Patents

Literature

38results about How to "Realize automatic sliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

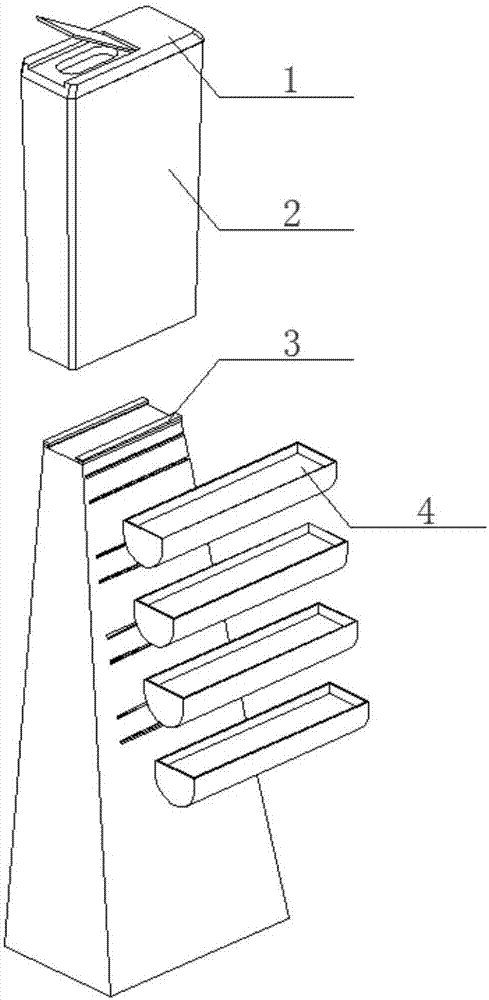

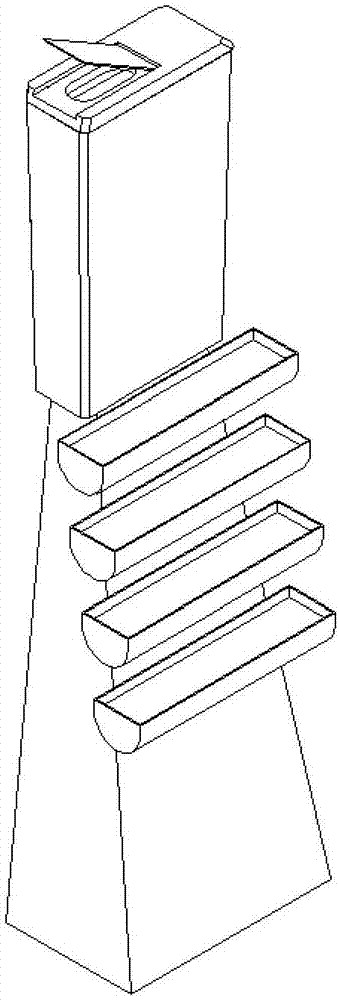

Grain separation bagging machine

InactiveCN106914416AAchieve separationImplement baggingSievingGas current separationEngineeringAir blower

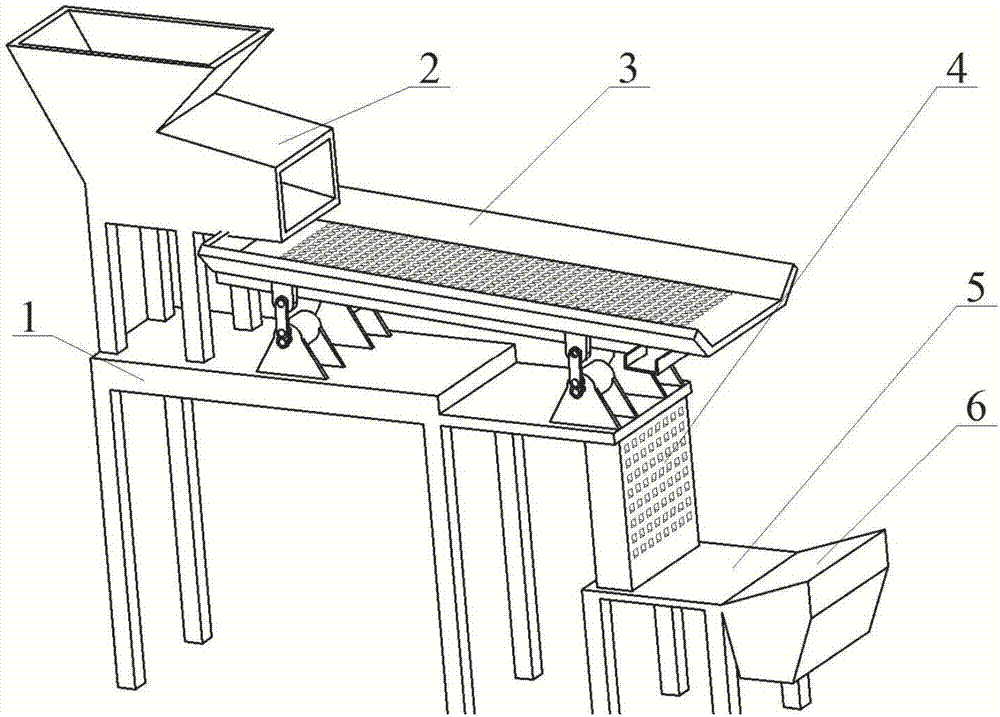

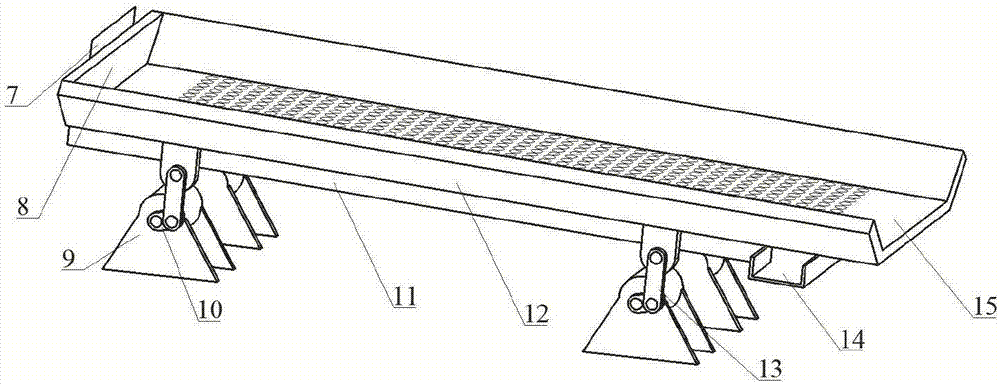

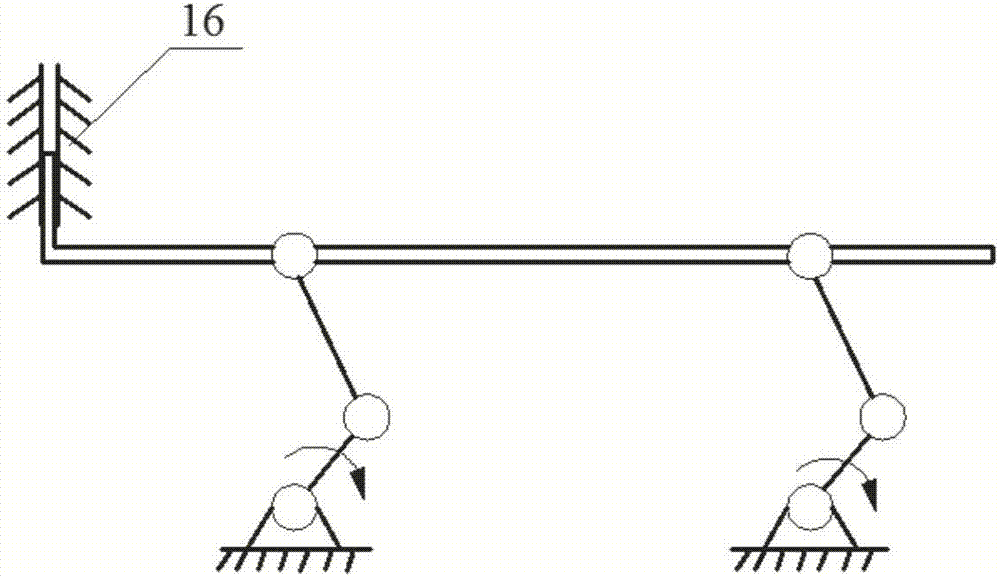

The invention discloses a grain separation bagging machine. The grain separation bagging machine comprises a back support frame (1), a filling funnel (2), a vibration separation mechanism (3), an air blower (4), a front support frame (5) and a bagging funnel (6); the filling funnel (2) is mounted at the back end of the back support frame (1); the vibration separation mechanism (3) is mounted at the front end of the back support frame (1); the lower end of the filling funnel (2) is connected with the upper end of the vibration separation mechanism (3); the front support frame (5) is arranged in front of the back support frame (1); the bagging funnel (6) is arranged below a discharge port of the vibration separation mechanism (3), and is fixed at the front end of the front support frame (5); the air blower (4) is arranged between the vibration separation mechanism (3) and the bagging funnel (6), and is fixed at the back end of the front support frame (5); and grains separated by the vibration separation mechanism (3) are fed in the bagging funnel (6) by an air blowing area of the air blower (4).

