Commercial gas stove waste heat utilization device

A technology of gas stoves and waste heat, which is applied in household stoves, household heating, household heating, etc., can solve the problems of poor working environment for chefs, high air temperature in kitchens, energy waste, etc., and achieve reduced energy consumption and high heat utilization efficiency , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

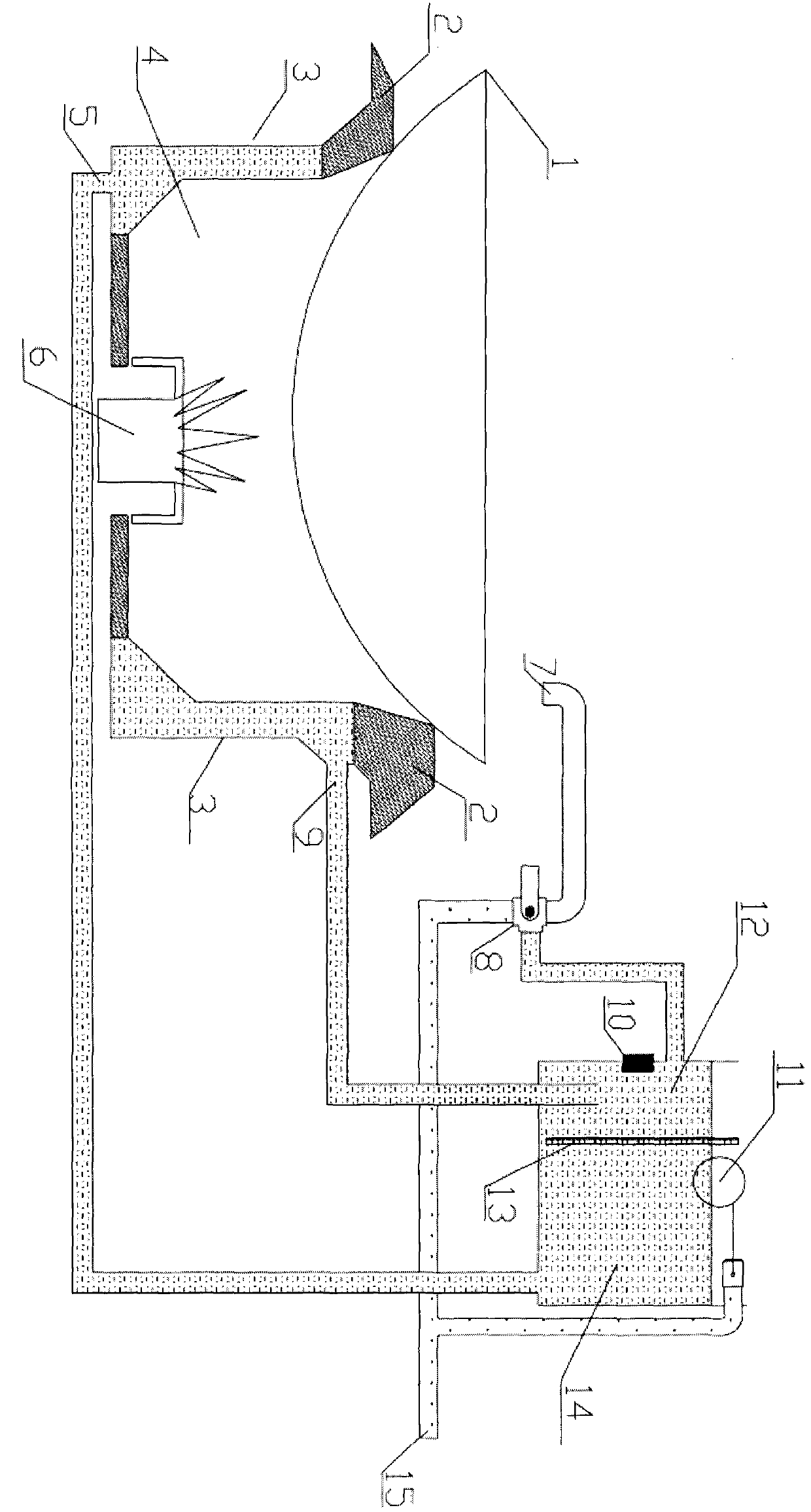

[0014] Such as figure 1 As shown, a commercial gas stove waste heat utilization device of the present invention is composed of a pot 1, a fort pan frame 2, a water jacket furnace 3, a combustion chamber 4, a furnace water inlet 5, a flame outlet 6, a water outlet 7, a water outlet switch 8, Furnace hearth water outlet 9, water temperature sensing alarm device 10, float valve 11, hot water tank 12, heat insulation baffle 13, cold water tank 14 and cold water inlet 15 are formed. Cold water enters the waste heat utilization device of the present invention through the cold water inlet 15, and enters the cold water tank 14 through the ball float valve 11; the furnace water inlet 5 is at the bottom of the water jacket furnace 3, and the furnace water outlet 9 is at the top of the water jacket furnace 3; The water inlet 5 is connected to the cold water tank 14, the furnace outlet 9 is connected to the hot water tank 12, the hot water tank is separated from the upper part of the cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com