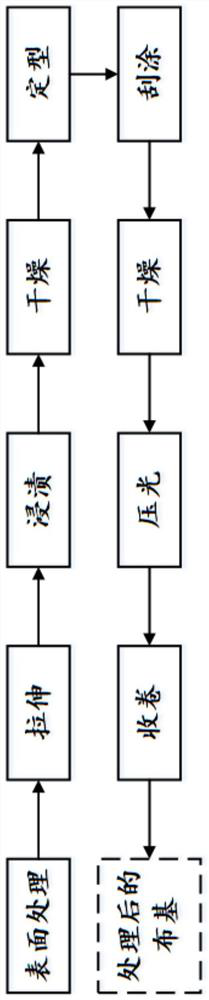

Treatment method and system for high-strength soft cloth base of abrasive belt

A processing method and cloth base technology, applied in textiles and papermaking, abrasives, manufacturing tools, etc., can solve the problems of reduced service life of abrasive belts, softness not suitable for the workpiece environment, insufficient softness and strength, etc., to achieve tight rubber layer even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

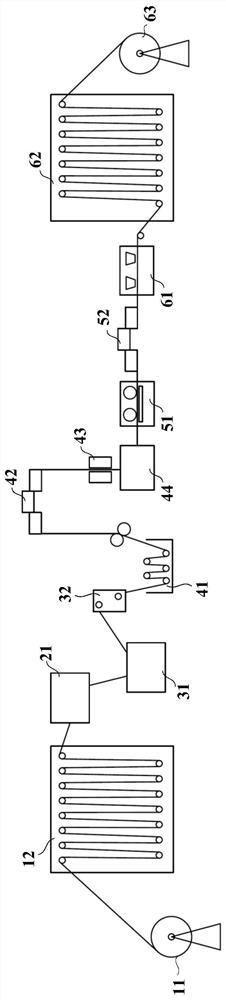

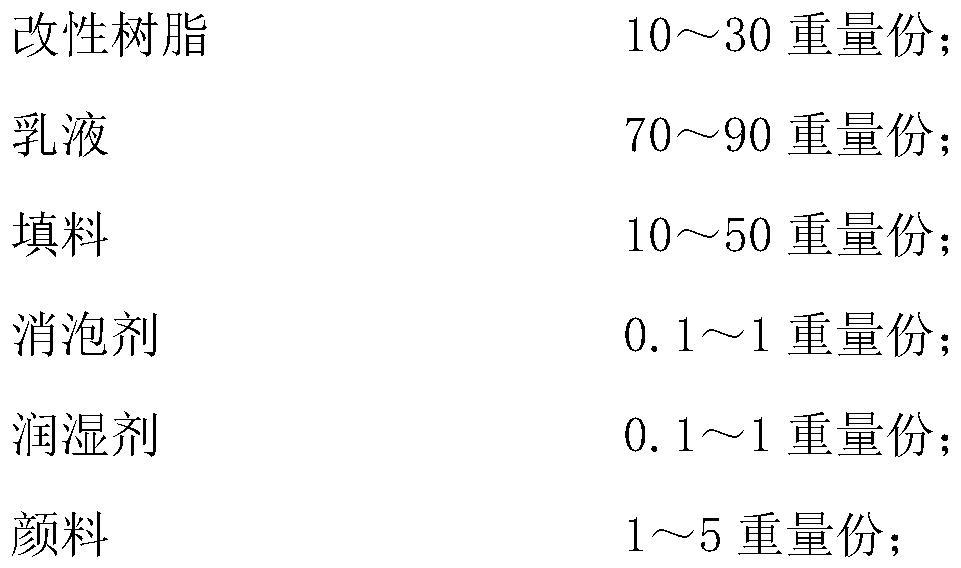

[0072] Use rayon as the raw material of the cloth base for weaving; perform surface treatment to remove the fluff on the surface of the cloth base; pass the cloth base through a stretching machine, with a warp stretch rate of 6% and a weft shrinkage rate of 8%. The warp strength of the cloth base is 1150N / 5cm; the weft strength is 450N / 5cm; the cloth base is impregnated through a dipping tank containing rubber; after impregnation, the cloth base is dried at 70°C and then set at a high temperature of 160°C; Including 10 parts by weight of modified resin; 70 parts by weight of emulsion; 0.1 part by weight of penetrant; the viscosity of the rubber material is 10CPS, and the pH value is 6; Dried under; Coating machine scratch coating used coating comprises modified resin 10 weight parts; Emulsion 70 weight parts; Filler 10 weight parts; Defoamer 0.1 weight part; Wetting agent 0.1 weight part; Pigment 1 weight part; It is 1000CPS, and the pH value is 8; the cloth base is calendered...

Embodiment 2

[0074] Use rayon as the raw material of the cloth base for weaving; perform surface treatment to remove the fluff on the surface of the cloth base; pass the cloth base through a stretching machine, with a warp stretch rate of 8% and a weft shrinkage rate of 10%. The warp strength of the cloth base is 1200N / 5cm; the weft strength is 480N / 5cm; the cloth base is impregnated through a dipping tank containing rubber; after impregnation, the cloth base is dried at 90°C and then set at a high temperature of 190°C; Including 10 parts by weight of modified resin; 70 parts by weight of emulsion; 0.1 part by weight of penetrant; the viscosity of the rubber material is 10CPS, and the pH value is 6; Dried under; Coating machine scratch coating used coating comprises modified resin 10 weight parts; Emulsion 70 weight parts; Filler 10 weight parts; Defoamer 0.1 weight part; Wetting agent 0.1 weight part; Pigment 1 weight part; It is 1000CPS, and the pH value is 8; the cloth base is calendere...

Embodiment 3

[0076] Compared with Example 2, the difference is that the stretch rate in the warp direction is 12%, and the shrinkage rate in the weft direction is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com