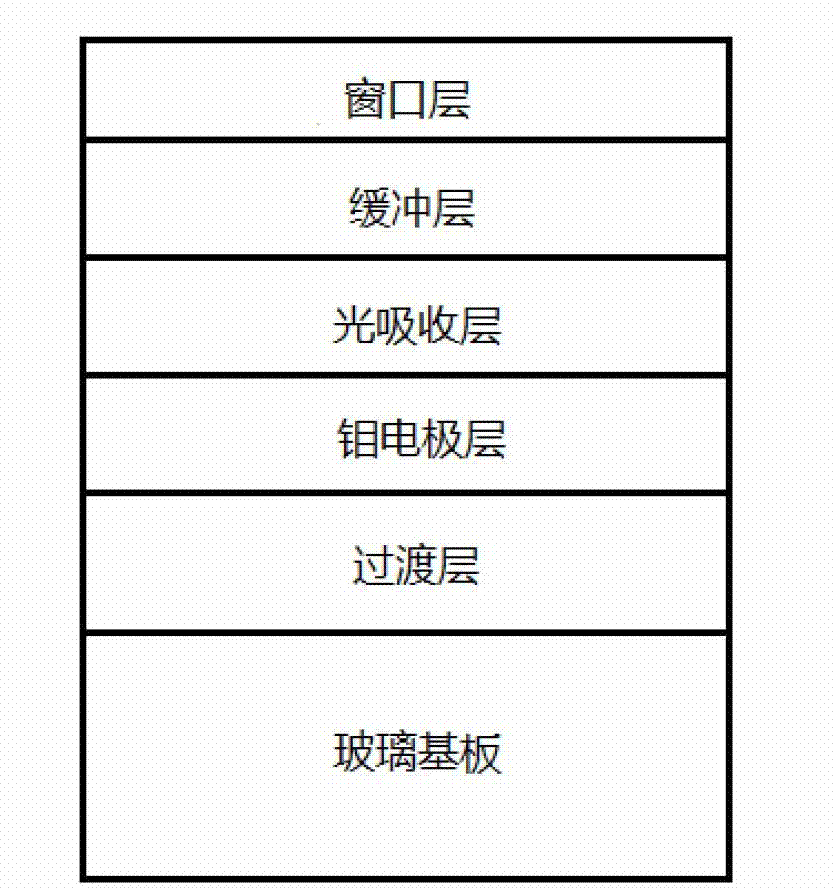

Transition layer for CIGS-based film photovoltaic cell and preparation method of transition layer

A thin-film photovoltaic cell and transition layer technology, which is used in circuits, electrical components, and final product manufacturing, etc., can solve the problems that the metal molybdenum electrode layer and the glass substrate are not firmly combined, and achieve the problem of poor adhesion, good transition connection, Combines a strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

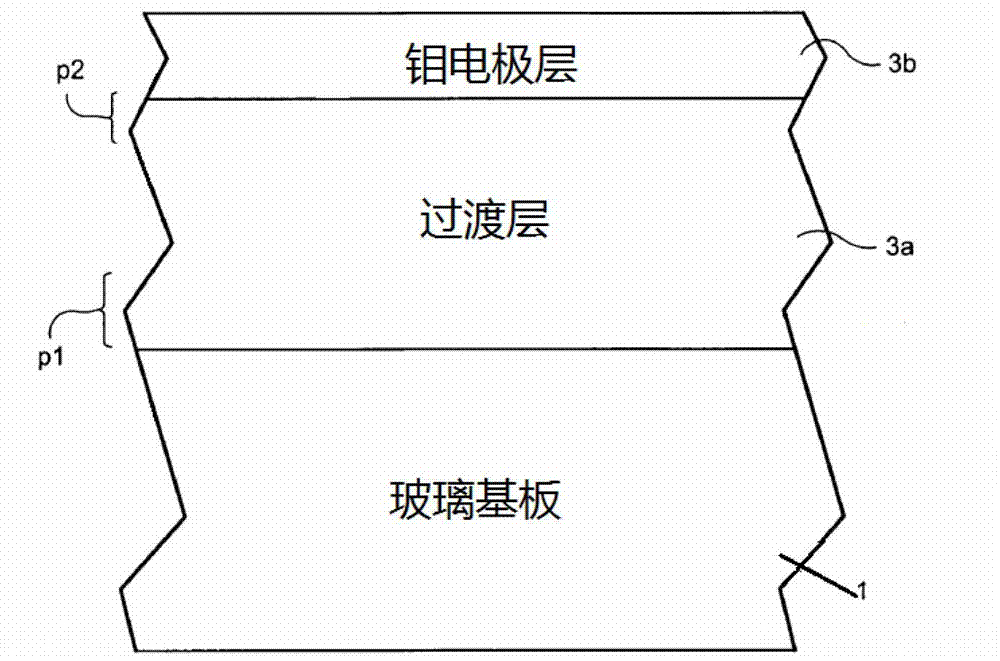

[0037] A transition layer 3 a with a thickness of 15 nm and a molybdenum electrode layer with a thickness of 400 nm are sequentially deposited on a soda lime glass substrate with a thickness of 3.0 mm. Both the transition layer 3a and the molybdenum electrode layer are deposited by magnetron sputtering, and the deposition of the transition layer 3a uses three kinds of targets: an alloy target containing 25% silicon, 70% zirconium, and 5% molybdenum is the first sputtering target. The target, the alloy target containing 35% silicon, 30% zirconium, and 35% molybdenum is the second sputtering target, and the alloy target containing 10% silicon, 5% zirconium, and 85% molybdenum is the third sputtering target. The soda-lime glass substrate is sequentially passed under the first sputtering target, the second sputtering target and the third sputtering target, and argon and oxygen are introduced during the sputtering deposition process to form each layer with a thickness of about 5 nm....

Embodiment 2

[0041] A transition layer 3 a with a thickness of 15 nm and a molybdenum electrode layer with a thickness of 400 nm are sequentially deposited on a soda lime glass substrate with a thickness of 3.0 mm. Both the transition layer 3a and the molybdenum electrode layer are deposited by magnetron sputtering, and the deposition of the transition layer 3a uses three targets: an alloy target containing 20% silicon, 70% zirconium, and 10% titanium is the first sputtering The target, the alloy target containing 35% silicon, 30% zirconium and 35% molybdenum is the second sputtering target, and the target containing 100% molybdenum is the third sputtering target. The soda-lime glass substrate is sequentially passed under the first sputtering target, the second sputtering target and the third sputtering target, and argon and nitrogen are introduced during the sputtering deposition process to form each layer with a thickness of about 5 nm. Transition layer 3a with a thickness of 15 nm. T...

Embodiment 3

[0045] A transition layer 3 a with a thickness of 15 nm and a molybdenum electrode layer with a thickness of 400 nm are sequentially deposited on a soda lime glass substrate with a thickness of 3.0 mm. Both the transition layer 3a and the molybdenum electrode layer were deposited by magnetron sputtering, and the transition layer 3a was deposited using an alloy target containing 15% silicon, 60% zirconium, and 25% molybdenum. The soda-lime glass substrate is passed under the sputtering target, and argon, oxygen and nitrogen are introduced during the sputtering deposition process to form a transition layer 3 a with a thickness of 15 nm. Thus obtained with figure 2 The transition layer of the structure shown.

[0046] Laminate coated glass, 0.76mm PVB and another 3.0mm original glass sheet to make laminated glass. Do a knock test on the laminated glass, and the level of the knock test is 3, which shows that the adhesion of the film layer to the glass substrate and PVB is very ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com