Patents

Literature

33results about How to "Solve the problem of poor bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

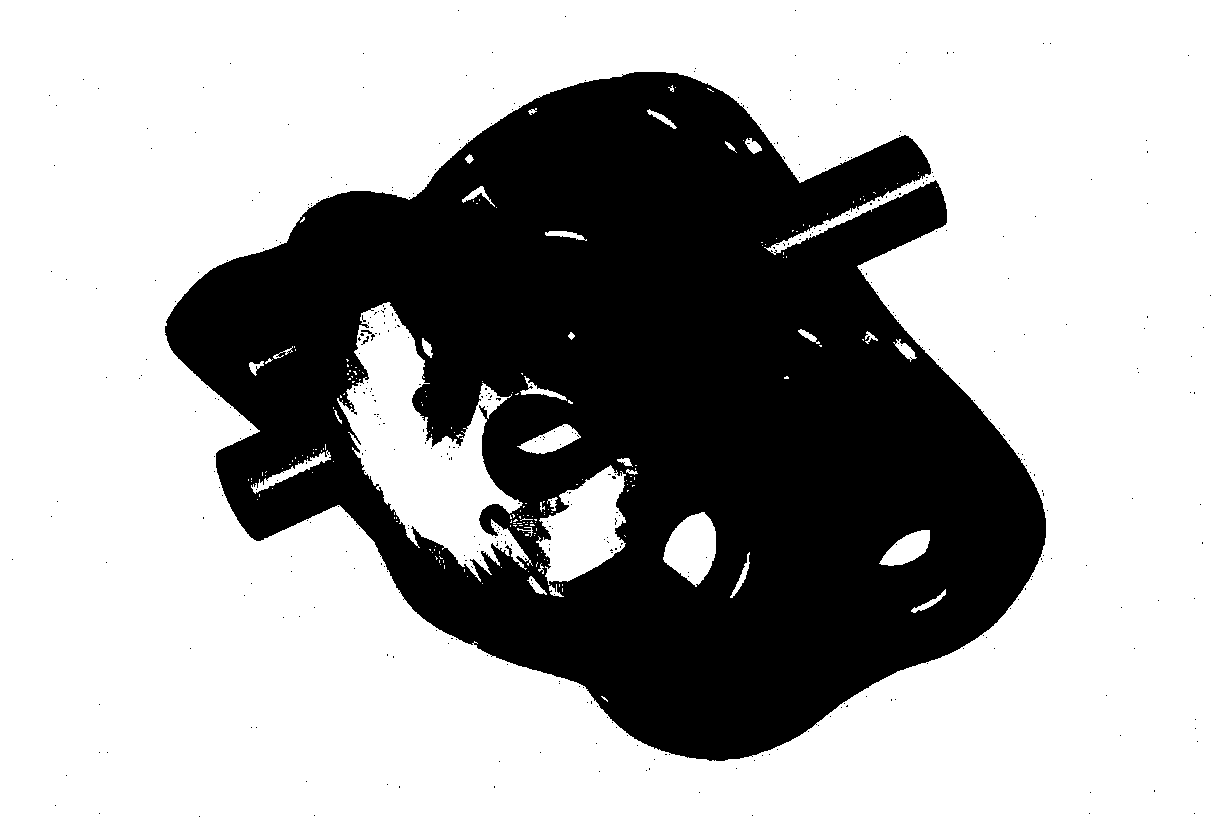

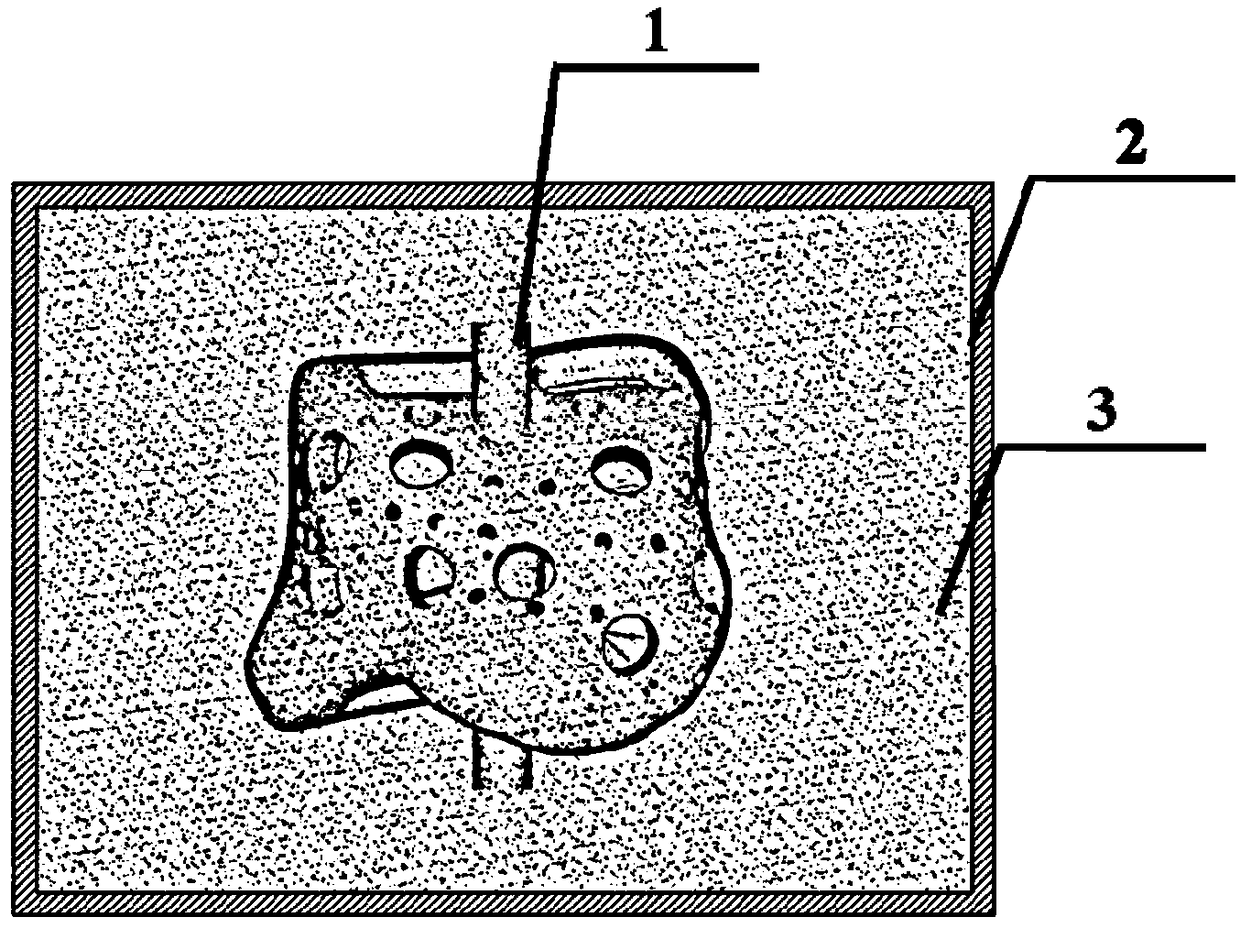

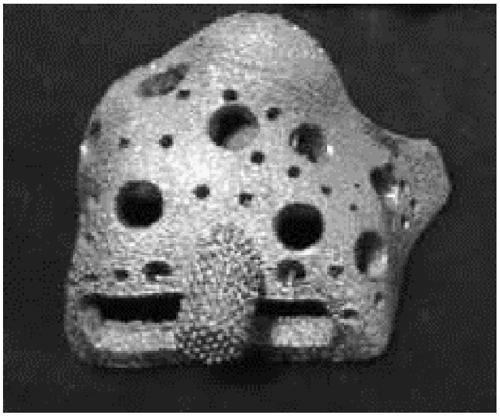

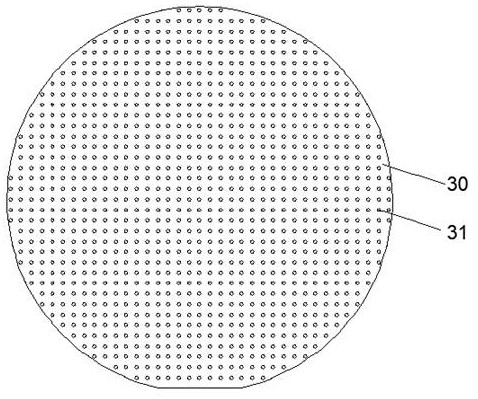

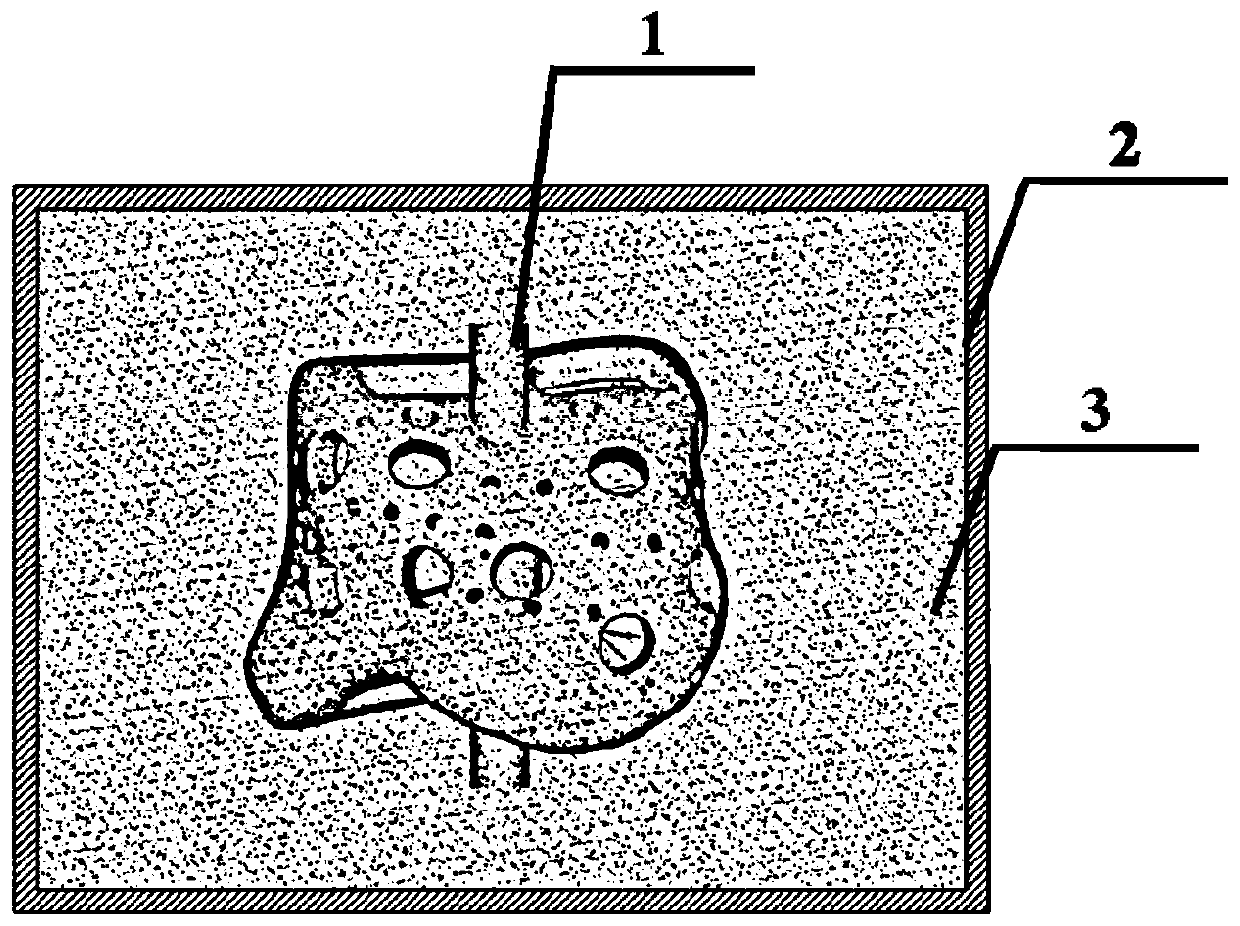

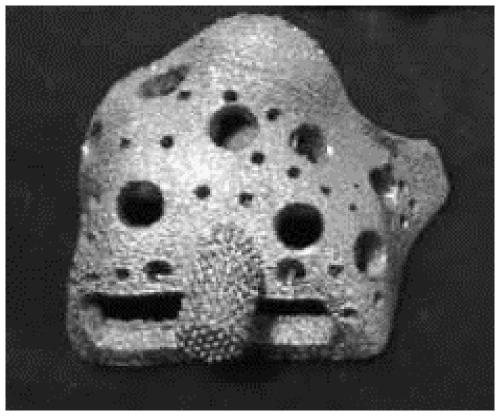

Preparation method of medical porous titanium or titanium alloy materials coated with tantalum coating on surfaces

ActiveCN109261958AImprove bindingSolve poor bondingAdditive manufacturing apparatusTransportation and packagingPorous titaniumTa element

The invention discloses a preparation method of medical porous titanium or titanium alloy materials coated with tantalum coatings on surfaces, which includes the following steps: firstly, preparing aporous titanium frame or a porous titanium alloy frame by adopting the 3D printing method; next etching the porous titanium frame or the porous titanium alloy frame, and cleaning and drying; then totally embedding the porous titanium frame or the porous titanium alloy frame in ultrafine tantalum powder in metal canning, vacuum sealing and diffusion sintering in low temperature; lastly taking out the frame, removing the powder and obtaining the medical porous titanium or titanium alloy materials coated with the tantalum coatings on surfaces. The preparation method of the medical porous titaniumor titanium alloy materials coated with the tantalum coatings on surfaces has the advantages that through embedding in powder and diffusion sintering in low temperature, tantalum coats the surfaces of the porous titanium frame or the porous titanium alloy frame, and metallurgical bonding is formed, thereby greatly enhancing the bonding force between tantalum and the surface of the porous titaniumframe or the porous titanium alloy frame, solving the difficulty of poor bonding force between the tantalum coatings and matrix, and overcoming the disadvantages of high cost and complicated processof the prior preparation method.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

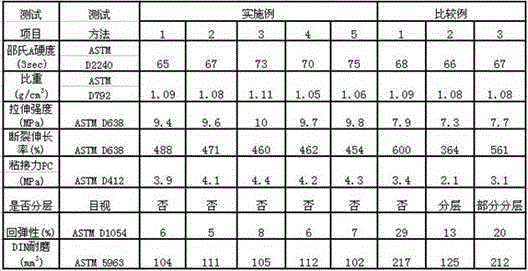

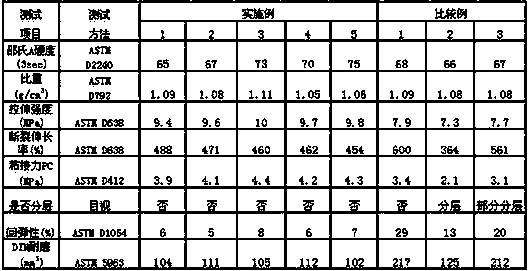

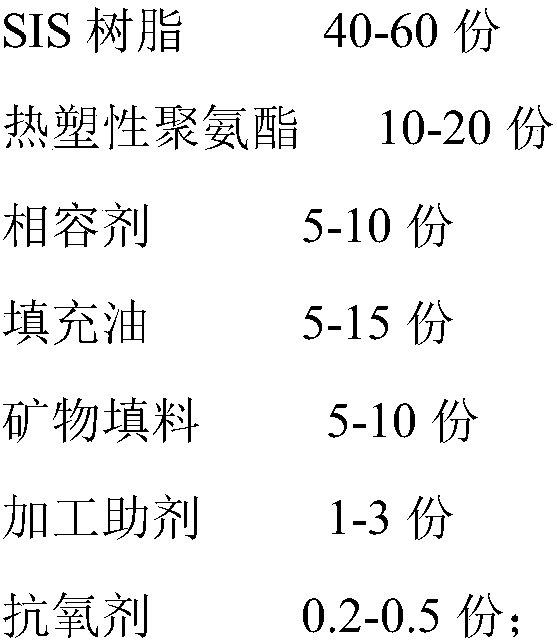

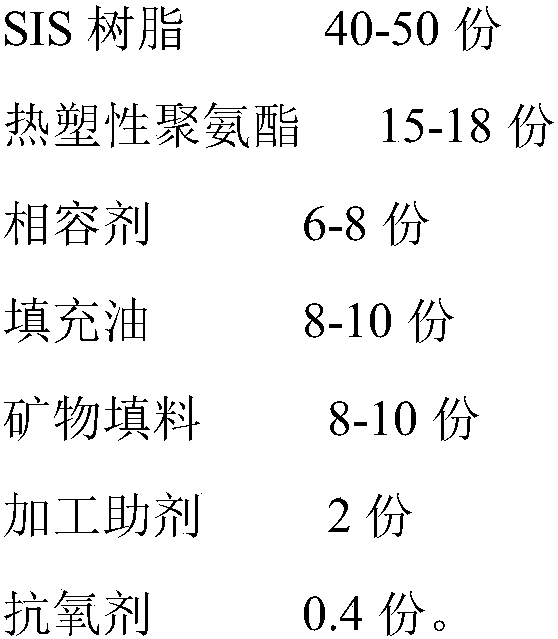

High-shock-absorbance wear-resistant thermoplastic elastomer and preparation method thereof

The invention relates to the technical field of thermoplastic elastomer materials and particularly relates to a high-shock-absorbance wear-resistant thermoplastic elastomer and a preparation method thereof. The high-shock-absorbance wear-resistant thermoplastic elastomer comprises the following components in parts by weight: 40-60 parts of SIS resin, 10-20 parts of thermoplastic polyurethane, 5-10 parts of a compatilizer, 5-15 parts of extending oil, 5-10 parts of mineral filler, 1-3 parts of a processing aid and 0.2-0.5 part of an antioxidant. The preparation method comprises the following steps of firstly, placing the SIS resin, carbonate calcium, the antioxidant, the processing aid and extending oil into a high-speed mixer, mixing, adding other raw materials and mixing to obtain a premix; and secondly, placing the premix into a twin-screw extruder, extruding and granulating. The thermoplastic elastomer has the characteristics of capability of secondary injection molding, good adhesion with PC and ABS materials and high shock absorbance and wear resistance.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

