A method for realizing anhydrous and oxygen-free operation and a process for producing cyclomanganese reaction of methylcyclopentadienyl manganese using the method

A technology of methylcyclopentadienyl manganese and an operation method is applied in the field of cyclomanganese reaction production technology of methylcyclopentadienyl manganese, which can solve the problems of large nitrogen consumption, economic loss and high energy consumption, and achieves Improve the success rate of the reaction, good economic benefits, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

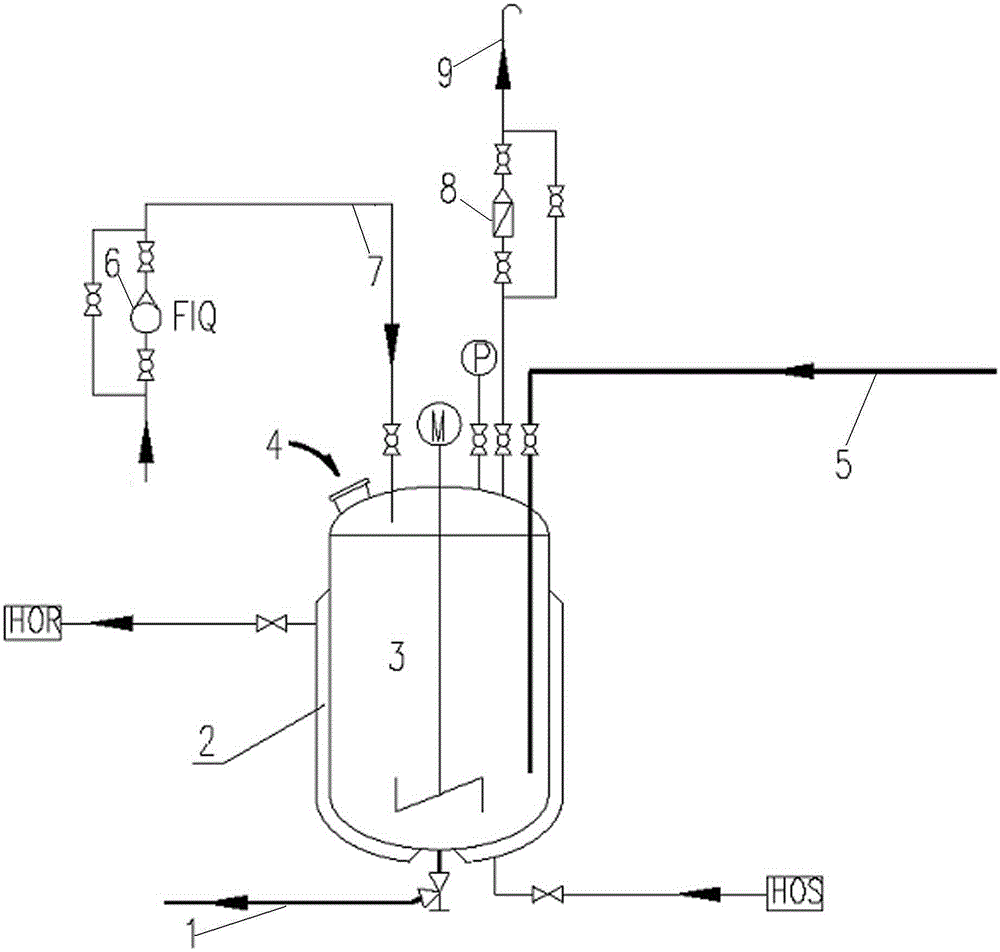

[0031] A kind of cyclomanganese reaction production technique of methylcyclopentadienyl manganese, its processing step is as follows:

[0032] (a) After the ring manganese reaction in the reactor 3 is completed, a certain amount of high-purity nitrogen gas is filled into the reactor, and after the pressure in the reactor rises to 0.2-0.3 MPa, the discharge valve of the reactor is opened, and the reaction liquid is discharged from the discharge pipeline 1. Discharge the reaction kettle 3 until the reaction kettle is emptied and the pressure drops to a slight positive pressure, then close the discharge valve and keep the reaction kettle with a slight positive pressure and a nitrogen atmosphere, ready to enter the next ring manganese reaction cycle;

[0033] (b) Fill the kettle with micro-flow high-purity nitrogen through the small-range flowmeter 6 and the inert gas inlet line 7, and the small-range rotameter 6 controls the flow rate of the micro-flow high-purity nitrogen at 70 l...

Embodiment 2

[0037] A cyclomanganese reaction production process of methylcyclopentadienyl manganese, on the basis of keeping other steps and process parameters unchanged in Example 1, only the inert gas is changed from high-purity nitrogen to helium.

example 3-10

[0039] A ring manganese reaction production process of methylcyclopentadienyl manganese, on the basis of embodiment 1, keep other steps and process parameters unchanged, the only difference is that the micro positive pressure single call valve 8 adopts different opening pressures (i.e. different micro positive pressure control ranges) and the small range rotameter 6 adopts different micro flow rates, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com