Dielectric composite film as well as preparation method and application thereof

A composite film and dielectric film technology, applied in the field of dielectric composite film and its preparation, can solve the problems of limited improvement of polymer properties, large specific surface area of nano-fillers, difficult to disperse, etc., to solve the problems of poor thermal stability and excellent mechanical properties. performance, the effect of preventing self-healing breakdown short-circuit failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

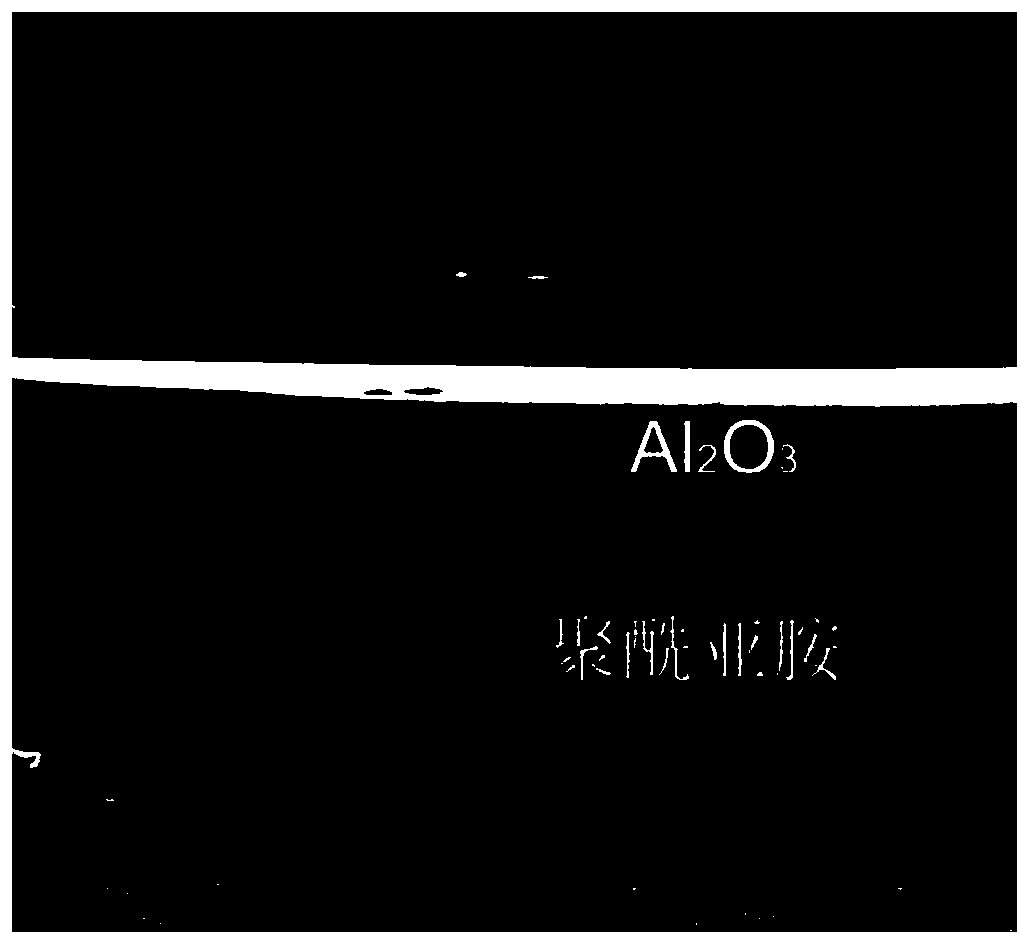

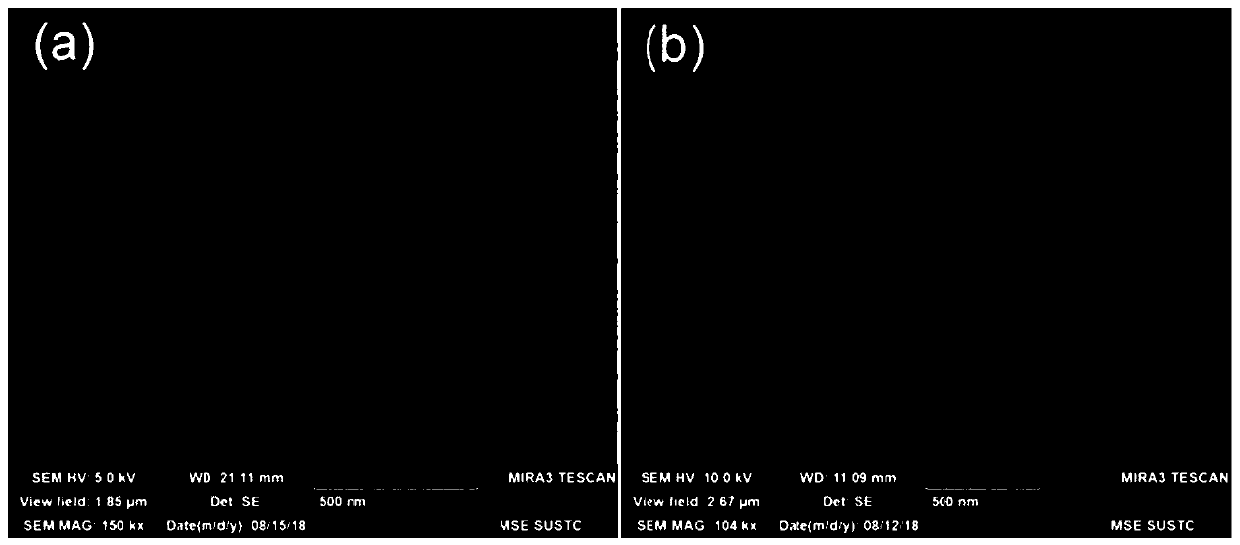

[0034] A preparation method of a dielectric composite film, which adopts polyimide (PI) as a substrate, and utilizes an ion exchange method to realize growth on the surface of the PI film to form aluminum oxide (Al 2 o 3 ) insulating metal oxide layer. Specifically include the following steps:

[0035] 1) Dissolve the PI polymer in N, N-dimethylacetamide (DMAc) solvent and stir it to fully dissolve to obtain a stable polyamic acid (PAA) solution with a certain concentration; PAA) solution is cast on a clean glass substrate, placed in an oven at a temperature of 250 to 350°C for heat treatment for 1 to 2 hours, to obtain a single-layer PI polymer film;

[0036] 2) Peel off the PI polymer film obtained in step 1) from the glass substrate, put it into distilled water and alcohol for ultrasonic cleaning, and remove surface oil and impurities;

[0037] 3) Completely immerse the film treated in step 2) in NaOH alkaline solution with a concentration of 0.5-2mol / L, keep it for 5-30...

Embodiment 2

[0044] A preparation method of a dielectric composite film, which adopts polyimide (PI) as a substrate, and utilizes an ion exchange method to realize growth on the surface of the PI film to form aluminum oxide (Al 2 o 3 ) insulating metal oxide layer. Specifically include the following steps:

[0045] 1) Dissolve the PI polymer in N, N-dimethylacetamide (DMAc) solvent and stir it to fully dissolve to obtain a stable polyamic acid (PAA) solution with a certain concentration; PAA) solution is cast on a clean glass substrate, placed in an oven at a temperature of 250 to 350°C for heat treatment for 1 to 2 hours, to obtain a single-layer PI polymer film;

[0046] 2) Put the PI polymer film obtained in step 1) into distilled water and alcohol for ultrasonic cleaning to remove surface oil and impurities;

[0047] 3) Completely immerse the film treated in step 2) in NaOH alkaline solution with a concentration of 0.5-2mol / L, keep it for 5-30min, take it out, and wash it repeatedly...

Embodiment 3

[0053] The invention discloses a preparation method of a dielectric composite film, which uses polyimide (PI) as a substrate, and utilizes an ion exchange method to grow and form a magnesium oxide (MgO) insulating metal oxide layer on the surface of the PI film. Specifically include the following steps:

[0054] 1) Dissolve the PI polymer in N, N-dimethylacetamide (DMAc) solvent and stir it to fully dissolve to obtain a stable polyamic acid (PAA) solution with a certain concentration; PAA) solution is cast on a clean glass substrate, placed in an oven at a temperature of 250 to 350°C for heat treatment for 1 to 2 hours, to obtain a single-layer PI polymer film;

[0055] 2) Peel off the PI polymer film obtained in step 1) from the glass substrate, put it into distilled water and alcohol for ultrasonic cleaning, and remove surface oil and impurities;

[0056] 3) Completely immerse the film treated in step 2) into Ca(OH) with a concentration of 0.5-2mol / L 2 In the alkaline solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com