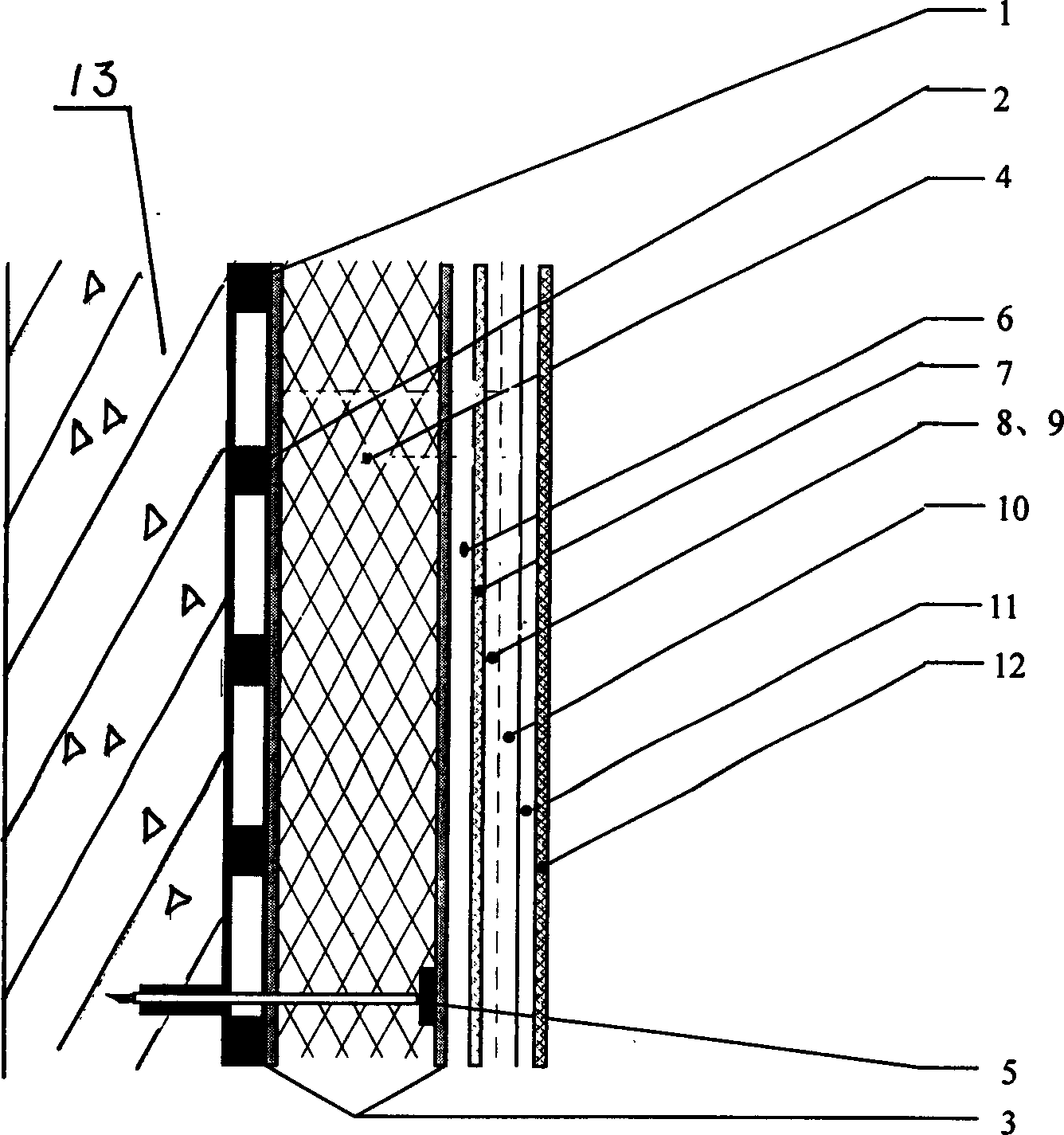

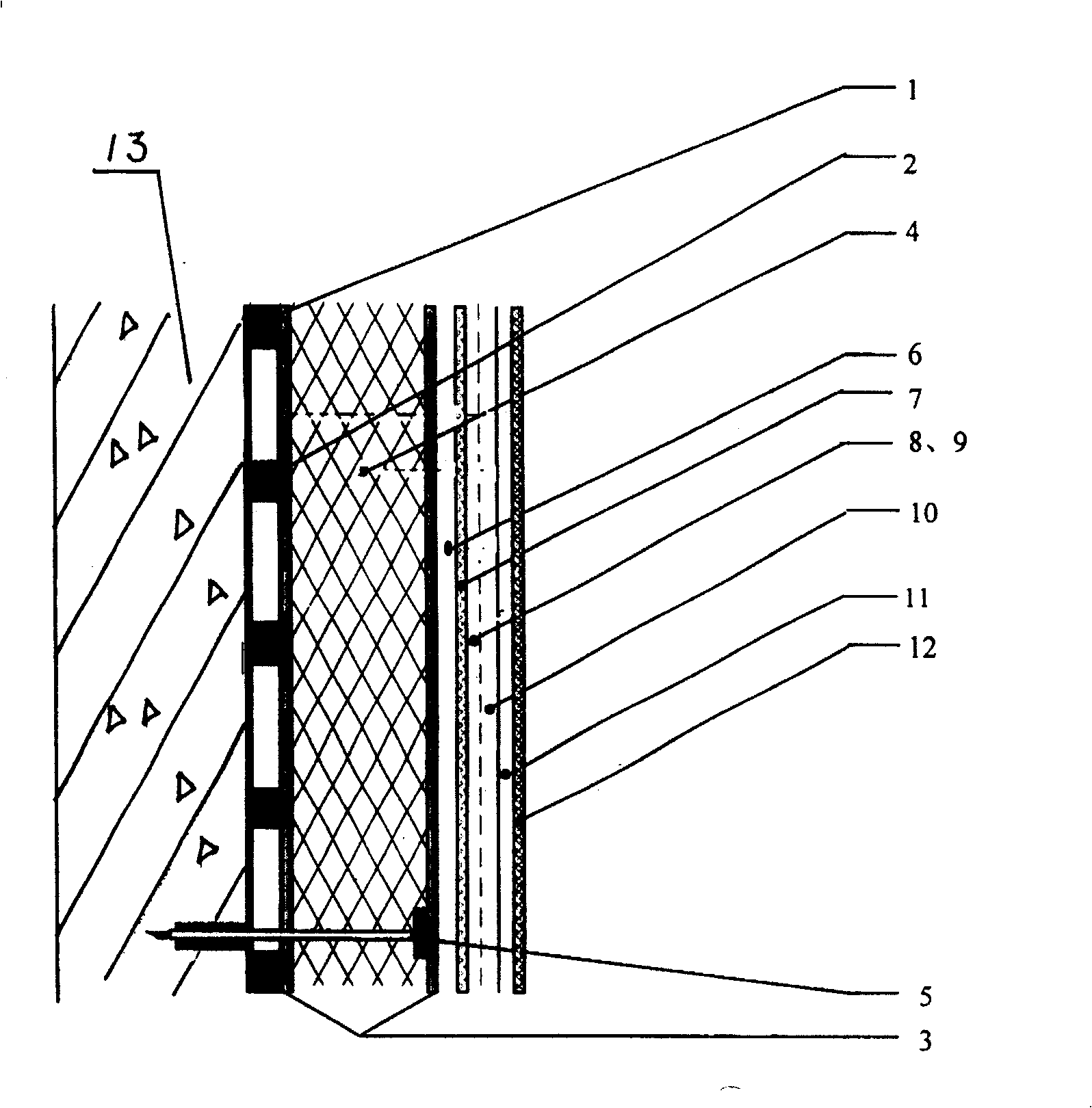

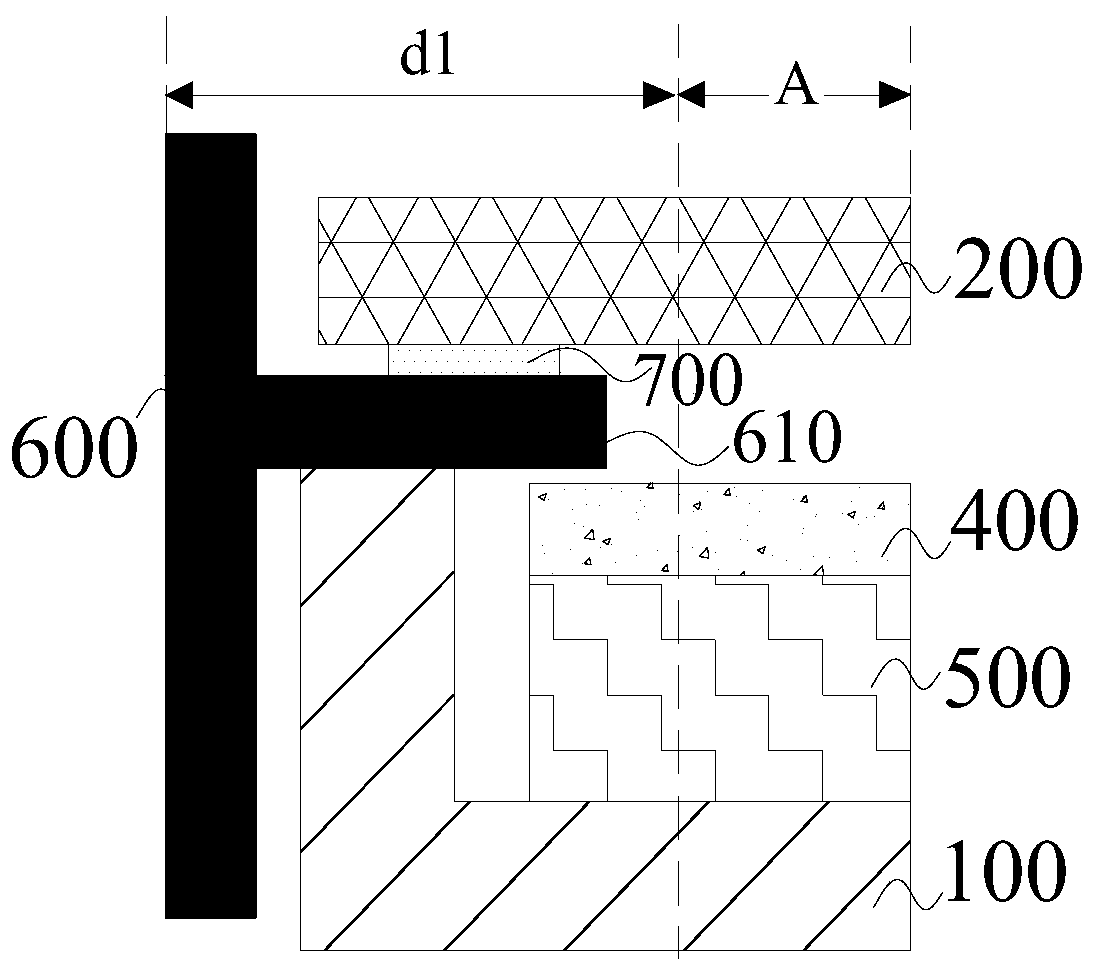

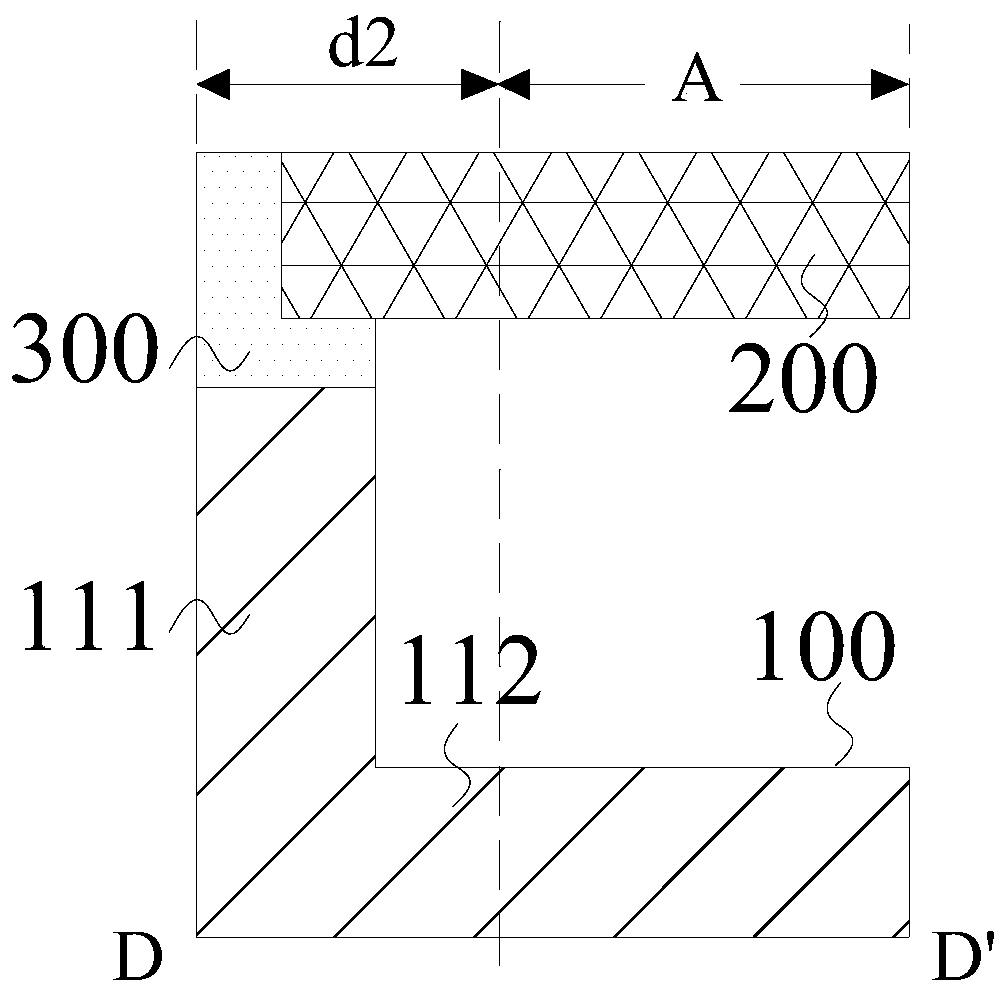

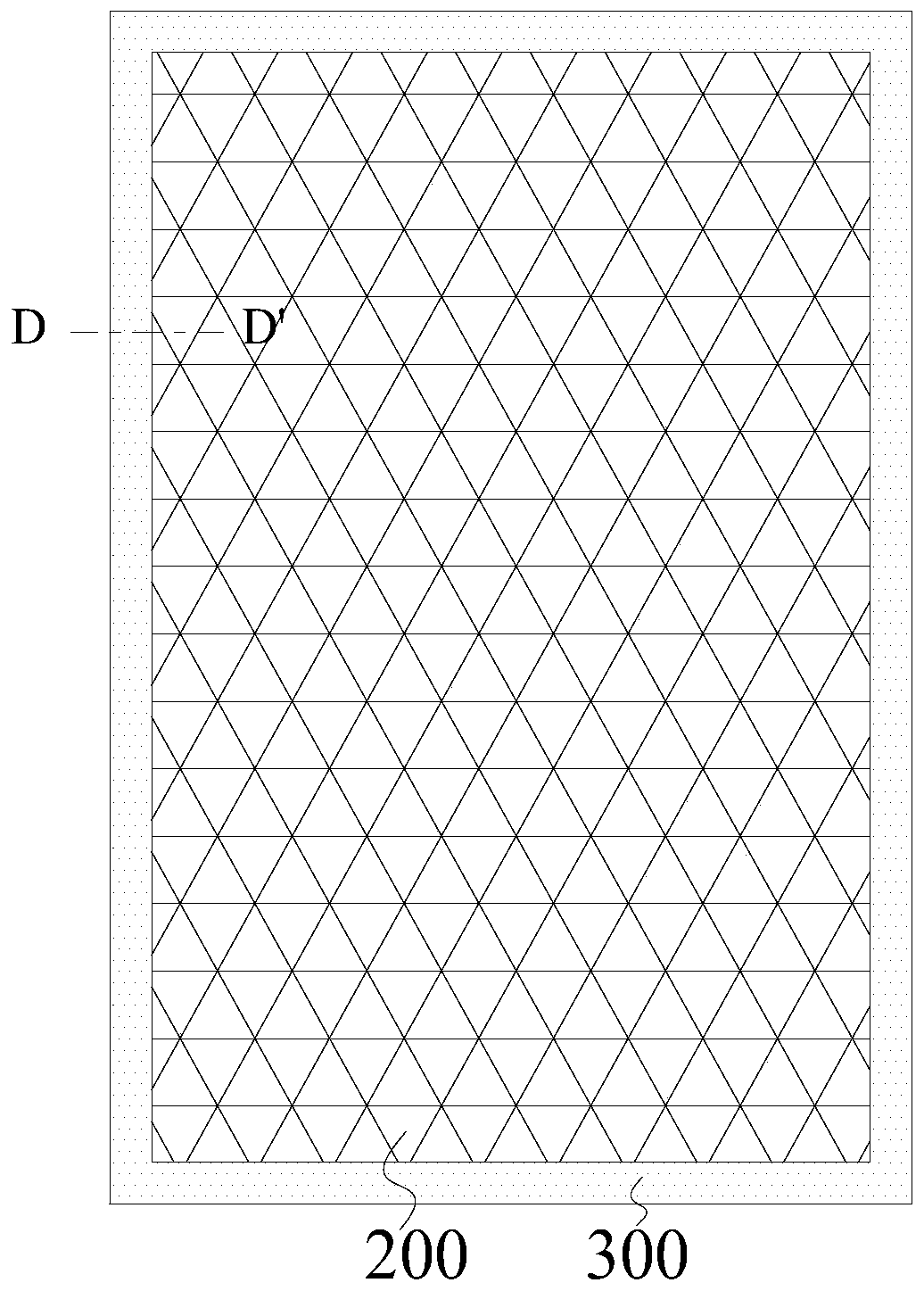

Heat insulating system outside external wall

InactiveCN1811088AAvoid spreadingStop crackingHeat proofingBuilding reinforcementsEngineeringFire retardant

The heat insulating system outside external wall features that there are base layer with alkali resistant strengthening treating agent outer the concrete base wall and connected to the heat insulating board through silicon modified polymer mortar adhesive and plastic anchor part, alkali resistant netted cloth outside the heat insulating board, elastic anticracking silicon modified polymer putty and self-structured waterproof anticracking closing layer between the heat insulating board and the alkali resistant netted cloth, facing silicon modified polymer mortar outside the alkali resistant netted cloth, fire retardant paint around the window and silicon modified acrylate paint in the outmost layer. The present invention has the advantages of simple structure, low cost, easy construction, raised wall surface quality and fire retarding function.

