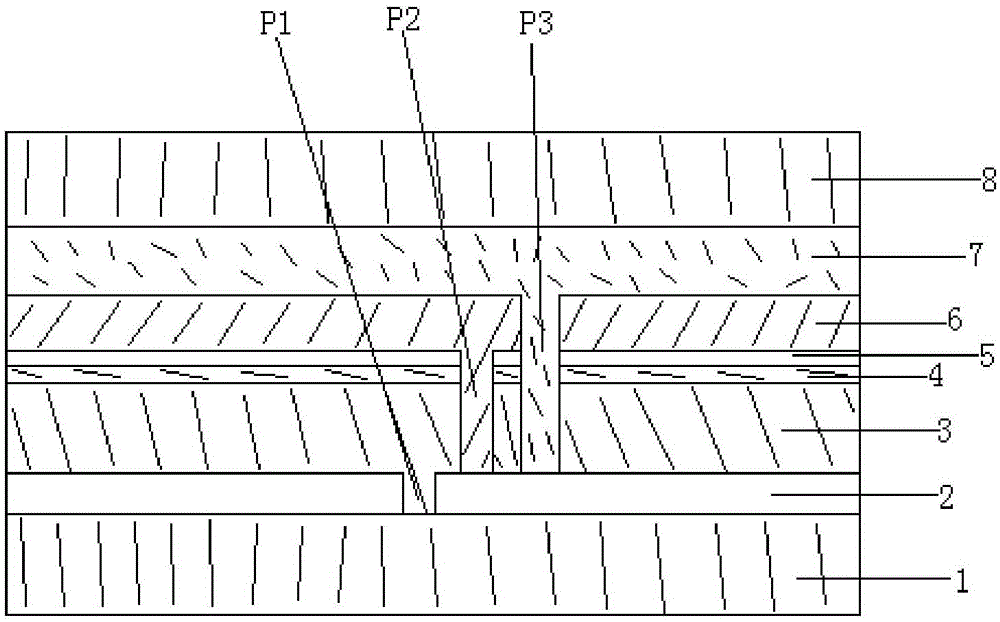

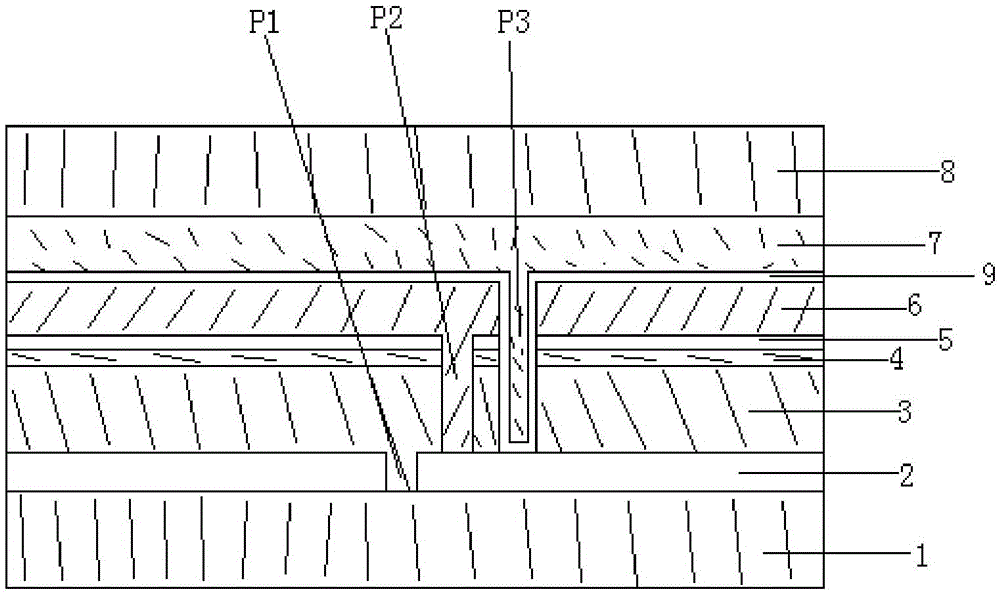

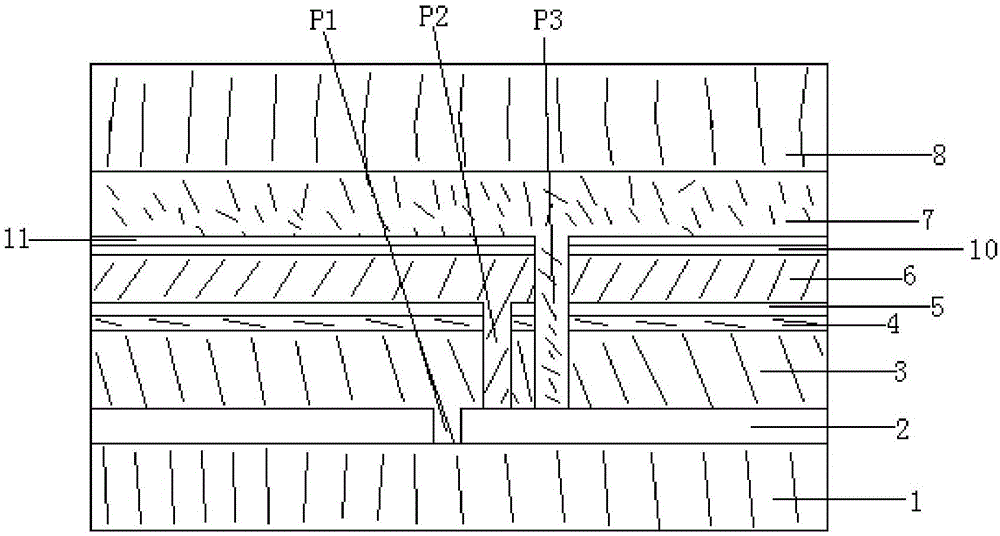

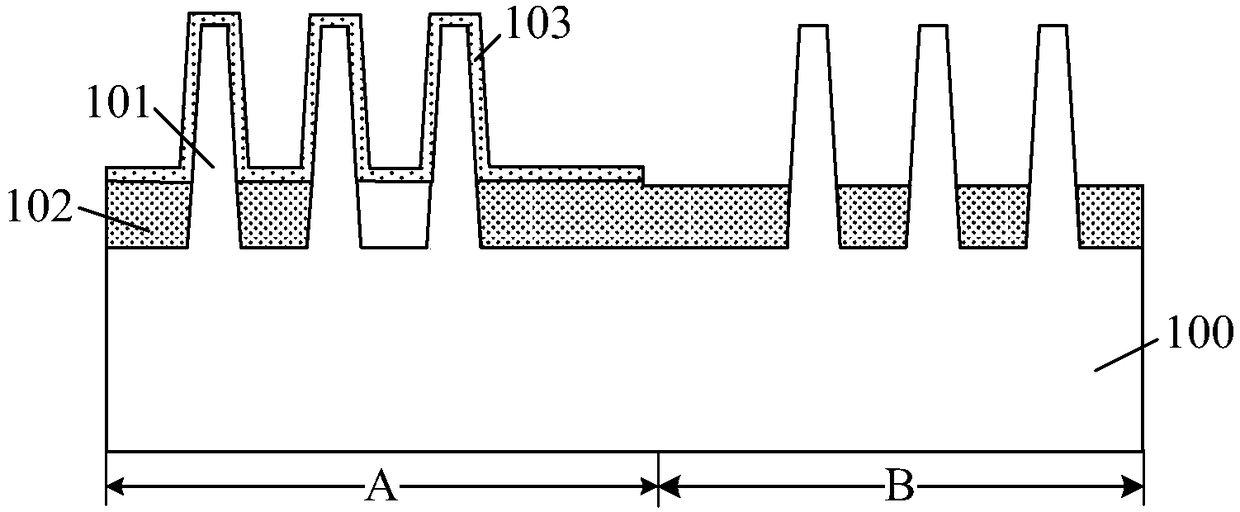

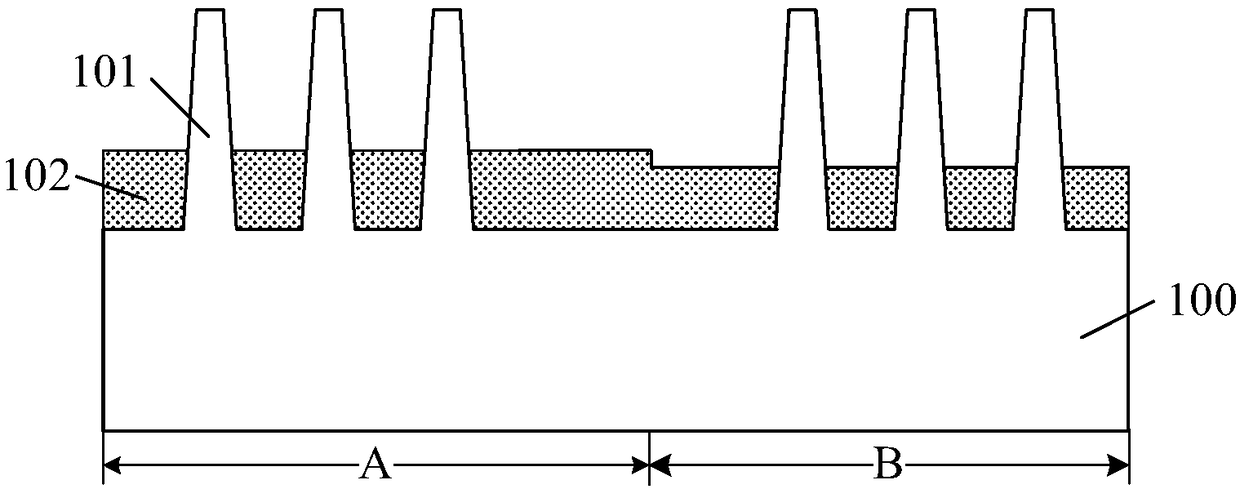

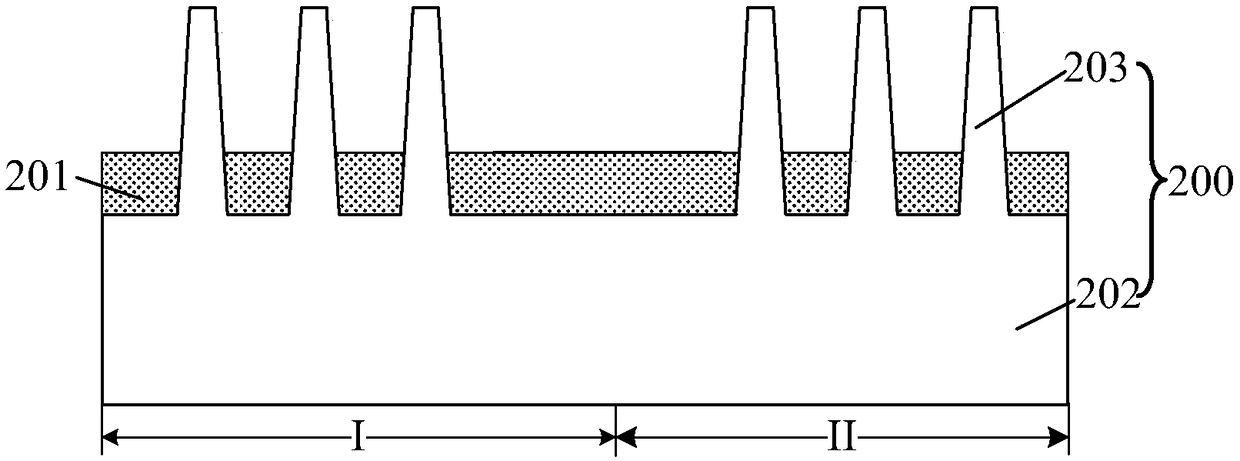

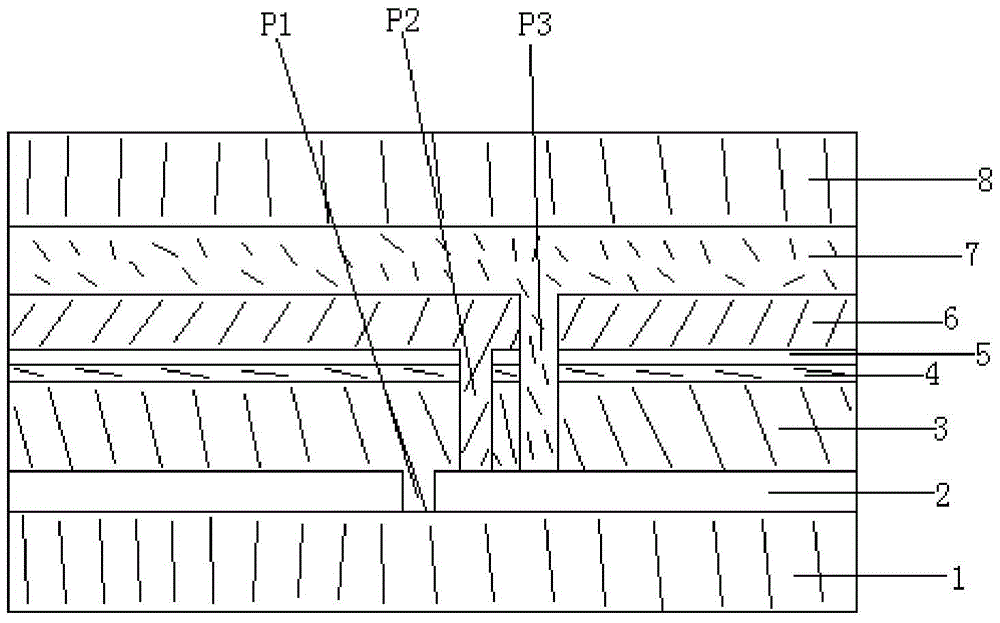

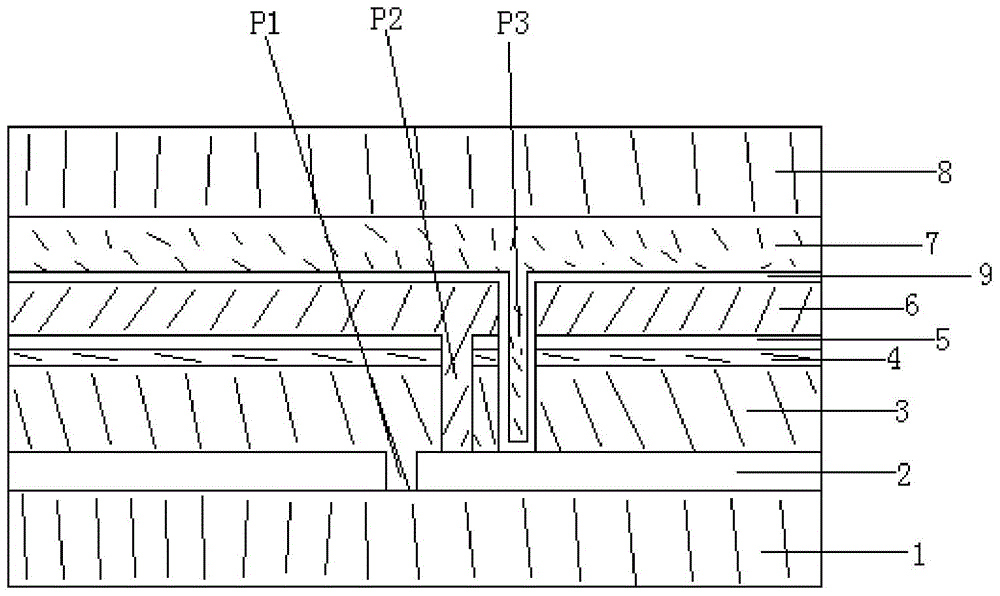

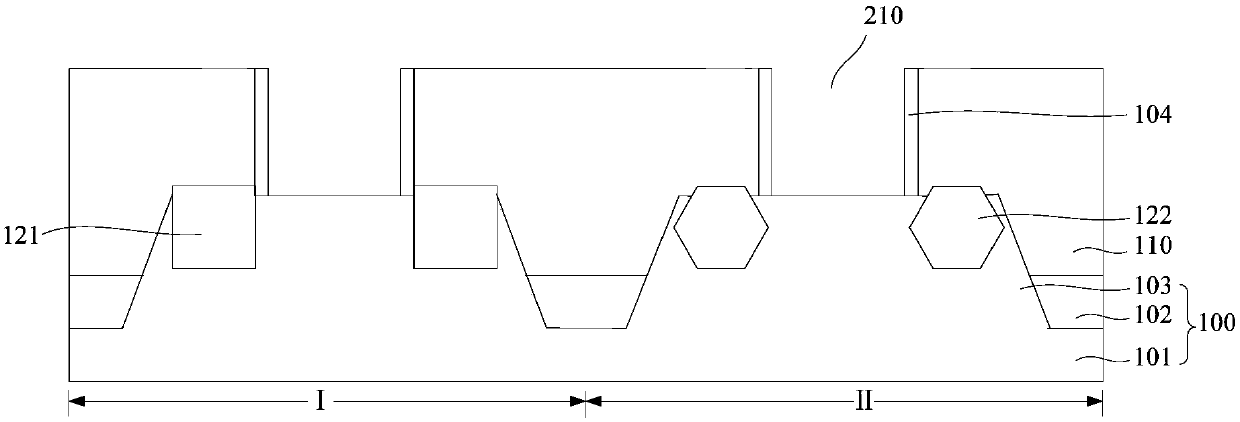

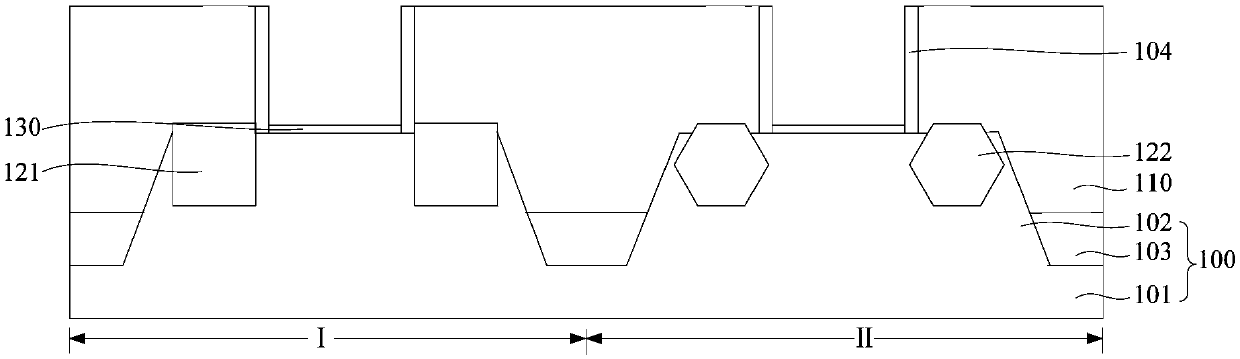

Thin-film solar cell module and preparation method thereof

ActiveCN105789351AReduce compoundingImprove performanceFinal product manufacturePhotovoltaic energy generationTitaniumEngineering

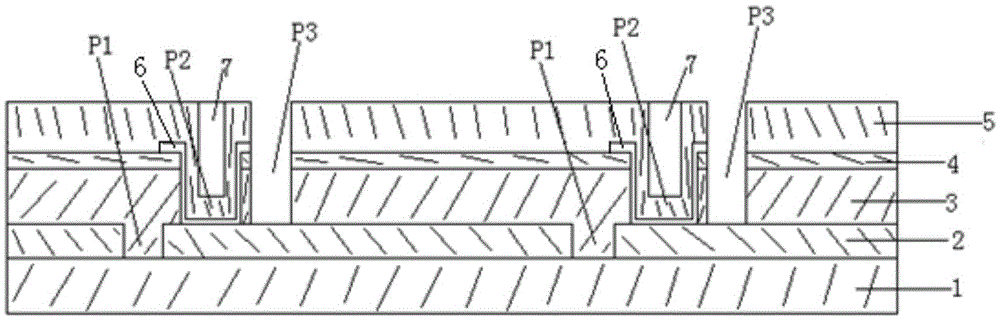

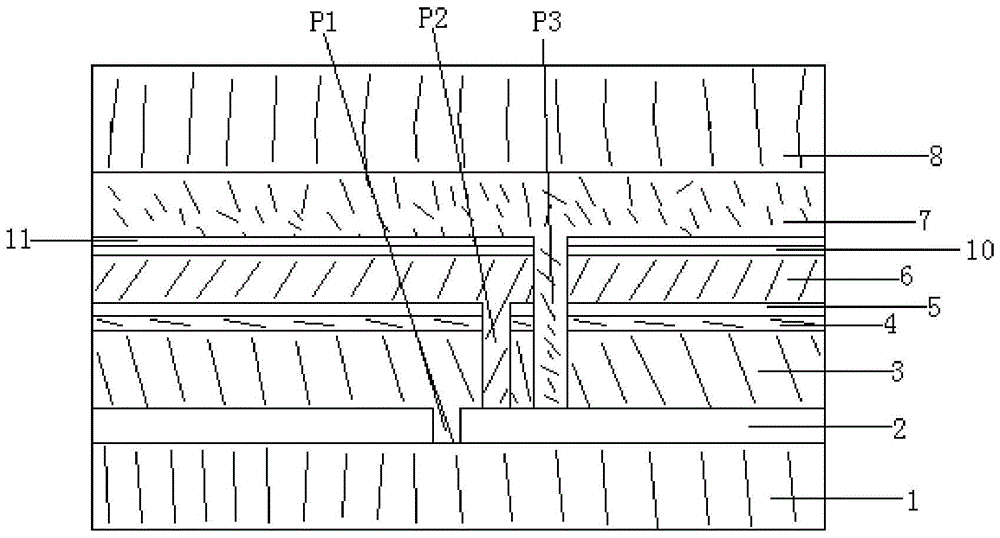

The invention provides a thin-film solar cell module and a preparation method thereof. The thin-film solar cell module comprises a substrate, a back electrode layer, a semiconductor layer, a transparent conductive layer and grooves P1, P2 and P3, wherein the groove P1 is filled with a semiconductor layer material; the side walls and the bottom part of the groove P2 are covered with a high-resistance material film layer; the groove P2 is filled with a conductive material; the high-resistance material film layer is located between the side walls and / or the bottom part of the groove P2 and the transparent conductive layer; the upper part and / or the lower part of the transparent conductive layer are filled with the conductive material; the conductive material is prepared from resin or ink containing conductive particles; and the conductive particles comprise silver, aluminum, titanium, copper, molybdenum, carbon or alloys thereof and the like. The performance of the thin-film solar cell module can be improved.

