Polymer nanometer floor and production method thereof

A production method and polymer technology, which can be applied to paints, coatings, buildings and other directions containing biocides, can solve problems such as poor wear resistance, and achieve the effects of enhanced thermal insulation, good sound insulation, and good thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

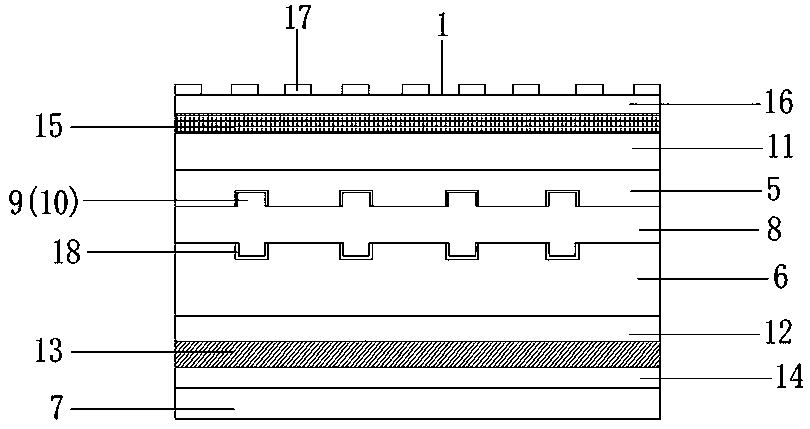

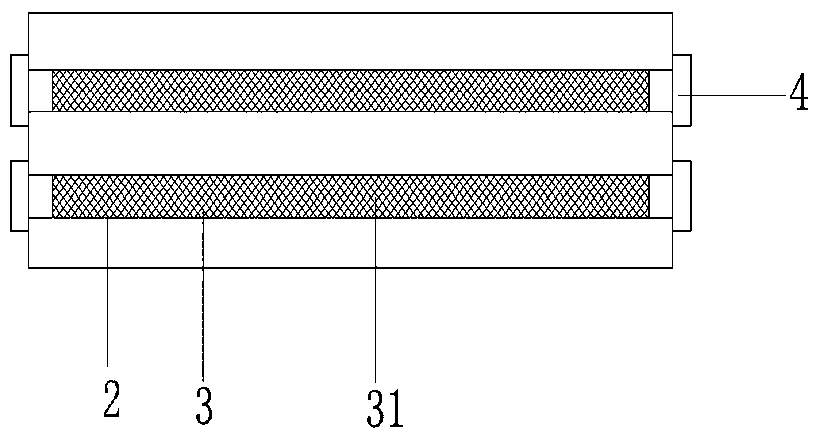

[0027] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0028] A polymer nano-floor, comprising a floor body 1, the inside of the floor body is provided with two cavities 2 along a transverse section, the cavities 2 are arranged inside a base material layer 6, and the cavities 2 penetrate through the base material layer 1. The cavity 2 is filled with a light foam material 3, and a number of through holes 31 are evenly distributed on the light foam material. Both ends of the cavity 2 are provided with plugs for blocking the cavity 4. The floor body 1 includes a top layer 5, a substrate layer 6 and a bottom layer 7 from top to bottom, and a polymer nanomaterial layer 8 with a thickness of 5mm is arranged between the top laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com