Owner:上海英硕聚合材料股份有限公司

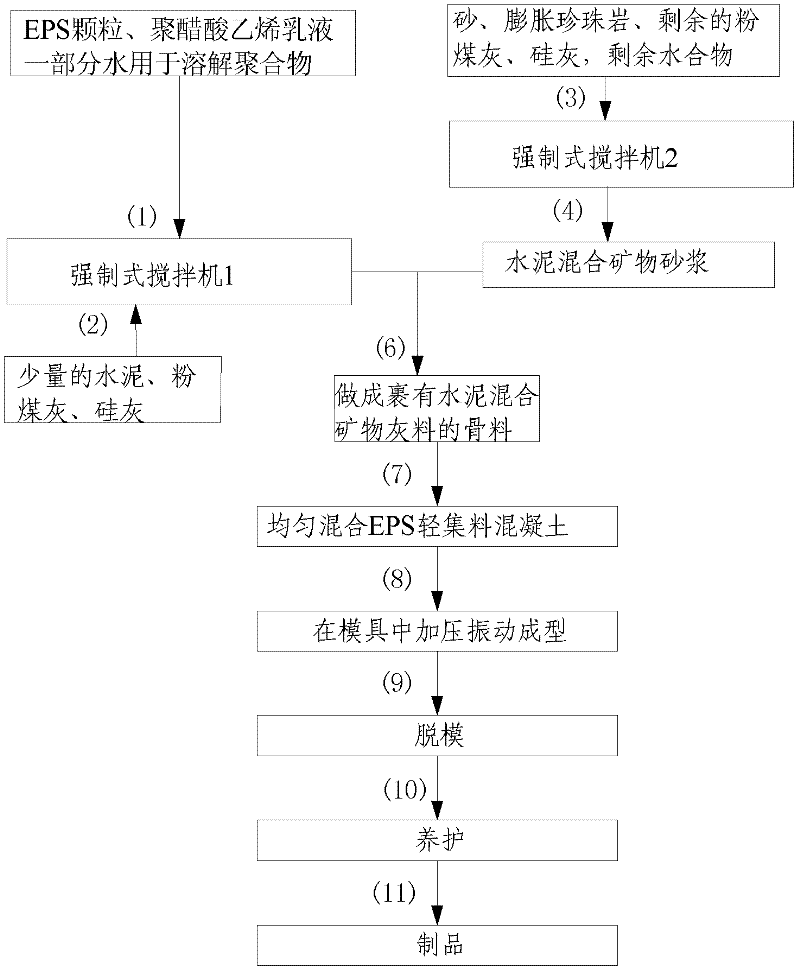

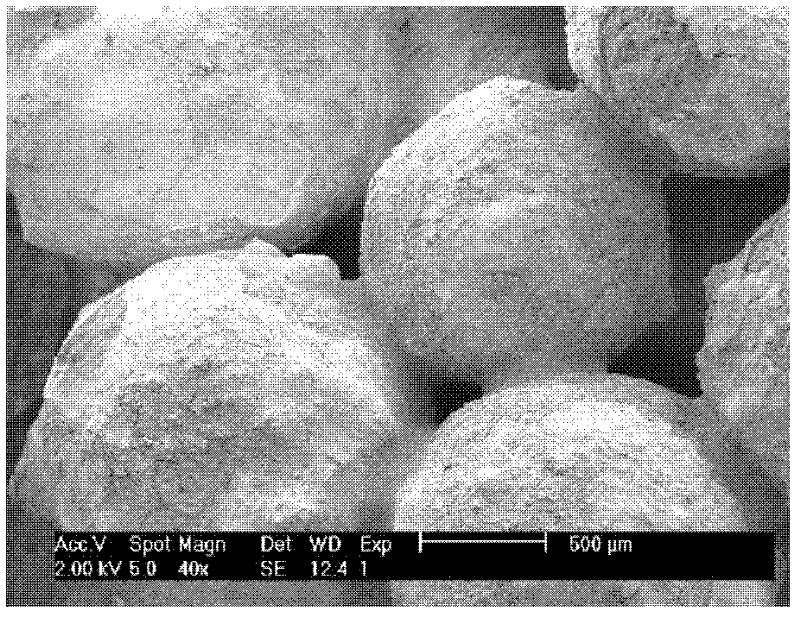

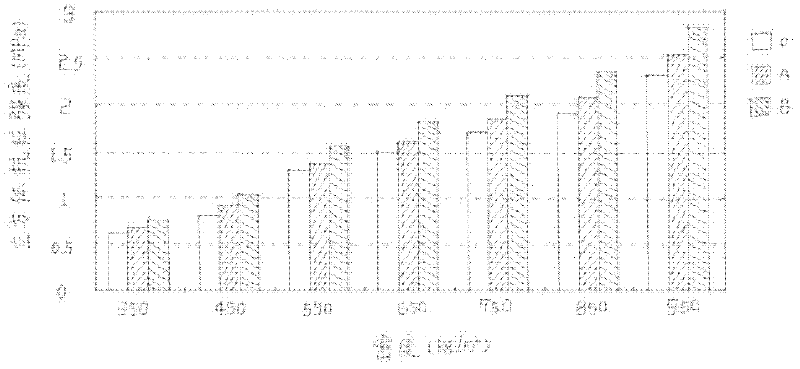

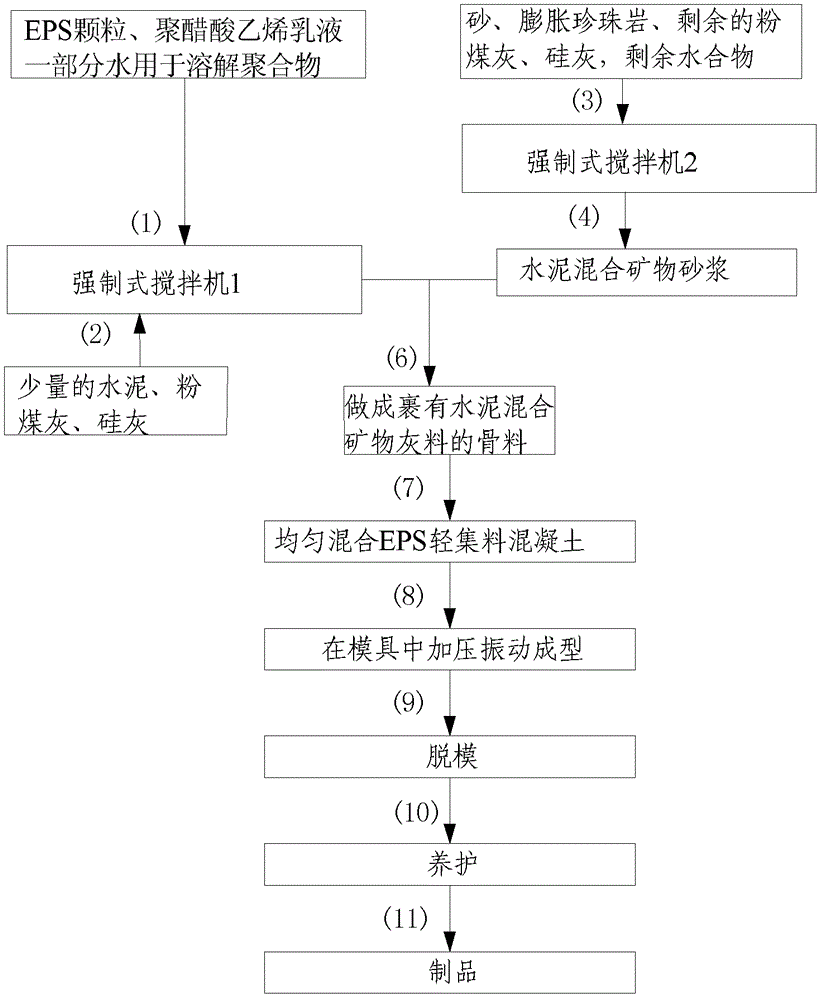

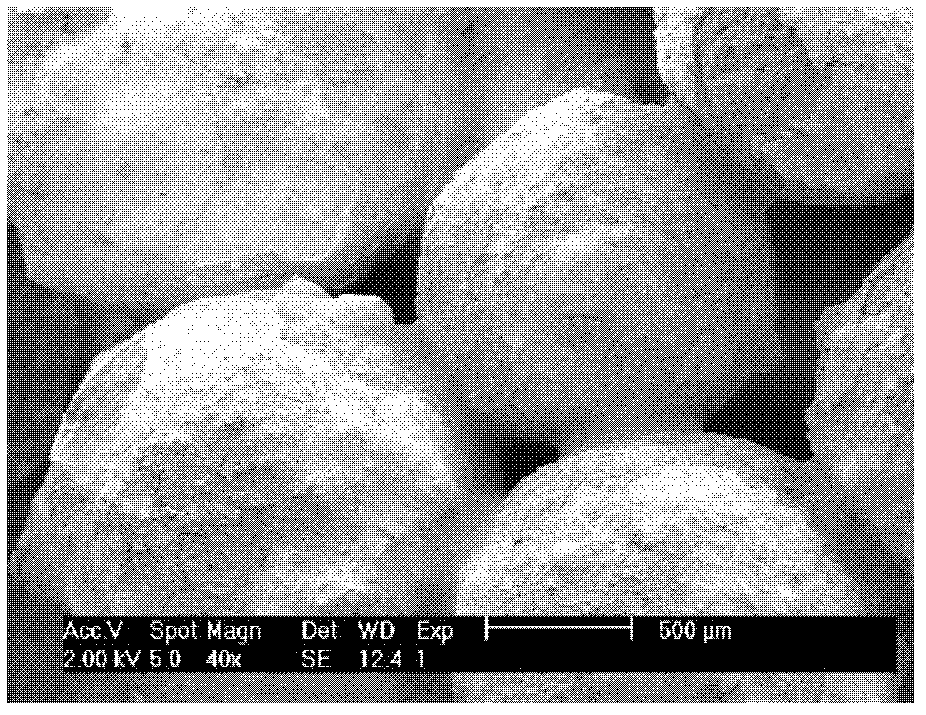

EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

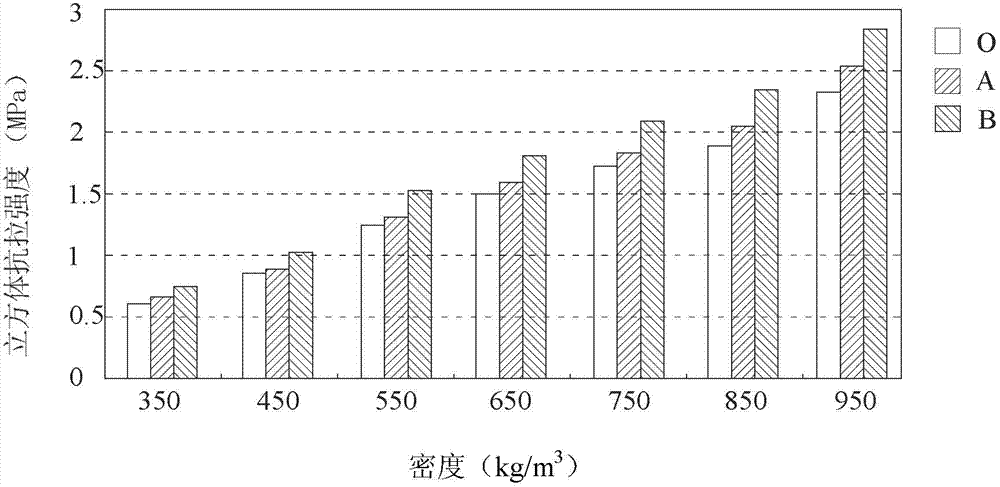

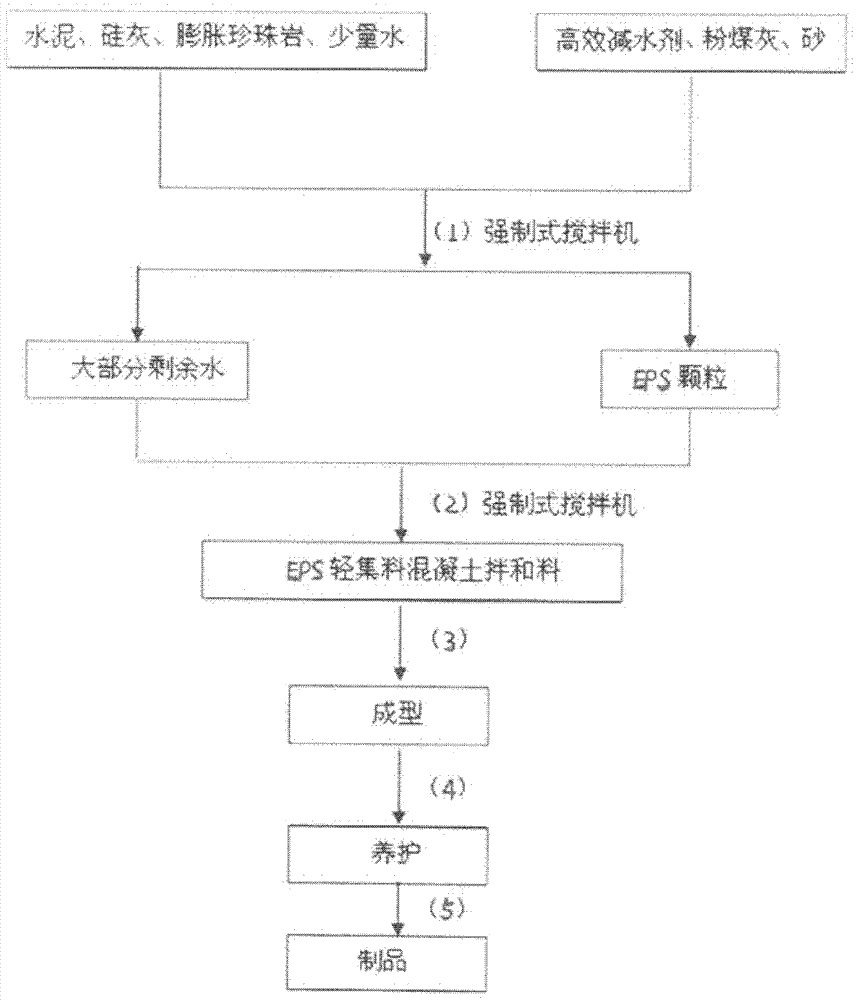

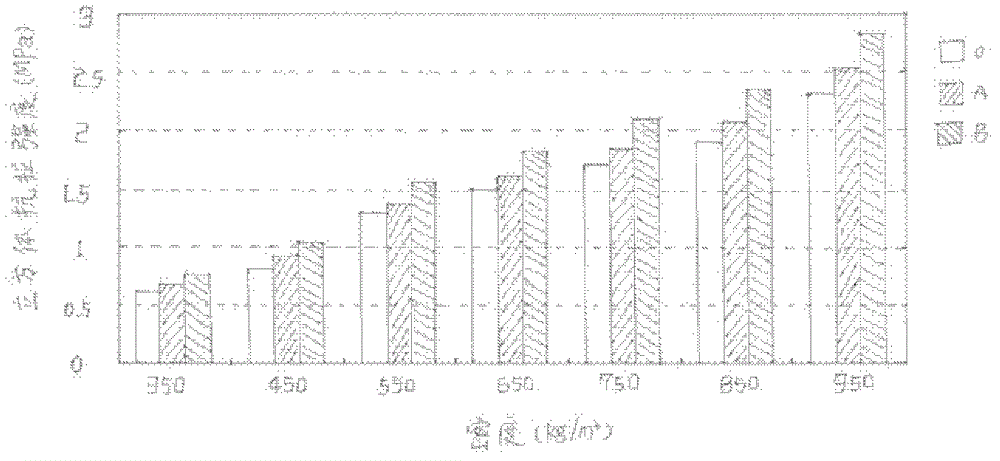

The invention provides EPS (Expandable Polystyrene) lightweight aggregate concrete and a preparation method thereof. The EPS lightweight aggregate concrete effectively meets the requirements of concrete on light weight, uniformity and density in the aspect of structure, and simultaneously has excellent comprehensive properties; the volume weight of the EPS lightweight aggregate concrete is higher than 650 kg / m<3>, the cube compressive strength can reach 1.6MPa, the strength meets the service requirements, and the lightweight aggregate concrete has excellent thermal properties and durability; and shown in a compression test, the concrete has larger deformation before the concrete is damaged due to deformation, so that the toughness of the concrete is improved. The lightweight aggregate concrete comprises the following raw materials in parts by weight: 350 parts of cement, 90-120 parts of fly coal ash, 30-70 parts of silica fume, 120-140 parts of river sand, 190-210 parts of water, 15-21 parts of EPS grains, 40-60 parts of perlite and 12-18 parts of polymer emulsion. The preparation method comprises the steps of crusting, slurry wrapping, mixing, forming and curing. The lightweight aggregate concrete obtained according to the mixture ratio and the preparation method is uniform and dense in structure, and various properties meet the design requirements, so that the EPS lightweight aggregate concrete has better application prospects.