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

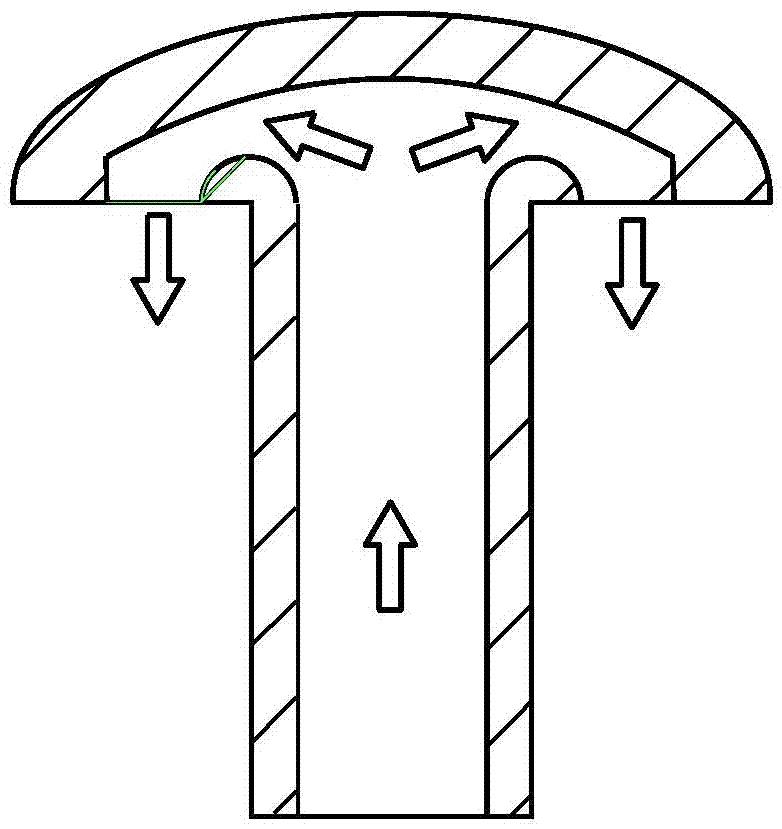

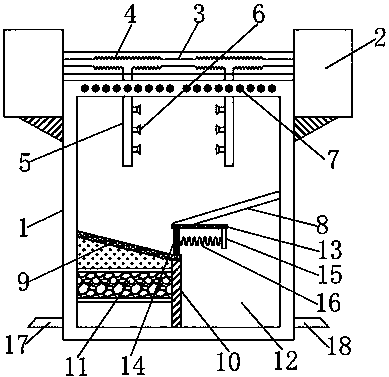

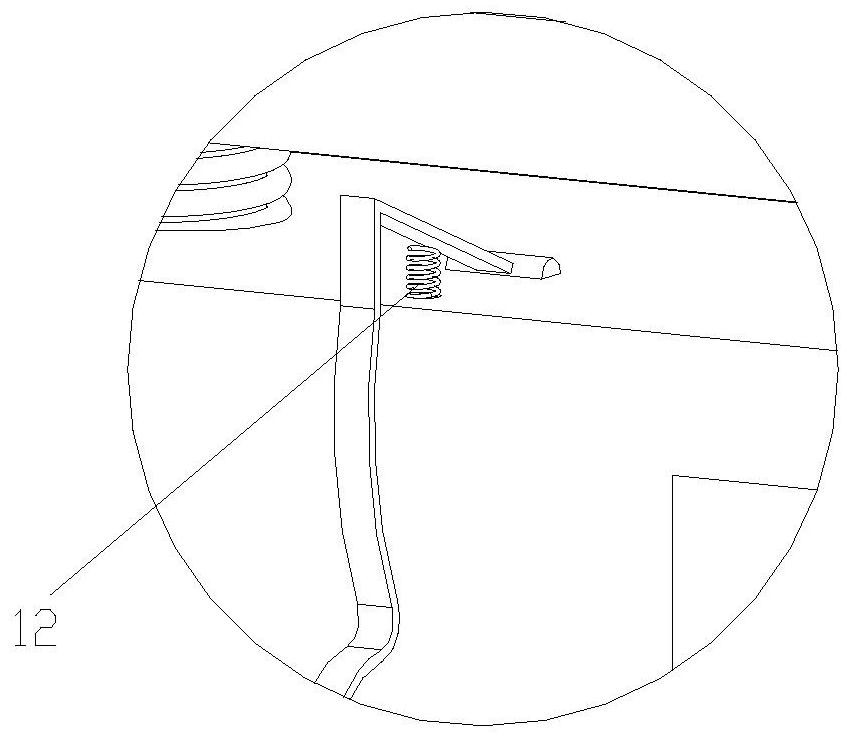

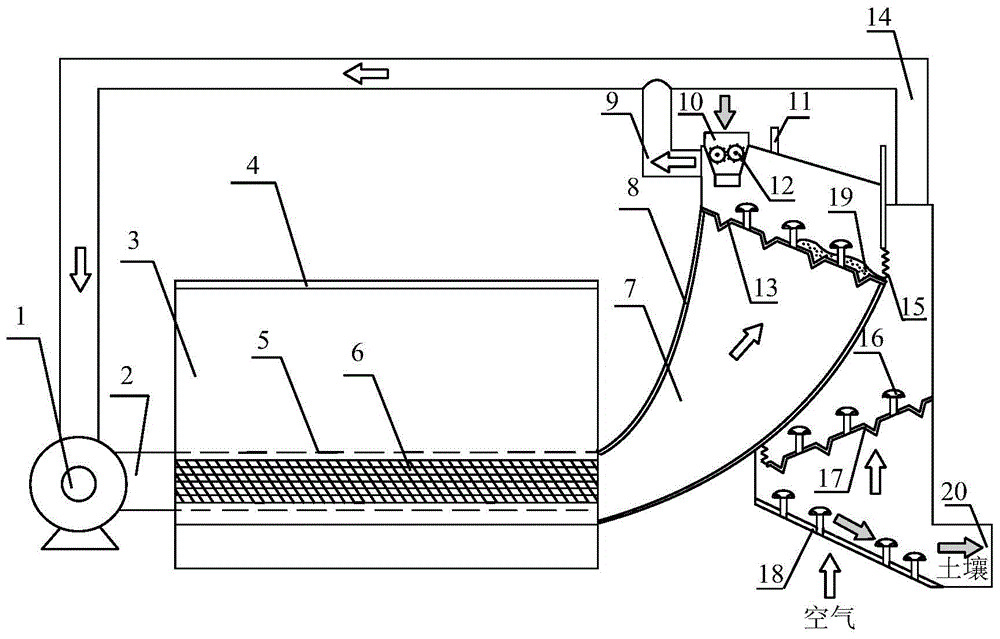

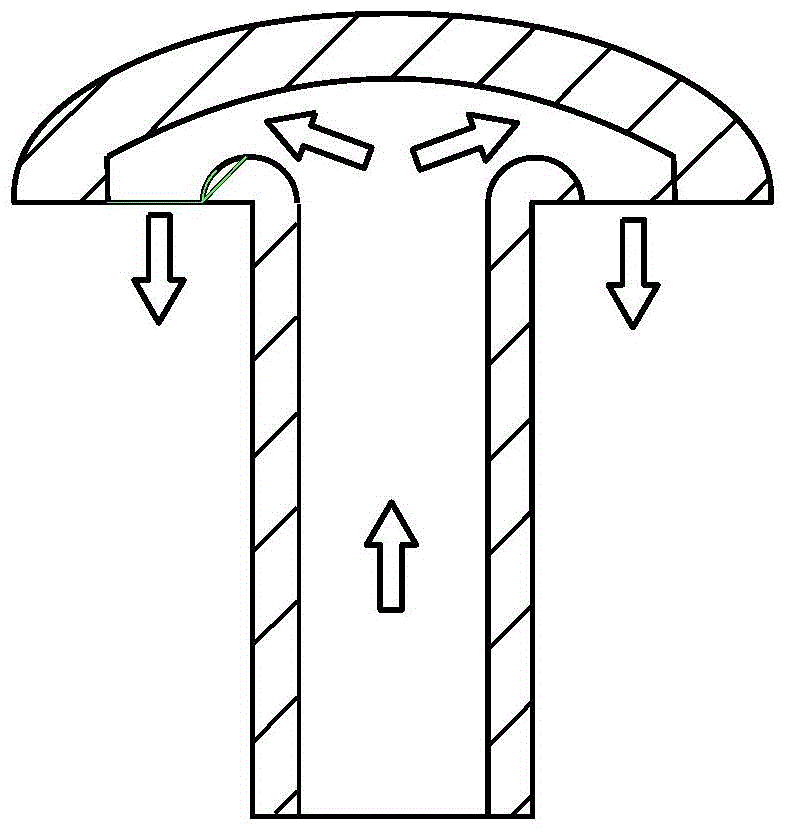

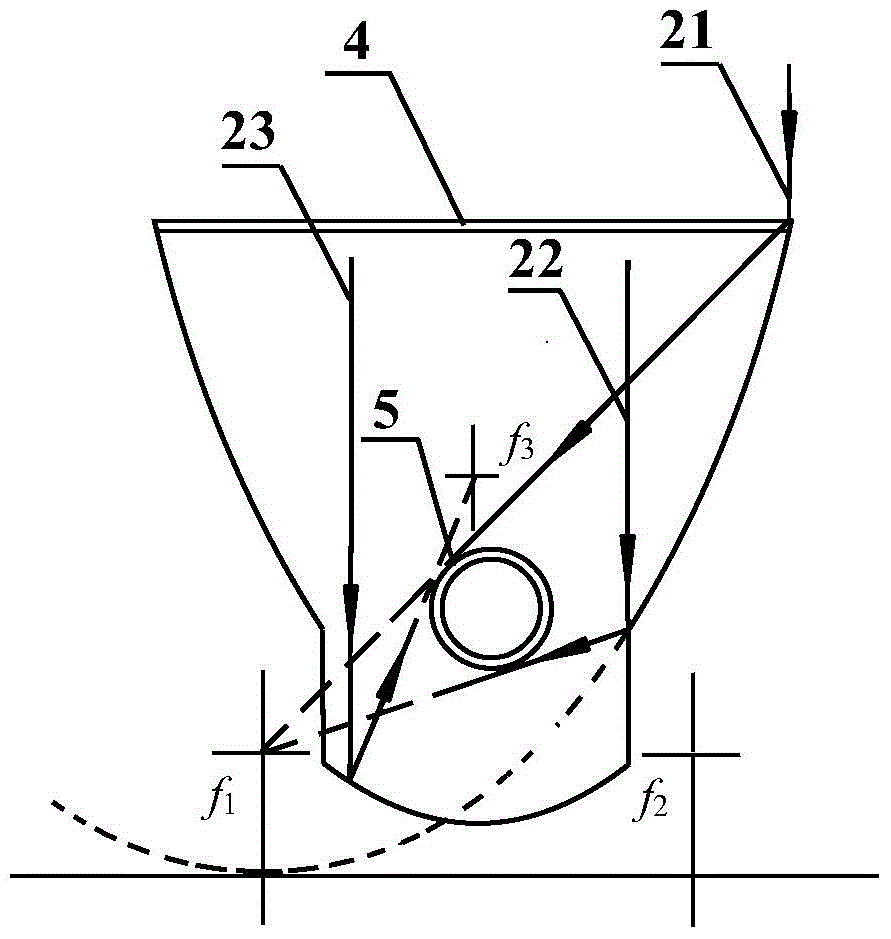

Light gathering and heat returning type soil disinfecting and repairing device

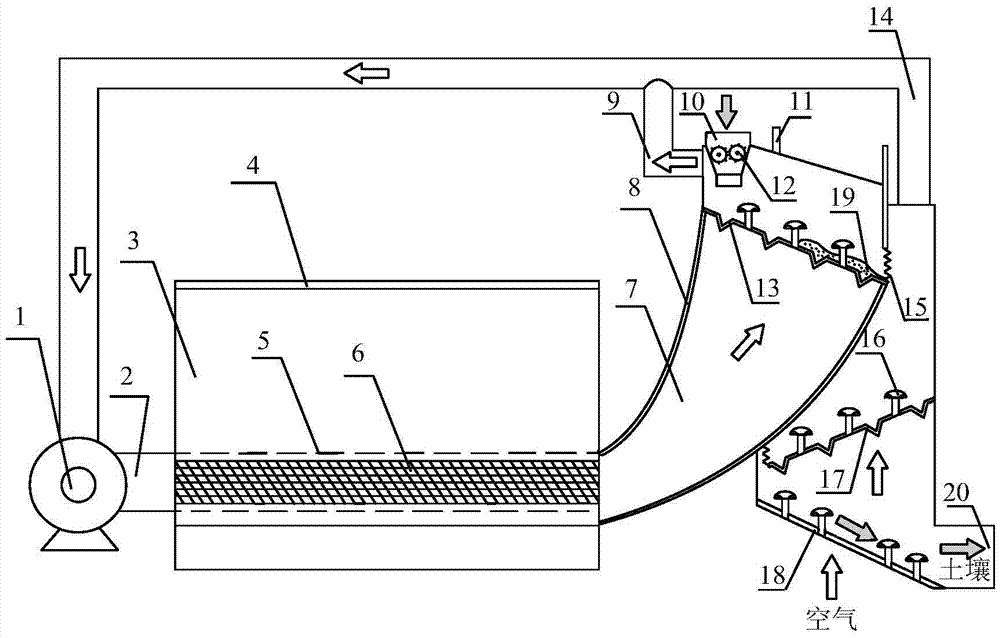

ActiveCN105432176AWon't clogRealize automatic slidingSoil lifting machinesRenewable energy machinesSoil treatmentGlass cover

The invention belongs to a solar application device, and particularly relates to a soil treatment device. A light gathering and heat returning type soil disinfecting and repairing device comprises an induced draft fan (1), an air outlet flue (2), a groove type multi-hook-face solar condenser (3), a glass cover plate (4), a double-layer glass vacuum pipe (5), a ventilation heat absorbing body (6), an insulating layer (8), a hot air cavity (7), a first-level metal heat exchange plate (13), a feeding hopper (10), a mushroom-shaped ventilation channel (16), a tail air backflow channel (9), an exhaust pipe (11), a natural vibration spring (15), a second-level metal heat exchange plate (17), a soil sliding conveying belt (18), a feeding air channel (14) and a discharging port (20). Soil is heated through high-temperature air heated through solar energy, then disinfecting and killing of injurious insects, pathogenic bacteria and weed seeds in the soil and separation of volatile organic compounds in the soil are carried out, the fossil energy does not need to be consumed, pollution to the soil is avoided, and food safety is effectively guaranteed.