Owner:厦门神科太阳能有限公司

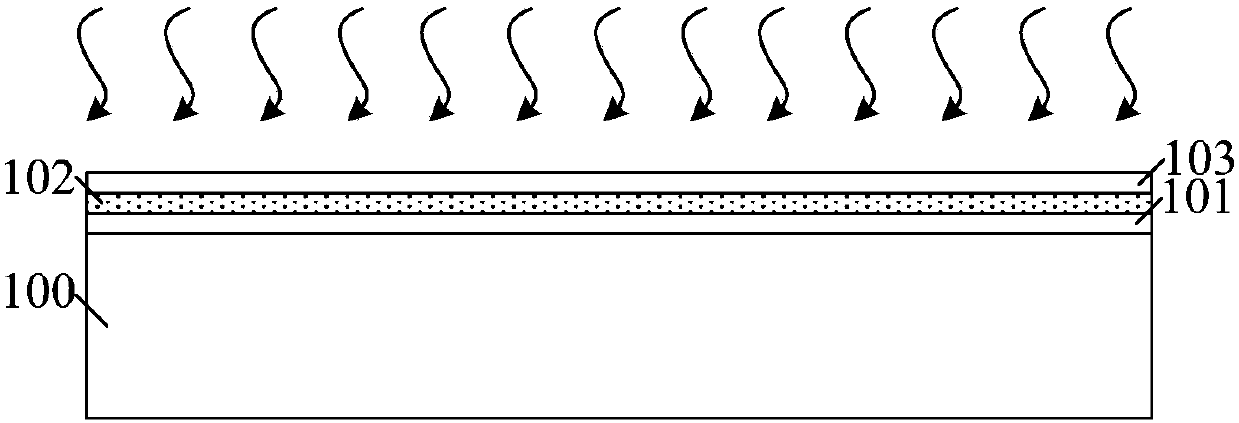

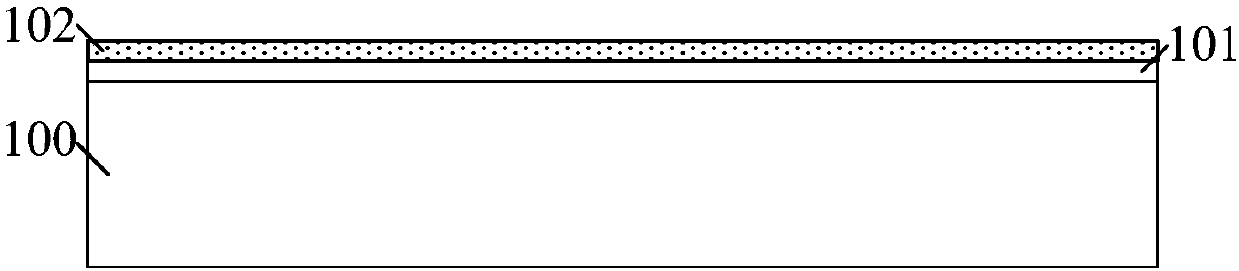

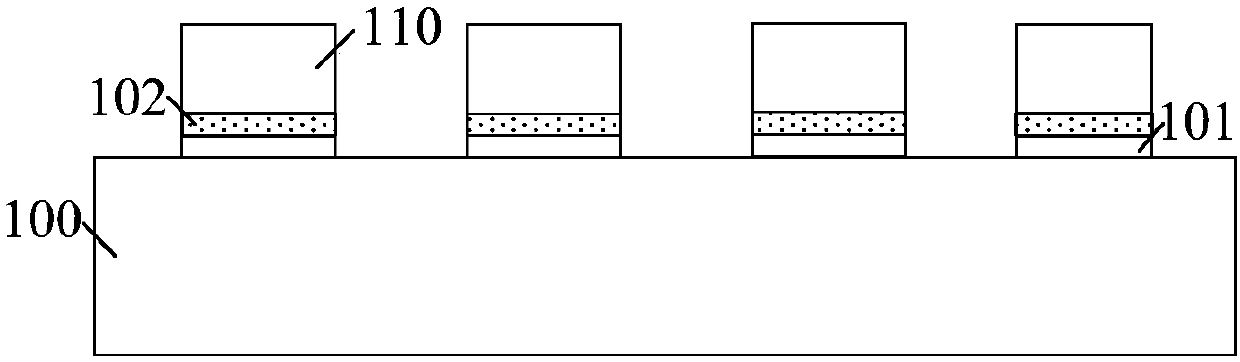

Composite insulating layer for thin film sensor and preparation method of composite insulating layer

InactiveCN105970168AFast film formationImprove compactnessMeasurement devicesVacuum evaporation coatingThin film sensorEvaporation

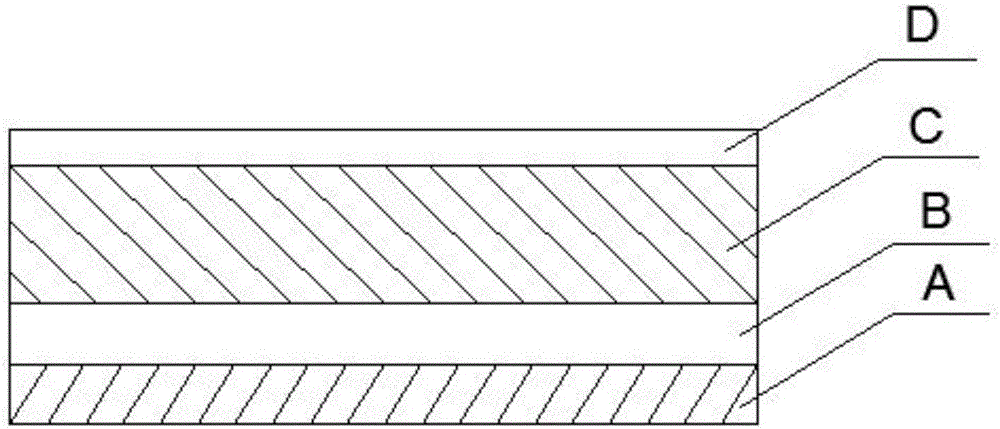

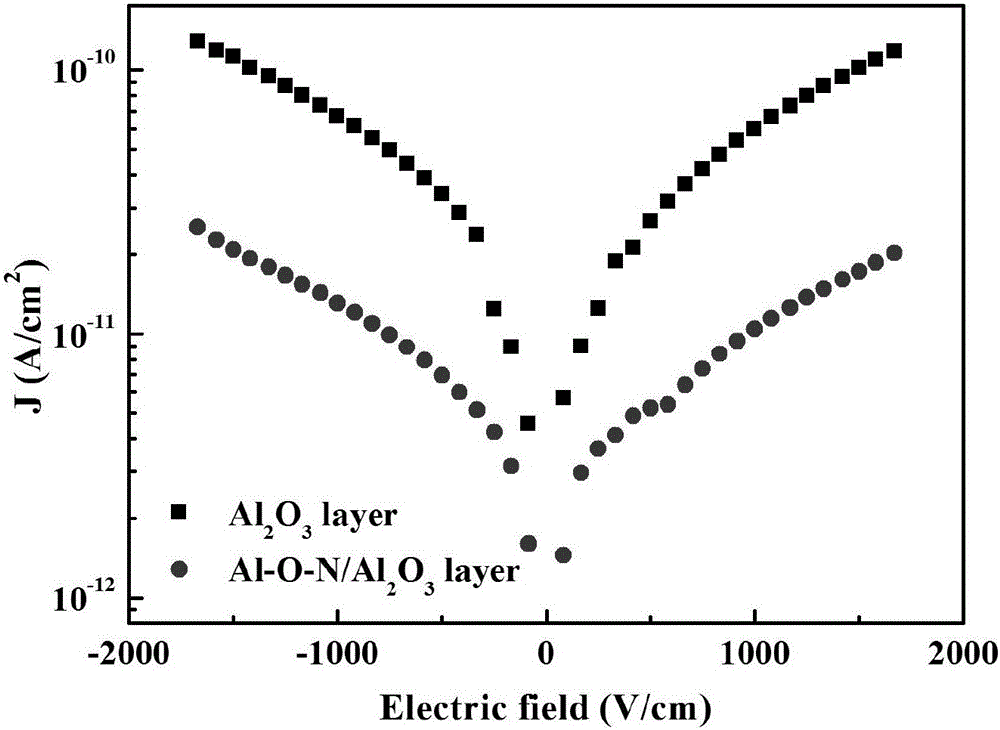

The invention belongs to the technical field of thin film sensors, and relates to a composite insulating layer for a thin film sensor. The composite insulating layer comprises four layers of structures which comprise the amorphous Al-O-N diffusion impervious layer, the Al-O-N-to-Al2O3 transition layer, the electron beam evaporation Al2O3 thin film layer and the microcrystal Al2O3 oxygen diffusion barrier layer in sequence from bottom to top. An amorphous Al-O-N thin film in the composite insulating layer is good in compactness and is in an amorphous state, and a good diffusion barrier effect is achieved for metal atoms. The adhesive force between the amorphous Al-O-N layer and the Al2O3 layer can be effectively improved through the transition layer. The microcrystal layer on the Al2O3 thin film layer can effectively prevent outside oxygen atoms from diffusing into the Al-O-N layer at a high temperature, the amorphous state of the Al-O-N thin film in the high-temperature oxygen-enriched environment is kept, and therefore the composite insulating layer still has good insulation performance in the high-temperature oxygen-enriched work environment, and the stability and the service life of the thin film sensor in the high-temperature environment are effectively guaranteed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

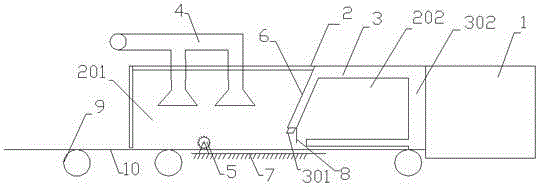

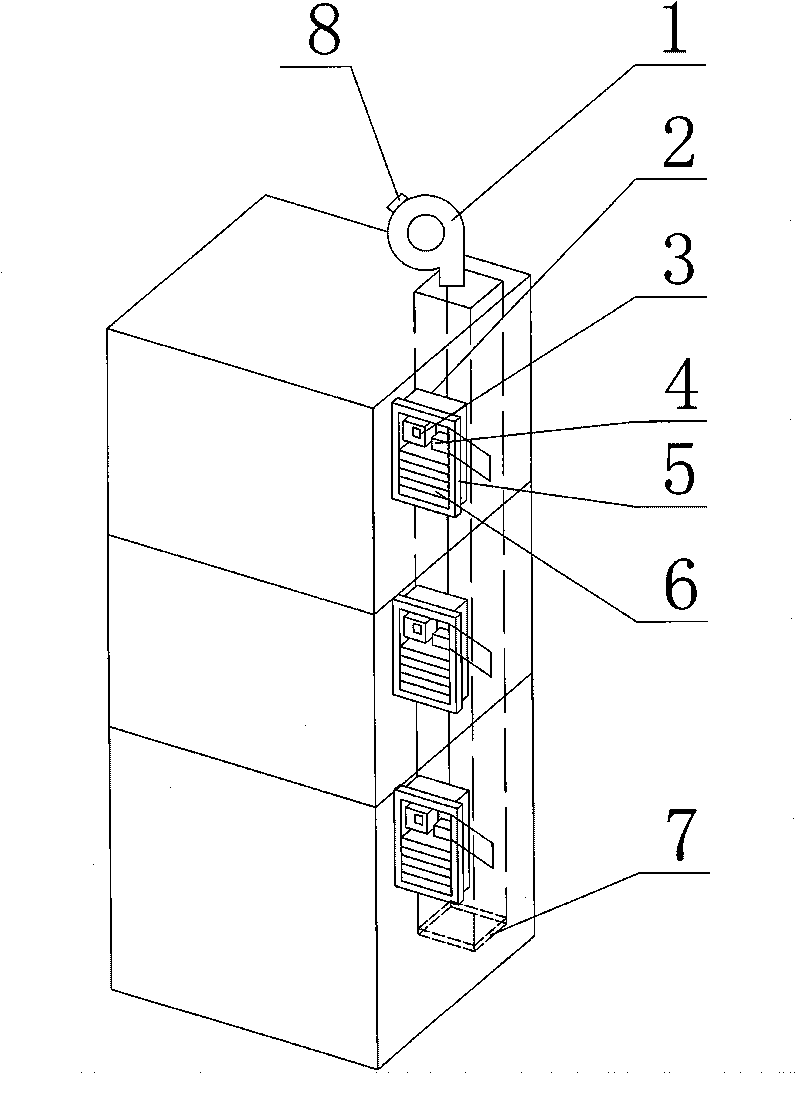

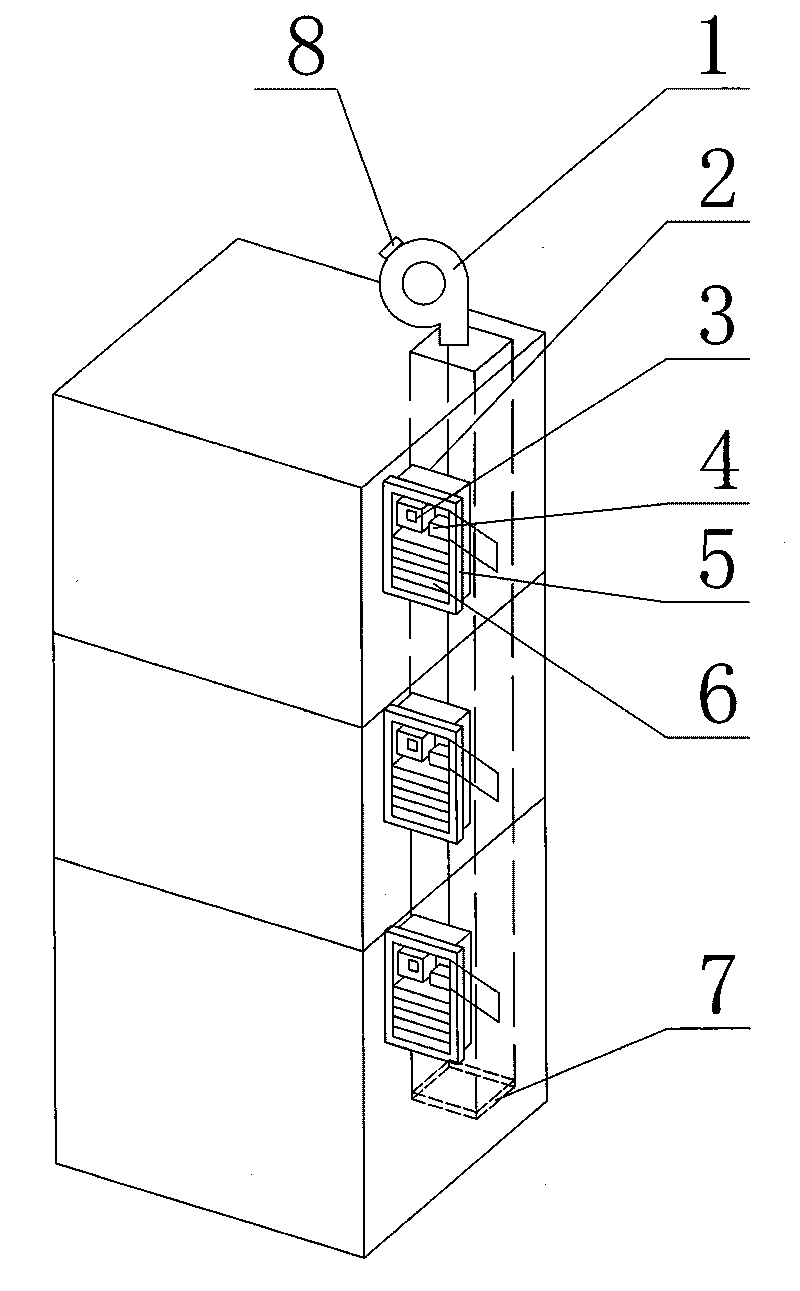

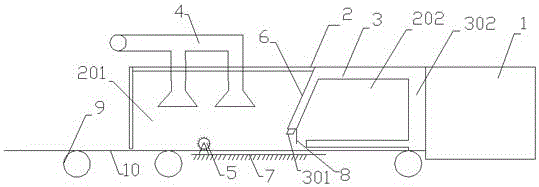

Closed type dust removal device for printing press

InactiveCN104442037APrevent proliferationPrevent diffusion from enteringOther printing apparatusPrinting pressVertical segment

A closed type dust removal device for a printing press comprises a cleaning box communicated with an inlet of the printing press, and a supporting plate inclining in the direction backing on to the printing press is arranged on the top of the inner side of the cleaning box and divides the cleaning box into a dust removing area and a cleaning area. A hairbrush and a dust exhaust mechanism are arranged in the dust removing area, and an air blowing mechanism is arranged in the cleaning area. The air blowing mechanism comprises a dust blowing pipe and an air curtain pipe. The dust blowing pipe is arranged in a cavity of the supporting plate, the air blowing direction of the dust blowing pipe is oblique, air blown out from the dust blowing pipe can raise dust on paper and attachments brushed up by the hairbrush, and the dust and the attachments can be exhausted by the dust exhaust mechanism. The air curtain pipe comprises a vertical segment and a horizontal segment, the vertical segment is arranged on one side of the inlet of the printing press, the air outlet direction of the vertical segment faces the other side of the inlet, and then an air curtain closing the inlet is formed; the horizontal segment is arranged on one side of the cleaning box, the air outlet direction of the horizontal segment faces the other side of the cleaning box, and then an air curtain closing the paper face is formed. According to the closed type dust removal device for the printing press, the dust on the paper is effectively cleared through cooperation of the hairbrush, the air blowing mechanism and the dust exhaust mechanism, and printing quality is guaranteed.