Owner:CHINA ELECTRIC POWER RES INST +1

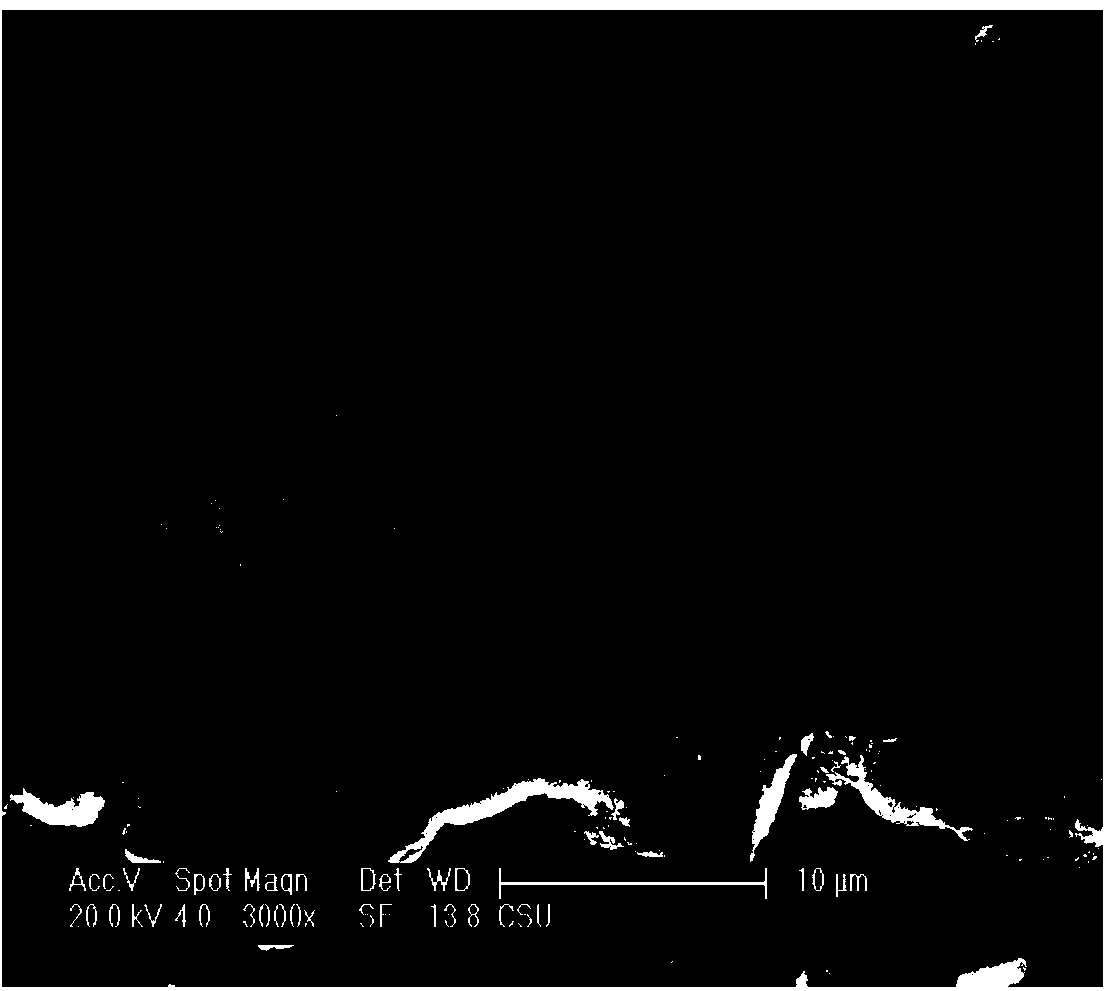

Expanded Polystyrene (EPS) light aggregate concrete and preparation method thereof

InactiveCN102875181AEvenly distributed pore structureImprove interface bondingSolid waste managementCeramic shaping apparatusExpanded polystyreneLarge deformation

The invention provides EPS light aggregate concrete and a preparation method thereof. The EPS light aggregate concrete effectively meets the requirements on a light-weight, uniform and dense structure of the concrete, and has an outstanding integrated performance; the EPS light aggregate concrete has a unit weight of up to 550 kg / m<3> and a cube crushing strength of up to 1.3 MPa which meets the using requirement; in addition, the light aggregate concrete has good thermal performance and durability. In a compression test for the concrete, a large deformation occurs before deformed breakage, and the toughness is improved. The light aggregate concrete comprises 350 parts of cement, 90 to 120 parts of coal ash, 30 to 70 parts of silica fume, 120 to 140 parts of river sand, 190 to 210 parts of water, 15 to 21 parts of EPS particles, 40 to 60 parts of perlite and 2 to 6 parts of water reducer. The light aggregate concrete prepared by the preparation method according to the proportion is uniform and dense in structure, and meets the design requirements on each performance and preparation, so as to have a good application prospect.

Owner:CHINA ELECTRIC POWER RES INST +1

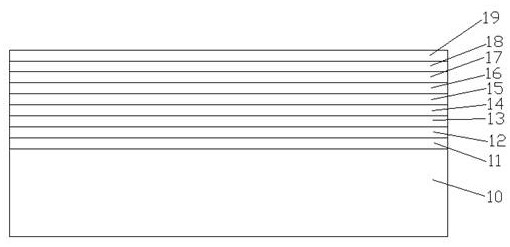

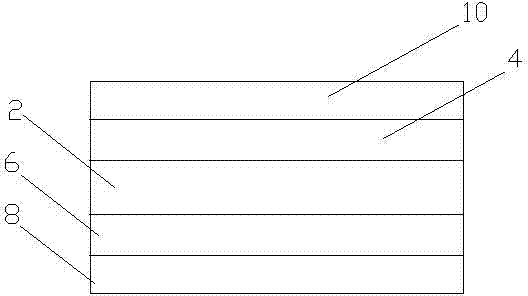

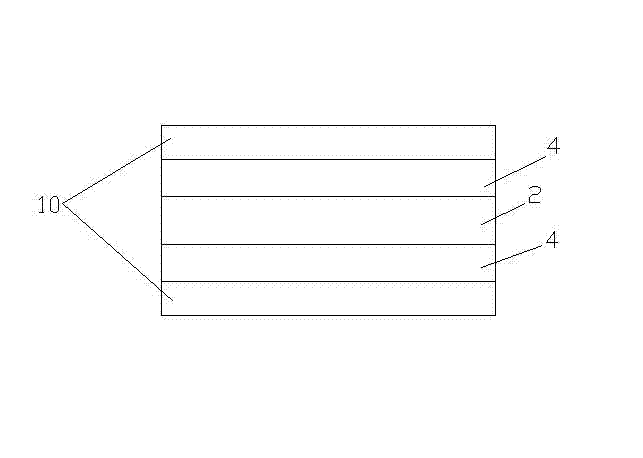

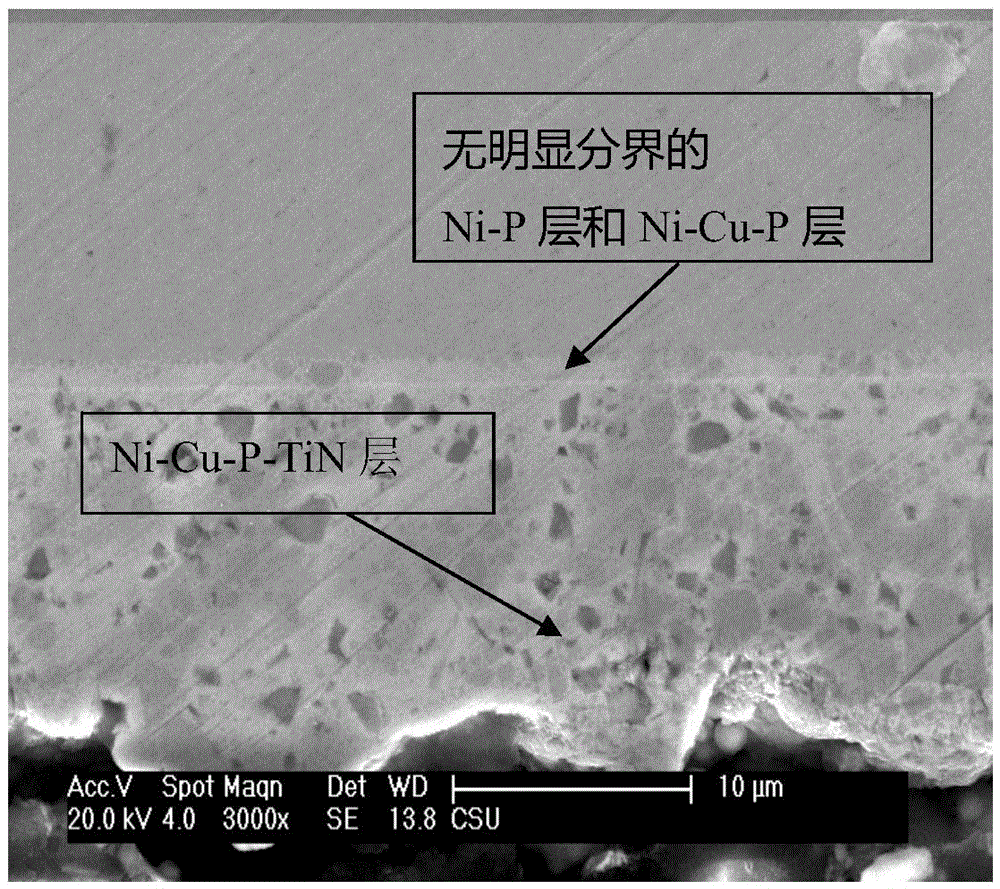

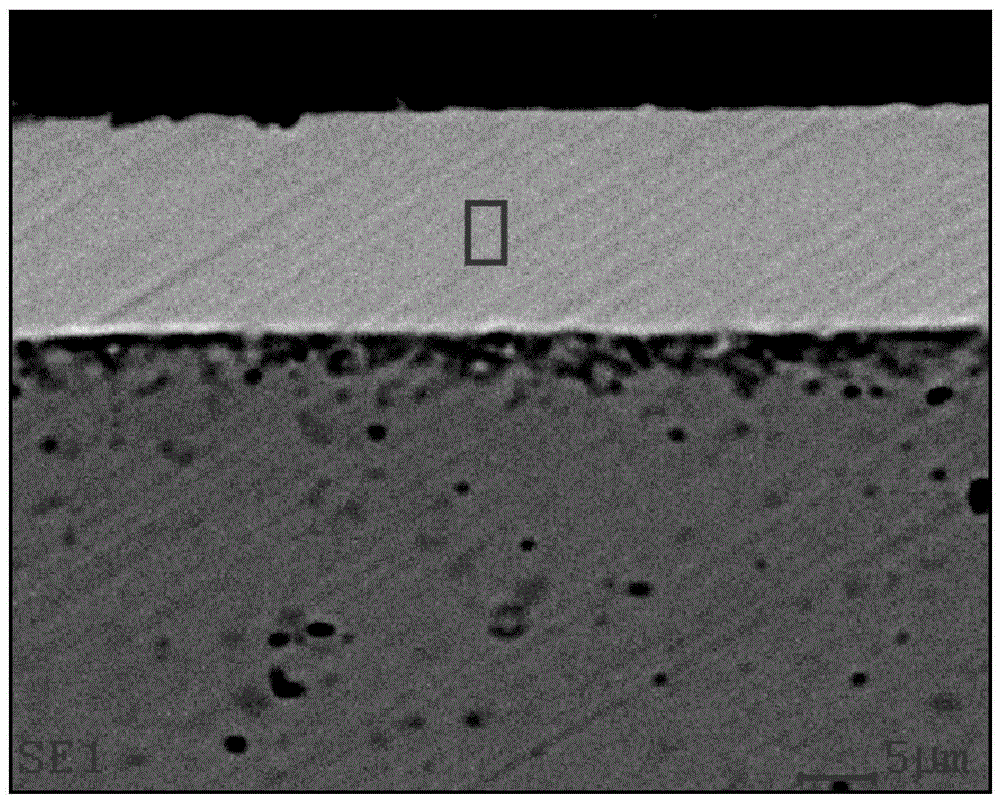

Anticorrosion abrasive-resistant material with Ni-Cu-P-TiN composite coating and preparation method of material

InactiveCN104339752AHigh hardnessLow shear strengthLiquid/solution decomposition chemical coatingMetal layered productsAlloyMetal

The invention discloses an anticorrosion abrasive-resistant material which sequentially comprises a base material, a Ni-P coating, a Ni-Cu-P coating and a Ni-Cu-P-TiN coating from inward to outward. According to the invention, flexible metal Cu and TiN nano particles are added into the Ni-P coating via a prior precipitation mechanism and a co-deposition mechanism, so that the Cu metal and the TiN particles have complementary performance advantages; meanwhile, in order to improve the wettability of the TiN particles and a Ni-P alloy, the TiN particles are subjected to Ni coating modification treatment, and the bonding intensity of the TiN particles and the coating is increased; on the other hand, by the multi-layer structural design of Ni-P / Ni-Cu-P / (Ni-Cu-P-TiN), the problem of poor bonding intensity of the coatings caused by the prior precipitation mechanism of Cu is solved. The method is simple in technology, and equipment is low in price; a subsequent technology is combined, a coating scraper with good corrosion resistance and tribology performance can be prepared, and the service life of the scraper can be multiplied.

