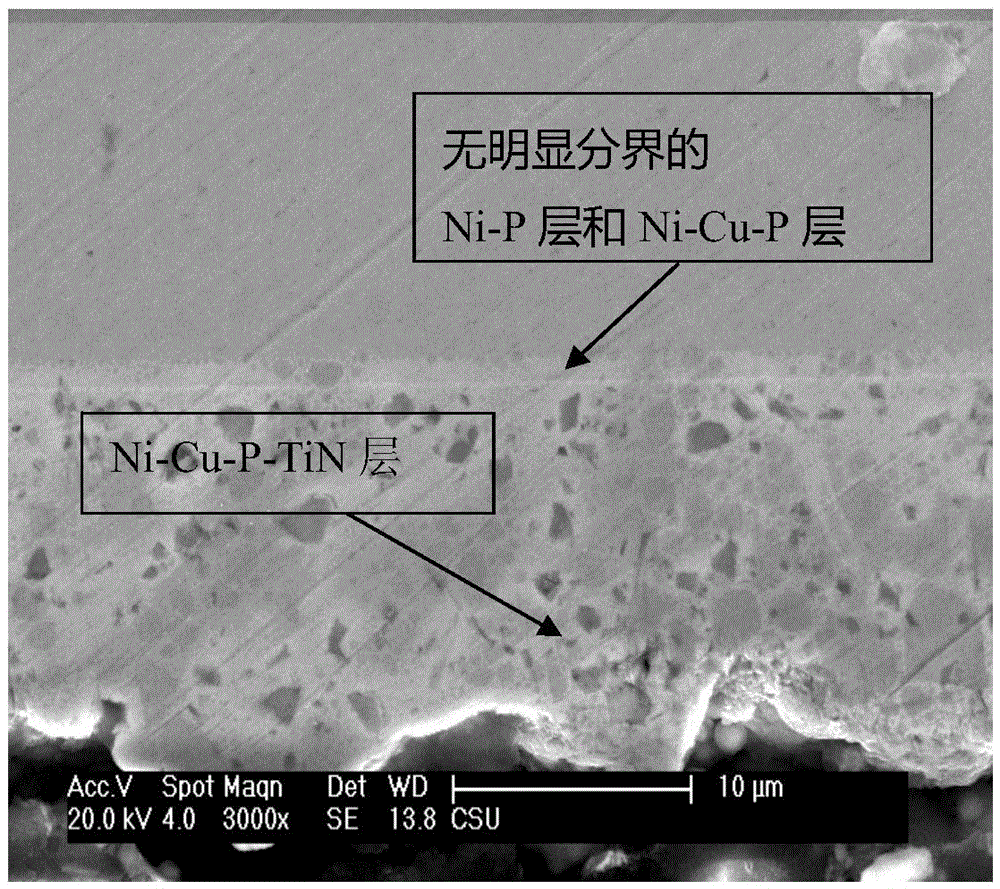

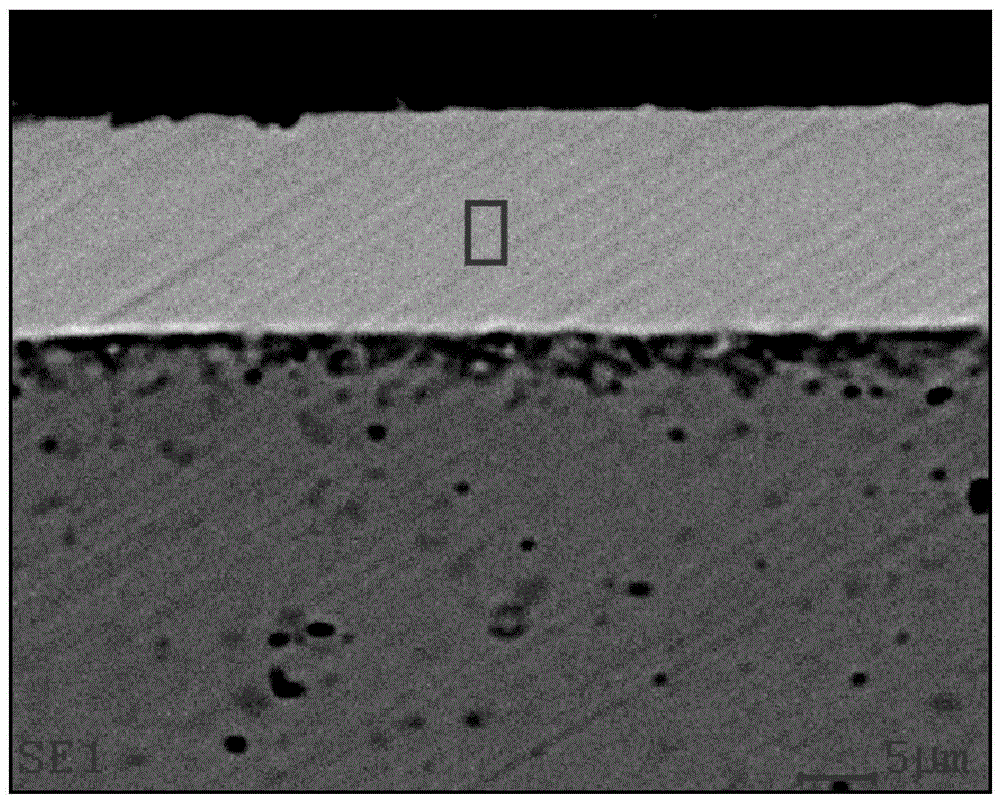

A kind of anti-corrosion and anti-wear material with ni-cu-p-tin composite coating and preparation method thereof

A ni-cu-p-tin, anti-wear material technology, applied in the field of anti-corrosion and anti-wear materials and its preparation, can solve the problem of easy peeling off of the coating in a corrosive and abrasive environment, reduction of the bonding strength between the coating and the substrate, and the embedding of second phase particles Insufficient strength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] First dissolve 30g nickel sulfate, 30g sodium hypophosphite, 8g citric acid, 25g trisodium citrate and 20mg potassium iodate with a small amount of deionized water respectively to obtain an aqueous solution of components such as nickel sulfate and sodium hypophosphite; , 20ml lactic acid, 15ml glacial acetic acid and citric acid solution were mixed and stirred for 5min to obtain a ternary complex complexing agent solution; the complex complexing agent solution was mixed with nickel sulfate solution and stirred for 5min to obtain solution A; then, lemon Trisodium acid solution, sodium hypophosphite solution and potassium iodate solution were added to solution A respectively, and stirred for 5 minutes each time to fully mix the components. Finally, use a pH meter to adjust the pH of the solution to 4.8, and set the volume to 1 L. The regulator is dilute ammonia water. At this time, the preparation of electroless plating solution A is completed; repeat the above operations ...

Embodiment 2

