Salinization sludge treatment method

A sludge treatment and salinization technology, applied in electrochemical sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of unfriendly environment, sludge bricks that cannot be used as building materials, and heavy metal recovery The use of value is not excavated and other problems, to achieve the effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

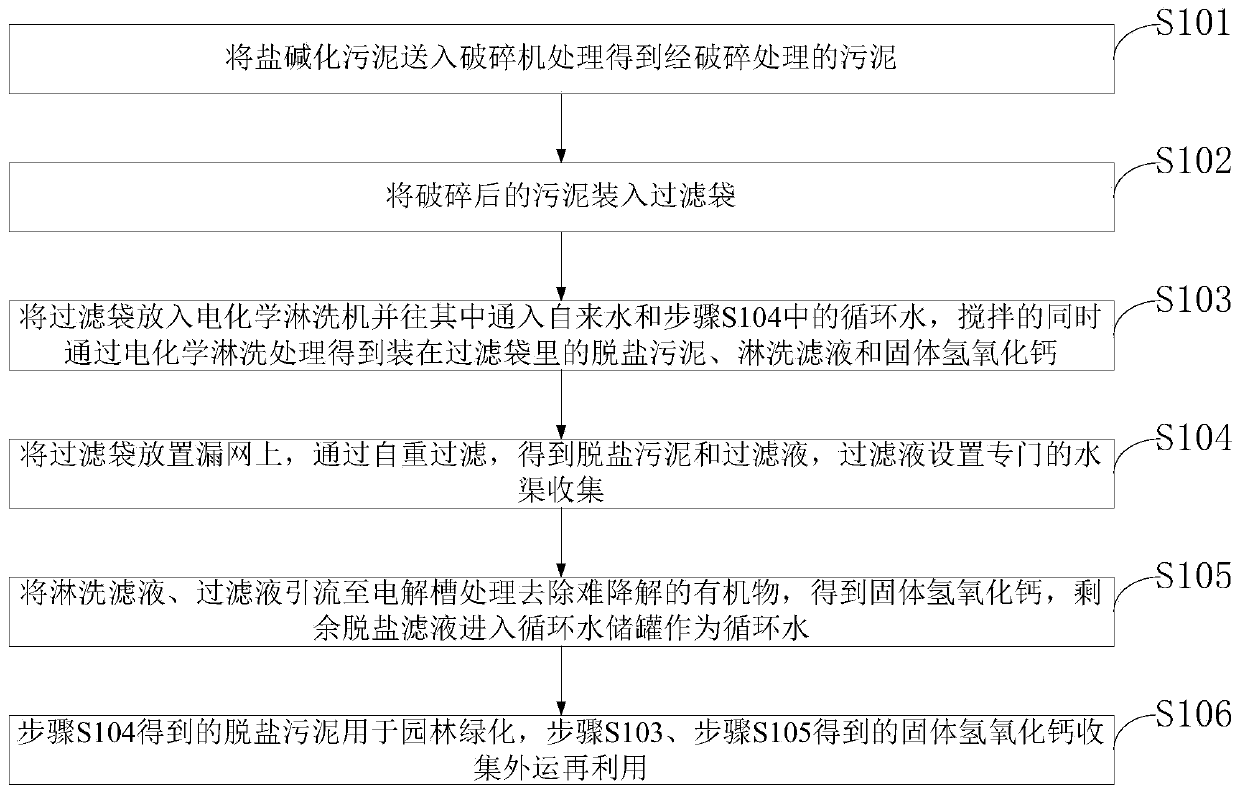

[0059] The present invention proposes a method for treating salinized sludge, the steps are:

[0060] (1) Send the salinized sludge into a crusher for processing to obtain crushed sludge, and the crushing ratio of the crusher is 10.

[0061] (2) Put the crushed sludge into the filter bag.

[0062] (3), put the filter bag into the electrochemical rinsing machine and feed tap water and the circulating water in step (4) to it, and get the desalted sludge contained in the filter bag by electrochemical rinsing while stirring, For rinsing filtrate and solid calcium hydroxide, the mass ratio of water and sludge added is 2:1, the stirring and rinsing time is 45 minutes, the removal rate of calcium salt after leaching is above 90%, and the anode used in electrochemical leaching machine The plate is a titanium-based iridium dioxide coated electrode, and the cathode plate is a titanium electrode plate.

[0063] (4) Put the filter bag on the sieve net, filter by gravity, and the gravity...

Embodiment 2

[0067] The present invention proposes a method for treating salinized sludge, the steps are:

[0068] (1) Send the salinized sludge into a crusher for processing to obtain crushed sludge, and the crushing ratio of the crusher is 3.

[0069] (2) Put the crushed sludge into the filter bag.

[0070] (3), put the filter bag into the electrochemical rinsing machine and feed tap water and the circulating water in step (4) to it, and get the desalted sludge contained in the filter bag by electrochemical rinsing while stirring, For rinsing filtrate and solid calcium hydroxide, the mass ratio of water and sludge added is 5:1, the stirring and rinsing time is 60 minutes, the removal rate of calcium salt after leaching is over 90%, and the anode used in electrochemical leaching machine The plate is a titanium-based iridium dioxide coated electrode, and the cathode plate is a titanium electrode plate.

[0071] (4) Put the filter bag on the sieve net, filter by gravity, and the gravity f...

Embodiment 3

[0075] The present invention proposes a method for treating salinized sludge, the steps are:

[0076] (1) Send the salinized sludge into a crusher for processing to obtain crushed sludge, and the crushing ratio of the crusher is 6.

[0077] (2) Put the crushed sludge into the filter bag.

[0078] (3), put the filter bag into the electrochemical rinsing machine and feed tap water and the circulating water in step (4) to it, and get the desalted sludge contained in the filter bag by electrochemical rinsing while stirring, For rinsing filtrate and solid calcium hydroxide, the mass ratio of water and sludge added is 3:1, the stirring and rinsing time is 40 minutes, and the removal rate of calcium salt after leaching is over 90%. The anode used in the electrochemical leaching machine The plate is a titanium-based iridium dioxide coated electrode, and the cathode plate is a titanium electrode plate.

[0079] (4) Place the filter bag on the sieve, filter by gravity, and the gravity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com