Owner:CENT SOUTH UNIV +1

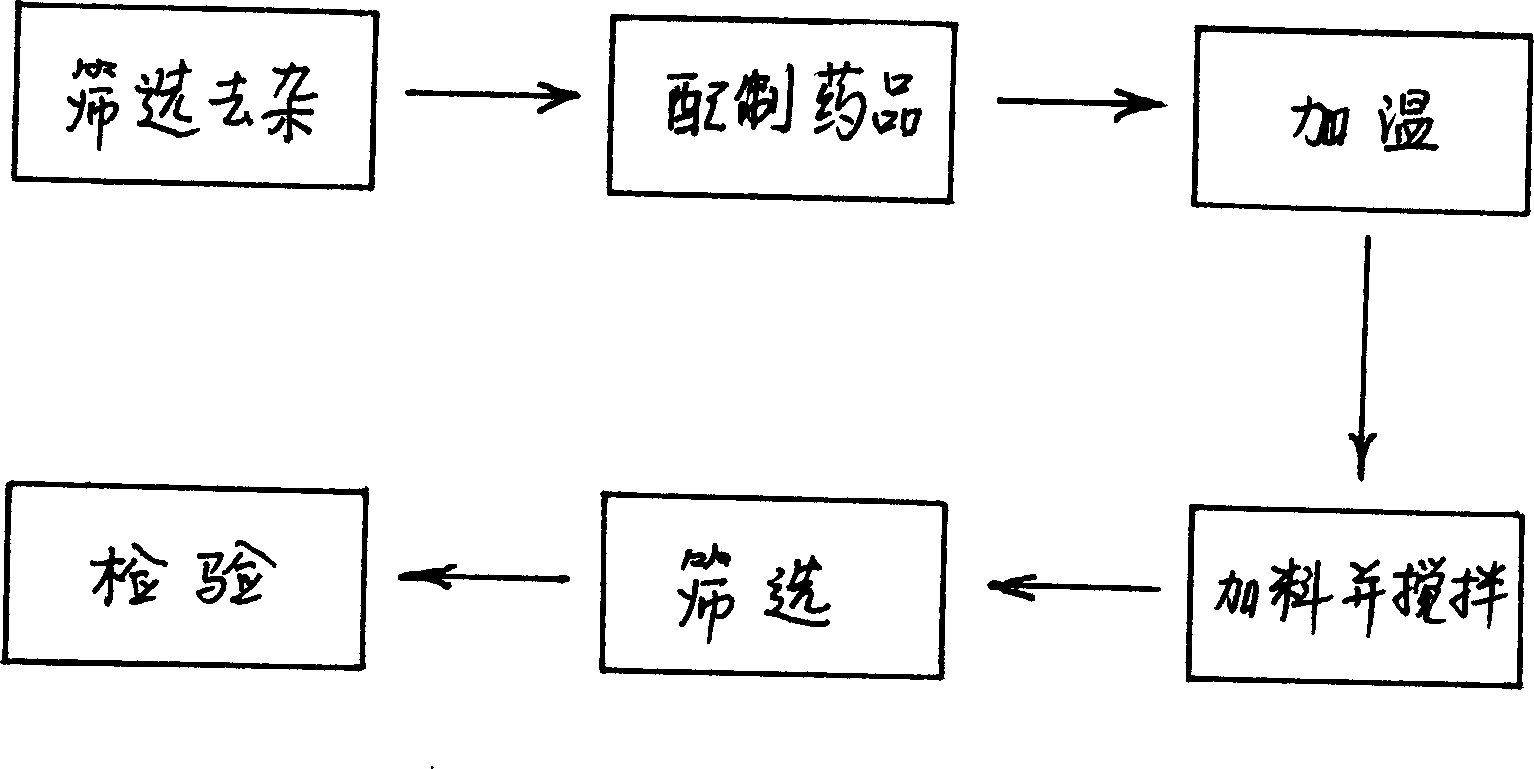

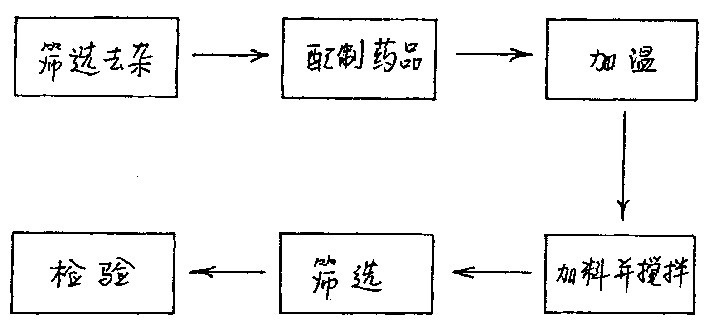

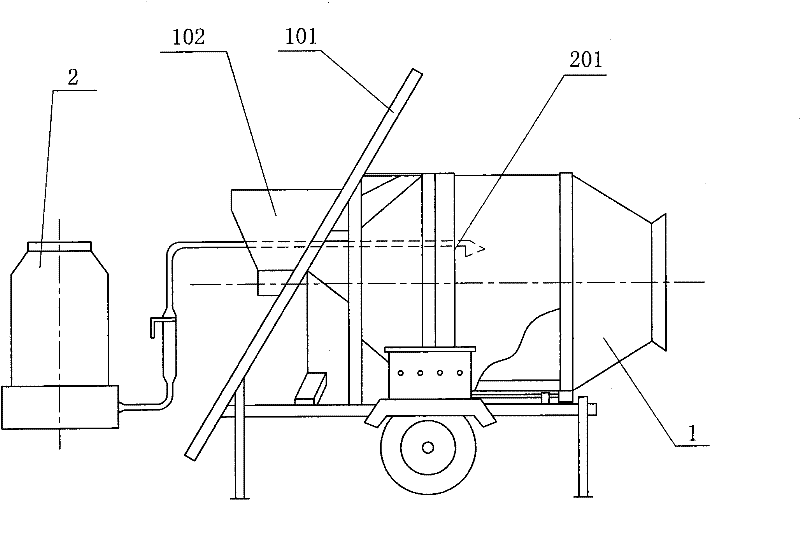

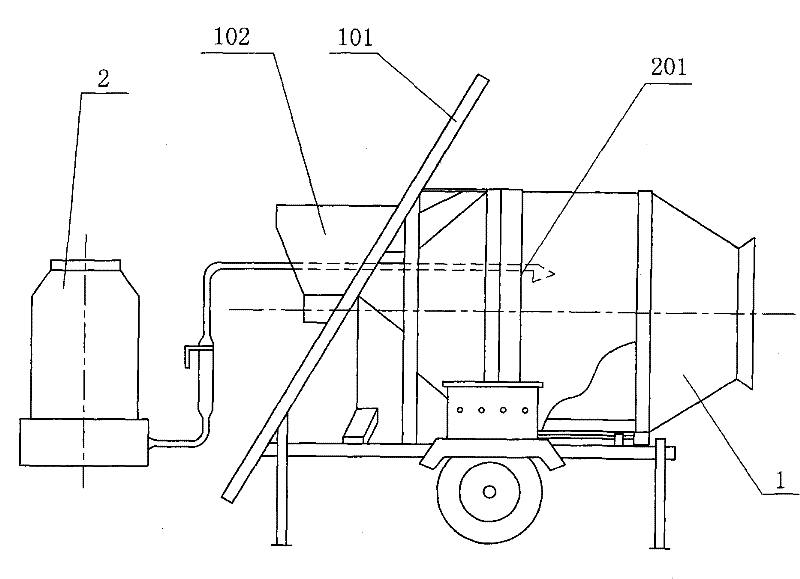

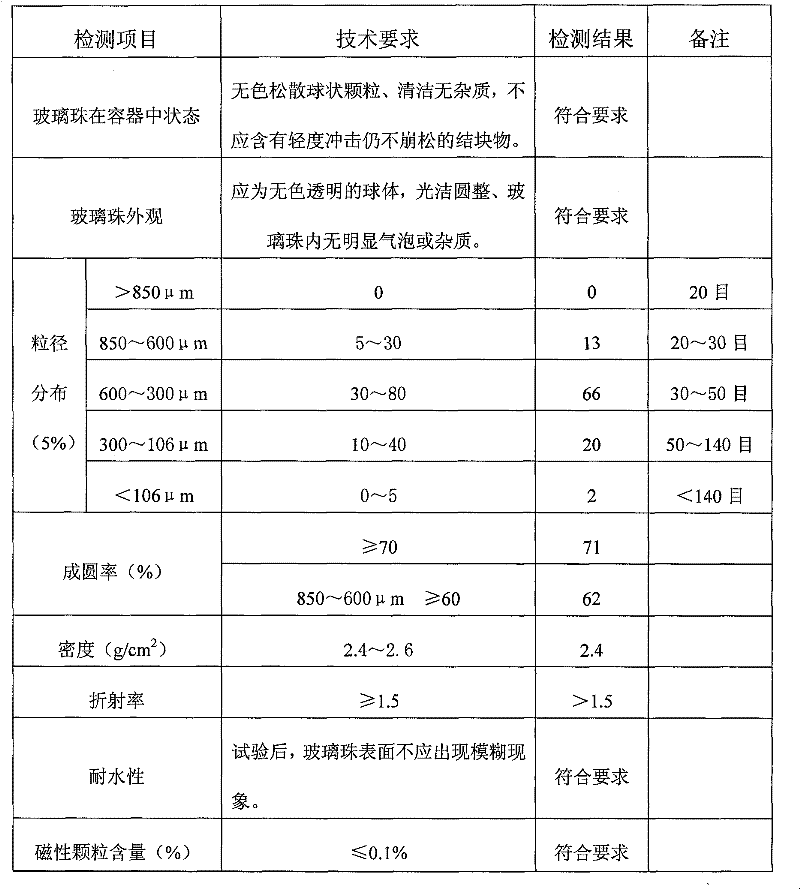

Technology for processing cold coated reflective glass beads

The invention discloses technology for processing cold coated reflective glass beads, which comprises the steps of: dumping qualified glass beads with the diameter between 0.05 and 1.00mm into a feeding funnel of a drum mixer; preparing a medicament, namely taking a silane coupling agent or mixed methyl silicone oil and sodium silicate or mixed thinner and methyl silicone oil as the medicament; adding the medicament, spraying the medicament and stirring the glass beads, namely loading the medicament into a high-pressure sprayer according to the proportion of adding 400 to 600g of the medicament into each ton of glass beads, arranging a nozzle of the high-pressure sprayer above the inside of the drum mixer, downward directly spraying the medicament to the surfaces of the glass beads to form moistureproof protective films, and stirring the glass beads at the same time, wherein the stirring time is between 8 and 10 minutes; and packaging and performing random inspection, namely using packaging bags lined with plastic inner films for packaging, placing the product for 3 days, then performing random inspection, and sending the product into a warehouse after the product is qualified through random inspection. The technology has the advantages that the technology has high production efficiency, raw material conservation, energy conservation, low production cost, good coating effect and strong adhesive power, has no harm to the health of workers, meets requirement of environmental protection, and can be used for pavement markings and various reflective materials and decorative materials.

Owner:张万春

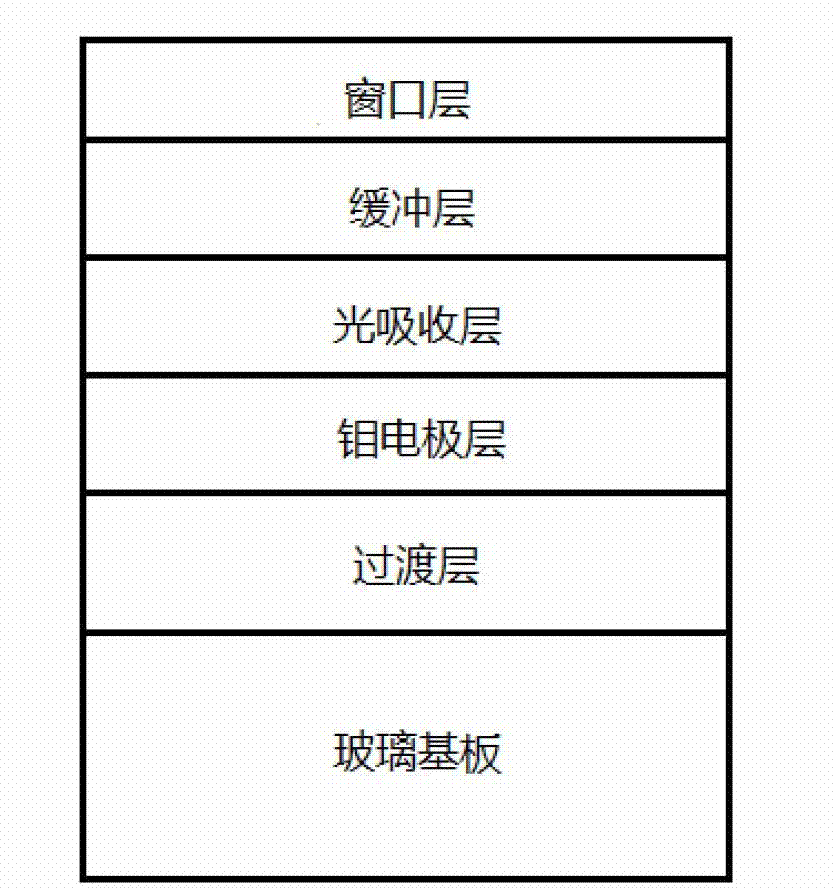

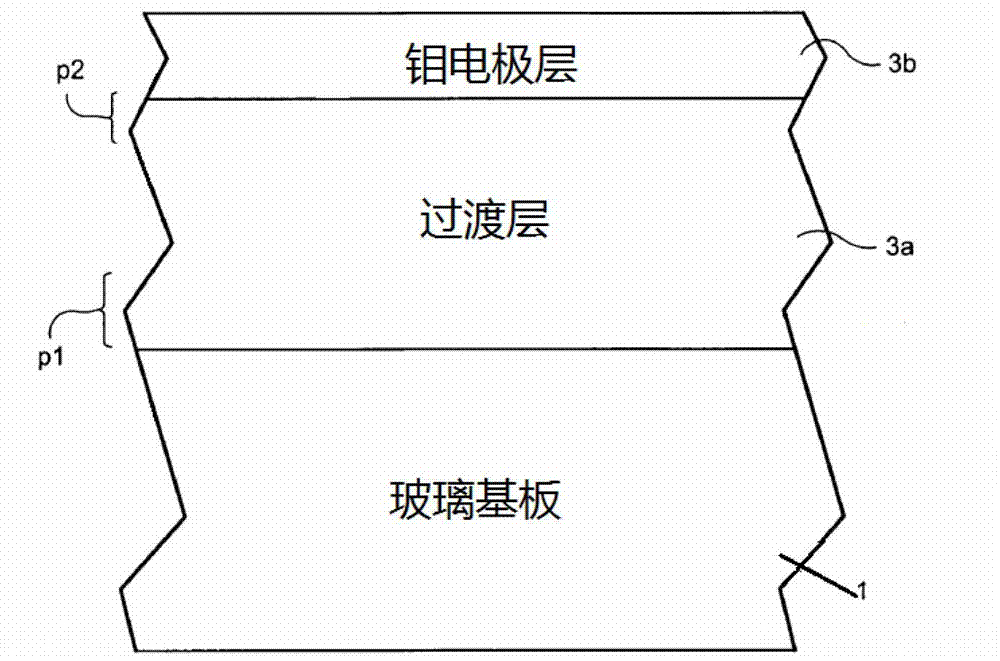

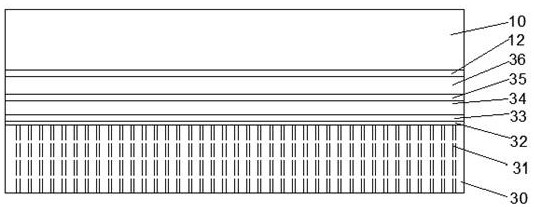

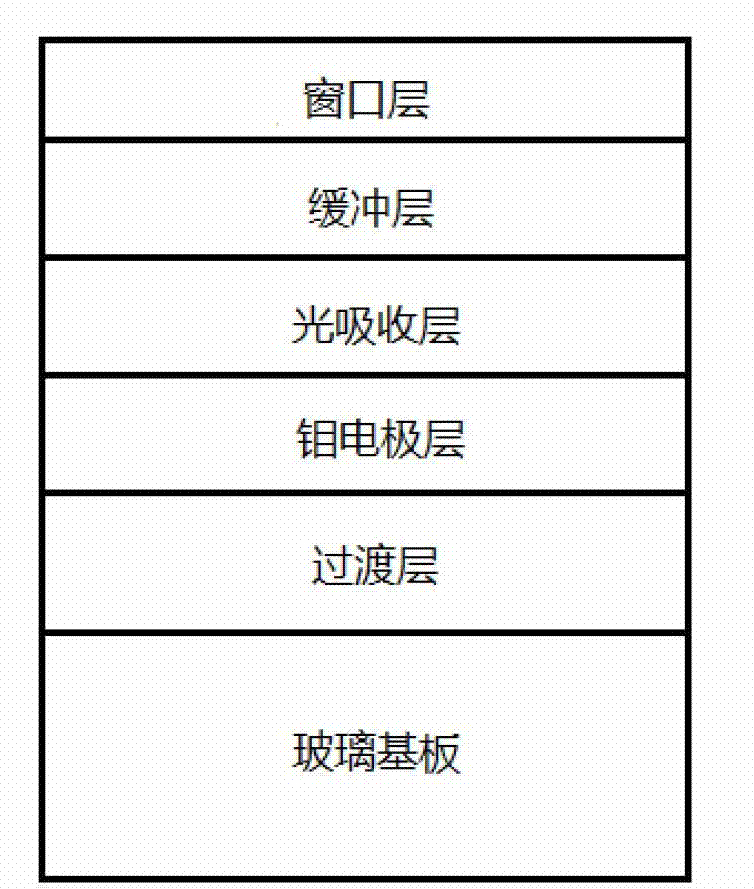

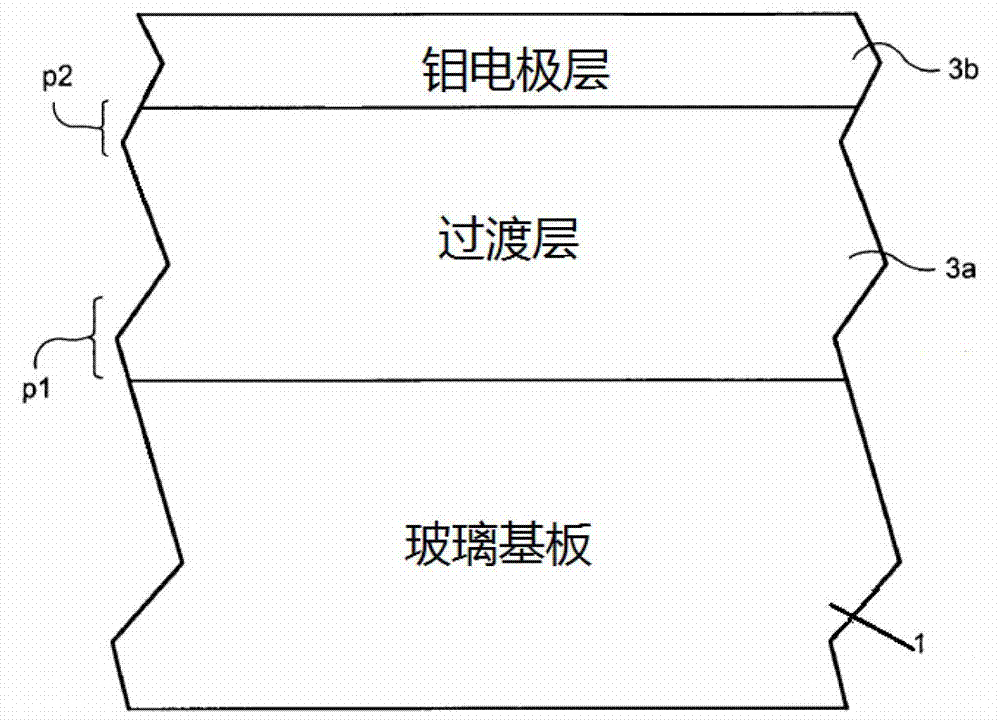

Transition layer for CIGS-based film photovoltaic cell and preparation method of transition layer

ActiveCN102867860AInhibited DiffusionPrevent diffusion from enteringFinal product manufactureSemiconductor devicesPyriteCopper

The invention discloses a transition layer for a CIGS-based film photovoltaic cell and a preparation method of the transition layer. The preparation method comprises the steps of: providing a soda-lime glass substrate, forming a transition layer covering the surface of the soda-lime glass substrate, forming a molybdenum layer covering the transition layer, forming a light absorbing layer having a copper pyrite structure and covering the molybdenum layer, forming a buffer layer covering the light absorbing layer, and forming a window layer covering the buffer layer. According to the invention, the transition layer is deposited on the surface of the glass substrate, thus the adhesion problem between a molybdenum electrode layer and the glass substrate can be efficiently solved, and sodium materials can be prevented from uncontrollably diffusing into the light absorbing layer.

Owner:厦门神科太阳能有限公司

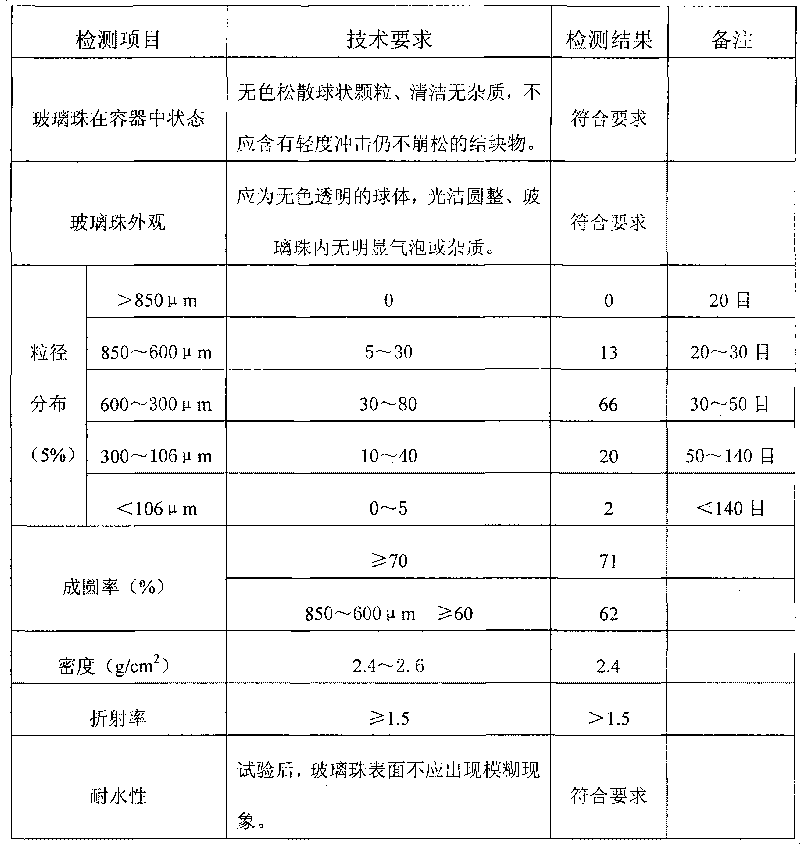

Film coated glass bead for screen and its processing technology

InactiveCN1478747AExtended service lifeIncrease brightness factorProjectorsPolymer scienceHydrophobe

A coated glass bead for the screen features that its particle diameter is 0.05-0.25 mm and its external surface is coated by a methyl silica oil film. Its advantages are high hydrophobicity, high adhesion to screen, high uniformity of arranging on screen surface, and low adsorption to dust.