[0055] First dissolve 32g nickel sulfate, 32g sodium hypophosphite, 9g citric acid, 30g trisodium citrate and 22mg potassium iodate respectively with a small amount of deionized water to obtain an aqueous solution of components such as nickel sulfate and sodium hypophosphite; , 22ml lactic acid, 17ml glacial acetic acid and citric acid solution were mixed and stirred for 5min to obtain a ternary complex complexing agent solution; the complex complexing agent solution was mixed with nickel sulfate solution and stirred for 5min to obtain solution A; then, lemon Trisodium acid solution, sodium hypophosphite solution and potassium iodate solution were added to solution A respectively, and stirred for 5 minutes each time to fully mix the components. Finally, use a pH meter to adjust the pH of the solution to 5.0, and set the volume to 1 L. The regulator is dilute ammonia water. At this time, the preparation of the electroless plating solution A is completed; repeat the above operati...

Embodiment 3

[0062] First dissolve 35g nickel sulfate, 35g sodium hypophosphite, 10g citric acid, 35g trisodium citrate and 25mg potassium iodate respectively with a small amount of deionized water to obtain an aqueous solution of components such as nickel sulfate and sodium hypophosphite; , 25ml lactic acid, 20ml glacial acetic acid and citric acid solution were mixed and stirred for 5min to obtain a ternary complex complexing agent solution; the complex complexing agent solution was mixed with nickel sulfate solution and stirred for 5min to obtain solution A; then, lemon Trisodium acid solution, sodium hypophosphite solution and potassium iodate solution were added to solution A respectively, and stirred for 5 minutes each time to fully mix the components. Finally, use a pH meter to adjust the pH of the solution to 5.1, and set the volume to 1 L. The regulator is dilute ammonia water. At this time, the preparation of the electroless plating solution A is completed; repeat the above operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com