Preparation method of high-adhesion moisture-proof glass cement

A high-adhesive, glass glue technology, applied in the preparation of animal glue or gelatin, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of moldy blackening and easy moisture absorption of glass glue , falling off and other problems, to achieve the effect of enhancing the anti-oxidation ability, inhibiting bacterial reproduction, and improving the antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

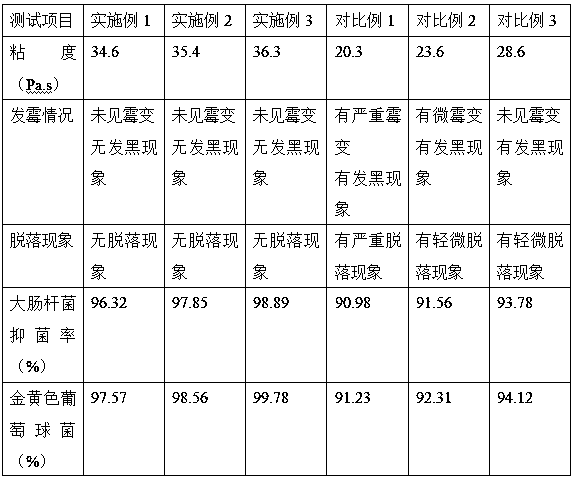

Examples

Embodiment 1

[0030] Preparation of acidified suspension:

[0031]Take 200g of soybeans and grind them in a soybean grinder, filter to obtain soybean meal, mix distilled water and soybean meal at a mass ratio of 7:2 to obtain a soybean meal suspension, and adjust the concentration of the soybean meal suspension with 10% sodium hydroxide solution. The pH is 8.0, stirred at room temperature for 1.5h, placed in a centrifuge, and centrifuged at 3000r / min for 13min to separate the supernatant, and adjust the pH of the supernatant to 4.5 with 2% hydrochloric acid to obtain an acidified suspension solution, put the acidified suspension in a centrifuge, and centrifuge at 4000r / min for 15min to separate and collect the protein precipitate;

[0032] Preparation of acid heat treated protein powder:

[0033] Mix the above protein precipitate with hydrochloric acid with a mass fraction of 10% at a mass ratio of 1:3 to obtain an acidified protein solution, place the acidified protein solution in a high-...

Embodiment 2

[0041] Preparation of acidified suspension:

[0042] Take 225g of soybeans and grind them in a soybean grinder, filter to obtain soybean meal, mix distilled water and soybean meal at a mass ratio of 7:2 to obtain a soybean meal suspension, and adjust the concentration of the soybean meal suspension with a mass fraction of 10% sodium hydroxide solution. The pH is 8.5, stirred at room temperature for 1.75h, placed in a centrifuge, and centrifuged at 3250r / min for 14min to separate the supernatant, and adjust the pH of the supernatant to 4.75 with 2% hydrochloric acid to obtain an acidified suspension solution, put the acidified suspension in a centrifuge, and centrifuge at a speed of 4500r / min for 16.5min to separate and collect the protein precipitate;

[0043] Preparation of acid heat treated protein powder:

[0044] Mix the above protein precipitate with hydrochloric acid with a mass fraction of 10% at a mass ratio of 1:3 to obtain an acidified protein solution, place the ac...

Embodiment 3

[0052] Preparation of acidified suspension:

[0053] Take 250g of soybeans and grind them in a soybean grinder, filter to obtain soybean meal, mix distilled water and soybean meal at a mass ratio of 7:2 to obtain a soybean meal suspension, and adjust the concentration of the soybean meal suspension with 10% sodium hydroxide solution. The pH is 9.0, stirred at room temperature for 2.0 hours, placed in a centrifuge, and centrifuged at 3500r / min for 15 minutes to separate the supernatant, and adjust the pH of the supernatant to 5.0 with 2% hydrochloric acid to obtain an acidified suspension solution, put the acidified suspension in a centrifuge, and centrifuge at a speed of 5000r / min for 18min to separate and collect the protein precipitate;

[0054] Preparation of acid heat treated protein powder:

[0055] Mix the above protein precipitate with hydrochloric acid with a mass fraction of 10% at a mass ratio of 1:3 to obtain an acidified protein solution, place the acidified prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com