Owner:刘会年

Method for transferring solar cell substrate

InactiveCN112018216ASolve the problem of poor bondingSolve cleaning difficultiesFinal product manufacturePhotovoltaic energy generationThin membraneSolar cell

The invention discloses a transfer method of a solar cell substrate. The method comprises the following steps of S1, battery structure growth; S2, metal bonding layer evaporation on the surfaces of abattery epitaxial layer and a flexible substrate; S3, temporary substrate manufacturing; S4, temporary substrate bonding layer evaporation; S5, substrate transfer; S6, substrate removal; S7, device manufacturing; S8, annealing; S9, temporary substrate transfer; and S10, scribing and testing. According to the invention, the method is simple in process and convenient to operate, can effectively solve the problems of infirm bonding of temporary bonding glue, difficulty in cleaning with glue, difficulty in alloy annealing with glue and bubbling and failure of the surface of the battery caused by mismatching of expansion coefficients of the flexible substrate and the epitaxial layer after the thin-film battery is stripped, can reduce the cost of the battery, and improves the yield of the battery.

Owner:NANCHANG KAIXUN PHOTOELECTRIC CO LTD

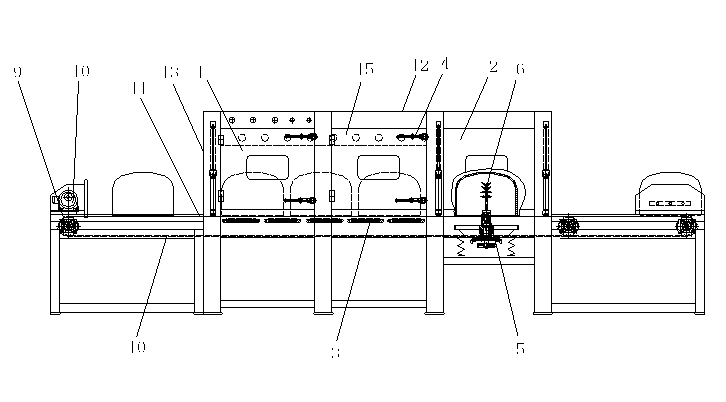

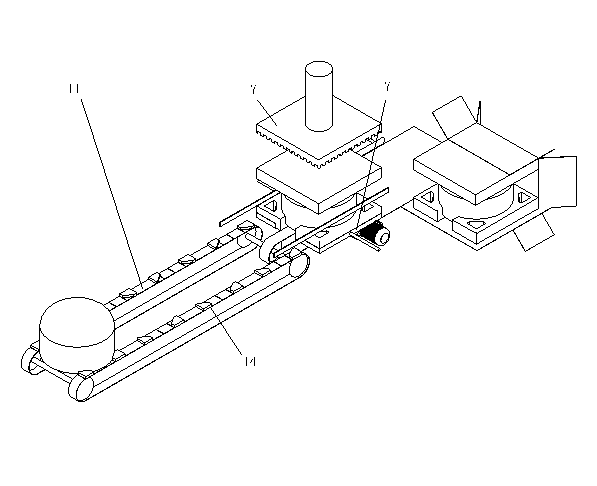

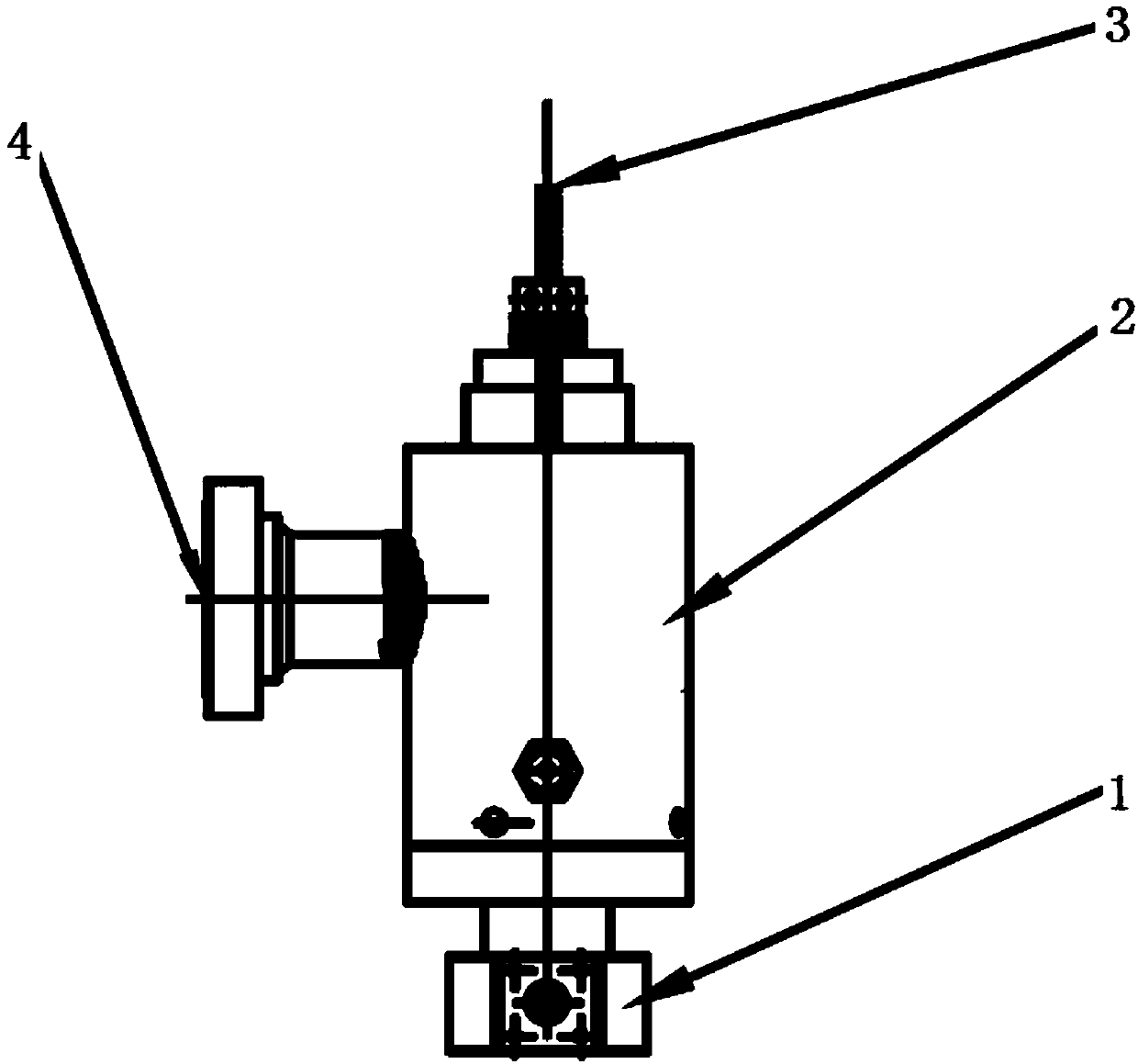

Quartz crucible heating, coating, and packaging integral machine

InactiveCN102992639AEffectively fixedConsistent spacingSpraying apparatusPackagingInfraredSpray coating

The invention discloses a quartz crucible heating, coating, and packaging integral machine. The machine comprises a quartz crucible conveying system. A heating system, a spray-coating system, and a packaging system are sequentially arranged on a conveying direction. The heating system comprises a sealable heating chamber. An infrared heating tube and a temperature sensor for keeping a constant temperature are arranged in the heating chamber. The spray-coating system comprises a sealable coating chamber. An automatic elevatable rotation joint and a nozzle are arranged in the coating chamber. The packaging system is composed of negative pressure adsorption manipulators provided above and beside the quartz crucible. The conveying system comprises a servo motor as a power source, a sprocket wheel, a chain, and a conveyor belt. The sprocket wheel and the chain are connected. The conveyor belt is arranged on the chain. With the machine provided by the invention, the quartz crucible can be effectively heated, coated, packaged, and stored, such that labor is greatly saved, working efficiency is improved, and a problem of quartz crucible coating powder poor bonding is effectively solved.

Owner:江苏华尔石英材料科技有限公司

EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

The invention provides EPS (Expandable Polystyrene) lightweight aggregate concrete and a preparation method thereof. The EPS lightweight aggregate concrete effectively meets the requirements of concrete on light weight, uniformity and density in the aspect of structure, and simultaneously has excellent comprehensive properties; the volume weight of the EPS lightweight aggregate concrete is higher than 650 kg / m<3>, the cube compressive strength can reach 1.6MPa, the strength meets the service requirements, and the lightweight aggregate concrete has excellent thermal properties and durability; and shown in a compression test, the concrete has larger deformation before the concrete is damaged due to deformation, so that the toughness of the concrete is improved. The lightweight aggregate concrete comprises the following raw materials in parts by weight: 350 parts of cement, 90-120 parts of fly coal ash, 30-70 parts of silica fume, 120-140 parts of river sand, 190-210 parts of water, 15-21 parts of EPS grains, 40-60 parts of perlite and 12-18 parts of polymer emulsion. The preparation method comprises the steps of crusting, slurry wrapping, mixing, forming and curing. The lightweight aggregate concrete obtained according to the mixture ratio and the preparation method is uniform and dense in structure, and various properties meet the design requirements, so that the EPS lightweight aggregate concrete has better application prospects.

Owner:CHINA ELECTRIC POWER RES INST +1

Adhesive tape for fixing display panels and manufacturing method thereof

InactiveCN102925070ASolve the problem of poor bondingShort processFilm/foil adhesivesDisplay deviceEngineering

The invention relates to an adhesive tape for fixing display panels and a manufacturing method thereof. The adhesive tape comprises a substrate layer, and is characterized in that at least one side of the substrate layer is provided with a hot-melt adhesive layer. The hot-melt adhesive surface is directly attached to the display panel to complete hot pressing, so that the adhesive tape has the advantages of high adhesive strength and high stability and firmness. The invention omits the hot-melt adhesive potting step in the existing technical process, and thus, overcomes the defect of poor adhesive property of the oil pressure-sensitive adhesive for the panel. The hot-melt adhesive layer with the special performance of easy peeling by heating can help to easily and quickly clean the adhesive surface of the product component for re-adhesion in case of unfavorable hot pressing, thereby greatly lowering the rejection rate of the product critical components.

Owner:苏州联科纳米净化科技有限公司

A kind of anti-corrosion and anti-wear material with ni-cu-p-tin composite coating and preparation method thereof

InactiveCN104339752BHigh hardnessLow shear strengthLiquid/solution decomposition chemical coatingMetal layered productsWear resistantAlloy

The invention discloses an anticorrosion abrasive-resistant material which sequentially comprises a base material, a Ni-P coating, a Ni-Cu-P coating and a Ni-Cu-P-TiN coating from inward to outward. According to the invention, flexible metal Cu and TiN nano particles are added into the Ni-P coating via a prior precipitation mechanism and a co-deposition mechanism, so that the Cu metal and the TiN particles have complementary performance advantages; meanwhile, in order to improve the wettability of the TiN particles and a Ni-P alloy, the TiN particles are subjected to Ni coating modification treatment, and the bonding intensity of the TiN particles and the coating is increased; on the other hand, by the multi-layer structural design of Ni-P / Ni-Cu-P / (Ni-Cu-P-TiN), the problem of poor bonding intensity of the coatings caused by the prior precipitation mechanism of Cu is solved. The method is simple in technology, and equipment is low in price; a subsequent technology is combined, a coating scraper with good corrosion resistance and tribology performance can be prepared, and the service life of the scraper can be multiplied.

Owner:CENT SOUTH UNIV +1

Polymer nanometer floor and production method thereof

PendingCN109372217ANot easy to fall offEffective protectionAntifouling/underwater paintsPaints with biocidesSolid woodEngineering

The invention discloses a polymer nanometer floor and a production method thereof. The polymer nanometer floor comprises a floor body; at least one cavity is formed in the floor body along a transverse section; the cavities penetrate through the floor body and are filled with a light foaming material; end caps for blocking the cavities are arranged at the two ends of the cavities; the floor body sequentially comprises a top layer, a substrate layer and a bottom layer from top to bottom; a polymer nanometer material layer is arranged between the top layer and the substrate layer; connection blocks are arranged on the upper surface and the lower surface of the polymer nanometer material layer; the top layer and the substrate layer are provided with connection grooves matched with the connection blocks; an abrasion-resistant layer is arranged on the upper portion of the top layer; and a waterproof layer, a flame-retardant layer and a buffer layer are sequentially arranged between the substrate layer and the bottom layer from top to bottom. The polymer floor is used for replacing solid wood floors, cyclic utilization is achieved, trees of the country are protected, and the path of sustainable development is taken.

Owner:JIANGSU RUISHENG NEW MATERIALS CO LTD

Processing method for improving conductivity of high-nickel ternary cathode material of lithium battery

InactiveCN109713296AImprove electrical conductivitySolve the problem of poor bondingActive material electrodesSecondary cellsNickelMaterials science

The invention provides a processing method for improving the conductivity of a high-nickel ternary cathode material of a lithium battery. The method comprises adding nickel foam to a solution containing cobalt acetate and manganese acetate; then mixing and pre-firing the mixture with a strong oxidant and a solid alkali; after solidification, adding a lithium source for high-temperature sintering to obtain a three-dimensional net-shaped high-nickel ternary cathode material; impregnating a conductive paste, performing curing at a low temperature so as to obtain the high-nickel ternary cathode material improved in conductivity. The method, by preparing the cathode material of the three-dimensional net-shaped structure, solves the defects that a traditional cathode material conductive agent and the cathode material are not firmly bonded due to the change of a material volume during the use, and the internal resistance is increased, and improves the conductive properties of the cathode material.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Preparation method of high-adhesion moisture-proof glass cement

InactiveCN110484193AImprove moisture resistanceImprove oxidation resistanceNon-macromolecular adhesive additivesProtein adhesivesPolymer scienceAdhesive

The invention belongs to the technical field of building material preparation, and particularly relates to a preparation method of high-adhesion moisture-proof glass cement. Soybeans are used as a rawmaterial, protein extracted from the soybeans is subjected to acid heat modification, and the moisture resistance of the water-soluble adhesive is improved; citric acid in the glass cement is a stabilizer and inhibits bacterial reproduction; tourmaline powder can also provide negative oxygen ions and improve the antibacterial ability, and the anti-oxidation ability of the glass cement is enhanced. According to the method, castor oil polyurethane and methyl silicone rubber are subjected to network interpenetration; the castor oil polyurethane is used as a continuous phase in the IPN interpenetrating structure; the methyl silicone rubber as dispersion phase, the silicon rubber has an open micropore structure; after vacuum defoaming, the surface tension is very small, an interpenetrating network structure is combined more tightly, and water absorption and falling are not likely to happen after curing; the silicon rubber can form hydrogen bonds with the surfaces of glass, glass and otherbase materials, the bonding force is improved, and therefore the problem that glass cement is not firmly bonded to the surface of the glass due to too much dust is solved, and wide application prospects are achieved.

Owner:韦权

Heat insulating system outside external wall

InactiveCN100424284CAvoid spreadingStop crackingHeat proofingBuilding reinforcementsEngineeringFire retardant

The heat insulating system outside external wall features that there are base layer with alkali resistant strengthening treating agent outer the concrete base wall and connected to the heat insulating board through silicon modified polymer mortar adhesive and plastic anchor part, alkali resistant netted cloth outside the heat insulating board, elastic anticracking silicon modified polymer putty and self-structured waterproof anticracking closing layer between the heat insulating board and the alkali resistant netted cloth, facing silicon modified polymer mortar outside the alkali resistant netted cloth, fire retardant paint around the window and silicon modified acrylate paint in the outmost layer. The present invention has the advantages of simple structure, low cost, easy construction, raised wall surface quality and fire retarding function.

Owner:上海英硕聚合材料股份有限公司

Method for preparing two-component vitrified brick backing glue

InactiveCN108485580AIncrease contact areaImprove water absorptionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseFiber

The invention relates to the technical field of preparation of building materials and in particular relates to a method for preparing two-component vitrified brick backing glue. The method disclosed by the invention comprises the following steps: treating sugarcane serving as a raw material to obtain pre-dispersed suspension, mixing the pre-dispersed suspension, cotton stalk bark fibers, ammoniumpersulfate, N,N-methylenebis acrylamide and the like, reacting, extracting with acetone, drying to obtain a component A, performing graft copolymerization on acrylic acid and sugarcane fibers, forminga three-dimensional network structure, and producing a water-absorbent resin, wherein the cotton stalk bark fibers easily crimp when meeting water, the water is difficultly squeezed out, the roughness of the vitrified brick can be improved by the cotton stalk bark fibers, and the bricks are conveniently adhered; mixing a cellulose ether and a castor oil polyurethane prepolymer, dispersing to obtain premixed emulsion, adding quick lime, carboxylic butadiene-styrene latex, fly ash and other materials into the pre-dispersed mixture, performing vacuum defoamation to obtain a component B, and performing network interpenetrating on castor oil polyurethane and methyl silicone rubber, thereby obtaining an adhesive with an IPN (Interpenetrating Polymer Network) structure. The network interpenetrating structure is compact in binding, and the application prospects are wide.

