Gallium oxide-based solar-blind detector and preparation method thereof

A gallium oxide and photodetector technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem that detectors cannot achieve high gain and large bandwidth at the same time, low photoresponsivity of solar-blind detectors, The problem of slow response speed of the device can achieve the effect of increasing the effective working area, super-light responsivity, and improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

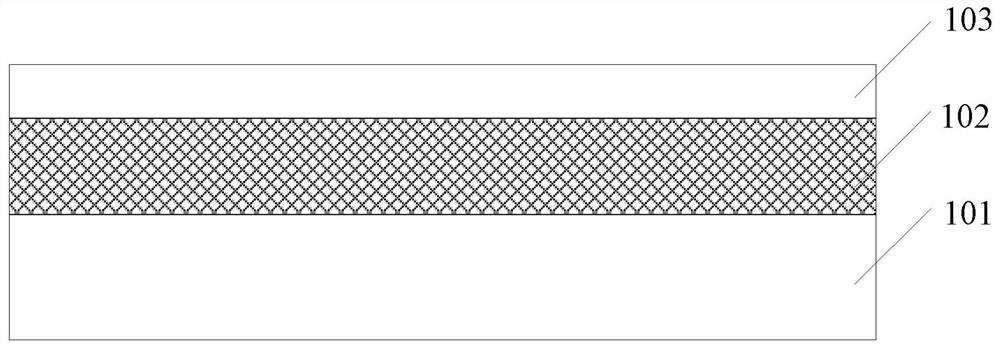

[0043] Preparation of the layer The epitaxial layer can also be prepared by various other deposition or growth methods, including but not limited to methods such as MOCVD or PLD to obtain gallium oxide epitaxial films.

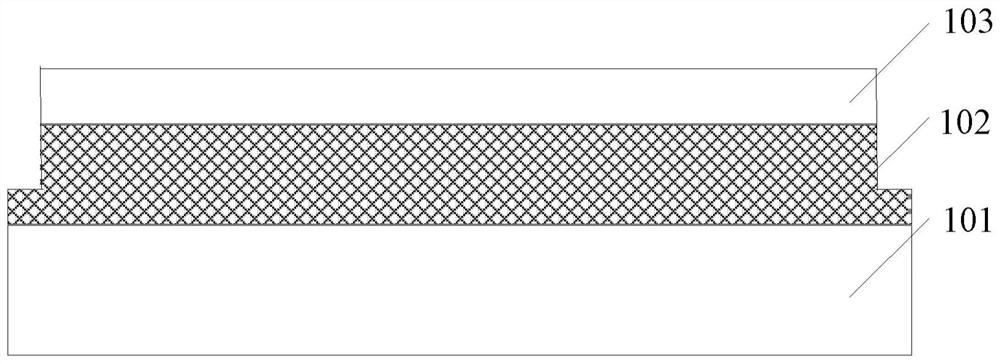

[0044] see figure 2 As shown, photolithographic patterning is used to isolate the device of the sample by reactive ion beam etching; the etching parameters can be: using Cl 2 / Ar gas for etching, where Cl 2 The flow rate was 15 sccm, the Ar flow rate was 5 sccm, the ICP (inductively coupled plasma) power was 400W, and the RF power was 200W.

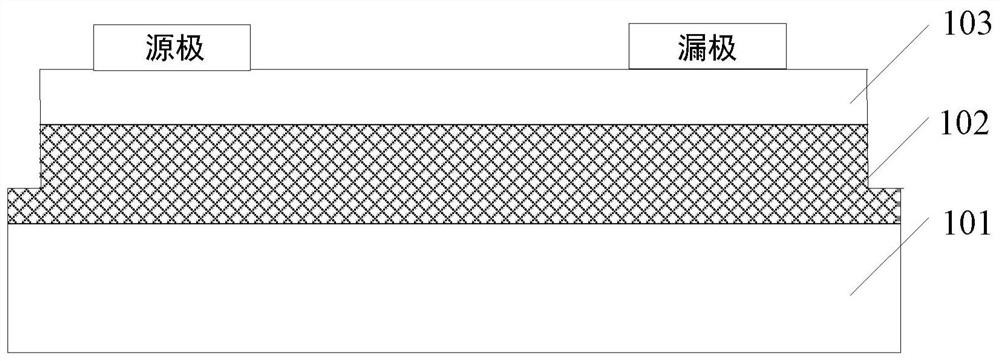

[0045] see image 3 As shown, using a standard photolithographic lift-off process, the source and drain electrodes are deposited by electron beam evaporation, and the metals used are platinum / titanium / gold, and gallium oxide (Ga 2 o 3) to form a Schottky contact, the electrode thicknesses are 40nm / 10nm / 50nm respectively; the thickness range of platinum is 10-60nm, the thickness range of titanium is 5-20nm, and the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com