Owner:HENAN GUOHUA COLOR PRINTING PACKAGING

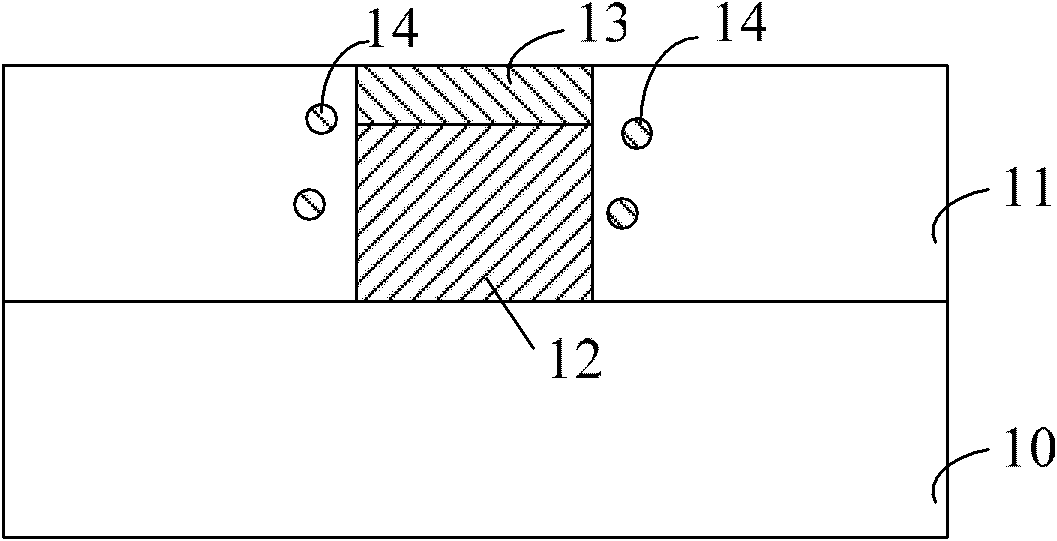

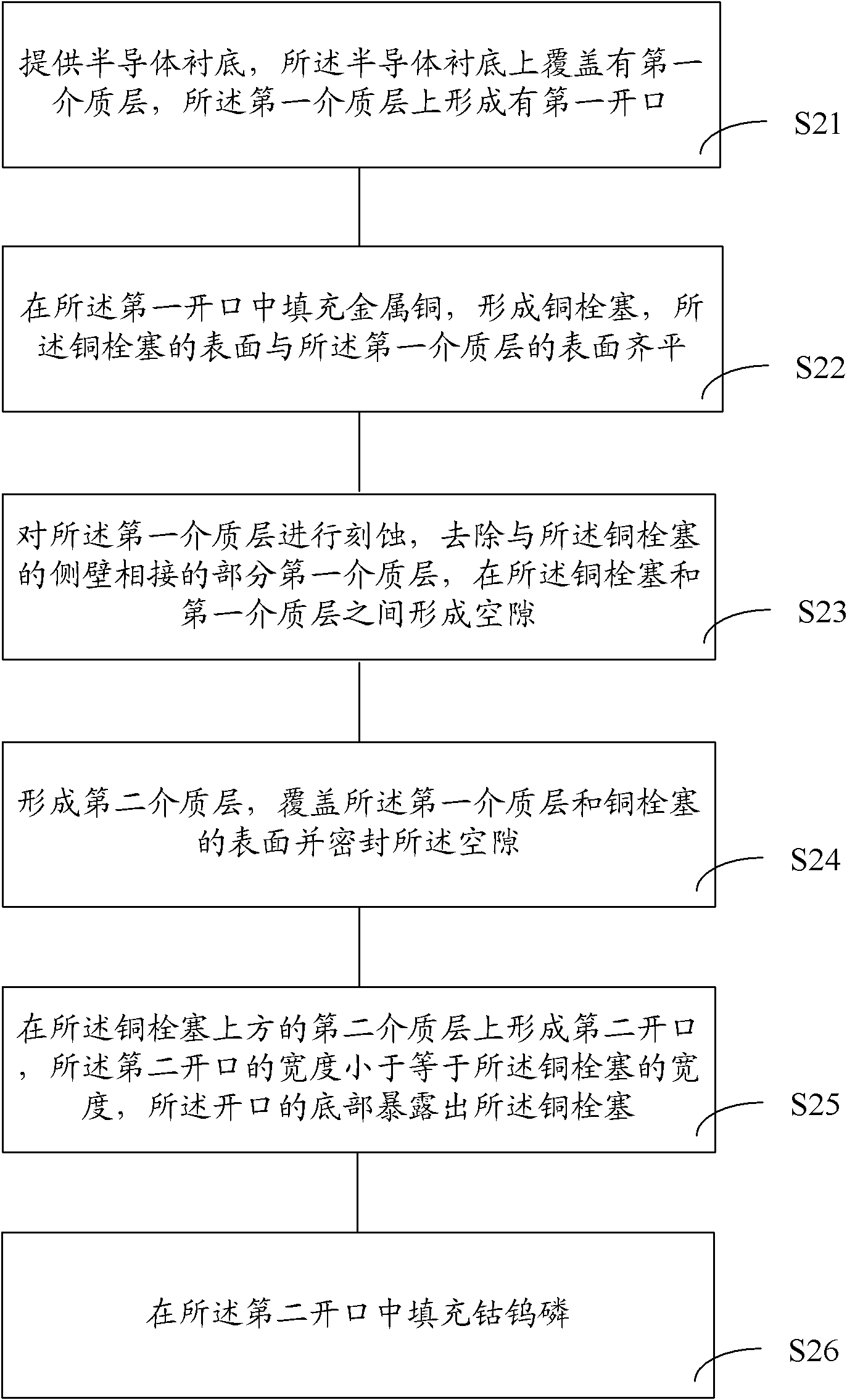

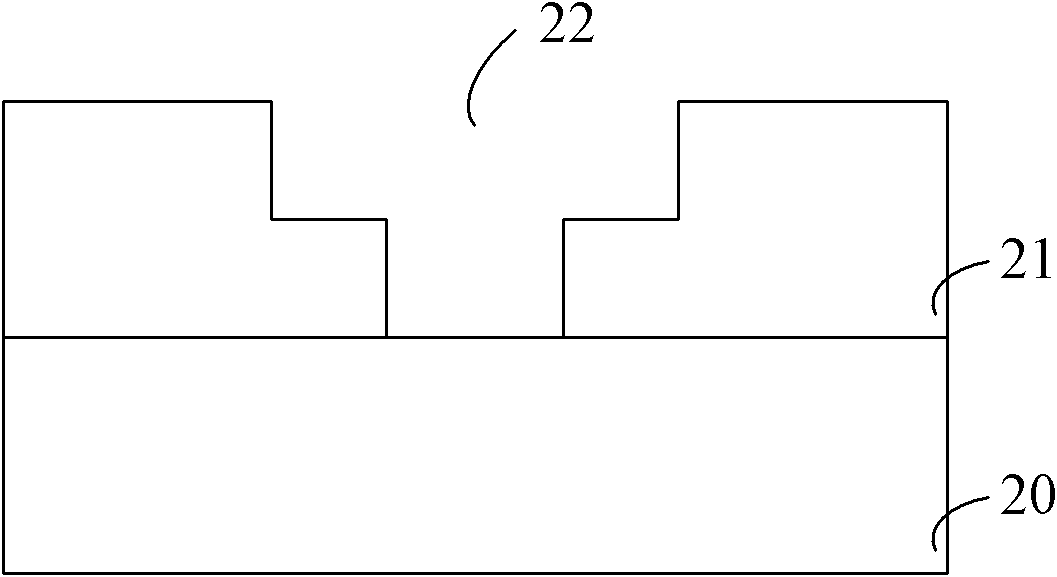

Copper interconnection structure and forming method thereof

ActiveCN102487038AAvoid TDDB problemsImprove reliabilitySemiconductor/solid-state device manufacturingIonTungsten

The invention provides a copper interconnection structure and a forming method thereof. The forming method of the copper interconnection structure comprises the following steps of: providing a semiconductor substrate, wherein the semiconductor substrate is covered with a first dielectric layer and a first opening is formed on the first dielectric layer; filling metal copper in the first opening to form a copper plug, wherein the surface of the copper plug is flush with the surface of the first dielectric layer; etching the first dielectric layer and removing a part of the first dielectric layer, which is connected with the side wall of the copper plug, so as to form a gap between the copper plug and the first dielectric layer; forming a second dielectric layer which covers the surfaces of the first dielectric layer and the copper plug and seals the gap; forming a second opening on the second dielectric layer above the copper plug, wherein the width of the second opening is less than the width of the copper plug and the copper plug is exposed out of the bottom of the second opening; and filling cobalt tungsten phosphorus in the second opening. Through adoption of the forming method of the copper interconnection structure, metal ions can be prevented from diffusing into the dielectric layers, thereby improving reliability.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

CIGS (Copper Indium Gallium Selenide)-based thin-film solar cell and manufacturing method thereof

ActiveCN105023958AStop the spreadPrevent diffusion from enteringFinal product manufacturePhotovoltaic energy generationComposite filmMaterials science

The invention provides a CIGS (Copper Indium Gallium Selenide)-based thin-film solar cell and a manufacturing method thereof. The CIGS-based thin-film solar cell comprises a substrate, a back electrode layer covering the surface of the substrate, a light absorption layer covering the back electrode layer, a buffer layer covering the light absorption layer, a transparent conducting layer covering the buffer layer, and an aluminum oxynitride silicon film layer covering the transparent conducting layer, or a composite film layer alternatively constructed by a zinc oxide silicon film layer and a silicon oxynitride film layer. Through the aluminum oxynitride silicon film layer or the composite film layer, external water molecules can be effectively prevented from entering the thin-film cell, and the decreasing degree of the efficiency of the thin-film solar cell is reduced. Meanwhile, an anti-reflection effect can be achieved, and the light absorption layer through which incident light reaches the cell is added, so that the short-circuit current of the thin-film cell can be increased.

Owner:厦门神科太阳能有限公司

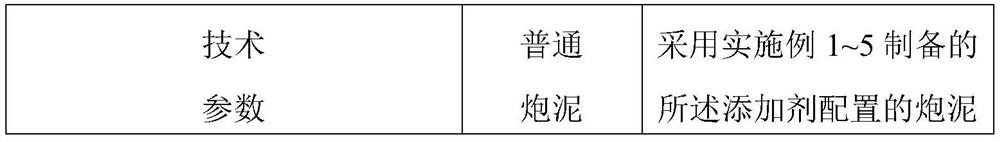

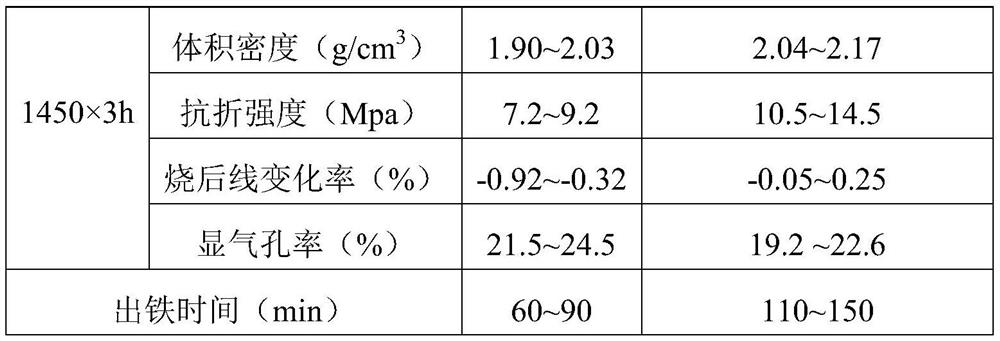

Additive for anhydrous stemming and preparation method thereof

ActiveCN111704472ACause potential harmAvoid the problem of high carcinogen benzopyreneProcess efficiency improvementPhysical chemistryCarbide

The invention relates to an additive for anhydrous stemming and a preparation method thereof. The preparation method comprises the following steps: preparing following raw materials in percentage by weight at first: 35 to 55 wt% of andalusite fine powder; 10-30 wt% of kyanite fine powder, 6-16 wt% of titanium oxide fine powder, 5-15 wt% of silicon oxynitride fine powder, 3-7 wt% of titanium aluminum carbide fine powder, 3-7 wt% of earthy graphite fine powder, 1-3 wt% of simple substance silicon fine powder, 2-5 wt% of bentonite fine powder and 2-5 wt% of nickel oxide fine powder; adding 0.5-2.5 wt% of polypropylene fibers and 7-15 wt% of cobalt modified phenolic resin fine powder into the raw materials, and mixing in a mixer for 20-30 minutes to obtain the additive for anhydrous stemming,wherein the Al2O3 content of the andalusite fine powder is more than 52 wt%, the particle size of the andalusite fine powder is less than 75 [mu]m; the Al2O3 content of the kyanite fine powder is larger than 54 wt%, and the particle size of the kyanite fine powder is smaller than 45 [mu]m. The prepared additive for the anhydrous stemming does not pollute the environment, and can obviously improvethe strength, the volume stability, the oxidation resistance and the erosion resistance of the anhydrous stemming.