Owner:许水仙

Preparation method of double-ingredient high-viscosity ceramic tile bonding agent

InactiveCN108795346AImprove water absorptionIncrease roughnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFiberMaterials preparation

The invention discloses a preparation method of a double-ingredient high-viscosity ceramic tile bonding agent, and belongs to the technical field of building material preparation. In the method, acrylic acid and sugarcane fiber in sugarcane powder take graft copolymerization under the temperature conditions of being 50 DEG C or more to form a three-dimensional reticular structure; water absorptionresin is generated; after cotton stalk peel fiber is subjected to modification crosslinking by water absorption resin, groove and cross section heteromorphosis can be generated on the surfaces; the bonding of ceramic tile bonding agents is convenient; the castor oil polyurethane prepolymers have high elasticity and relatively good low-temperature-resistant performance; the heat resistance and thebonding performance need to be improved; after the curing of methyl silicone rubber bonding agents, the texture is crispy, but the bonding performance is excellent; the heat resistance performance isgood. The castor oil polyurethane and the methyl silicone rubber are subjected to network interpenetration; the bonding agent with IPN structures is obtained through preparation, so that the surfaceof a concrete substrate is cleaned; the combination of the interpenetration network structure is tighter; therefore the problem of infirm bonding of the ceramic tile bonding agent due to excessive dust on the surface of the concrete can be solved; the application prospects are wide.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

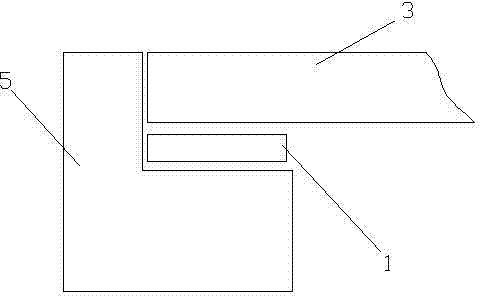

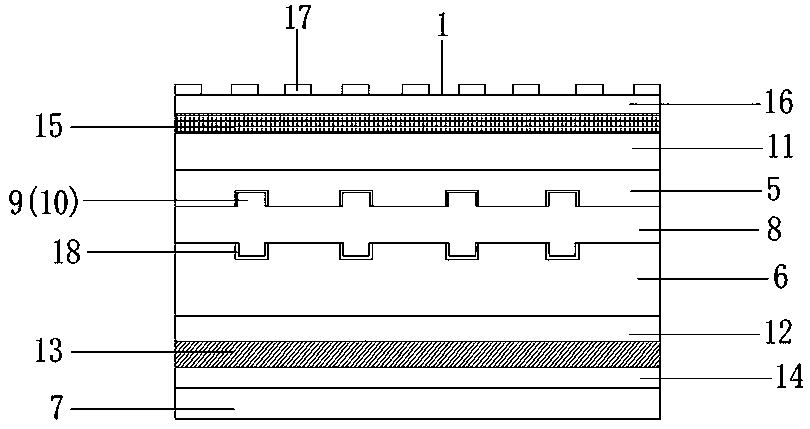

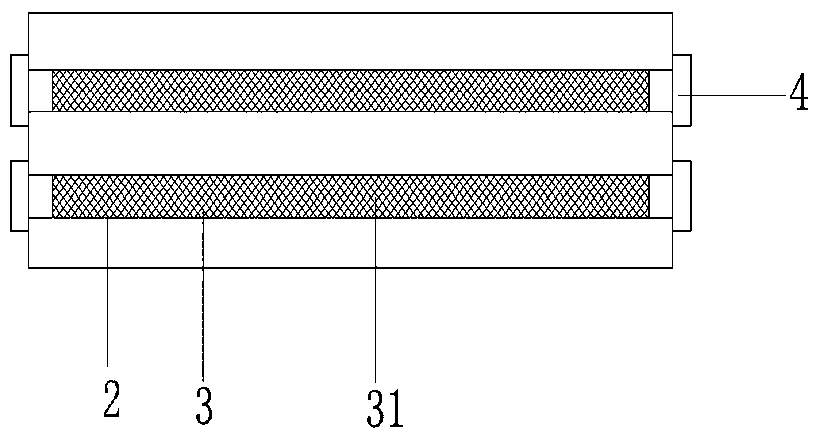

Display device and preparation method thereof

PendingCN111580295AReduce widthSolve the problem of poor bondingNon-linear opticsBackplaneStructural engineering

The invention provides a display panel and a manufacturing method thereof. The display device includes: a backboard having an L-shaped bent portion including a bottom plate and a side plate; the display panel is arranged on the side, away from the bottom plate, of the side plate, and the orthographic projection of the display panel on the upper surface of the bottom plate partially coincides withthe orthographic projection of the side plate on the upper surface of the bottom plate; the lower surface of the display panel and the upper surface of the side plate are directly bonded through the adhesive layer, and the adhesive layer further makes contact with the side face of the display panel. The invention provides a display device. The lower surface of the display panel is directly bondedwith the upper surface of the side plate of the backboard through the adhesive layer; according to the display device, the double-faced adhesive tape is arranged on the display panel, and the side periphery of the display panel is covered, so that the width of the double-faced adhesive tape can be reduced, a middle frame arranged on the periphery can be further omitted, the perfect frameless appearance effect of the display device is facilitated, and a display area of the display device is close to full-screen design.

Owner:BOE TECH GRP CO LTD +1

A kind of high shock absorption and wear resistance thermoplastic elastomer and preparation method thereof

ActiveCN104629243BSolve the problem of poor bondingImprove shock absorptionProcedure AgentsWear resistant

The invention relates to the technical field of thermoplastic elastomer materials and particularly relates to a high-shock-absorbance wear-resistant thermoplastic elastomer and a preparation method thereof. The high-shock-absorbance wear-resistant thermoplastic elastomer comprises the following components in parts by weight: 40-60 parts of SIS resin, 10-20 parts of thermoplastic polyurethane, 5-10 parts of a compatilizer, 5-15 parts of extending oil, 5-10 parts of mineral filler, 1-3 parts of a processing aid and 0.2-0.5 part of an antioxidant. The preparation method comprises the following steps of firstly, placing the SIS resin, carbonate calcium, the antioxidant, the processing aid and extending oil into a high-speed mixer, mixing, adding other raw materials and mixing to obtain a premix; and secondly, placing the premix into a twin-screw extruder, extruding and granulating. The thermoplastic elastomer has the characteristics of capability of secondary injection molding, good adhesion with PC and ABS materials and high shock absorbance and wear resistance.

Owner:东莞市银禧特种材料科技有限公司

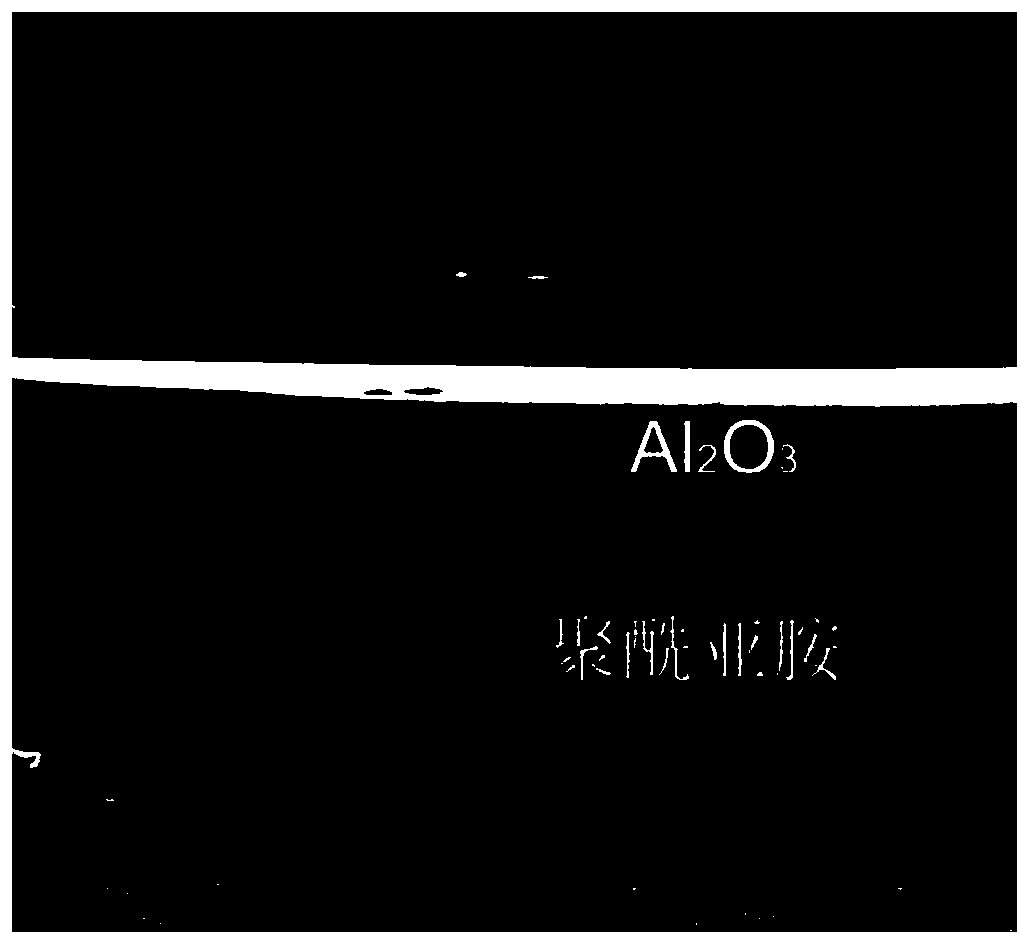

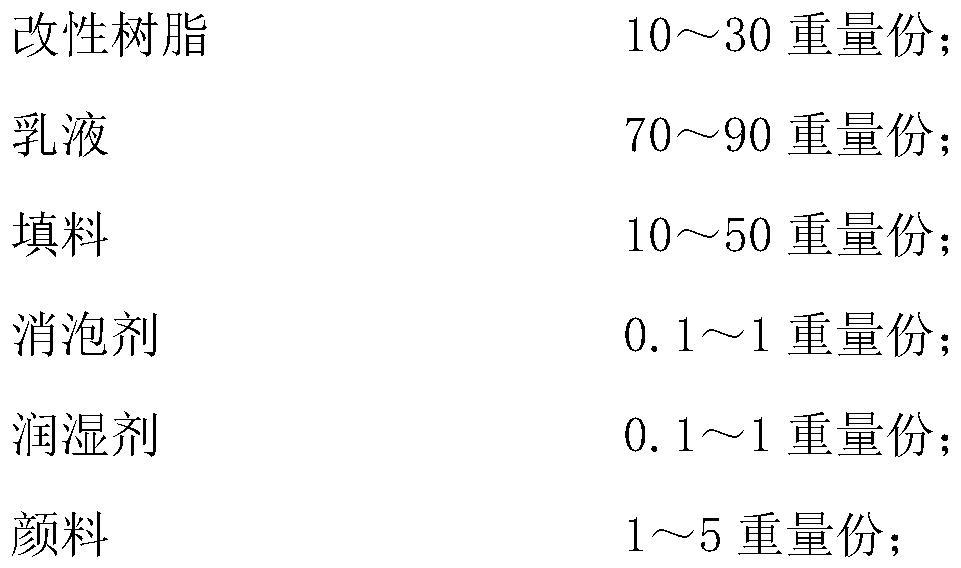

Dielectric composite film as well as preparation method and application thereof

PendingCN110818940ATightly boundHigh breakdown field strengthThin/thick film capacitorFixed capacitor dielectricComposite filmPolymer dielectrics

The invention discloses a dielectric composite film as well as a preparation method and application thereof. The preparation method includes the following steps: performing hydrolysis treatment on a polymer dielectric film to open a polymer chain of the upper surface layer of the polymer dielectric film; immersing the treated film into a metal salt solution, taking out the immersed film, performing washing by using water, and removing moisture of the surface; and performing heat treatment to form an insulating metal oxide layer on the surface of the polymer dielectric film. According to the above technical solution, the dense and uniform insulating metal oxide layer is formed at the surface of the polymer dielectric film by using the chemical method, the insulating metal oxide layer can realize effective regulation and control from a nanometer level to a micron level, and the insulating metal oxide layer is tightly combined with the polymer dielectric film, and can effectively inhibitthe surface charge injection and internal charge transfer and diffusion of the polymer dielectric film under the high-temperature high-electric-field condition, and reduce the conductivity loss of thepolymer dielectric film; and the insulating metal oxide layer can realize the excellent isolation self-healing function, improve the energy storage characteristic of the film and guarantee the continuous and stable operation under the high-temperature high-electric-field condition.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

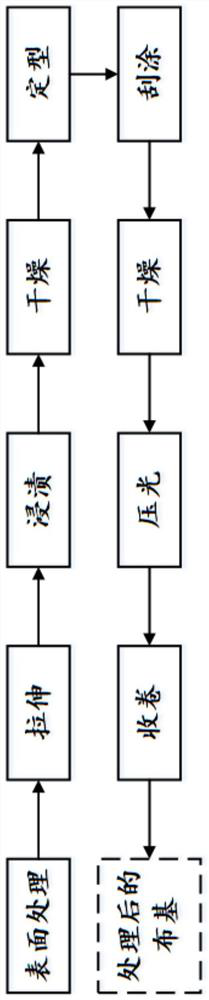

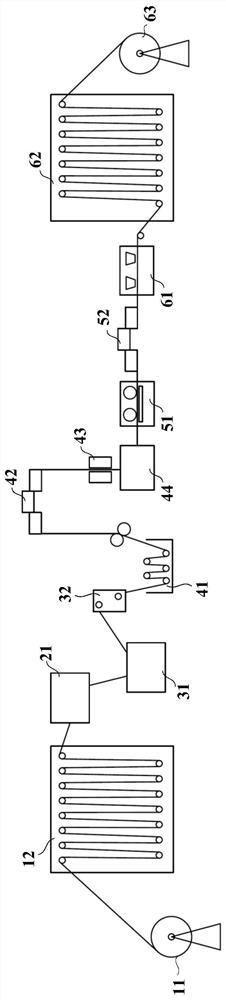

Treatment method and system for high-strength soft cloth base of abrasive belt

InactiveCN112709076ASolve the environmental protection problems of washingLow elongationAbrasion apparatusTextiles and paperPolymer sciencePolymer chemistry

The invention relates to a treatment method for a high-strength soft cloth base of an abrasive belt. The treatment method comprises the steps that rayon is adopted as a cloth base raw material for weaving; fluff on the surface of the cloth base is removed; the cloth base is stretched, wherein the warp-wise stretching rate is 6%-12%, and the weft-wise shrinkage rate is 8%-20%; the cloth base is impregnated in an impregnating tank containing a sizing material; the impregnated cloth base is dried at the temperature of 70-160 DEG C, and shaped at the high temperature of 160-190 DEG C; and after blade coating is conducted on the cloth base, the cloth base is dried at the temperature of 70-160 DEG C, calendered and rolled. According to the method, rayon weaving is adopted, and the double-strand filaments are adopted, so that the problem of protruding defects caused by weaving can be effectively solved, and production of P600 and fine gauze is guaranteed; after singeing, stretching is adopted to reduce the elongation of the cloth base; and a low-boiling-point solvent is firstly removed during drying, then high-temperature setting is performed to cure and mold the impregnated sizing material, the obtained sizing material layer is compact and uniform, and the defect that the low-boiling-point solvent is quickly gasified to form the sizing material layer due to direct high-temperature drying is avoided.

Owner:SUZHOU FAR EAST ABRASIVES

Technology for processing cold coated reflective glass beads

The invention discloses technology for processing cold coated reflective glass beads, which comprises the steps of: dumping qualified glass beads with the grain size between 0.05 and 1.00mm into a feeding funnel of a drum mixer; preparing a medicament, namely taking a silane coupling agent or mixed methyl silicone oil and sodium silicate as the medicament; adding the medicament, spraying the medicament and stirring the glass beads, namely loading the medicament into a high-pressure sprayer according to the proportion of adding 400 to 600g of the medicament into each ton of glass beads, arranging a nozzle of the high-pressure sprayer above the inside of the drum mixer, downward directly spraying the medicament to the surfaces of the glass beads to form moisture proof protective films, and stirring the glass beads at the same time, wherein the stirring time is between 8 and 10 minutes; and packaging and performing random inspection, namely using packaging bags lined with plastic inner films for packaging, placing the product for 3 days, then performing random inspection, and sending the product into a warehouse after the product is qualified through random inspection. The technology has the advantages that the technology has high production efficiency, raw material conservation, energy conservation, low production cost, good coating effect and strong adhesive power, has no harm to the health of workers, meets requirement of environmental protection, and can be used for pavement markings and various reflective materials and decorative materials.

Owner:张万春

Preparation method of medical porous titanium or titanium alloy material coated with tantalum coating

ActiveCN109261958BImprove bindingSolve the problem of poor bondingAdditive manufacturing apparatusTransportation and packagingTitanium alloyPorous titanium

The invention discloses a method for preparing a medical porous titanium or titanium alloy material coated with a tantalum coating on the surface. The method first adopts a 3D printing method to prepare a porous titanium skeleton or a porous titanium alloy skeleton, and then makes the porous titanium skeleton or porous titanium alloy After the skeleton is corroded, it is cleaned and dried, and then completely embedded in the ultrafine tantalum powder in the metal sheath, vacuum-sealed and then subjected to low-temperature diffusion sintering. Finally, the powder is removed after taking it out, and the medical porous titanium coated with tantalum coating is obtained. or titanium alloy material. The present invention coats tantalum on the surface of porous titanium skeleton or porous titanium alloy skeleton through powder embedding and low-temperature diffusion sintering to form a metallurgical bond, which greatly improves the bonding force between tantalum and the surface of porous titanium skeleton or porous titanium alloy skeleton, and solves the problem of The problem of poor bonding between the tantalum coating and the substrate overcomes the shortcomings of high cost and complicated procedures of the existing preparation methods.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A transition layer for cigs-based thin film photovoltaic cells and preparation method thereof

ActiveCN102867860BInhibited DiffusionPrevent diffusion from enteringFinal product manufactureSemiconductor devicesPyriteOptoelectronics

The invention discloses a transition layer for a CIGS-based film photovoltaic cell and a preparation method of the transition layer. The preparation method comprises the steps of: providing a soda-lime glass substrate, forming a transition layer covering the surface of the soda-lime glass substrate, forming a molybdenum layer covering the transition layer, forming a light absorbing layer having a copper pyrite structure and covering the molybdenum layer, forming a buffer layer covering the light absorbing layer, and forming a window layer covering the buffer layer. According to the invention, the transition layer is deposited on the surface of the glass substrate, thus the adhesion problem between a molybdenum electrode layer and the glass substrate can be efficiently solved, and sodium materials can be prevented from uncontrollably diffusing into the light absorbing layer.