Owner:INNER MONGOLIA UNIV OF TECH

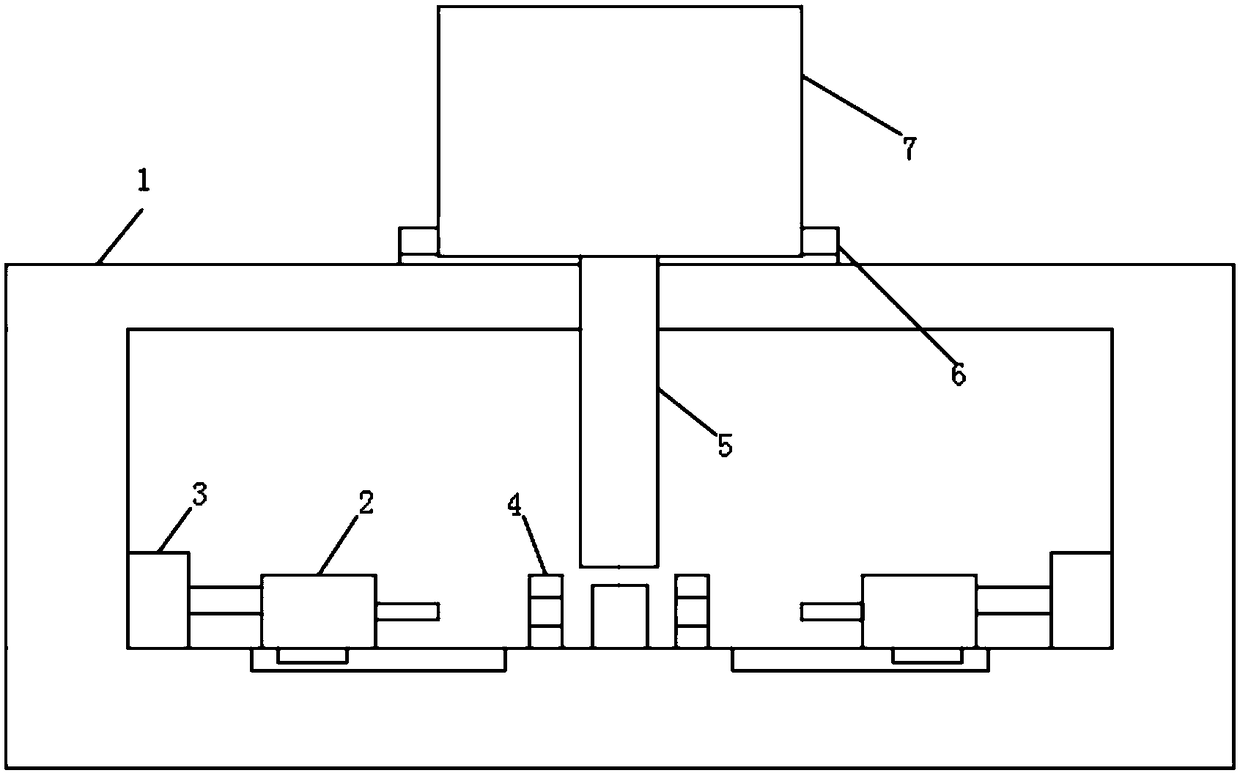

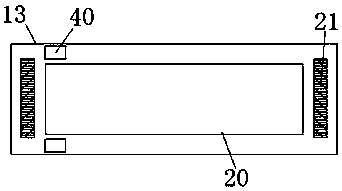

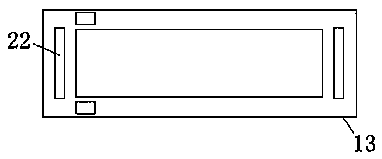

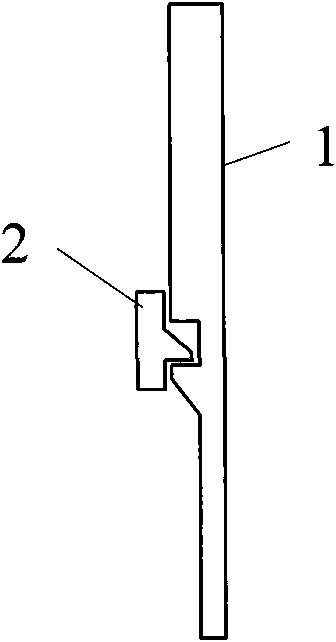

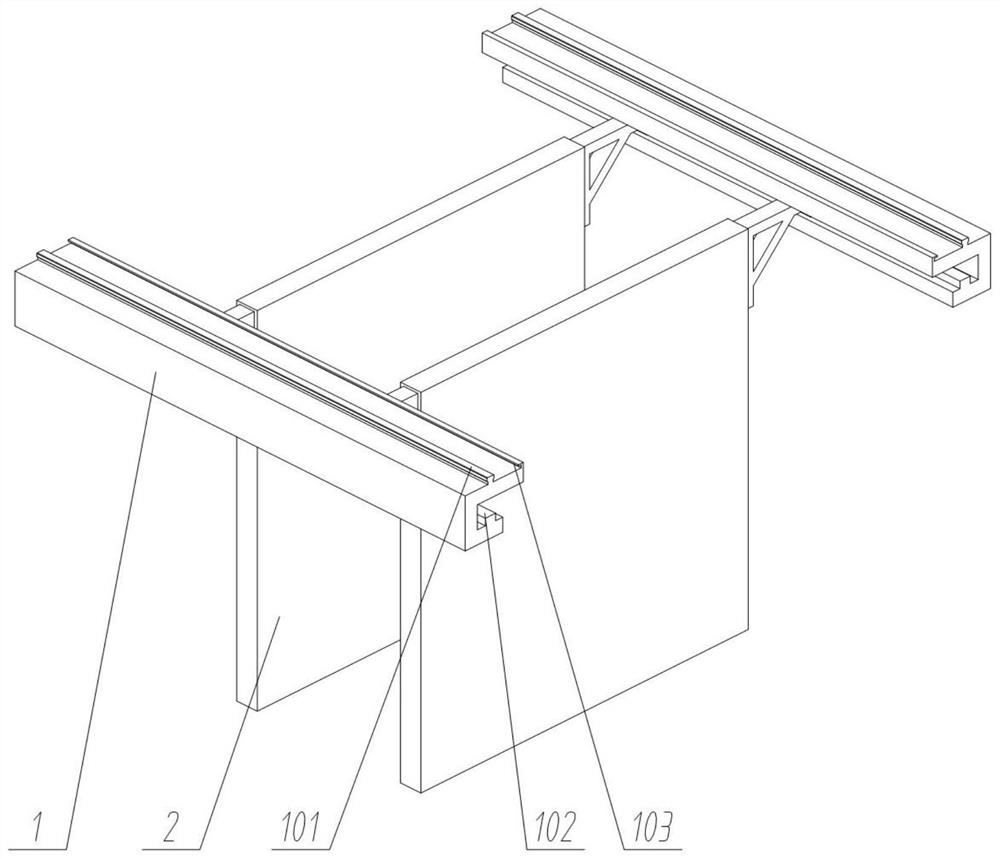

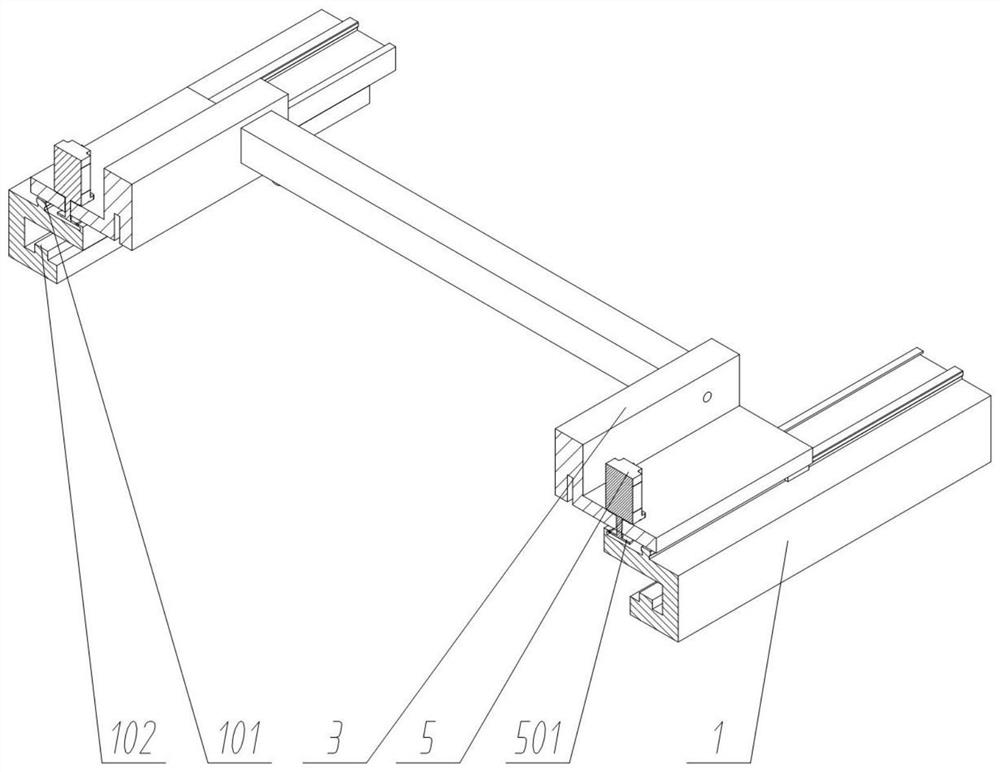

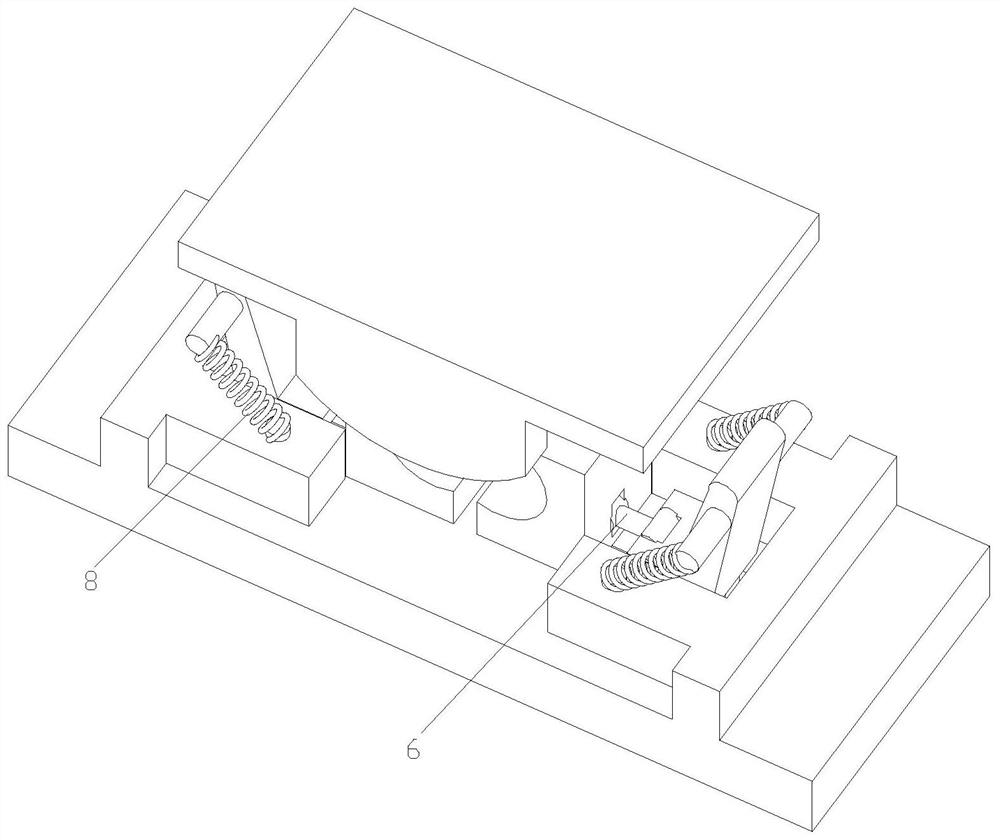

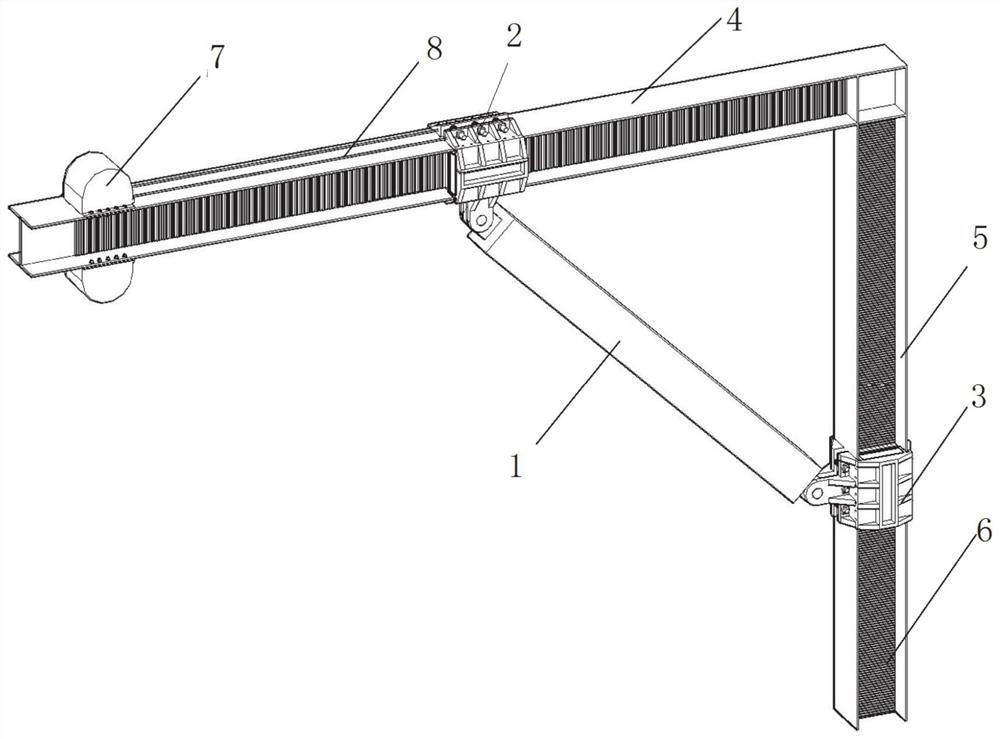

Primer double-way automatic conveying interface

InactiveCN104229413ARealize automatic slidingSimple structureConveyor partsMechanical conveyorsEngineeringFlange

The invention discloses a primer double-way automatic conveying interface. The primer double-way automatic conveying interface comprises a bearing platform, two groups of primer slide ways, two groups of time-sequence push rods and two groups of primer elastic fixtures, wherein the primer slide ways, the time-sequence push rods and the primer elastic fixtures are symmetrically arranged on the bearing platform; the time-sequence push rods and the primer elastic fixtures are arranged on the tail ends of the primer slide ways; by virtue of an inclined sliding platform provided with primer flange strips one two sides, the primer slides to the tail ends of the primer slide ways, and automatic slide of the primer is realized; a PLC (Programmable Logical Controller) is used for controlling the push and retraction time sequence of an air cylinder, so that the opportunity of pushing the primer to a specified blanking position by virtue of the push rod is controlled, and automatic pushing of the primer is realized; the fixed clamping side and the elastic clamping side automatically adapt to clamp and locate the primer, and easily disassembled and assembled design with double locating pins for locating is adopted, so that automatic clamping and locating of the primer are realized, the structure is simple, and maintenance is convenient. The primer double-way automatic conveying interface is simple in structure, convenient in maintenance, low in cost and high in automation degree.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