Owner:湖南立达高新材料有限公司 +1

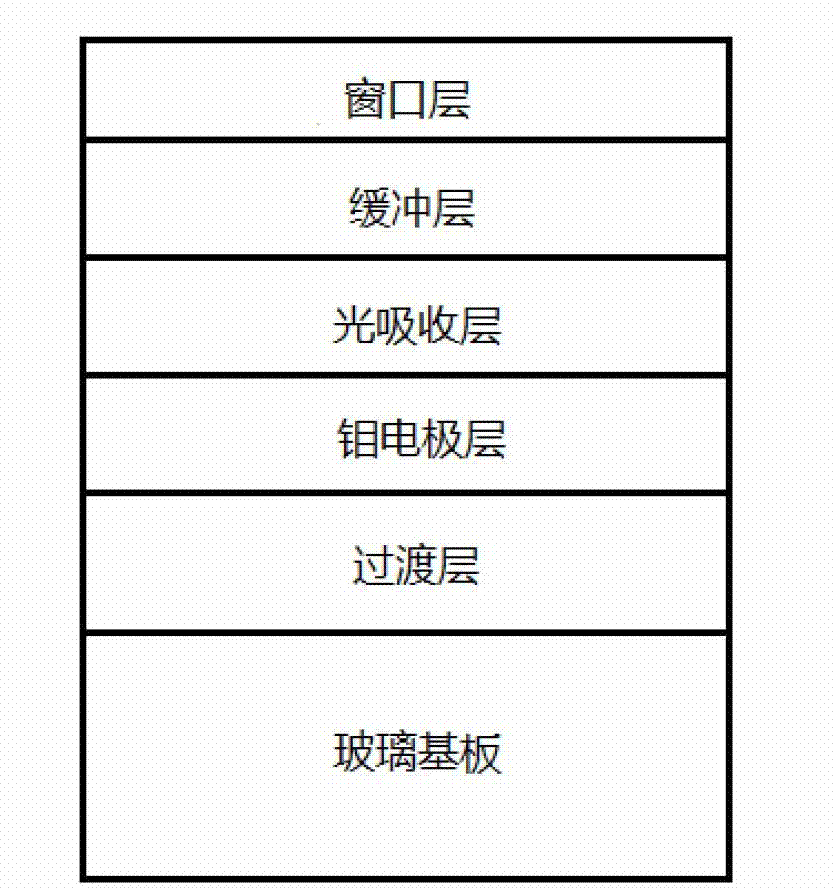

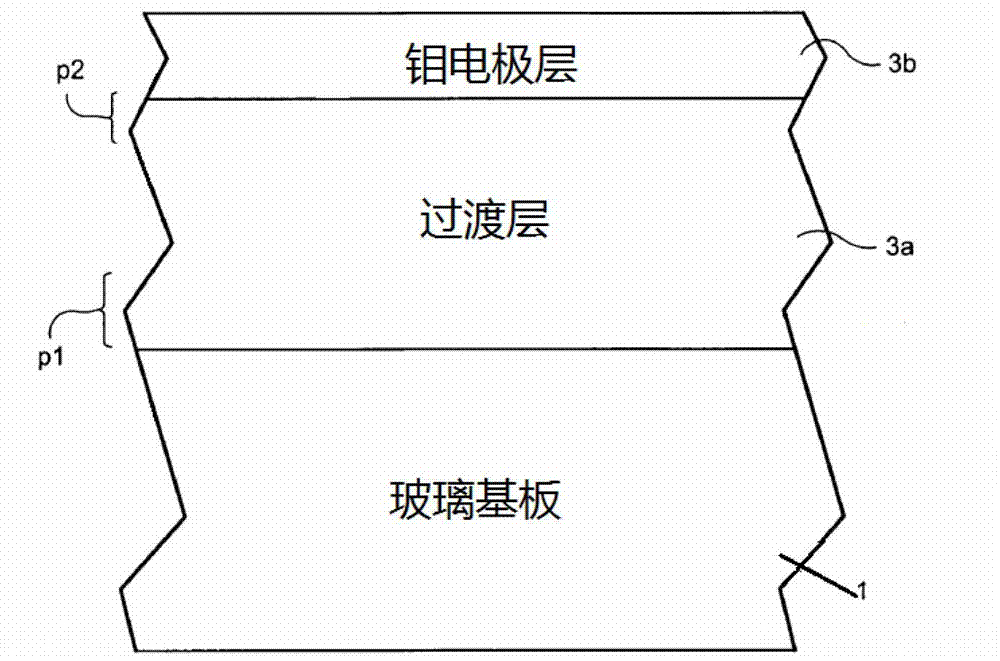

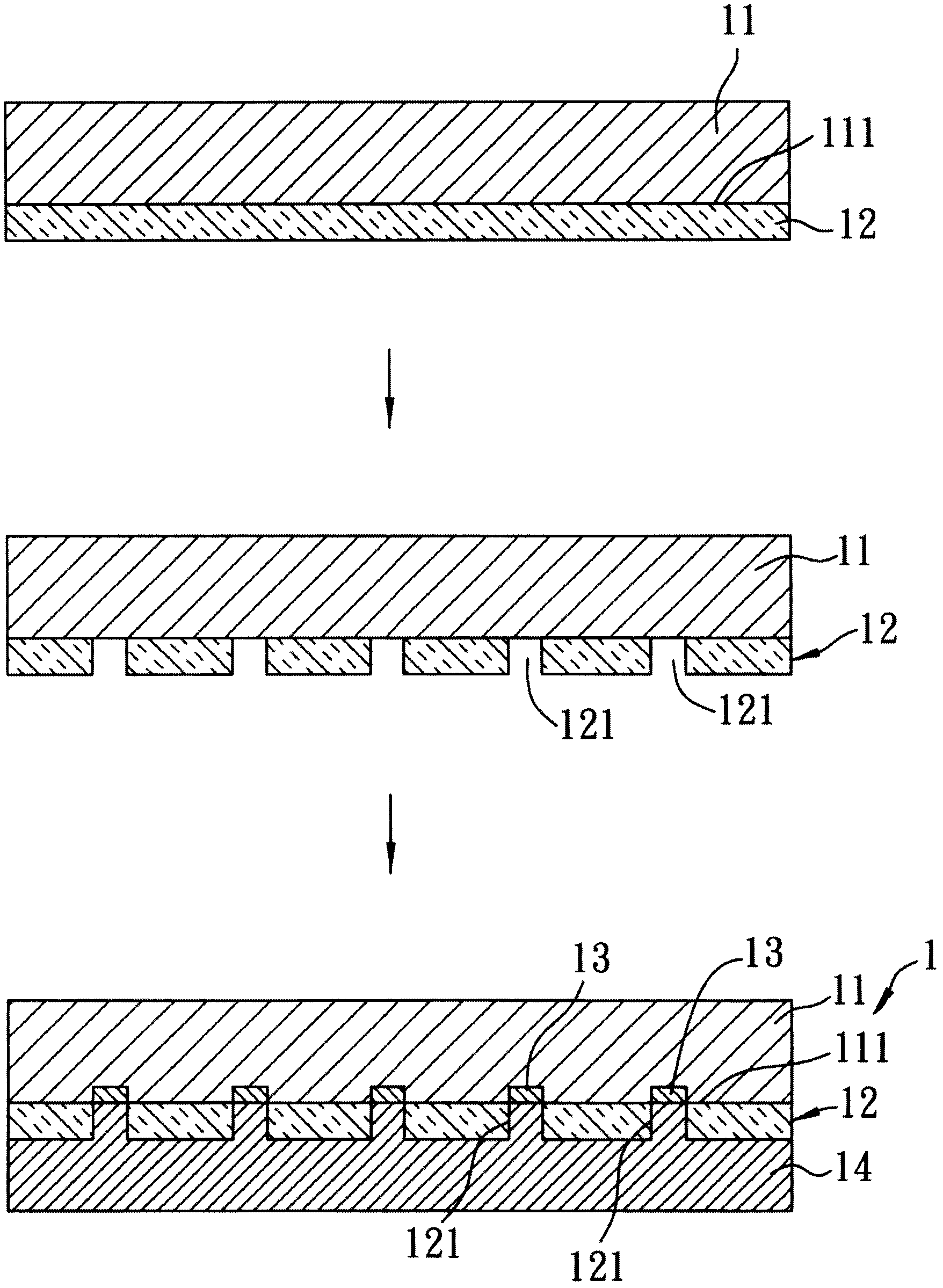

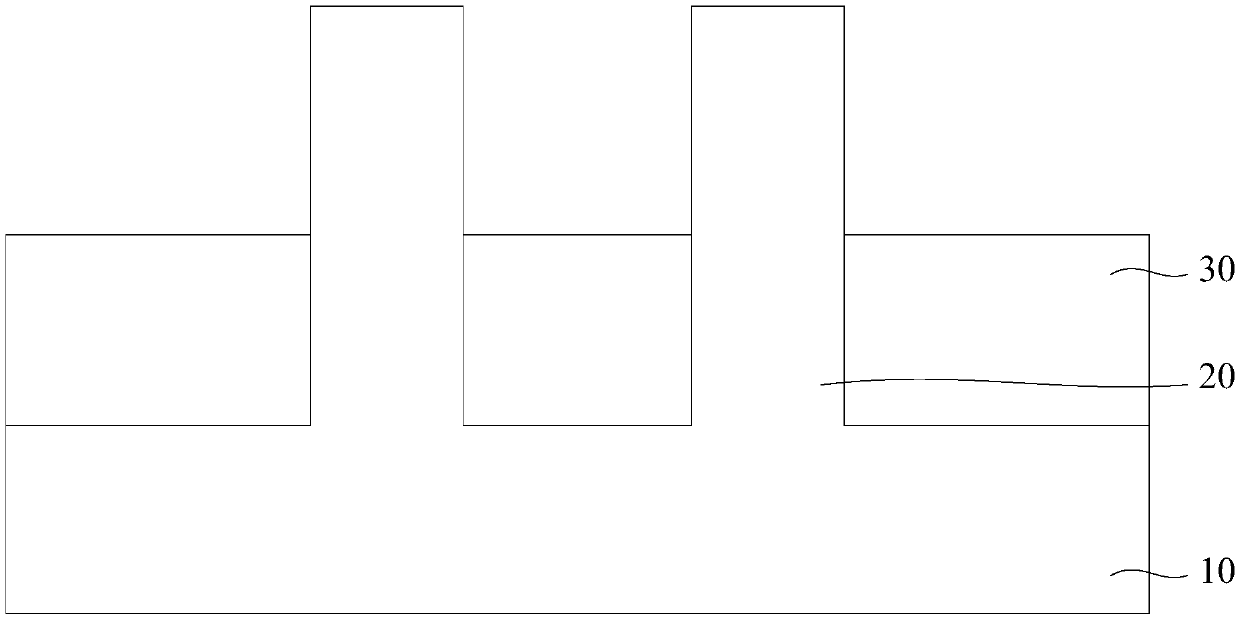

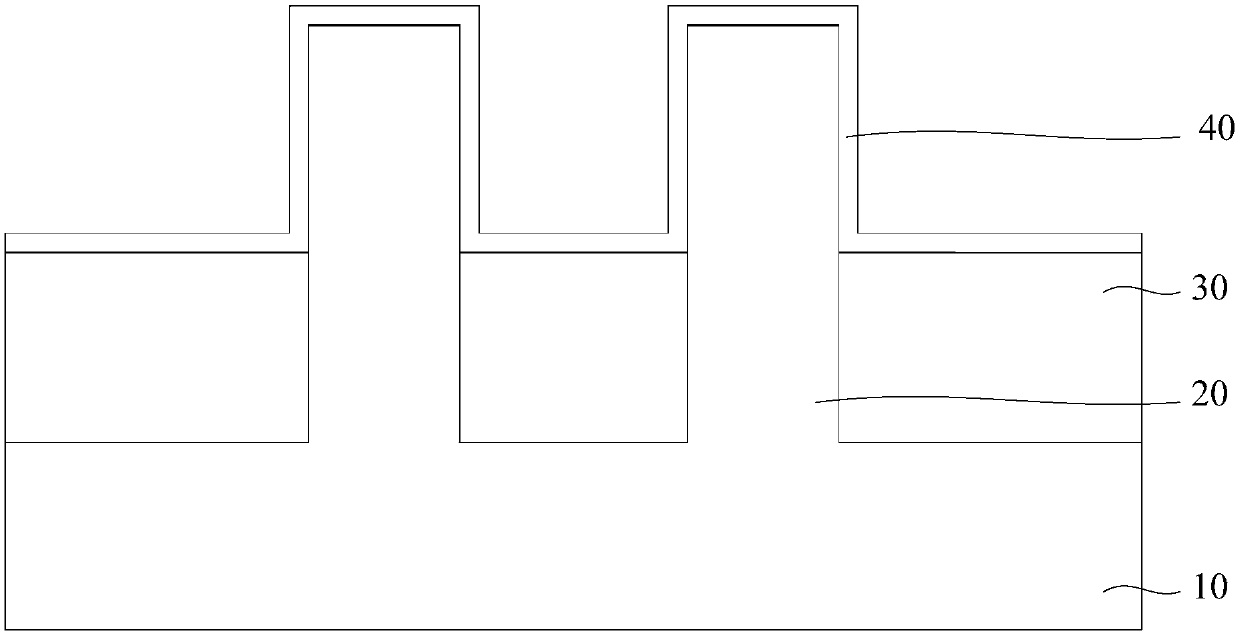

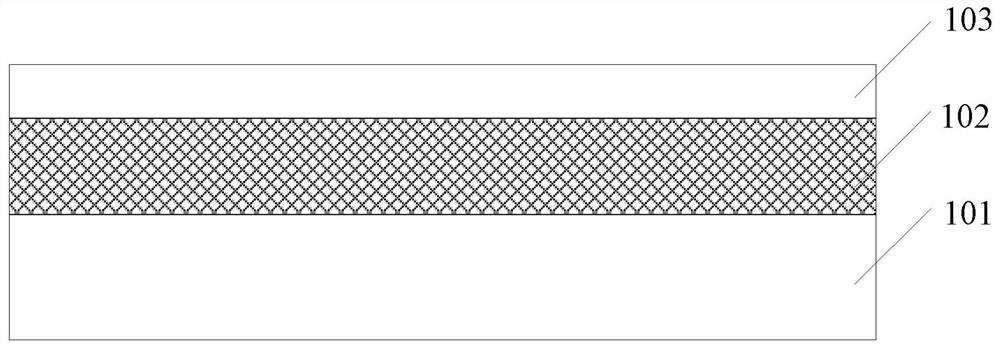

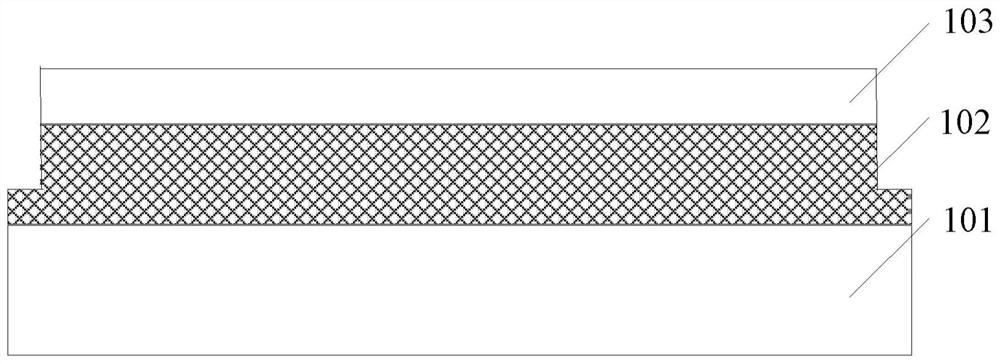

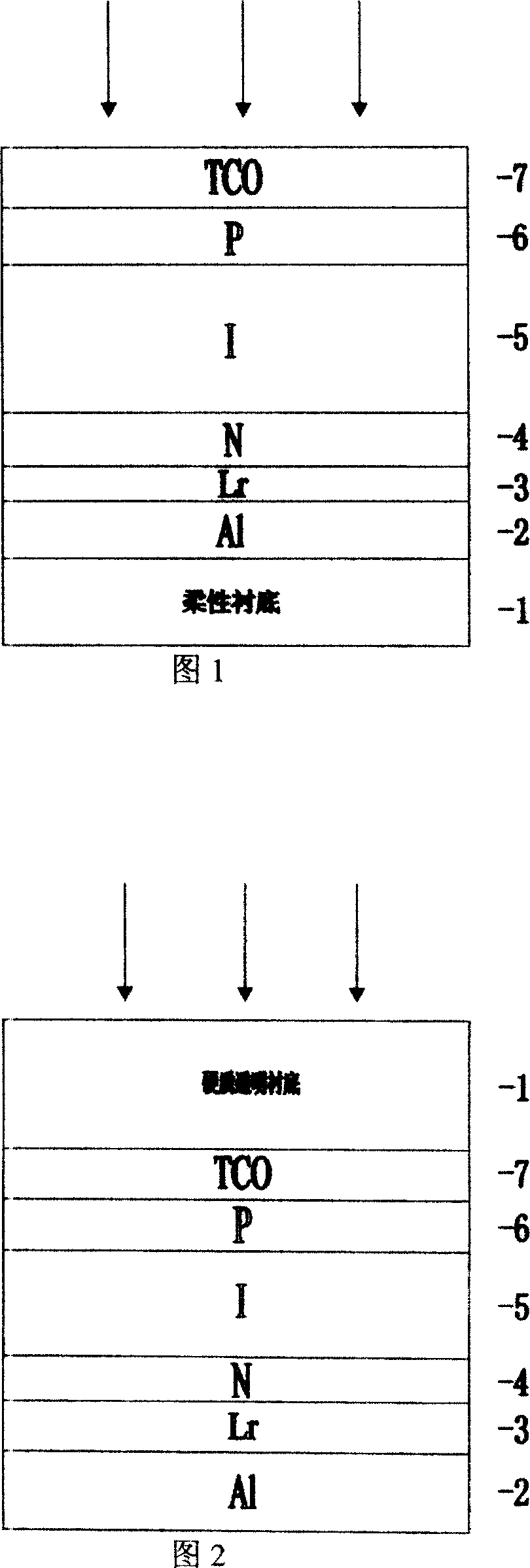

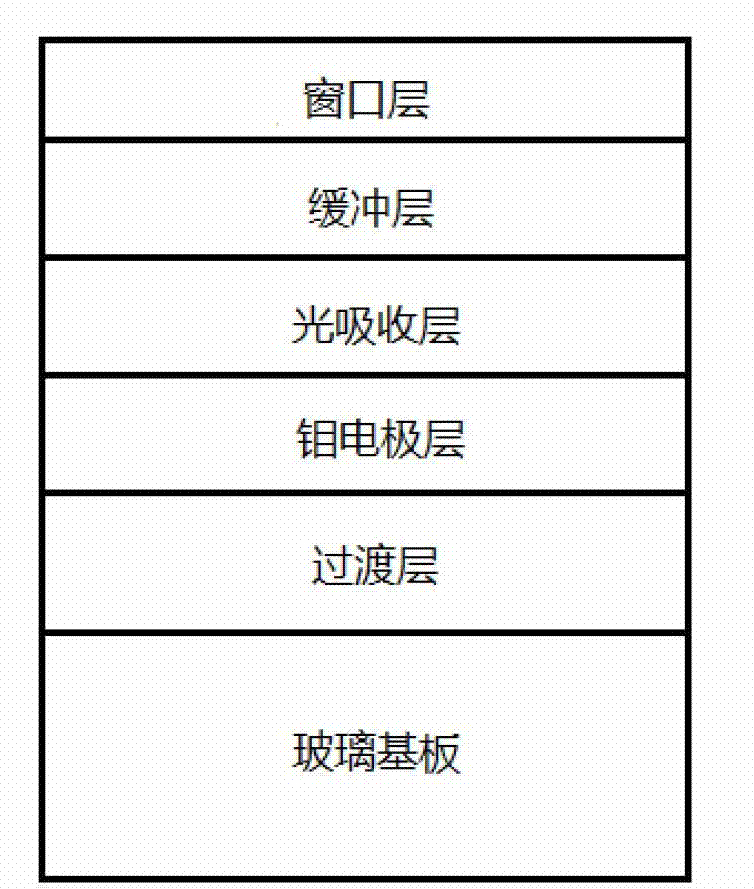

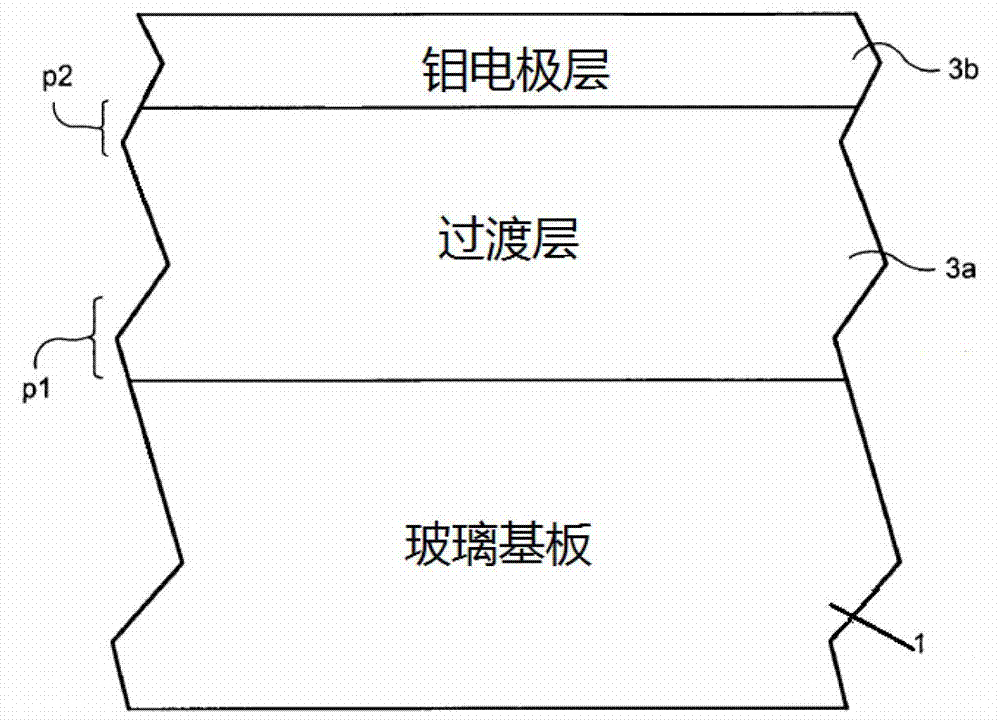

Transition layer for CIGS-based film photovoltaic cell and preparation method of transition layer

ActiveCN102867860AInhibited DiffusionPrevent diffusion from enteringFinal product manufactureSemiconductor devicesPyriteCopper

The invention discloses a transition layer for a CIGS-based film photovoltaic cell and a preparation method of the transition layer. The preparation method comprises the steps of: providing a soda-lime glass substrate, forming a transition layer covering the surface of the soda-lime glass substrate, forming a molybdenum layer covering the transition layer, forming a light absorbing layer having a copper pyrite structure and covering the molybdenum layer, forming a buffer layer covering the light absorbing layer, and forming a window layer covering the buffer layer. According to the invention, the transition layer is deposited on the surface of the glass substrate, thus the adhesion problem between a molybdenum electrode layer and the glass substrate can be efficiently solved, and sodium materials can be prevented from uncontrollably diffusing into the light absorbing layer.

Owner:厦门神科太阳能有限公司

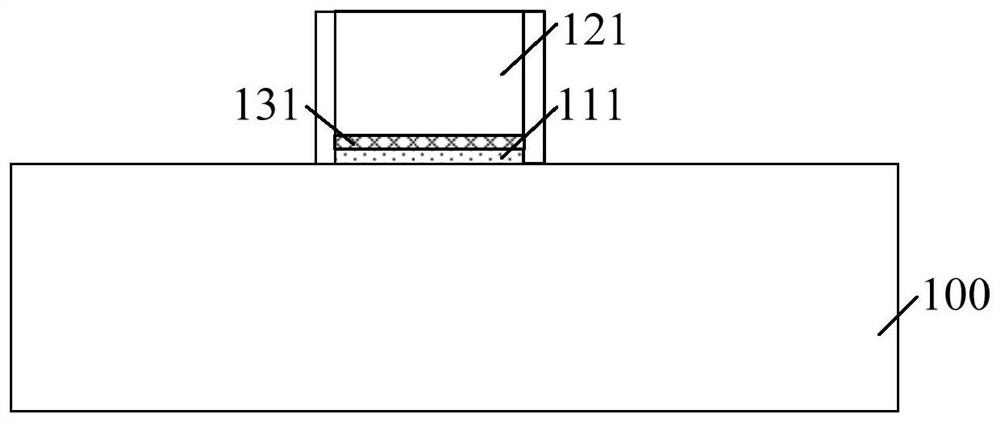

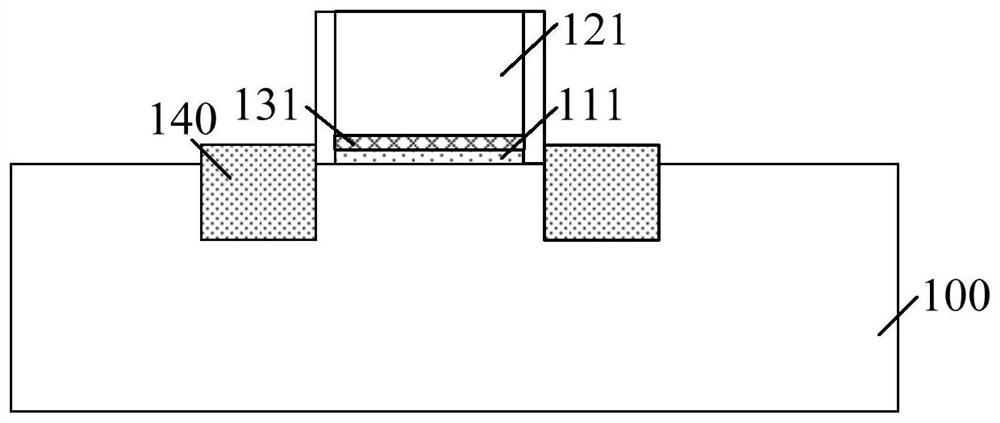

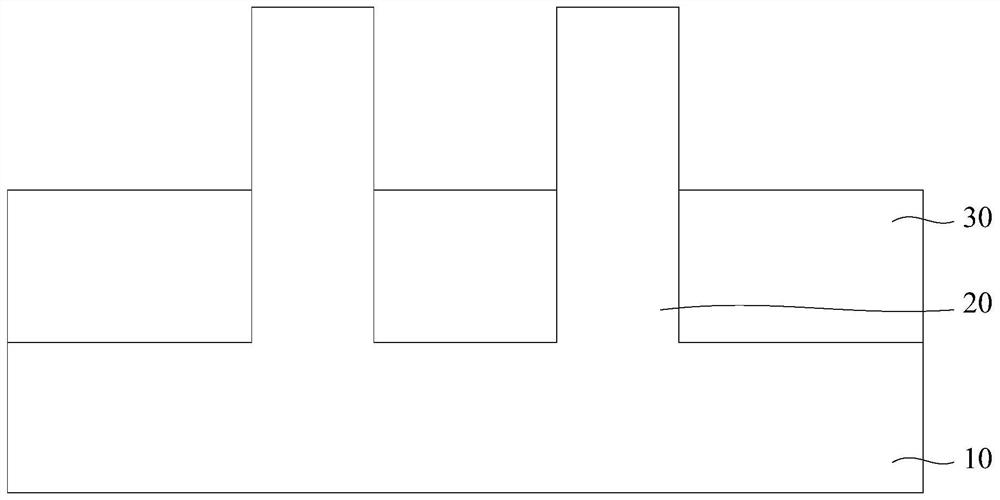

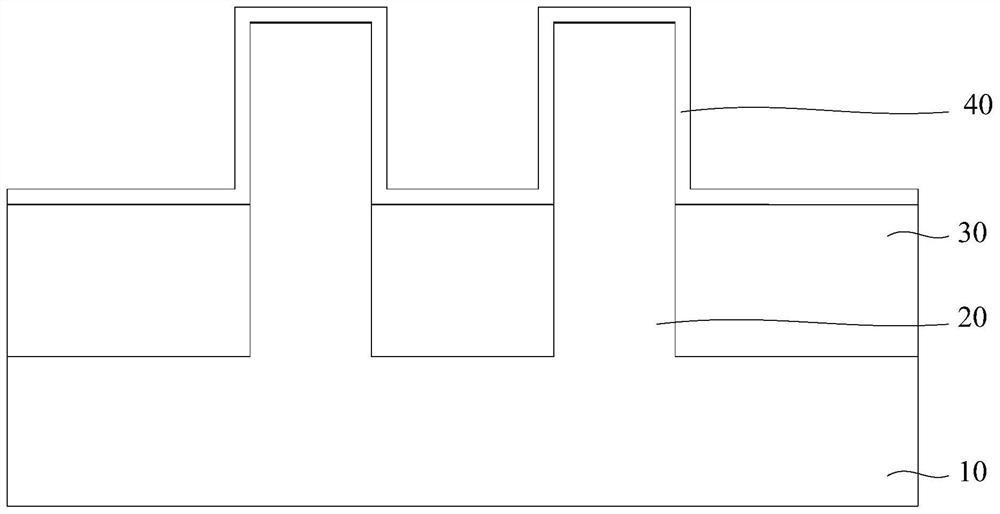

Semiconductor structure and formation method thereof

ActiveCN110391285AReduce lossImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricSemiconductor structure