Owner:厦门神科太阳能有限公司

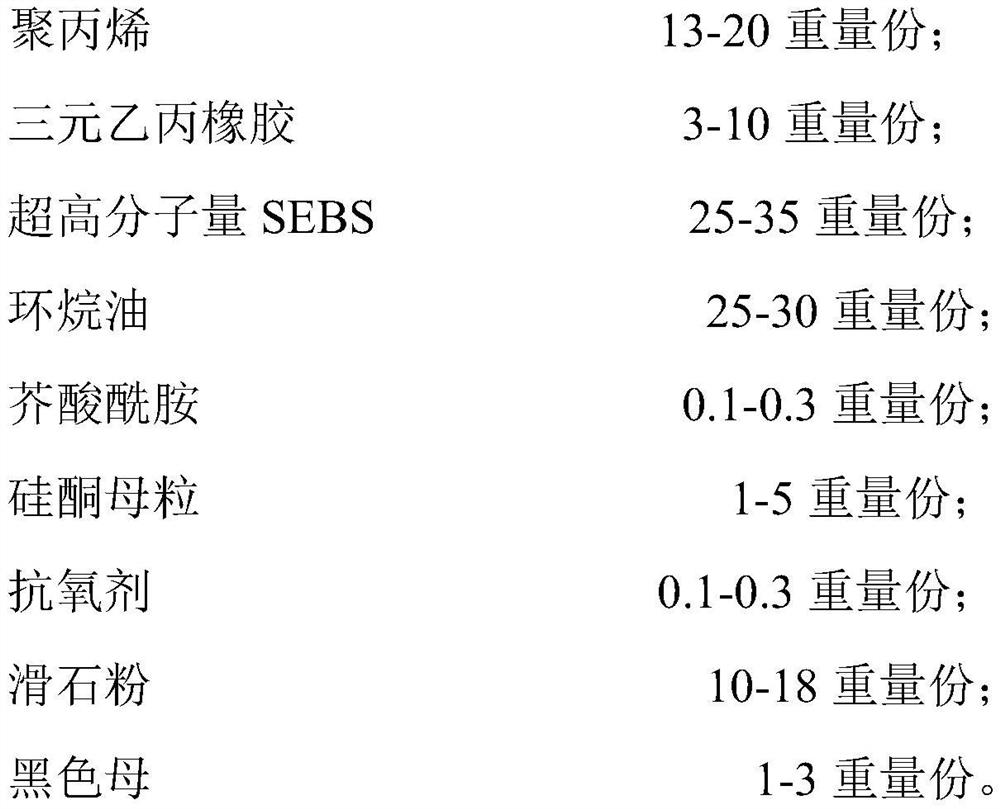

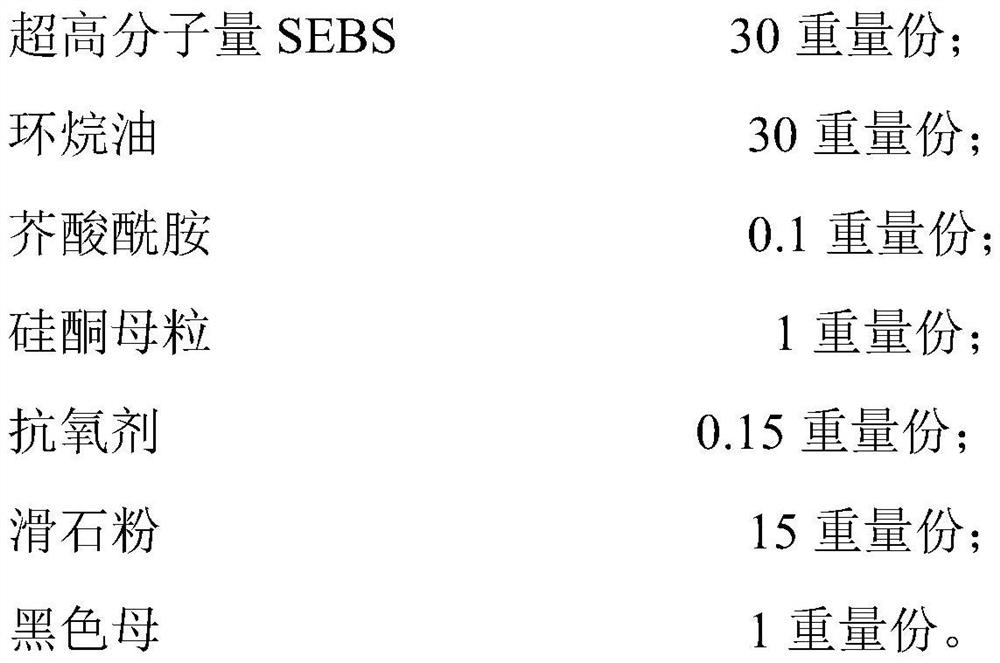

Corner connecting material for bonding ethylene-propylene-diene monomer rubber, and preparation method thereof

The invention discloses a corner connecting material for bonding ethylene-propylene-diene monomer rubber. The corner connecting material comprises, by weight, 13-20 parts of polypropylene; 3-10 parts of ethylene-propylene-diene monomer rubber; 25-35 parts of ultra-high molecular weight SEBS; 25-30 parts of naphthenic oil; 0.1-0.3 part of erucyl amide; 1-5 parts of silicone master batch; 0.1-0.3 part of an antioxidant; 10-18 parts talcum powder; and 1-3 parts of black master match. The corner connecting material for bonding the ethylene-propylene-diene monomer rubber is high in bonding strength and good in using effect.

Owner:张家港市美特高分子材料有限公司

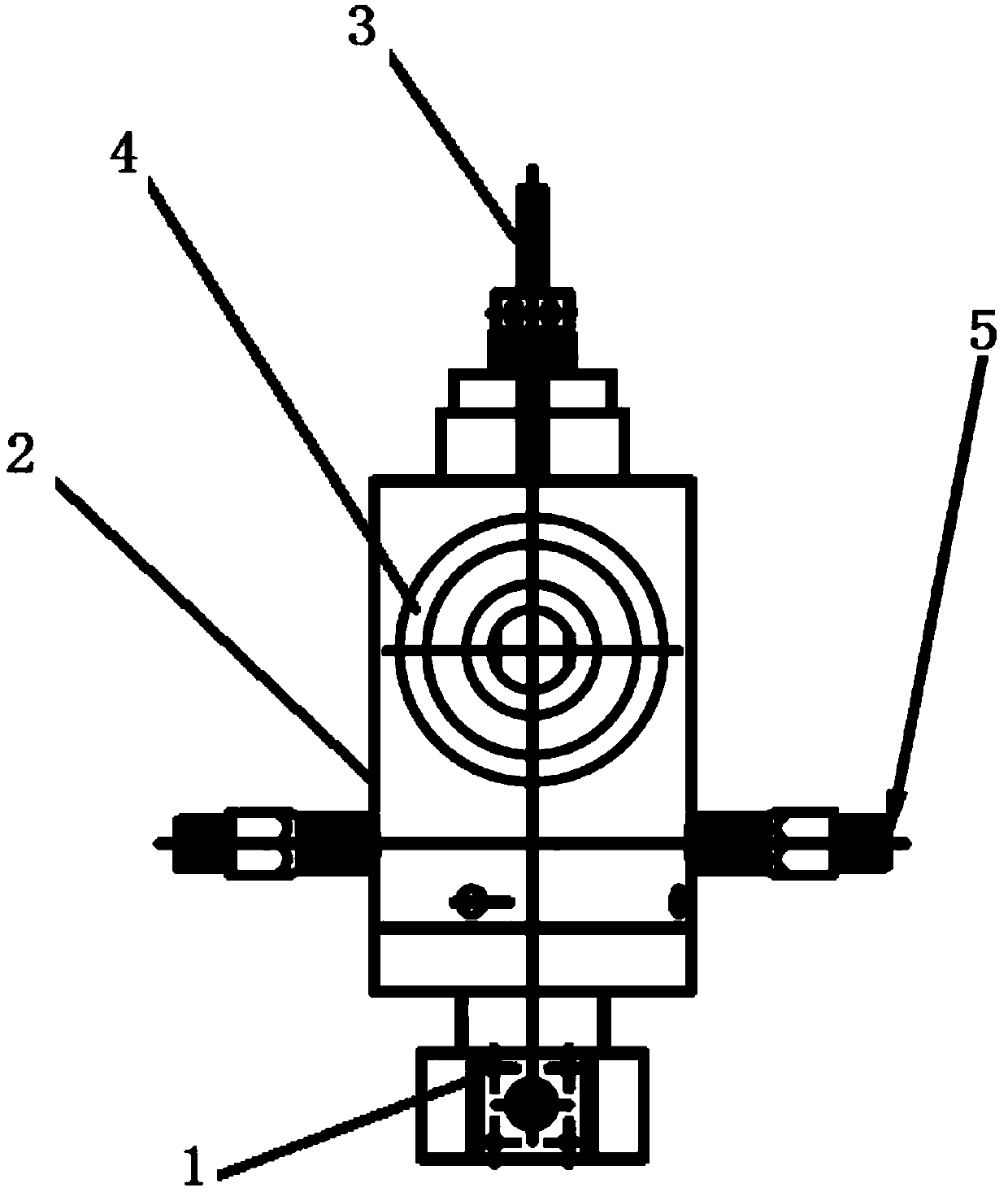

Integrated forming device for silicone rubber double-form tube

PendingCN107718486AProduction makes senseQuality assuranceDomestic articlesRubber materialEngineering

The invention discloses an integrated forming device for a silicone rubber double-form tube. The integrated forming device comprises an integrated forming device body. A shell is arranged outside theintegrated forming device body. A composite mold A and a composite mold B are arranged in the shell. A main material channel and auxiliary channels are arranged on the side face of the shell. The composite mold A is formed by combining a crossed frame and a core pattern mold in a sleeving manner. The composite mold B is formed by combining a circular mouth-like mold and four injection needles in asleeving manner. A connecting rod is arranged at one end of the integrated forming device body. A fixing seat of the composite mold B is arranged at the other end of the integrated forming device body. A silicone rubber circular tube is formed by combining the cylindrical mouth mold composite B and the cylindrical core mold composite A. The silicon rubber circular tube can be produced in a gap where a rubber material flows. A silicon rubber crossed-shaped pattern strip is completed on the dependence of the crossed mouth mold, and on this basis, in order to achieve integrated production, continuous switching of the circular tube and the related molds of the crossed strip is completed, coherent actions can be achieved, and the desired production product is obtained.

Owner:JINAN CHENSHENG MEDICAL SILICONE RUBBER PROD

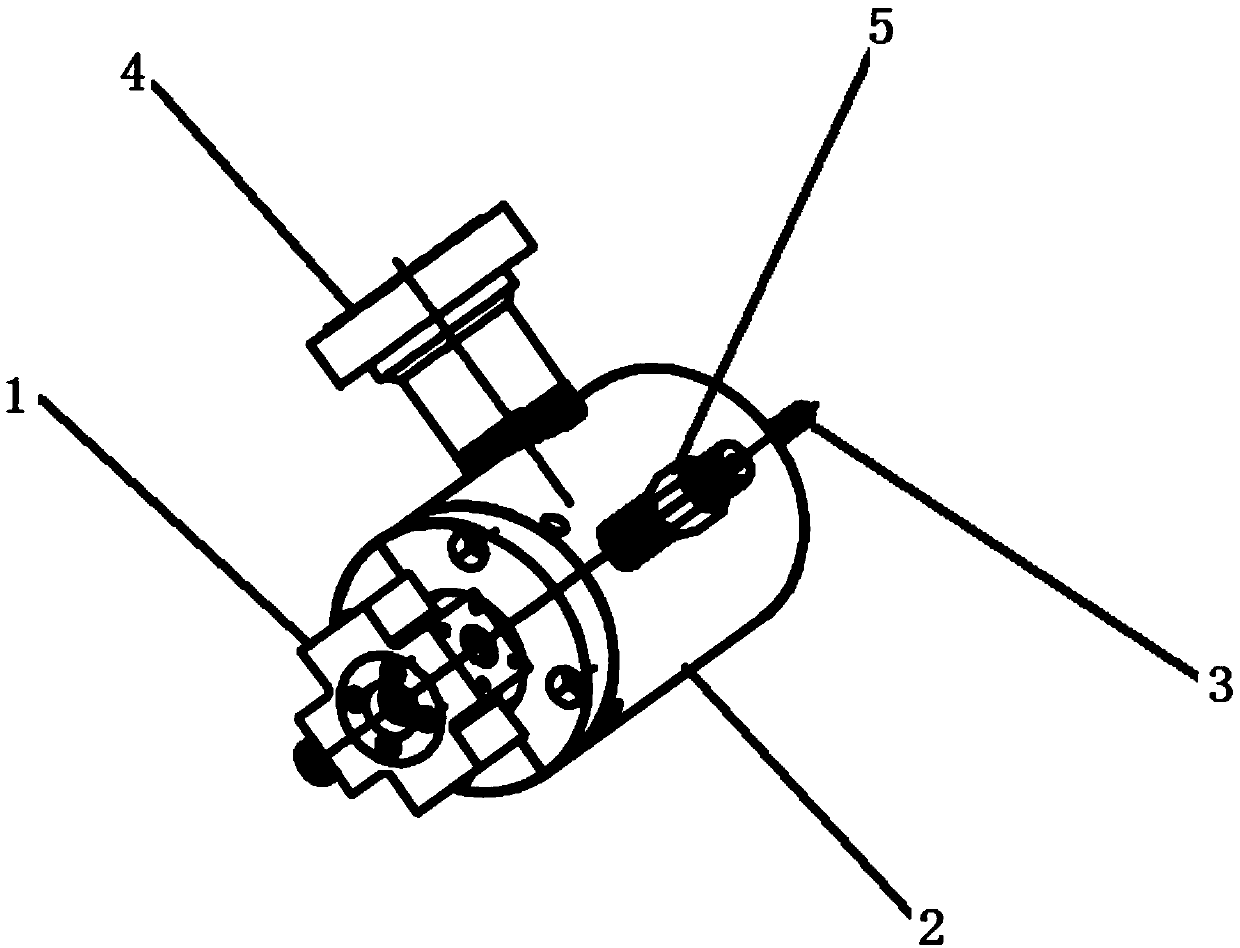

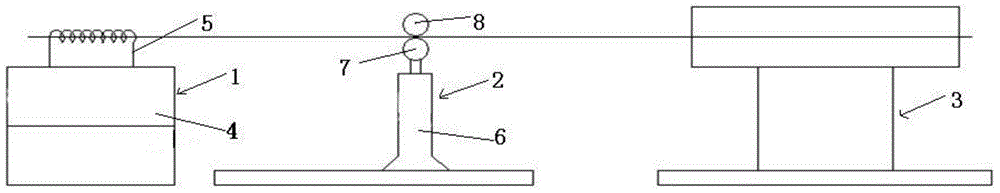

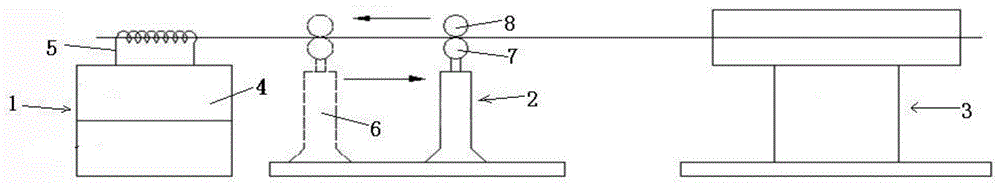

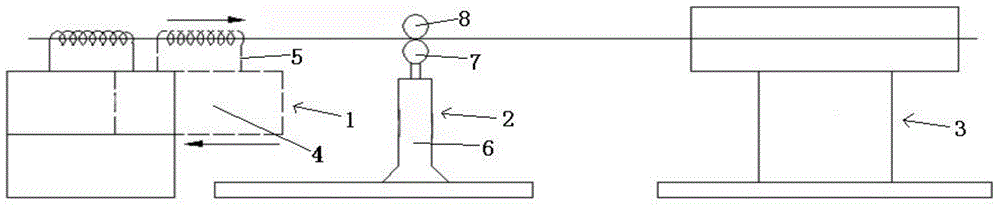

Film sintered electromagnetic wire induction heating bonding system and method for making the electromagnetic wire

ActiveCN103489534BSolve the problem of poor bondingEasy to operateCable/conductor manufactureElectrical conductorSintered magnets

The invention relates to a thin film sintering electromagnetic wire induction heating bonding system and a method for manufacturing an electromagnetic wire. The system comprises a paying-off rack, a straightening device, a polishing machine, a water scrubbing device, an air drying device, a lapping device, a crawler, an induction heating device, a rolling device, an oven, a water-cooling blow-drying device and a take-up machine. Both the induction heating device and the rolling device can move back and forth. Because the induction heating device and the rolling device can move back and forth, when shutdown occurs to equipment, a thin film, namely a thin film located between a pressing device and the induction device, heated by the induction heating device can also be rolled by the rolling device to be tightly attached to a conductor, and therefore the problem that the thin film located between the pressing device and the induction device cannot be firmly bonded each time shutdown occurs to the equipment is solved; operation is simple and convenient, production efficiency is improved, and quality of products is stable.

Owner:SUZHOU GUANLONG MAGNET WIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com