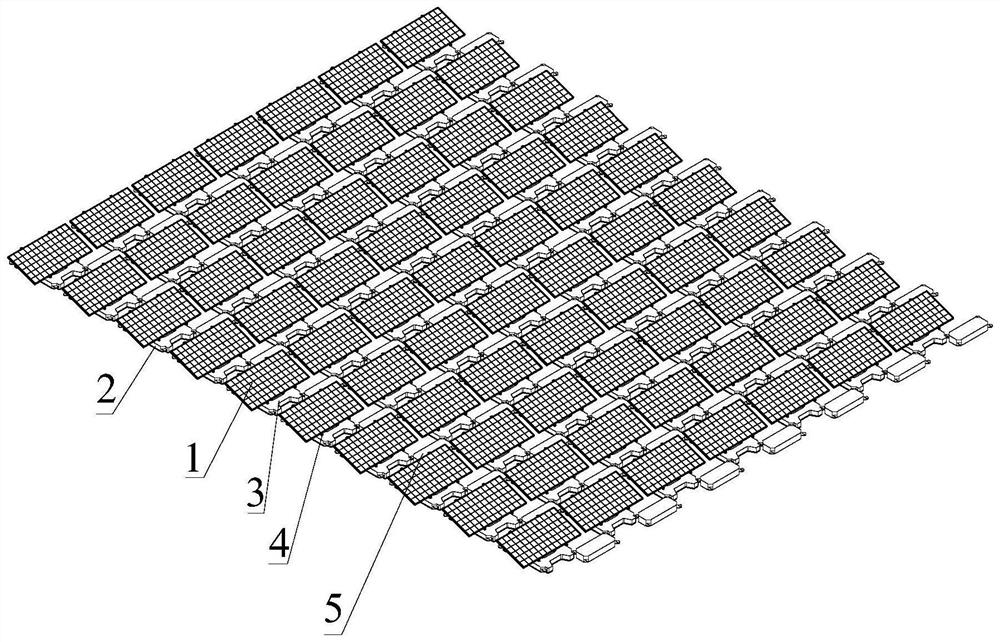

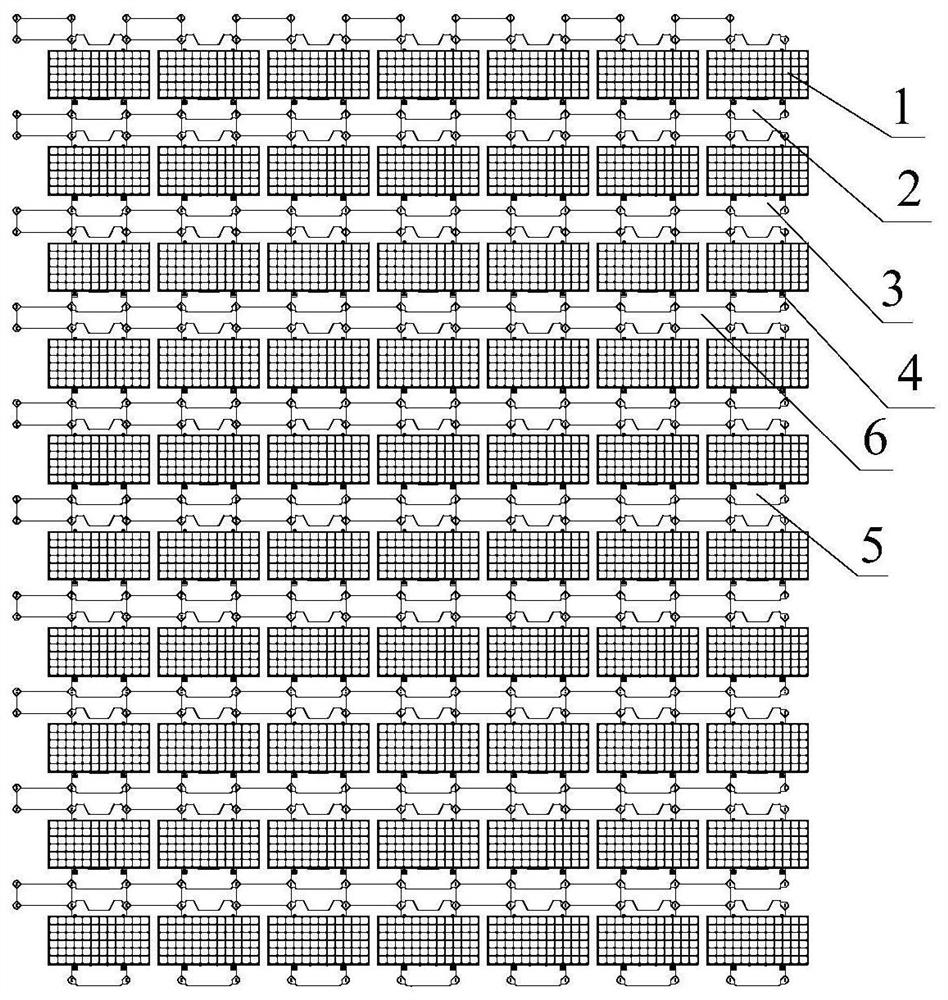

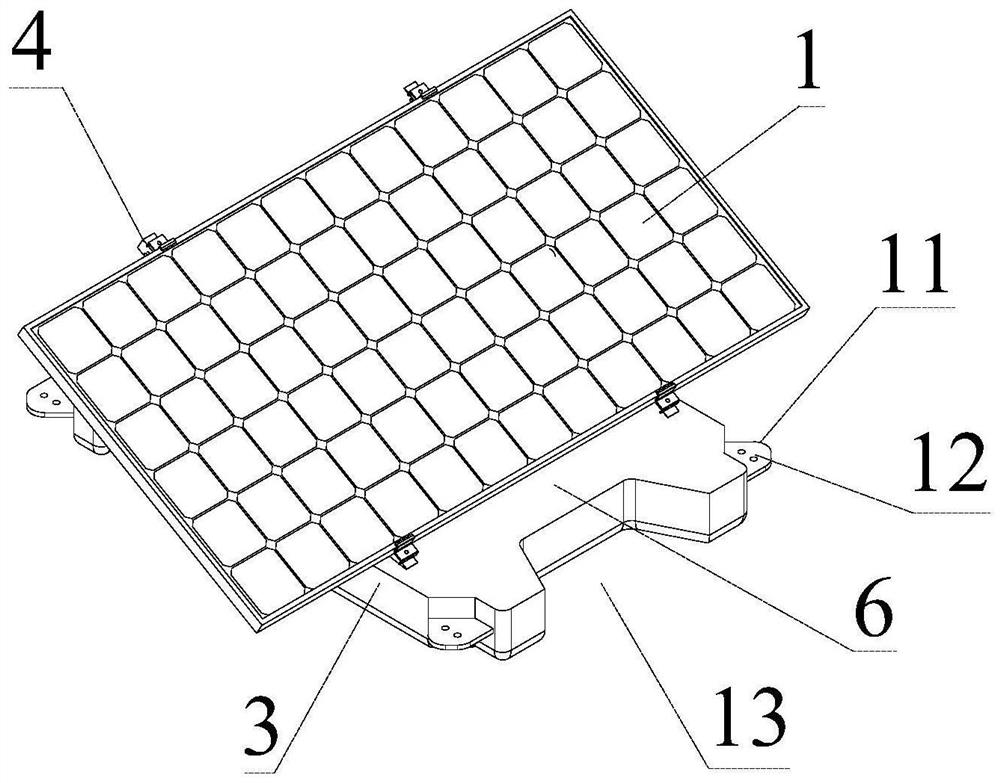

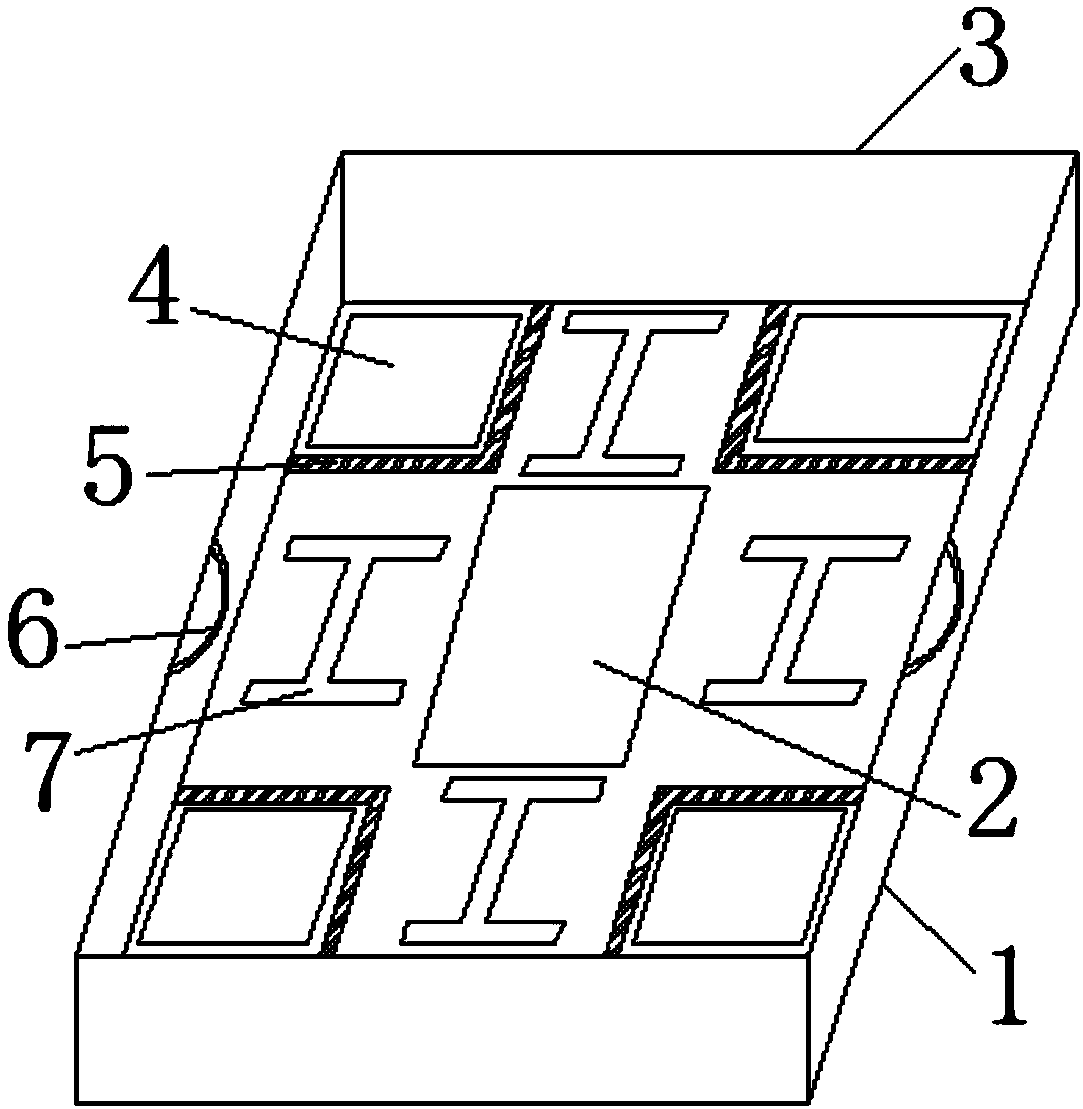

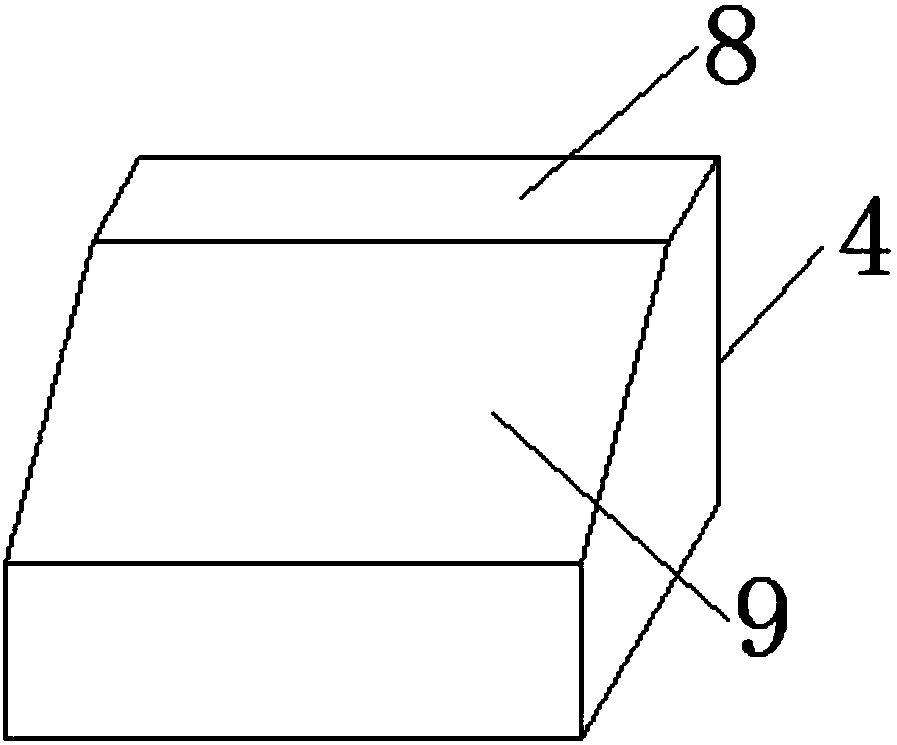