The invention discloses a semiconductor structure and a formation method thereof. The method includes providing a substrate, wherein the substrate includes a first area; forming a gate dielectric layer on the first area of the substrate; forming a protective layer on the gate dielectric layer of the first area, wherein the material of the protective layer is a non-crystalline material, and the protective layer has doped ions; and forming a grid electrode on the protective layer of the first area. The protective layer can be taken as a work function layer of the formed semiconductor structure,so that the protective layer cannot be removed in follow-up process, and therefore, technological process can be simplified; and the protective layer can be protected from damaging the gate dielectriclayer during removing, so that the performance of the formed semiconductor structure can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

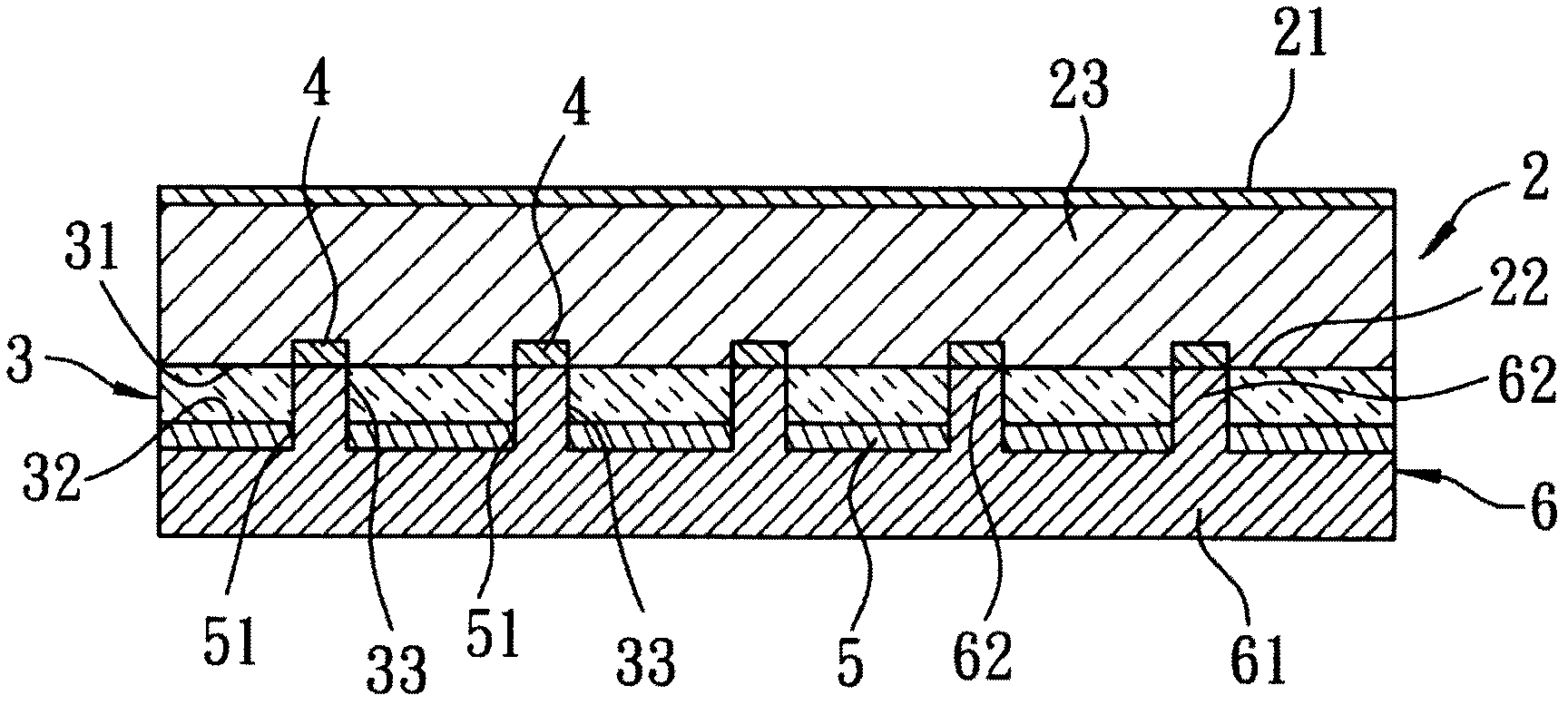

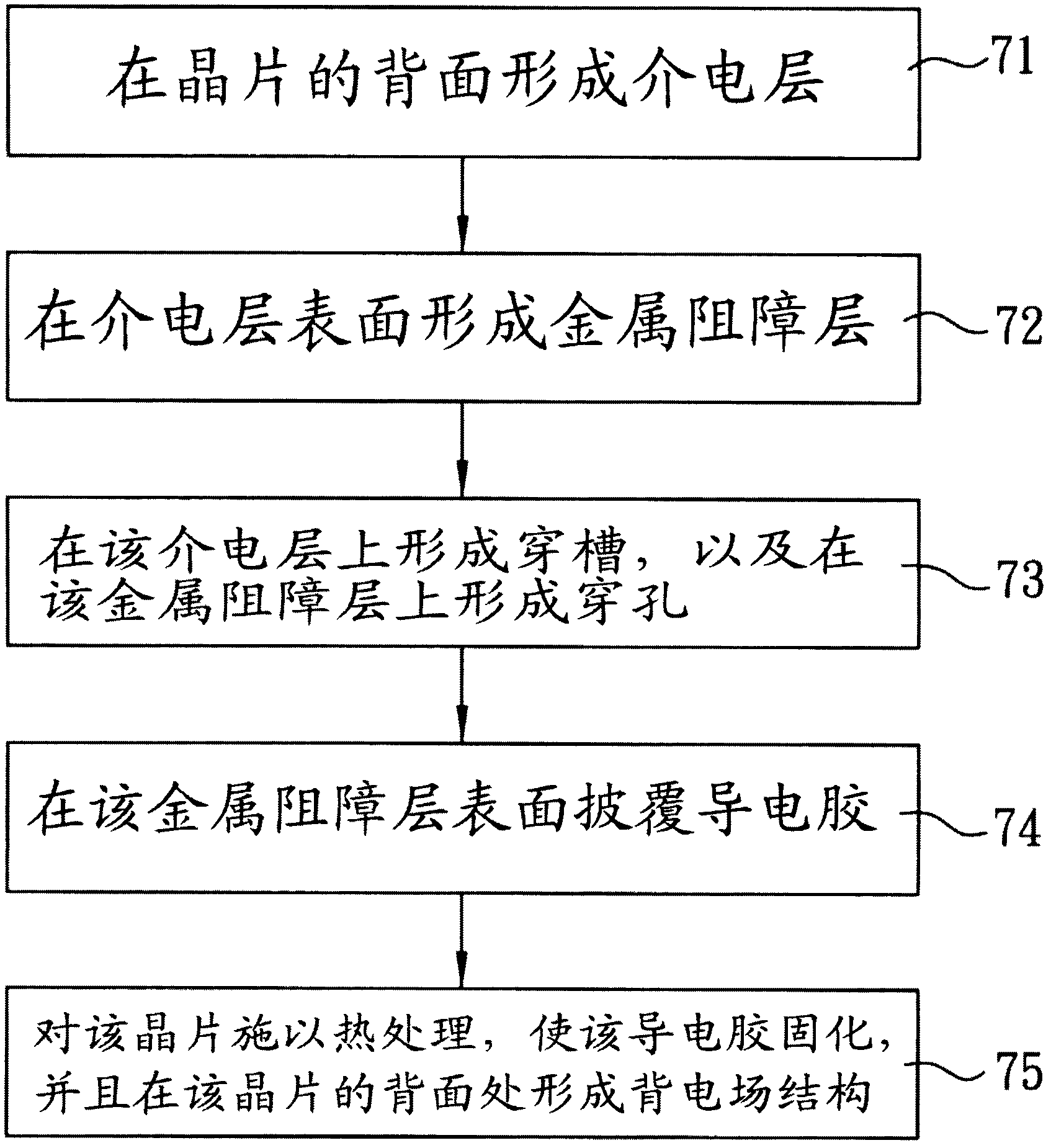

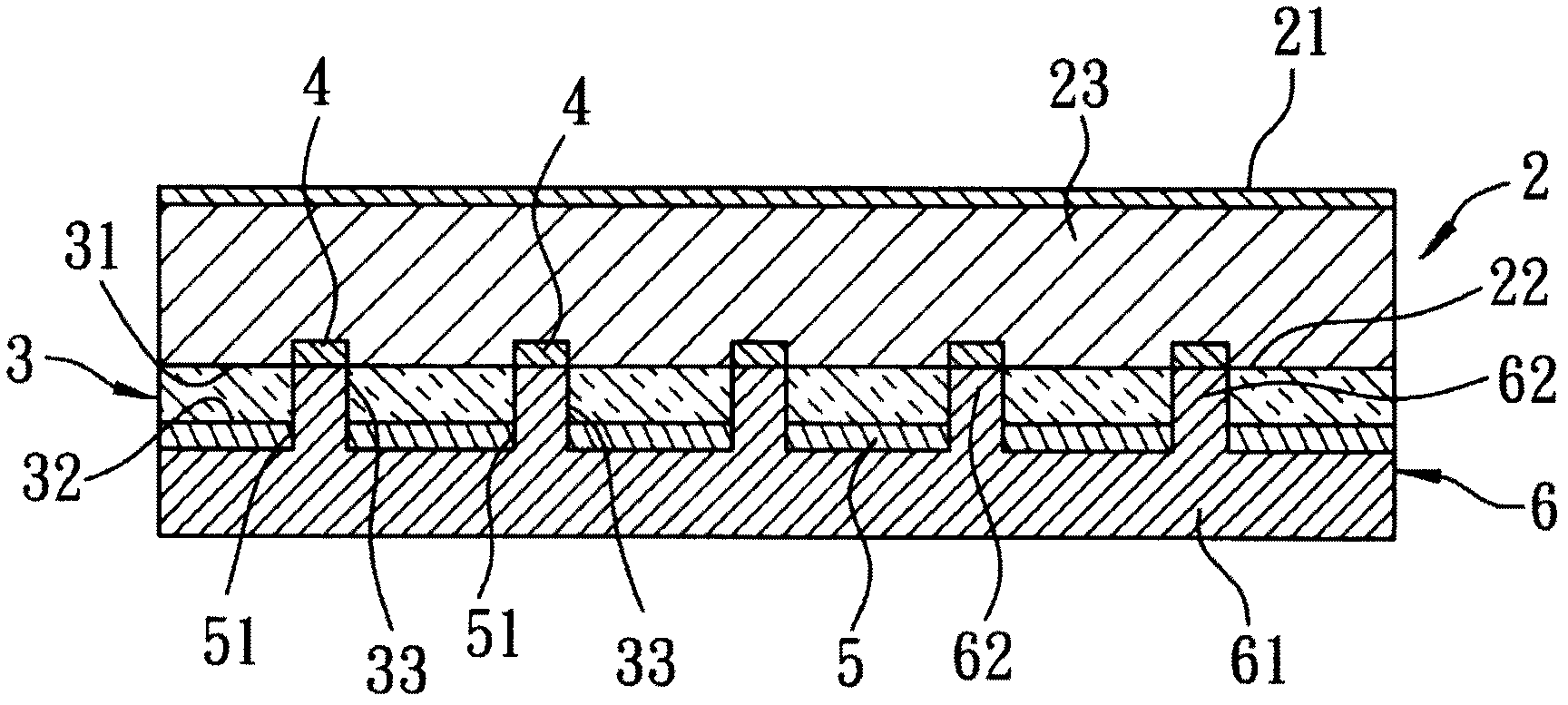

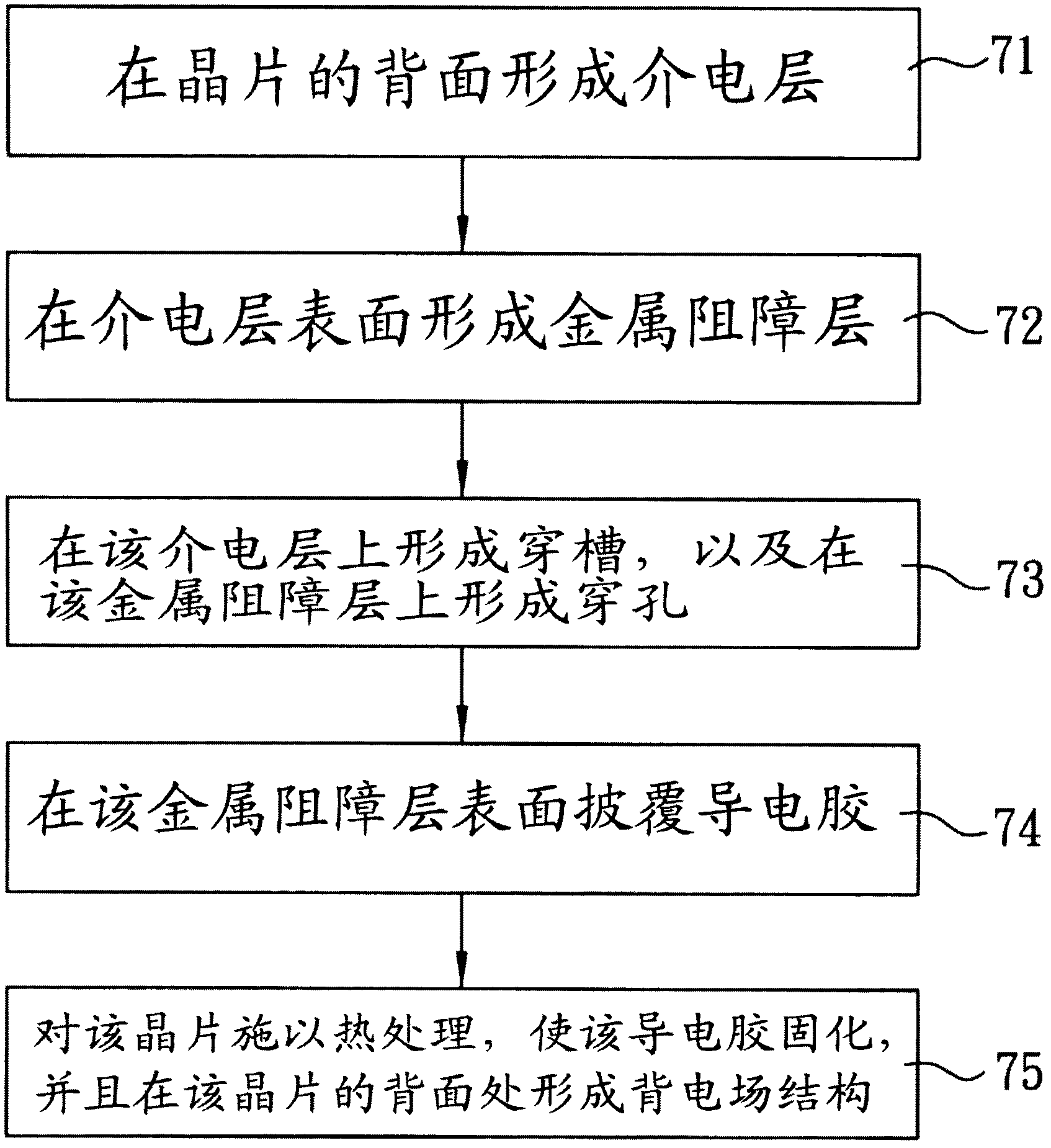

Solar cell having back surface field structures and manufacturing method thereof

InactiveCN102832263AAvoid damageImprove qualityFinal product manufactureSemiconductor devicesBack surface fieldSurface barrier

The invention discloses a solar cell having back surface field structures and a manufacturing method of the solar cell. The cell comprises a wafer, a dielectric layer, multiple back surface filed structures, a metal barrier layer and a conductive rubber layer. The improvement of the manufacturing method mainly lies in the fact that before forming the conductive rubber layer, the metal barrier layer is formed on the surface of the dielectric layer, and the material is silver, molybdenum, titanium-tungsten alloy, tungsten, titanium, chromium, molybdenum-tungsten alloy, platinum, gold, nickel or alloy of any combination of the materials mentioned above. By using the metal barrier layer as a surface barrier of the dielectric layer, the material of the conductive rubber layer can be prevented from diffusing in the dielectric layer in the sintering process, and further, the damage of the conductive rubber layer to the dielectric layer can be avoided, so that the dielectric layer has good quality and good effect of reducing the carrier recombination rate, and the cell conversion efficiency can be increased.

Owner:MOTECH INDUSTRIES

Zinc borate corrosion preventing and flame retarding agent

The invention relates to a zinc borate corrosion preventing and flame retarding agent which is solvent prepared from effective ingredients and water. The effective ingredients comprise 10-20 wt% of zinc borate, 0-47 wt% of ammonia, 6-60 wt% of 2-aminoethanol and 10-20 wt% of quaternary ammonium surfactants. According to the zinc borate corrosion preventing and flame retarding agent, the problem that a borate flame retarding and corrosion preventing agent is poor in leachability is solved, and the zinc borate which cannot be easily dissolved in water is prepared into a soluble complex which can enable wood to be completely permeated and is finally combined with wood fiber in the mode of the zinc borate; the treated wood is colorless and odorless, the flame retarding and corrosion preventing effects are simultaneously achieved, harm of fungi, moulds, termites, longhorn beetles, lyctus and carpenter bees to the wood can be effectively resisted, the good smoke inhibiting effect and the good leachability resistance are achieved, the leachability of the normally-used borate flame retarding and corrosion preventing agent is larger than or equal to 80 percent, and the leachability of the zinc borate is about 3 percent.

