Adhesive tape for fixing display panels and manufacturing method thereof

A technology for a display panel and a manufacturing method, which is applied in the field of adhesive tapes, can solve the problems of increased operating procedures, low bonding strength, and large equipment investment, and achieves the advantages of eliminating technological processes, reducing scrap rates, and high bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

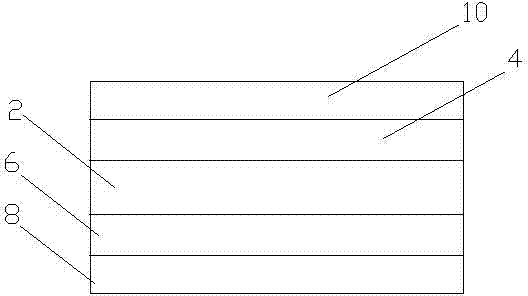

[0023] Embodiment 1: as figure 1 As shown, an adhesive tape 1 for fixing a display panel includes a substrate layer 2, and a hot melt adhesive layer 4 and a pressure-sensitive adhesive layer 6 respectively arranged on both sides of the substrate layer 2. The outer sides of the pressure-sensitive adhesive layer 6 and the hot-melt adhesive layer 4 are respectively provided with a release layer 8 and a release layer 10 . The thickness of the substrate layer 2 is 0-100 mm, the thickness of the hot-melt adhesive layer 4 is 0-10 mm, and the thickness of the pressure-sensitive adhesive layer 6 is 0-10 mm. Among them, the substrate layer 2 is made of foam substrate, the hot melt adhesive layer 4 is water-based polyester, solvent-based hot melt system, the pressure-sensitive adhesive layer 6 is a glue system with pressure-sensitive adhesive properties, and the release layer 8 , The release layer 10 is made of release paper or release film respectively.

[0024] The production method ...

Embodiment 2

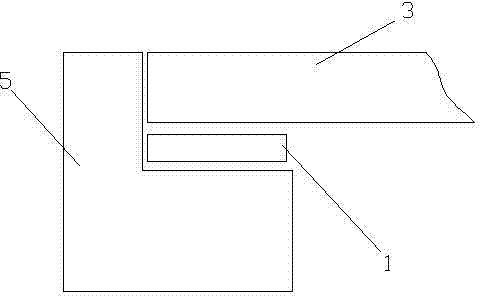

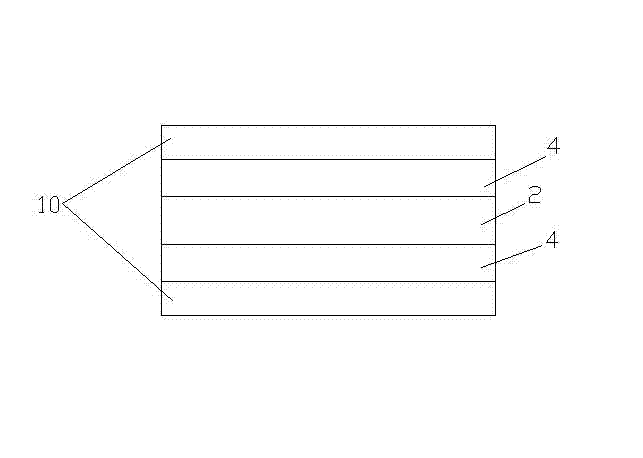

[0027] Embodiment 2: as image 3 As shown, a kind of adhesive tape for fixing the display panel, the only difference from Example 1 is that both sides of the substrate layer 2 are provided with a hot-melt adhesive layer 4, and the outer sides of the two hot-melt adhesive layers 4 are respectively provided with separate Type layer 10. During production, hot-melt adhesive is coated on both sides of the base material layer, and dried in an oven to form two hot-melt adhesive layers 4 . When in use, the release layer 10 is peeled off, and the two hot melt adhesive layers 4 are hot-pressed and bonded to the panel 1 and the panel frame 3 of the display respectively. The hot-pressing temperature is 50-200°C, the pressure is 2-10 kgf / cm2, and the time is 2-60s , to complete the fixation.

[0028] It should be noted that the above-mentioned water-based polyesters, solvent-based hot-melt systems, and glue systems with pressure-sensitive adhesive properties can all use corresponding raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com