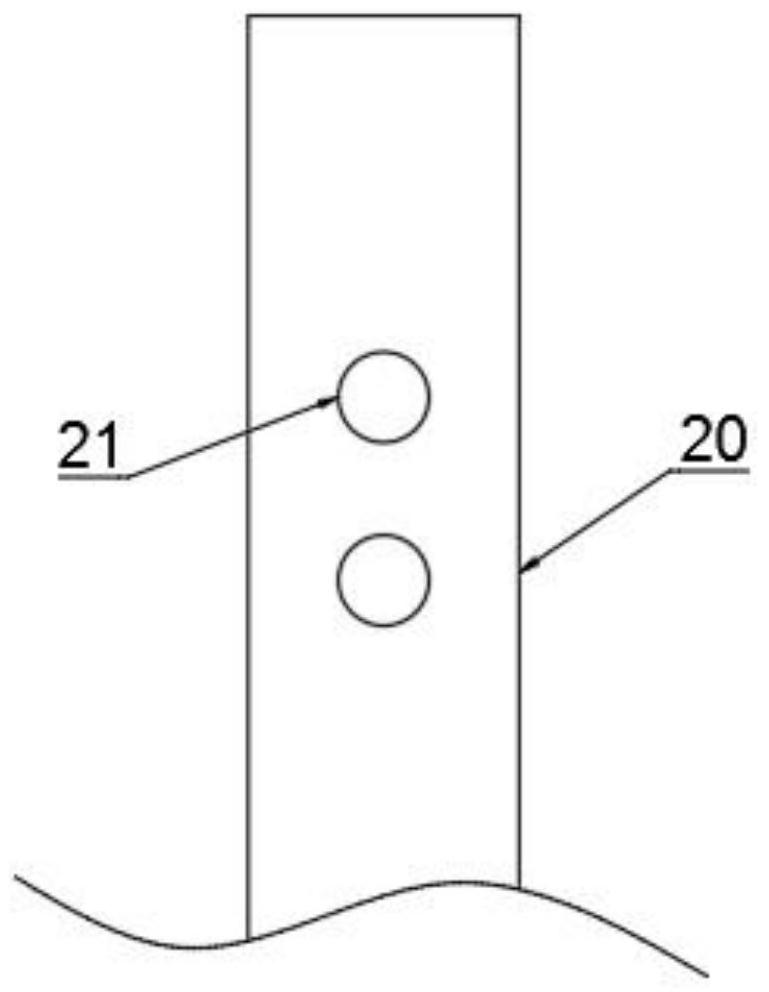

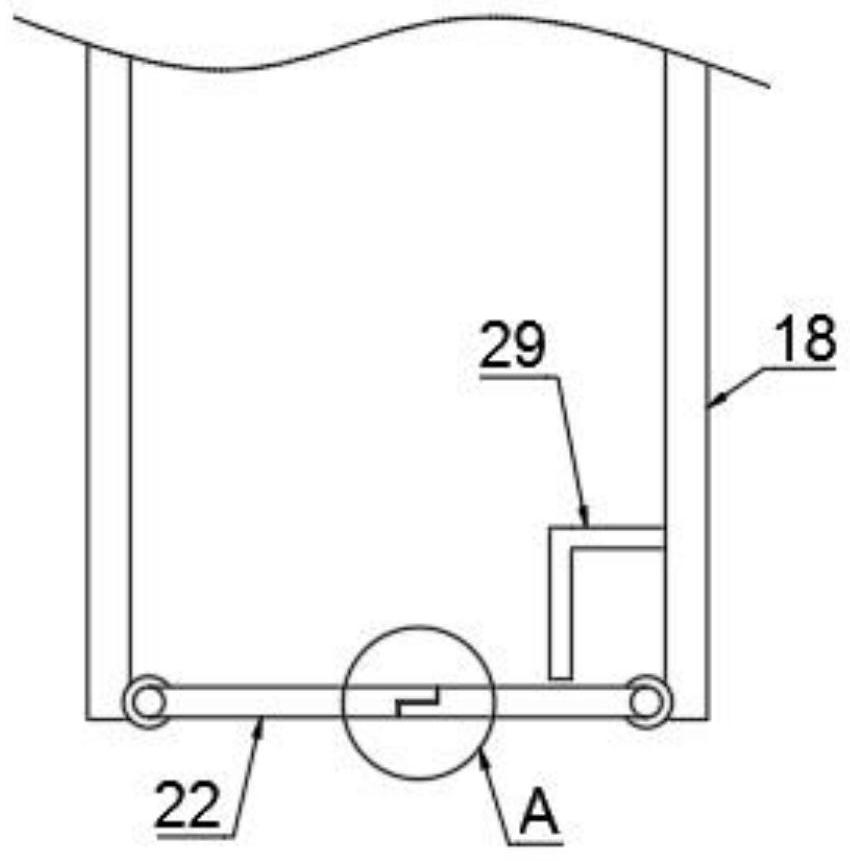

Ice-pushing upward-sliding snow-accumulation-preventing type water surface photovoltaic floating system suitable for alpine regions

