Additive for anhydrous stemming and preparation method thereof

A technology of water-free clay and additives, which is applied in the field of additives for clay, can solve the problems of not being able to effectively improve the anti-oxidation performance of the clay, not being able to obtain high strength of the clay, and reducing the anti-erosion performance of the clay, so as to achieve the promotion of material Transmission and sintering process, promotion of solid phase reaction and sintering process, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

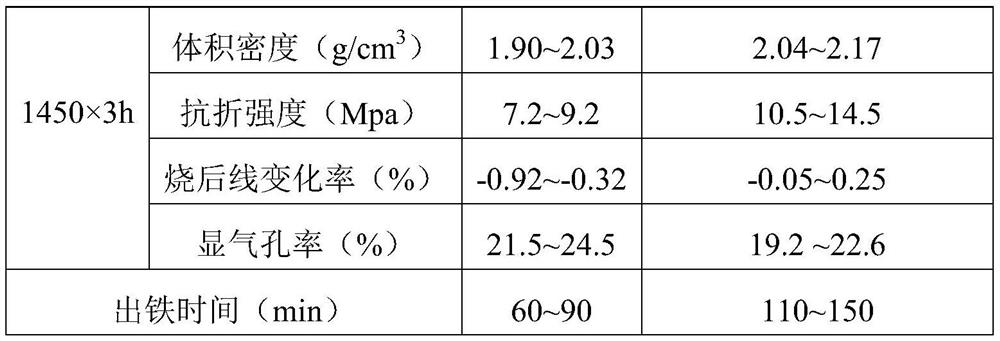

Embodiment 1

[0036] An additive for anhydrous taphole clay and a preparation method thereof. The preparation method described in this embodiment is:

[0037] First with 35wt% andalusite fine powder, 30wt% kyanite fine powder, 6wt% titanium oxide fine powder, 9wt% silicon oxynitride fine powder, 3wt% titanium aluminum carbide fine powder, 7wt% earthy graphite Micropowder, 3wt% elemental silicon fine powder, 2wt% bentonite micropowder and 5wt% nickel oxide fine powder are raw materials, plus 0.5wt% polypropylene fiber and 7wt% cobalt modified phenolic resin fine powder of the raw materials, Mix in a mixer for 20 minutes to obtain an additive for anhydrous taphole clay.

Embodiment 2

[0039] An additive for anhydrous taphole clay and a preparation method thereof. The preparation method described in this embodiment is:

[0040]First with 55wt% andalusite fine powder, 10wt% kyanite fine powder, 12wt% titanium oxide fine powder, 5wt% silicon oxynitride fine powder, 7wt% titanium aluminum carbide fine powder, 3wt% earthy graphite Micropowder, 1wt% elemental silicon fine powder, 5wt% bentonite micropowder and 2wt% nickel oxide fine powder are raw materials, plus 1.0wt% polypropylene fiber and 9wt% cobalt modified phenolic resin fine powder of the raw material, Mix in a mixer for 24 minutes to obtain an additive for anhydrous taphole clay.

Embodiment 3

[0042] An additive for anhydrous taphole clay and a preparation method thereof. The preparation method described in this embodiment is:

[0043] First with 40wt% andalusite fine powder, 11wt% kyanite fine powder, 16wt% titanium oxide fine powder, 15wt% silicon oxynitride fine powder, 5wt% titanium aluminum carbide fine powder, 5wt% earthy graphite Micropowder, 2wt% elemental silicon fine powder, 3wt% bentonite micropowder and 3wt% nickel oxide fine powder are raw materials, and then add 1.5wt% polypropylene fiber and 11wt% cobalt modified phenolic resin fine powder of the raw material, Mix in a mixer for 28 minutes to obtain an additive for anhydrous taphole clay.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com