Owner:FUJIAN ZHANGPING KIMURA FORESTRY PROD

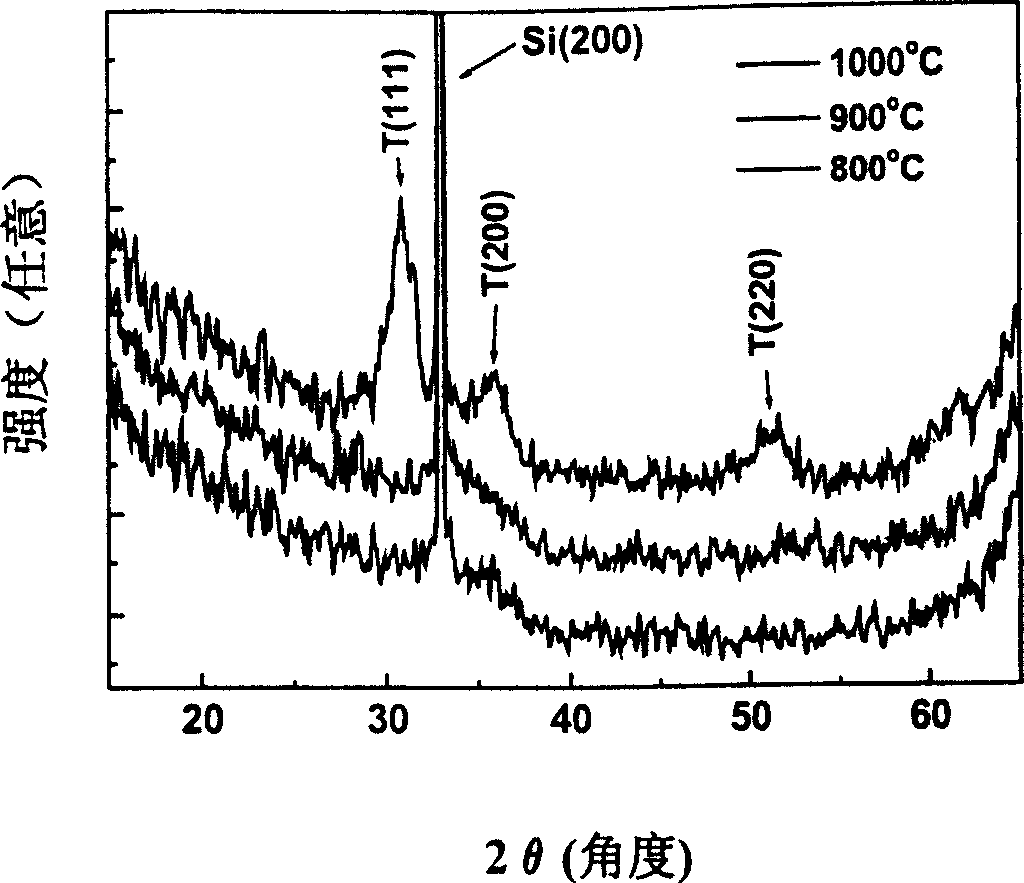

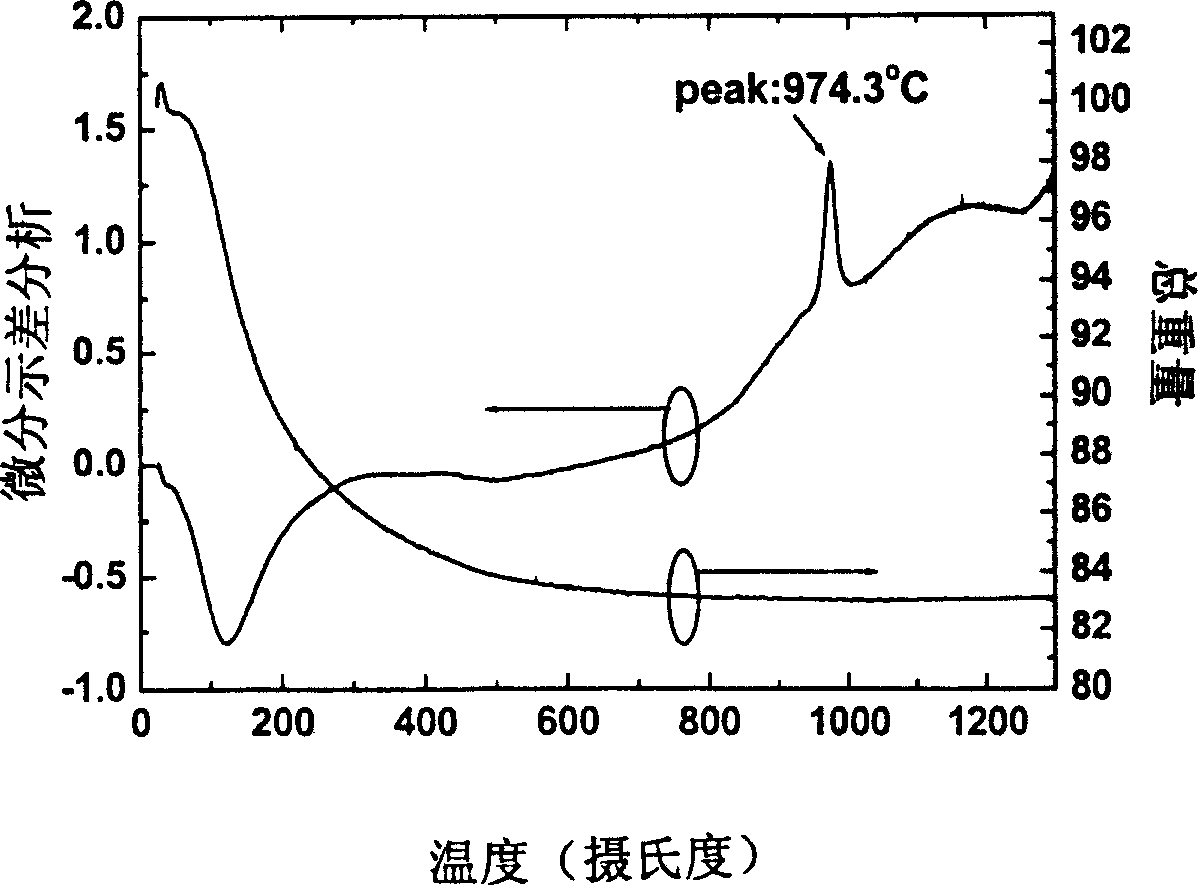

High dielectric coefficient gate dielectric material hafnium aluminate fil mand preparing method thereof

InactiveCN1471138AHigh thermodynamic stabilityMeet the requirements of high temperature heat treatmentVacuum evaporation coatingSputtering coatingMOSFETAluminate

Through ball mill mixing, the powder of hafnium oxide and alumina is cold pressed to piece. Then, ceramics target of hafnium aluminate is made through agglomeration under high temperature. Based on pulse laser deposit (PLD) technique, under high vacuum and low oxygen partial pressure, peeling off ceramic target of hafnium aluminate and generating laser plasma deposited on silicon substrate to produce amorphous hafnium nitronic aluminate film. The film possesses the features of high thermodynamic stability, higher dielectric coefficient and low leakage current. The performance index of the product reaches advanced stage of international similar products and meets practical application requirement of MOSFET with not high power consumption.

Owner:NANJING UNIV

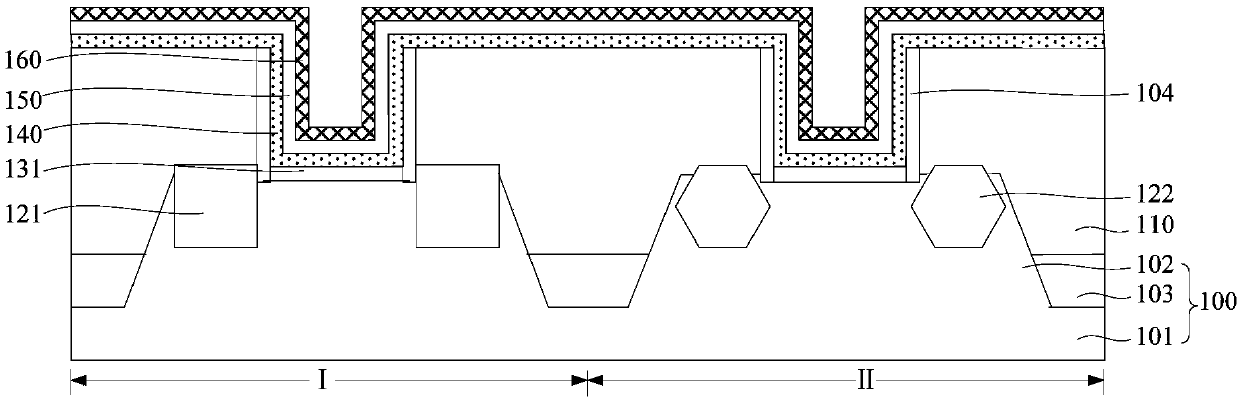

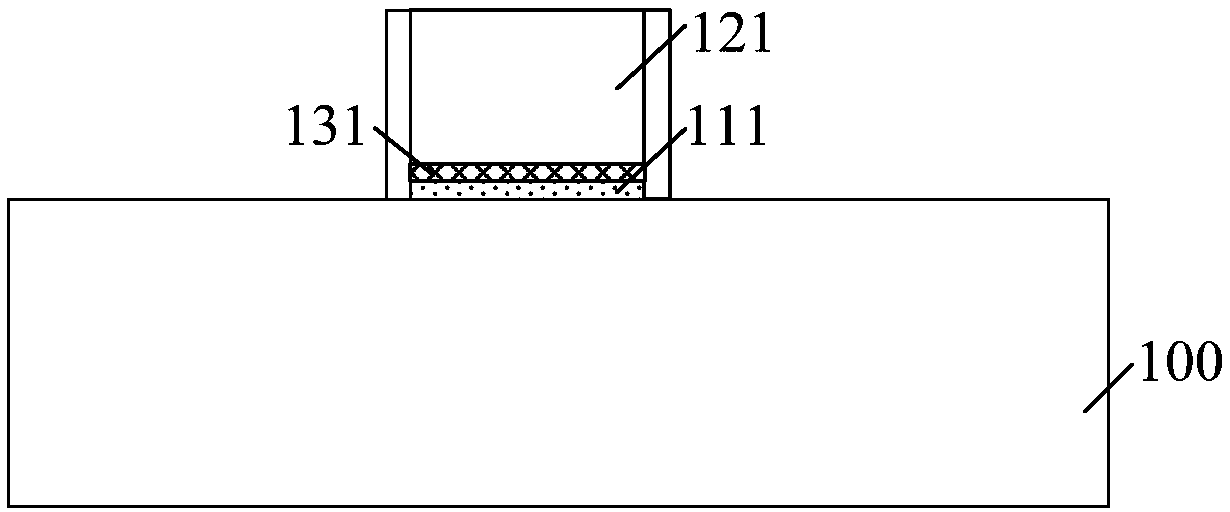

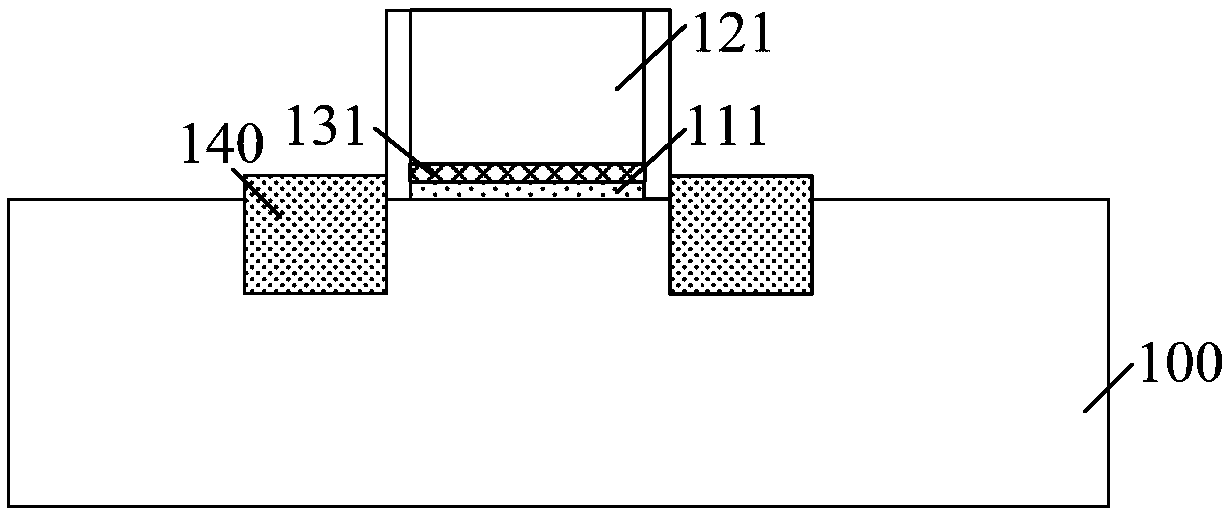

Semiconductor structure and method for forming semiconductor structure

ActiveCN109841525APrevent proliferationPrevent diffusion from enteringSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureIsolation layer

The invention provides a semiconductor structure and a method for forming the semiconductor structure. The method comprises a step of providing a substrate and fins protruding from the substrate, wherein the materials of the fins contain germanium elements, an isolation layer covering partial sidewalls of the fins are on the substrate, and the top of the isolation layer is lower than the tops of the fins, a step of forming a dummy gate oxide layer on the tops and sidewalls of the fins exposed by the isolation layer by using the atomic layer deposition process, wherein the process temperature of the atomic layer deposition process is a first temperature, a step of forming a dummy gate across the fins, wherein the dummy gate covers the surface of a dummy gate oxide layer, a step of forming adielectric layer on the isolation layer, wherein the dielectric layer covers a sidewall of the dummy gate and exposes a top wall of the dummy gate, a step of removing the dummy gate and the dummy gate oxide layer and exposing the tops and partial sidewalls of the fins, and a step of forming an interface layer on the exposed tops and sidewalls of the fins, wherein the process temperature of forming the interface layer is a second temperature which is lower than or equal to the first temperature. According to the invention, the germanium elements in the fins can be prevented from diffusing intothe interface layer, therefore, the interface characteristics between the interface layer and the fins can be improved, and the carrier mobility is enhanced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Fume-resisting system

InactiveCN101718458APrevent proliferationPrevent diffusion from enteringSpace heating and ventilation safety systemsLighting and heating apparatusFire controlChamber pressure

The invention relates to a fume-resisting system comprising a blower, a wind pressure control valve II, a wind pressure control device and a wind pressure control valve I. The wind pressure control valve II is arranged on the blower; the wind pressure control device comprises a wind pressure control box, a pressure adjustor, a motor and a fan device; the pressure adjustor and the motor are arranged in the wind pressure control box; and the output end of the pressure adjustor is connected with the input end of the motor which is connected with the fan device. The fume-resisting system can reach the technical requirements on smoke resistance in fire control, keep the front chamber pressure, prevent fume from spreading into a front chamber and well protect the life security of human beings.

Owner:高香顺

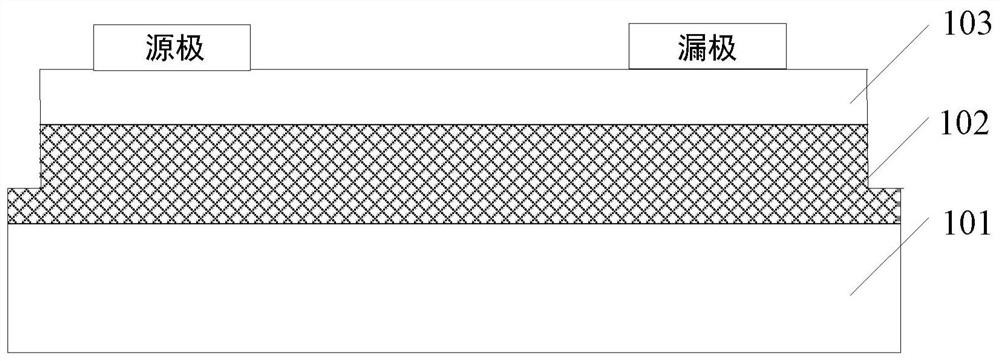

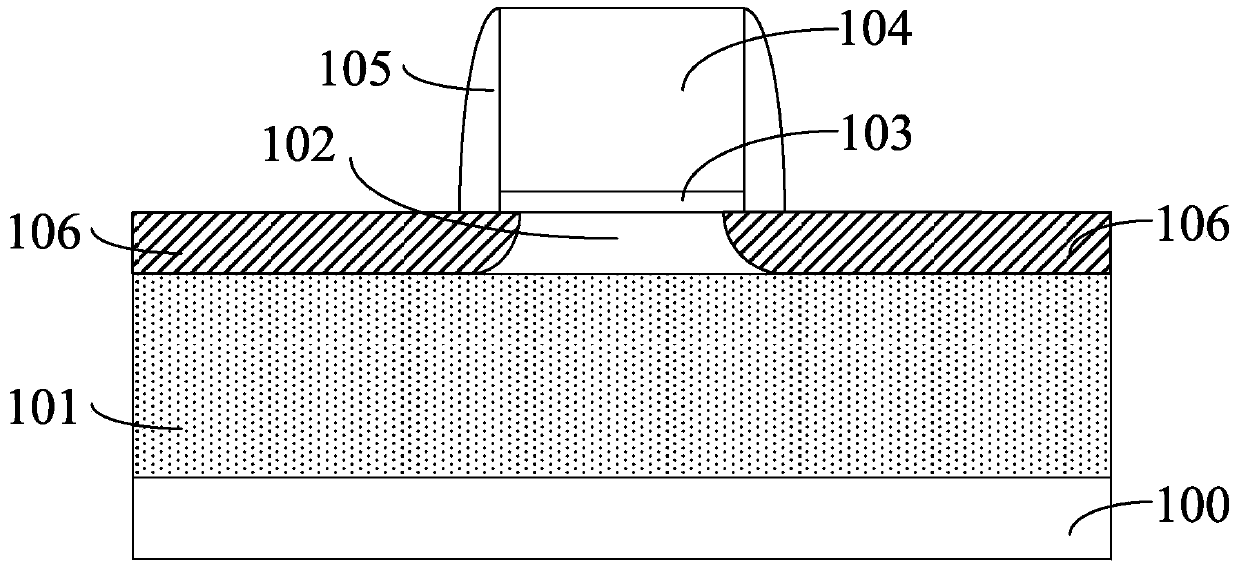

Gallium oxide-based solar-blind detector and preparation method thereof

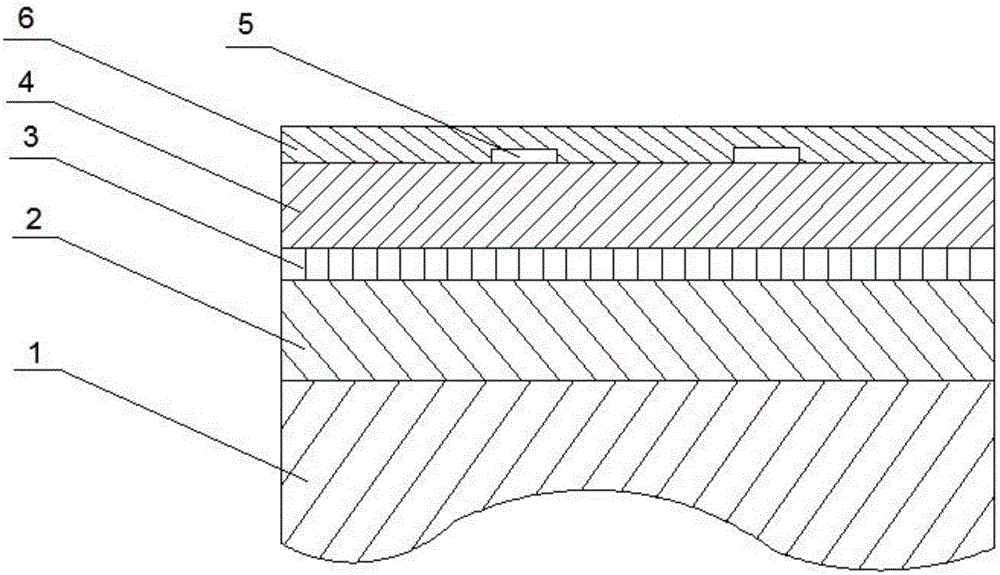

ActiveCN110571301BImprove film qualityPrevent diffusion from enteringFinal product manufactureSemiconductor devicesPhotovoltaic detectorsEngineering

The invention provides a solar-blind photodetector and a preparation method thereof. The solar-blind photodetector comprises: a gallium oxide substrate containing a gallium oxide epitaxial layer; a source electrode and a drain electrode respectively form Schottky contacts with the gallium oxide substrate The silicon oxide passivation layer is formed on the gallium oxide substrate, the source and the drain; the groove in the gallium oxide substrate is opened from the silicon oxide passivation layer; the aluminum oxide layer is formed on the bottom of the groove and the groove Trench sidewalls; gates, over the aluminum oxide layer of the trench and over the silicon oxide passivation layer. The invention adopts a specific three-terminal structure, and the carrier concentration of the channel can be adjusted through the gate, so that the dark current of the device can be adjusted conveniently.

