High-shock-absorbance wear-resistant thermoplastic elastomer and preparation method thereof

A technology of thermoplastic elastomer and thermoplastic polyurethane, which is applied in the field of high shock absorption and wear-resistant thermoplastic elastomer and its preparation, can solve the problems of high shock absorption, achieve high shock absorption performance, broad application prospects, and good protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

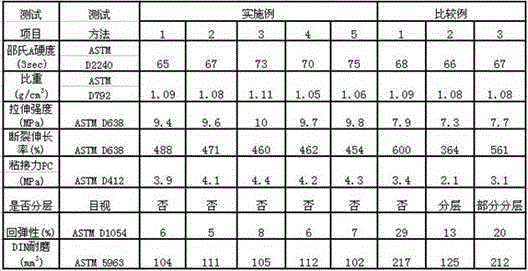

Examples

Embodiment 1

[0040] A high shock-absorbing and wear-resistant thermoplastic elastomer, comprising the following components by weight:

[0041] SIS resin 40 parts

[0042] 15 parts thermoplastic polyurethane

[0043] SEBS-co-TPU 6 parts

[0044] Paraffin-based rubber oil 10 parts

[0046] LDPE carrier silicone masterbatch 2 parts

[0047] Antioxidant 0.4 parts.

[0048] The high shock-absorbing and wear-resistant thermoplastic elastomer is prepared through the following steps:

[0049] Step 1. First put SIS resin, calcium carbonate, antioxidant, processing aid and extender oil into a high-speed mixer, mix for 10 minutes at 30°C, then add the remaining other raw materials and mix for 3 minutes to obtain a premix.

[0050] Step 2. Put the above-mentioned premix into a twin-screw extruder to extrude and granulate. The extrusion temperature is 170-200°C. Specifically, the temperatures in the first to eighth zones of the twin-screw extruder are: 150°C and 160°...

Embodiment 2

[0052] A high shock-absorbing and wear-resistant thermoplastic elastomer, comprising the following components by weight:

[0053] SIS resin 50 parts

[0054] 15 parts thermoplastic polyurethane

[0055]Hydrogenated thermoplastic styrene-butadiene rubber-maleic anhydride graft 8 parts

[0056] Paraffin-based rubber oil 10 parts

[0057] Calcium carbonate 8 parts

[0058] LDPE carrier silicone masterbatch 2 parts

[0059] Antioxidant 0.4 parts.

[0060] The high shock-absorbing and wear-resistant thermoplastic elastomer is prepared through the following steps:

[0061] Step 1. First put SIS resin, calcium carbonate, antioxidant, processing aid and extender oil into a high-speed mixer, mix at 40°C for 5 minutes, then add the rest of the raw materials and mix for 4 minutes to obtain a premix.

[0062] Step 2. Put the above-mentioned premix into a twin-screw extruder to extrude and granulate. The extrusion temperature is 170-200°C. Specifically, the temperatures in the first ...

Embodiment 3

[0064] A high shock-absorbing and wear-resistant thermoplastic elastomer, comprising the following components by weight:

[0065] SIS resin 45 parts

[0066] Thermoplastic polyurethane 18 parts

[0067] Hydrogenated thermoplastic styrene-butadiene rubber-maleic anhydride graft 8 parts

[0068] Naphthyl rubber oil 8 parts

[0069] Kaolin 8 parts

[0070] Surface treatment nano-SiO 2 2 copies

[0071] Antioxidant 0.4 part.

[0072] The high shock-absorbing and wear-resistant thermoplastic elastomer is prepared through the following steps:

[0073] Step 1. First put SIS resin, calcium carbonate, antioxidant, processing aid and extender oil into a high-speed mixer, mix at 60°C for 8 minutes, then add the rest of the raw materials and mix for 5 minutes to obtain a premix.

[0074] Step 2. Put the above-mentioned premix into a twin-screw extruder to extrude and granulate. The extrusion temperature is 170-200°C. Specifically, the temperatures in the first to eighth zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com