Thin-film solar cell module and preparation method thereof

A technology of solar cells and components, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as high film resistance, alkali metal diffusion, resistance increase, etc., to reduce series resistance, avoid performance deterioration, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

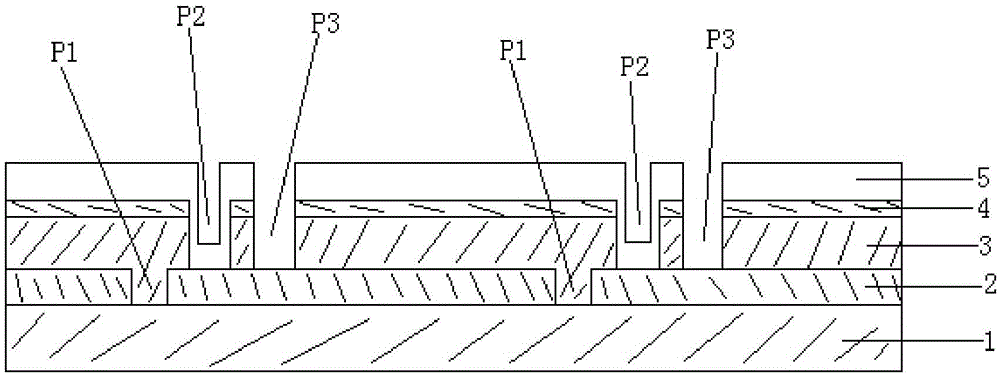

[0043] see figure 2 As shown, a kind of thin-film solar cell assembly of the present invention, when making, adopts the metal molybdenum layer of magnetron sputtering deposition 500nm on a substrate to be soda-lime glass 1 as the back electrode layer 2; Then use laser on the metal molybdenum electrode Scribe to form a P1 groove; then form copper indium gallium selenide with a chalcopyrite structure on the back electrode layer 2 as the light absorbing layer 3; deposit a 50nm CdS film layer on the light absorbing layer 3 by chemical bath (CBD) method As a buffer layer 4; then use a mechanical stylus to scribe to form a P2 trench; sputter-deposit a 15nm titanium oxide film layer on the sidewall, bottom and buffer layer 4 of the P2 trench as a high-resistance material film layer 6 , the sheet resistance of the high-resistance material film layer 6 is 350kΩ / □; adopt magnetron sputtering to deposit 800nmAZO (Al-doped ZnO) film layer on the high-resistance material film layer 6 as t...

Embodiment 2

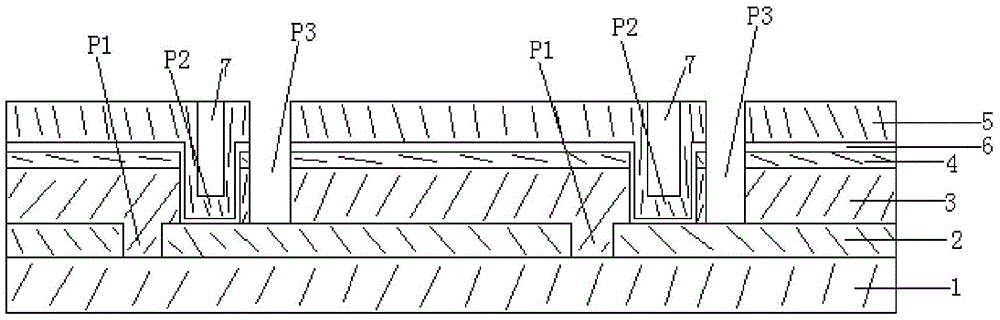

[0045] see image 3 As shown, a kind of thin-film solar cell assembly of the present invention, when making, adopts the metal molybdenum layer of magnetron sputtering deposition 500nm on a substrate to be soda-lime glass 1 as the back electrode layer 2; Then use laser on the metal molybdenum electrode Scribe to form a P1 groove; then form copper indium gallium selenide sulfur with a chalcopyrite structure on the back electrode layer 2 as the light absorbing layer 3; use a chemical bath (CBD) method to deposit a 60nm CdS film on the light absorbing layer 3 layer as the buffer layer 4; then use a mechanical stylus to scribe to form a P2 trench; then use a mask to sputter-deposit 10 nm of silicon oxide on the sidewall, bottom and part of the buffer layer 4 of the P2 trench Film layer is as high-resistance material film layer 6, and the sheet resistance of described high-resistance material film layer 6 is 5kΩ / □; Adopt magnetron sputtering deposition 600nmGZO (Ga-doped ZnO) film l...

Embodiment 3

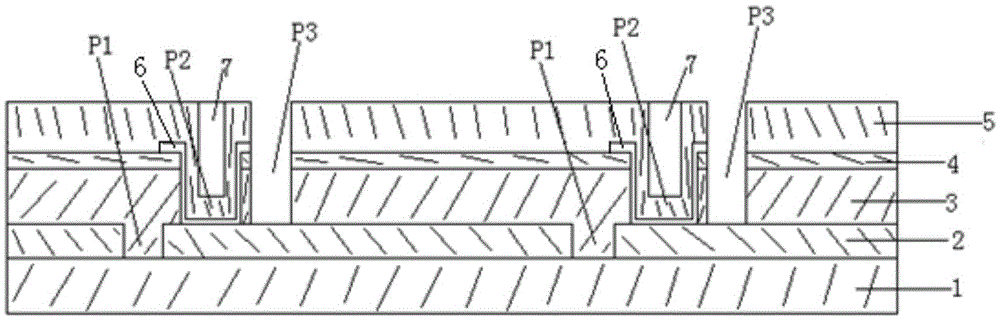

[0047] see Figure 4 As shown, a kind of thin-film solar cell assembly of the present invention, when making, adopts the metal molybdenum layer of magnetron sputtering deposition 500nm on a substrate to be soda-lime glass 1 as the back electrode layer 2; Then use laser on the metal molybdenum electrode Scribing to form a P1 groove; then forming copper indium gallium sulfide with a chalcopyrite structure on the back electrode layer 2 as the light absorbing layer 3; depositing a 40nm CdS film layer on the light absorbing layer 3 by chemical bath (CBD) method As a buffer layer 4; then use a mechanical stylus to scribe to form a P2 trench; then use a mask to sputter-deposit a 20nm aluminum-doped zinc oxide film layer on the side walls of the P2 trench and the buffer layer 4 As the high-resistance material film layer 6, the sheet resistance of the high-resistance material film layer 6 is 100kΩ / □; on the high-resistance material film layer 6, 800nm BZO (B-doped ZnO) film layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com