Closed type dust removal device for printing press

A dust removal device and printing machine technology, applied in the direction of printing device, printing, etc., can solve the problems of clogged equipment, dust falling on the paper surface, unclear printing, etc., to achieve the effect of ensuring flatness and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

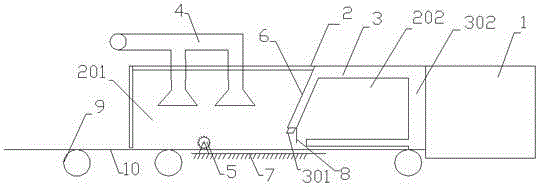

[0016] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

[0017] As shown in the figure, a paper surface cleaning device for a printing machine includes a cleaning box 2 connected to the entrance of the printing machine 1, and a conveying path for paper 10 is provided at the bottom of the cleaning box 2, and the paper 10 is placed between the rollers 9. Under transportation, enter and pass through the lower part of the cleaning box 2, and enter the printing machine 1 for inkjet printing. The lower edge of the cleaning box 2 is smoothly arranged, and a support plate 6 with a cavity inside is provided on the inside of the cleaning box 2, and one end of the support plate 6 is fixed. On the top of the cleaning box 2, the other end is inclined away from the entrance of the printing machine 1, and the cleaning box 2 is divided into a dust removal area 201 at the front and a cleaning area 202 at the rear....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com