Graphene oxide modified electric heating membrane and preparation method and application thereof

A graphene modification, electric heating film technology, applied in the direction of heating element materials, epoxy resin coatings, coatings, etc., can solve the problems of inability to retain the excellent properties of graphene, complex operation processes, and difficulty in fiber dispersion. Reduce the consumption of raw materials, simplify the process, improve the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The first step: preparation of graphene oxide ink

[0062] Weigh 6 grams of graphene oxide, 3 grams of water, an appropriate amount of diluent (TMPTA), 1 gram of diazonium fluoroborate, 20 grams of novolac epoxy resin (Shengquan SQAN-201, as a binder), stir and mix evenly, Add 3 grams of isopropanol thereinto, mix and stir evenly, obtain the graphene oxide ink containing isopropanol, wherein, the concentration of graphene oxide is 1%.

[0063] The second step: printing of graphene oxide heating film

[0064] Graphene oxide ink containing isopropanol was printed on polyimide film by gravure printing. The printed thickness is 15 μm. Preliminary solidification results in a graphene oxide film.

[0065] Step 3: Irradiation of graphene oxide heating layer

[0066] Cobalt-60 ( 60 Co) γ-ray radiation source, adopting a dose rate of 300KGy / h, irradiating the graphene oxide film obtained in the second step for 1h, and drying the irradiated film in an oven at 160°C for 10min...

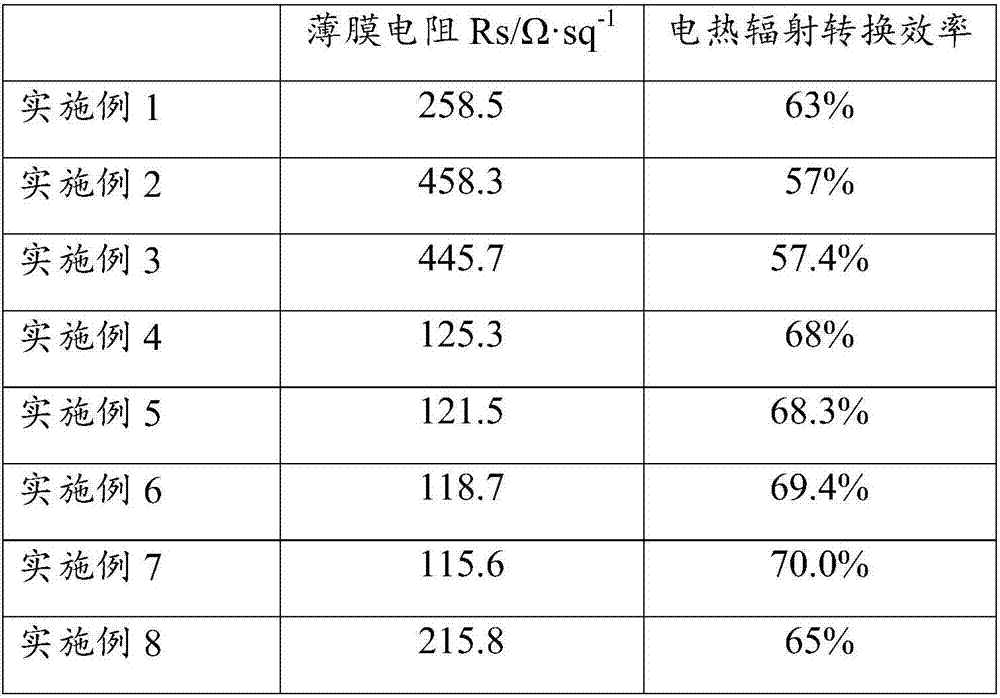

Embodiment 2-7

[0070] The only difference from Example 1 is that the irradiation dose is different, which are: 1KGy / h, 10KGy / h, 100KGy / h, 200KGy / h, 400KGy / h, 600KGy / h.

Embodiment 8-9

[0072] The difference from Example 1 is only that the amount of water added in the first step is different, which are respectively: 15 grams (Example 8), 30 grams (Example 9).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com