Owner:UNIV OF SCI & TECH OF CHINA

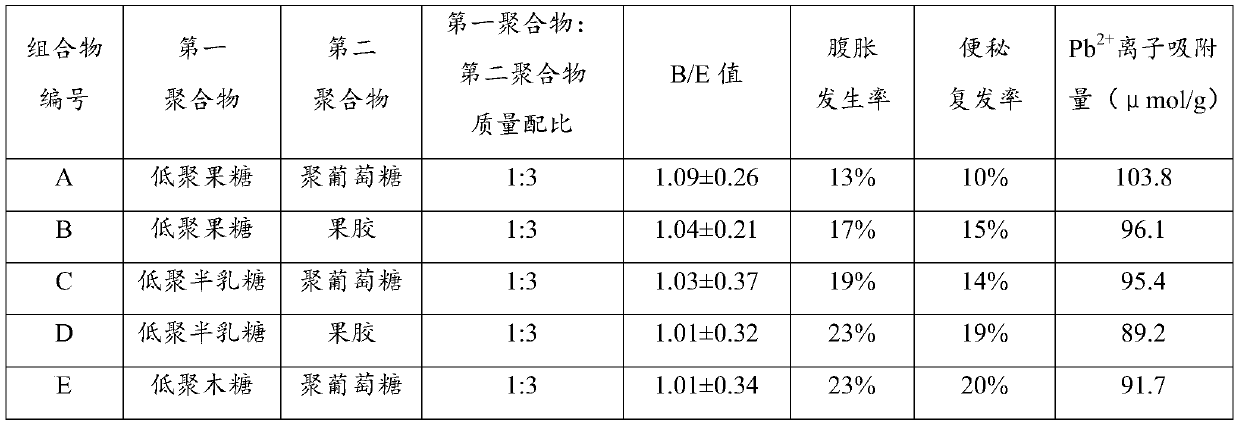

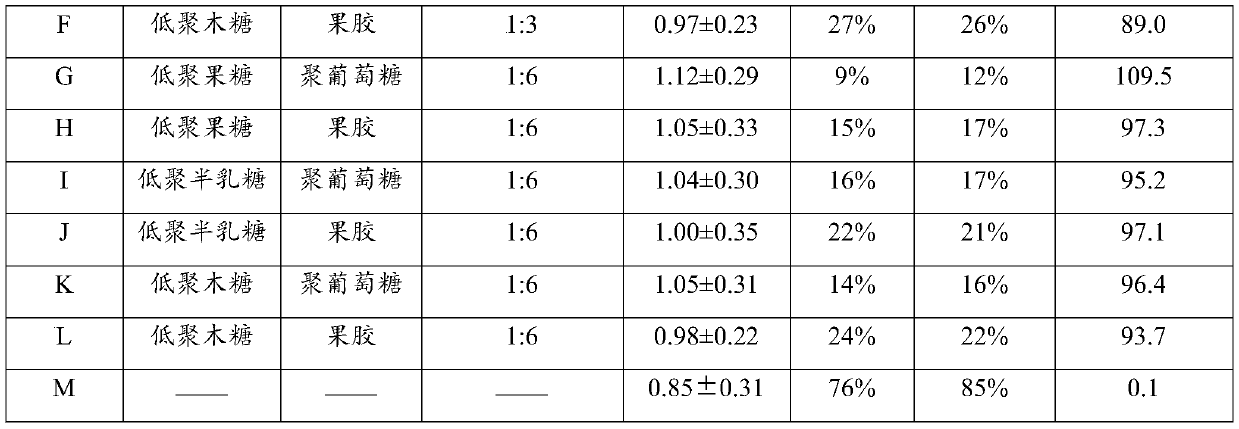

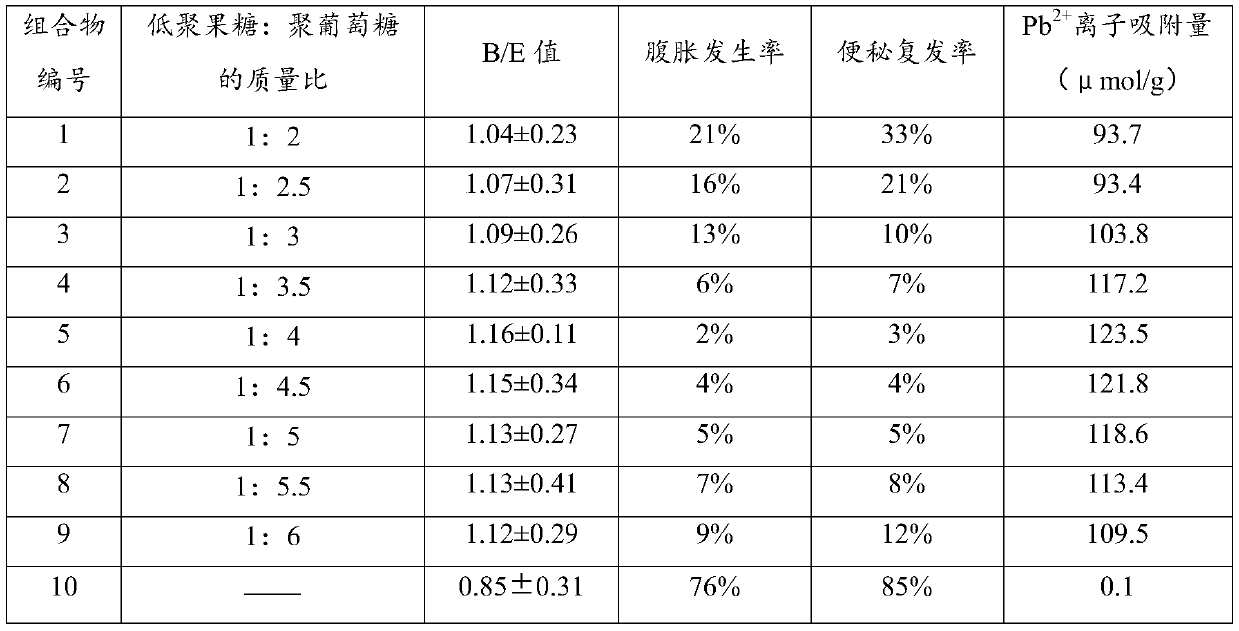

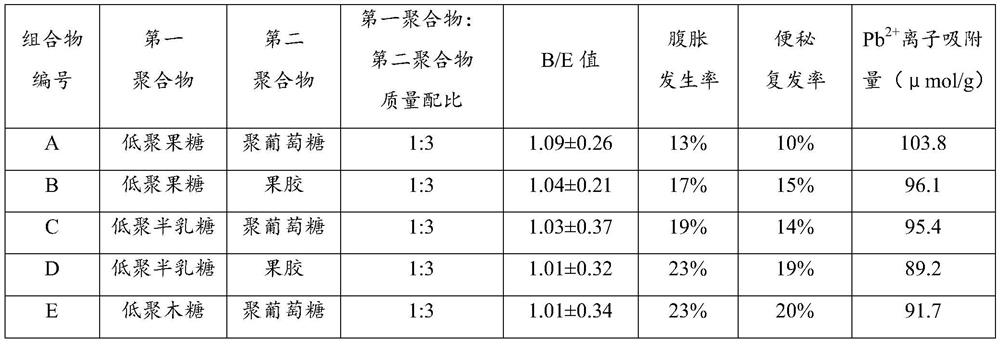

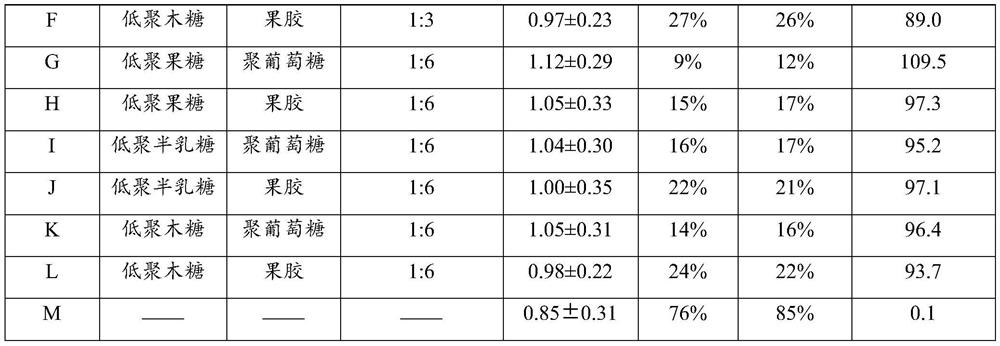

Composition with constipation prevention and treatment effect, and preparation method and application thereof

ActiveCN110559310ALower pHSimple structureOrganic active ingredientsDigestive systemTreatment effectPolymer science

The invention relates to a composition with a constipation prevention and treatment effect, and a preparation method and an application thereof. Effective components in the composition are a first polymer and a second polymer, wherein the first polymer and the second polymer are obtained through glycosidic bond polymerization of monosaccharide and / or uronic acid of monosaccharide, the polymerization degree of the first polymer is an integer of 2-100, the polymerization degree of the second polymer is an integer of 10-3000, and the mass ratio of the first polymer to the second polymer is 1:3-1:6. The composition disclosed by the invention is suitable for tumor-associated diarrhea, has a bidirectional regulation effect on constipation and diarrhea, and can be taken for a long time.

Owner:麦孚营养科技(北京)有限公司 +1

A closed dust removal device for printing presses

InactiveCN104442037BPrevent proliferationPrevent diffusion from enteringOther printing apparatusPrinting pressWaste management

A closed type dust removal device for a printing press comprises a cleaning box communicated with an inlet of the printing press, and a supporting plate inclining in the direction backing on to the printing press is arranged on the top of the inner side of the cleaning box and divides the cleaning box into a dust removing area and a cleaning area. A hairbrush and a dust exhaust mechanism are arranged in the dust removing area, and an air blowing mechanism is arranged in the cleaning area. The air blowing mechanism comprises a dust blowing pipe and an air curtain pipe. The dust blowing pipe is arranged in a cavity of the supporting plate, the air blowing direction of the dust blowing pipe is oblique, air blown out from the dust blowing pipe can raise dust on paper and attachments brushed up by the hairbrush, and the dust and the attachments can be exhausted by the dust exhaust mechanism. The air curtain pipe comprises a vertical segment and a horizontal segment, the vertical segment is arranged on one side of the inlet of the printing press, the air outlet direction of the vertical segment faces the other side of the inlet, and then an air curtain closing the inlet is formed; the horizontal segment is arranged on one side of the cleaning box, the air outlet direction of the horizontal segment faces the other side of the cleaning box, and then an air curtain closing the paper face is formed. According to the closed type dust removal device for the printing press, the dust on the paper is effectively cleared through cooperation of the hairbrush, the air blowing mechanism and the dust exhaust mechanism, and printing quality is guaranteed.

Owner:HENAN GUOHUA COLOR PRINTING PACKAGING

Composition with anti-constipation effect, preparation method and application thereof

ActiveCN110559310BLower pHSimple structureOrganic active ingredientsDigestive systemPolymer scienceTreatment effect

The invention relates to a composition with a constipation prevention and treatment effect, and a preparation method and an application thereof. Effective components in the composition are a first polymer and a second polymer, wherein the first polymer and the second polymer are obtained through glycosidic bond polymerization of monosaccharide and / or uronic acid of monosaccharide, the polymerization degree of the first polymer is an integer of 2-100, the polymerization degree of the second polymer is an integer of 10-3000, and the mass ratio of the first polymer to the second polymer is 1:3-1:6. The composition disclosed by the invention is suitable for tumor-associated diarrhea, has a bidirectional regulation effect on constipation and diarrhea, and can be taken for a long time.

Owner:麦孚营养科技(北京)有限公司 +1

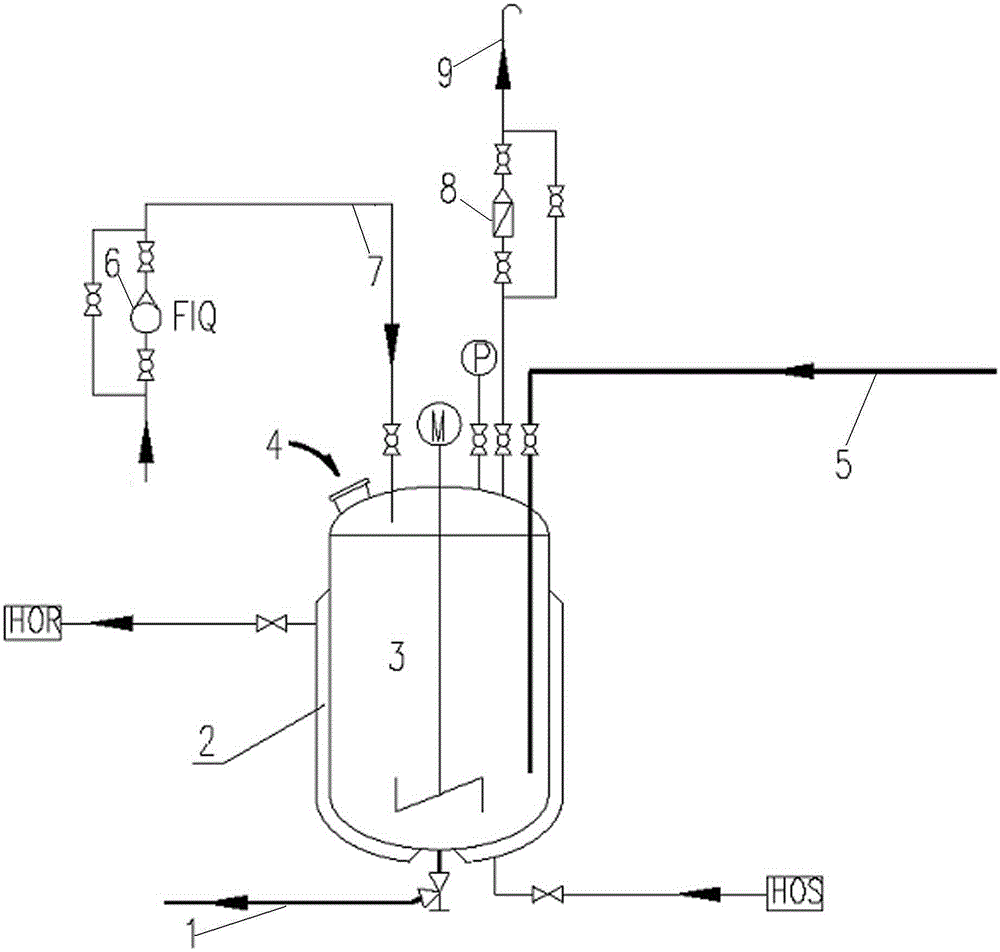

A method for realizing anhydrous and oxygen-free operation and a process for producing cyclomanganese reaction of methylcyclopentadienyl manganese using the method

ActiveCN104084102BEasy to operatePrevent regurgitationInert gas productionMetallocenesBreatherPositive pressure

The invention relates to a method for realizing anhydrous anaerobic operation and a ring manganese reaction production process of methyl cyclopentadienyl manganese by the method. The method comprises the following steps: (1) arranging a micro-positive pressure breather valve on a venting pipeline of a reaction still, and injecting inert gas to keep the micro-positive pressure state in the reaction still before feeding, wherein the gauge pressure of the micro-positive pressure is not greater than 400 Kpa; and (2) filling the reaction still with micro-flow inert gas through a small-range flowmeter, and opening a charging hole for charging, wherein inert gas always flows out of the still, and the flow of inert gas is controlled within 20-200 L / minute. According to the method, the reaction still is capable of using inert gas as less as possible and completing material charging and discharging under the protection of inert gas, so that the risk of reaction failure is decreased.

Owner:山东东昌精细化工科技有限公司

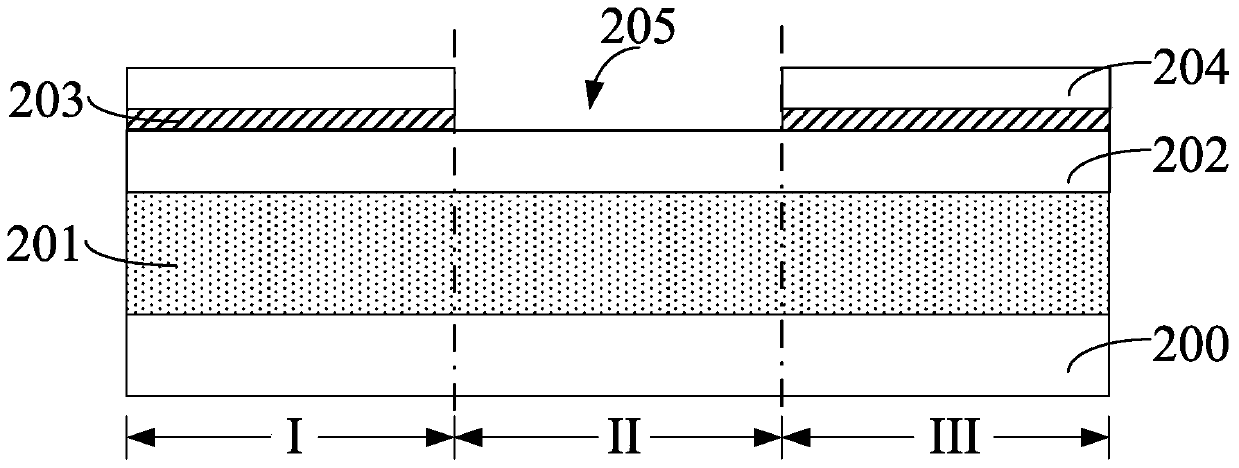

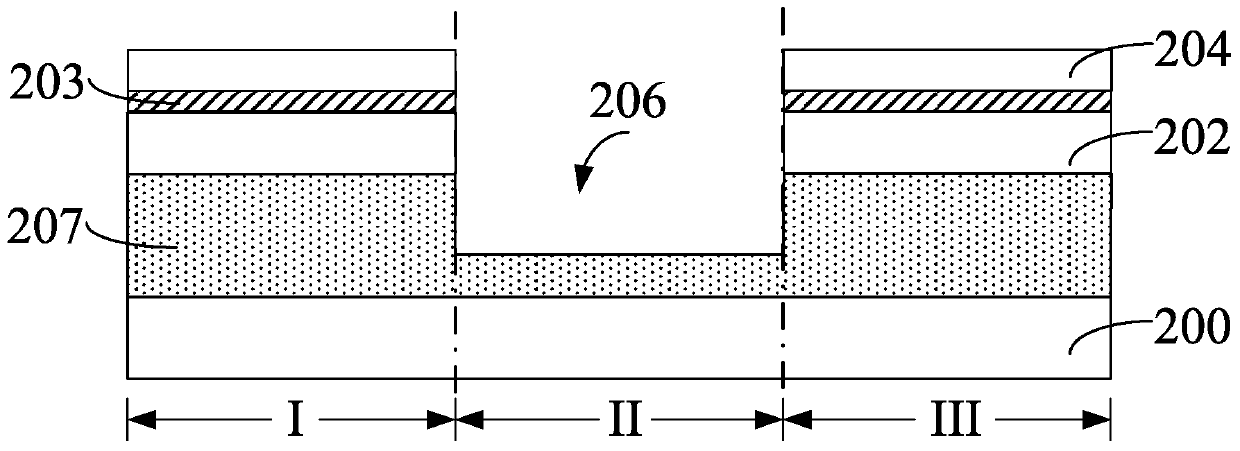

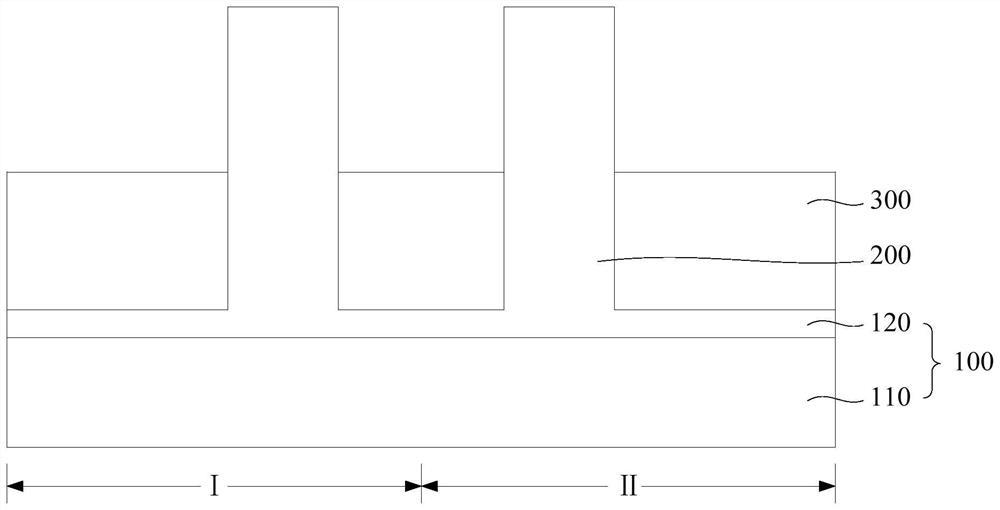

Semiconductor device and method of forming the same

ActiveCN105097711BAdjust Threshold VoltageImprove electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceElectrical conductor

A semiconductor device and a method for forming the same, wherein the method for forming the semiconductor device includes: providing a substrate, the substrate including a first semiconductor layer, an insulating layer positioned on the surface of the first semiconductor layer, and a second semiconductor layer positioned on the surface of the insulating layer, The substrate has a first region, a second region and a third region, the second region is adjacent to the first region and the third region, wherein the thickness of the insulating layer in the first region and the third region is greater than that of the insulating layer in the second region The bottom surface of the insulating layer in the first region, the second region and the third region is flush; the gate structure is formed on the surface of the second semiconductor layer in the second region; the first region and the third region on both sides of the gate structure A doped region is formed in the second semiconductor layer. The thickness of the insulating layer under the gate structure of the present invention is smaller than the thickness of the insulating layer under the doped region. Since the effective resistance of the insulating layer under the gate structure is small, the threshold voltage of the semiconductor device can be effectively improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Semiconductor structures and methods of forming them

ActiveCN110400746BReduce bias temperature instabilityInhibited DiffusionSemiconductor devicesGate dielectricSemiconductor structure

A semiconductor structure and its forming method, wherein, the forming method includes: providing a substrate; forming a gate dielectric layer on the substrate; performing a ventilation treatment on the gate dielectric layer to form a modified gate dielectric layer; A work function layer is formed on the modified gate dielectric layer; a gate layer is formed on the work function layer. The ventilation treatment can make nitrogen atoms fill the vacancies and gaps in the gate dielectric layer, thereby preventing the metal atoms in the work function layer from diffusing into the gate dielectric layer, thereby reducing the change of the work function of the gate dielectric layer , thereby reducing the drift of the threshold voltage of the formed semiconductor structure, and reducing the instability of the bias voltage of the formed semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A cold storage air curtain system that can form a positive pressure space

ActiveCN108759253BGood heat insulationStable temperatureLighting and heating apparatusStationary refrigeration devicesEngineeringRefrigeration

Owner:TIANJIN UNIV OF COMMERCE

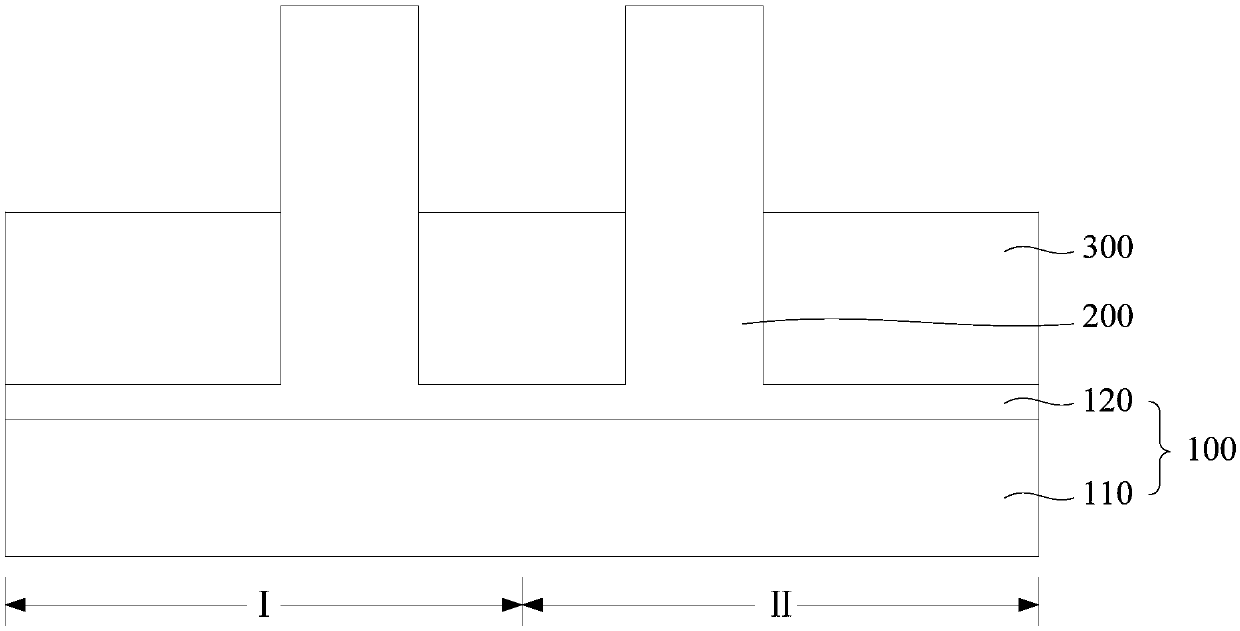

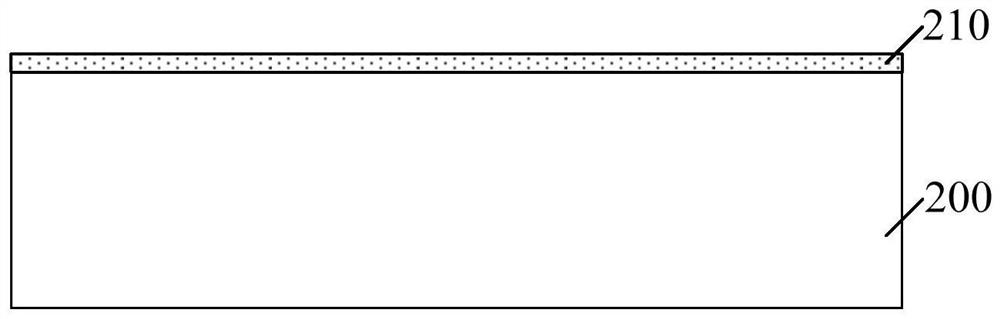

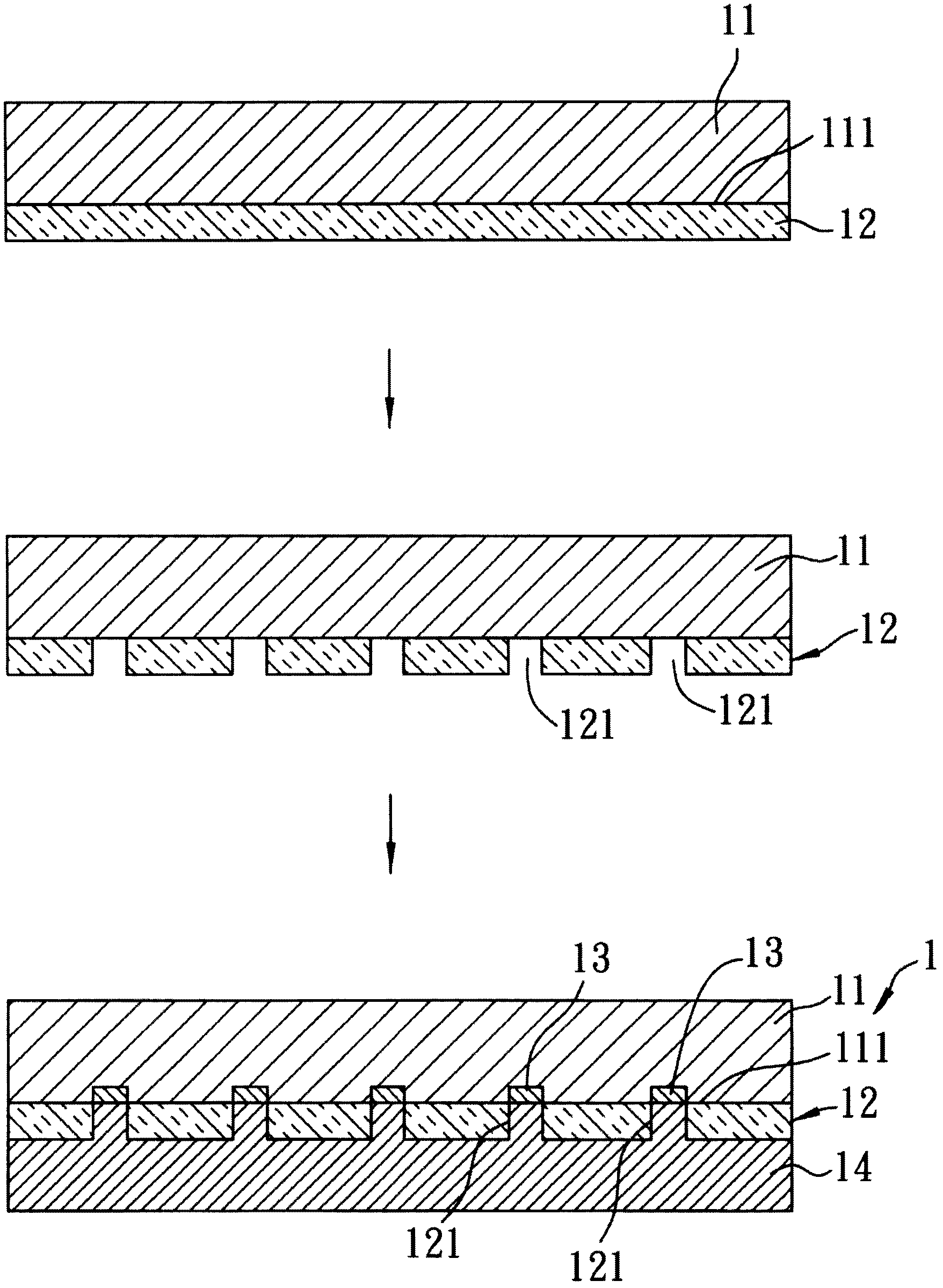

Semiconductor structure and formation method thereof

InactiveCN108962753ASimple processReduce leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureProtection layer

The invention provides a semiconductor structure and a formation method thereof. The method comprises the following steps: providing a substrate, wherein the substrate comprises a first region and a second region, and the substrate has an isolation structure; forming a protection layer on the second region substrate and the second region isolation structure; forming a doping layer on the first region substrate, the first region isolation structure and the protection layer; carrying out annealing treatment on the doping layer to enable doping ions in the doping layer to diffuse into the first region substrate to form a first doped region; and after carrying out annealing treatment on the doping layer, removing the doping layer. The method enables the performance of the semiconductor structure to be good, and the formation process of the semiconductor structure is simple.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Semiconductor structures and methods of forming them

ActiveCN109841525BPrevent proliferationPrevent diffusion from enteringSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureCharge carrier mobility

A semiconductor structure and its forming method, the forming method comprising: providing a substrate and fins protruding from the substrate, the material of the fins contains germanium, the substrate has an isolation layer covering the side walls of the fins, and isolating The top of the layer is lower than the top of the fin; an atomic layer deposition process is used to form a dummy gate oxide layer on the top and side walls of the fin exposed by the isolation layer, and the process temperature of the atomic layer deposition process is the first temperature; a dummy gate oxide layer across the fin is formed. Gate, the dummy gate covers the surface of the dummy gate oxide layer; a dielectric layer is formed on the isolation layer, the dielectric layer covers the sidewall of the dummy gate and exposes the top of the dummy gate; removes the dummy gate and dummy gate oxide layer, exposing the top of the fin and part of the sidewall ; Forming an interface layer on the exposed top and sidewall of the fin, the process temperature for forming the interface layer is a second temperature, and the second temperature is less than or equal to the first temperature. The invention can prevent the germanium element in the fin from diffusing into the interface layer, thereby improving the interface characteristics between the interface layer and the fin, and enhancing carrier mobility.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Solar cell having back surface field structures and manufacturing method thereof

InactiveCN102832263BAvoid damageImprove qualityFinal product manufactureSemiconductor devicesBack surface fieldSurface barrier

The invention discloses a solar cell having back surface field structures and a manufacturing method of the solar cell. The cell comprises a wafer, a dielectric layer, multiple back surface filed structures, a metal barrier layer and a conductive rubber layer. The improvement of the manufacturing method mainly lies in the fact that before forming the conductive rubber layer, the metal barrier layer is formed on the surface of the dielectric layer, and the material is silver, molybdenum, titanium-tungsten alloy, tungsten, titanium, chromium, molybdenum-tungsten alloy, platinum, gold, nickel or alloy of any combination of the materials mentioned above. By using the metal barrier layer as a surface barrier of the dielectric layer, the material of the conductive rubber layer can be prevented from diffusing in the dielectric layer in the sintering process, and further, the damage of the conductive rubber layer to the dielectric layer can be avoided, so that the dielectric layer has good quality and good effect of reducing the carrier recombination rate, and the cell conversion efficiency can be increased.

Owner:MOTECH INDUSTRIES

Cigs-based thin film solar cell and preparation method thereof

ActiveCN105023958BStop the spreadPrevent diffusion from enteringFinal product manufacturePhotovoltaic energy generationComposite filmAluminum oxynitride

The invention provides a CIGS (Copper Indium Gallium Selenide)-based thin-film solar cell and a manufacturing method thereof. The CIGS-based thin-film solar cell comprises a substrate, a back electrode layer covering the surface of the substrate, a light absorption layer covering the back electrode layer, a buffer layer covering the light absorption layer, a transparent conducting layer covering the buffer layer, and an aluminum oxynitride silicon film layer covering the transparent conducting layer, or a composite film layer alternatively constructed by a zinc oxide silicon film layer and a silicon oxynitride film layer. Through the aluminum oxynitride silicon film layer or the composite film layer, external water molecules can be effectively prevented from entering the thin-film cell, and the decreasing degree of the efficiency of the thin-film solar cell is reduced. Meanwhile, an anti-reflection effect can be achieved, and the light absorption layer through which incident light reaches the cell is added, so that the short-circuit current of the thin-film cell can be increased.

Owner:厦门神科太阳能有限公司

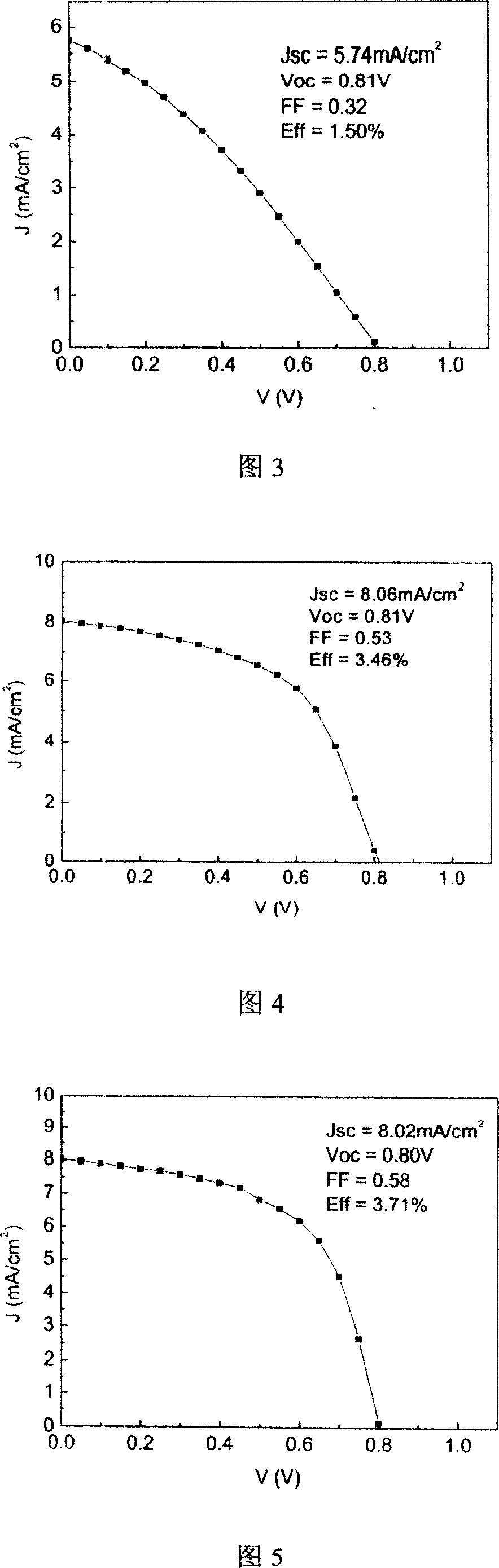

Thin-film solar battery barrier with flexible substrate and production method thereof

InactiveCN100373635CGuaranteed performancePrevent proliferationFinal product manufactureVacuum evaporation coatingMetallic aluminumTitanium

The barrier layer of thin film solar cell with a flexible substrate is composed of a metallic nickel layer or metallic titanium layer with 30-50nm thickness. It can prevent from metallic aluminum of back electrode entering into main body of cell at preparation of cell. Forming a barrier layer between back electrode and silicon-based film of cell doesní»t influence reflection of incident light, and meanwhile increases its light path action in absorbing layer of cell.

Owner:NANKAI UNIV

A transition layer for cigs-based thin film photovoltaic cells and preparation method thereof

ActiveCN102867860BInhibited DiffusionPrevent diffusion from enteringFinal product manufactureSemiconductor devicesPyriteOptoelectronics

The invention discloses a transition layer for a CIGS-based film photovoltaic cell and a preparation method of the transition layer. The preparation method comprises the steps of: providing a soda-lime glass substrate, forming a transition layer covering the surface of the soda-lime glass substrate, forming a molybdenum layer covering the transition layer, forming a light absorbing layer having a copper pyrite structure and covering the molybdenum layer, forming a buffer layer covering the light absorbing layer, and forming a window layer covering the buffer layer. According to the invention, the transition layer is deposited on the surface of the glass substrate, thus the adhesion problem between a molybdenum electrode layer and the glass substrate can be efficiently solved, and sodium materials can be prevented from uncontrollably diffusing into the light absorbing layer.

Owner:厦门神科太阳能有限公司

Semiconductor structure and forming method thereof

ActiveCN110233134AImprove performanceIncreasing the thicknessTransistorSolid-state devicesSemiconductor structureEngineering

The invention provides a semiconductor structure and a forming method thereof. The forming method of the semiconductor structure comprises the following steps that a substrate is provided, wherein a dielectric layer is arranged on the substrate, and an opening penetrating through the thickness of the dielectric layer is formed in the dielectric layer; a first oxidation layer is formed at the bottom of the opening; a sacrificial layer is formed on the first oxidation layer; in the process of forming the sacrificial layer, oxidation treatment is carried out on a part of thickness of the substrate which is positioned at the bottom of the first oxidation layer, so that the first oxidation layer is converted into a second oxidation layer, material of the second oxidation layer is the same as the material of the first oxidation layer, and the thickness of the second oxidation layer is larger than that of the first oxidation layer; and the sacrificial layer is removed. According to the method, the leakage current can be effectively reduced, and the performance of the semiconductor structure can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Semiconductor structure and forming method thereof

ActiveCN110400746APrevent proliferationImprove performanceSemiconductor devicesGate dielectricSemiconductor structure

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises steps: a substrate is provided; a gate dielectric layer is formed on the substrate; aeration is carried out on the gate dielectric layer to form a modified gate dielectric layer; a work function layer is formed on the modified gate dielectric layer; and a gate layer is formed on the work function layer. Nitrogen atoms can fill the vacancies and gaps in the gate dielectric layer through aeration, metal atoms in the work function layer can thus be blocked from diffusing into the gate dielectric layer, the work function change of the gate dielectric layer can be further reduced, the drift of threshold voltage of the formed semiconductor structure can be further reduced, and the bias temperature instability of the formed semiconductor structure is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com