PendingCN112550577ARealize automatic slidingAvoid loss of power generationWaterborne vesselsFloating buildingsSnowpackStructural engineering

The invention relates to the technical field of photovoltaic power generation, and discloses an ice-pushing upward-sliding snow-accumulation-preventing type water surface photovoltaic floating systemsuitable for alpine regions. The system comprises a photovoltaic module and a plurality of module floating body groups, each module floating body group comprises a plurality of module floating body units arranged side by side, and the photovoltaic module is mounted on the module floating body units through a bracket system. A plurality of channel floating bodies are arranged between every two adjacent rows of assembly floating body groups, each channel floating body is located in the center of the corresponding four adjacent assembly floating body units, and the four corners of each channel floating body are connected with the corners of the corresponding four adjacent assembly floating body units respectively. The two ends, facing the channel floating body, of each assembly floating bodyunit extend outwards to the outer side of the projection of the photovoltaic assembly to form aisles. The ice-pushing upward-sliding snow-accumulation-preventing type water surface photovoltaic floating system suitable for the alpine regions can achieve the functions of resisting freezing loads, preventing snow accumulation coverage and increasing the shadow distance between assemblies, and has the advantages of being simple in structure, easy to achieve, convenient to operate and maintain, safe and reliable.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +1

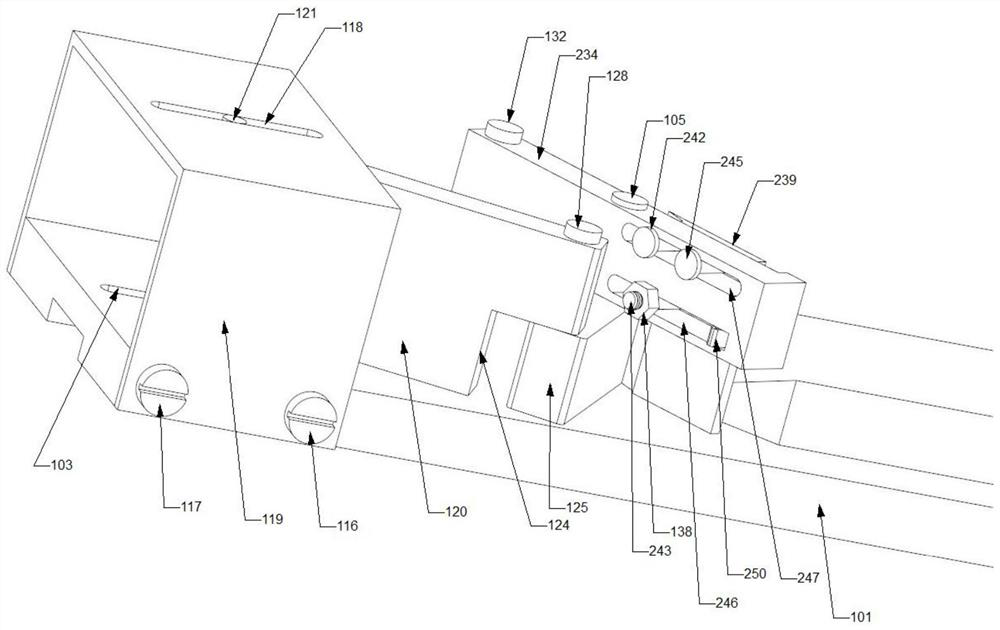

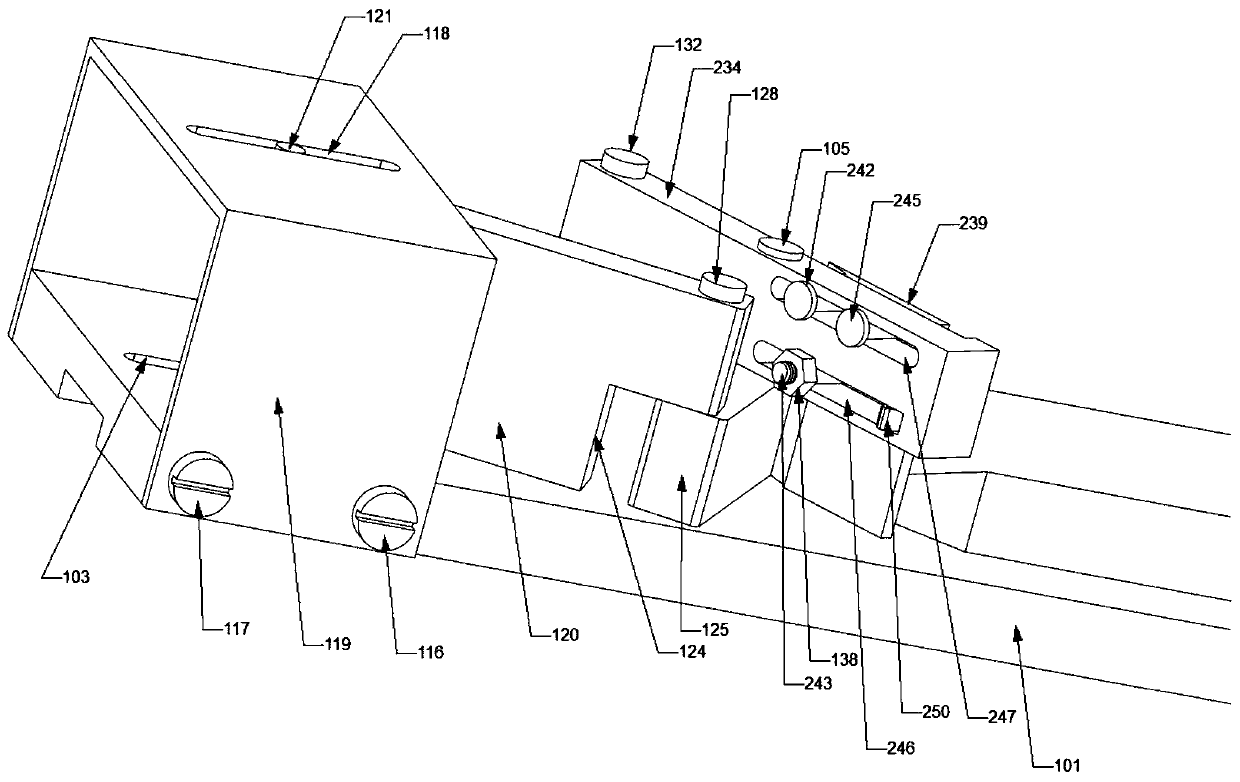

Processing device for two-way opening of supporting ring conveniently

InactiveCN108543977AReasonable structureFunctionalBoring/drilling componentsBoring/drilling machinesEngineeringDrill

The invention discloses a processing device for two-way opening of a supporting ring conveniently. The processing device comprises a supporting ring opening machine, a feed delivery pipe, a storage barrel and a feeding clamp. The supporting ring opening machine is of a rectangular frame body structure, electric drills are slidably connected to the surface of the supporting ring opening machine, the electric drills are fixedly connected to the end portions of electric push rods, the electric push rods are fixedly connected to side plates of the supporting ring opening machine, and limiting plates are fixedly connected to the plate surfaces of the supporting ring opening machine. The feed delivery pipe is arranged on the upper portion of the limiting plates, the feed delivery pipe penetratesthrough the supporting ring opening machine and the outer walls of base plates simultaneously and is fixedly connected to the bottom end of the storage barrel, the storage barrel is in lap joint withthe upper ends of the base plates, the base plates are fixedly connected to the top of the supporting ring opening machine, and a material leakage opening is formed in the bottom end of the storage barrel. The two electric drills are arranged on the supporting ring opening machine, the electric drills are matched with the electric push rods to penetrate through locating holes of the limiting plates to perform two-way opening on the supporting ring, the production efficiency is improved, and the labor capacity of workers is reduced.

Owner:郁霞

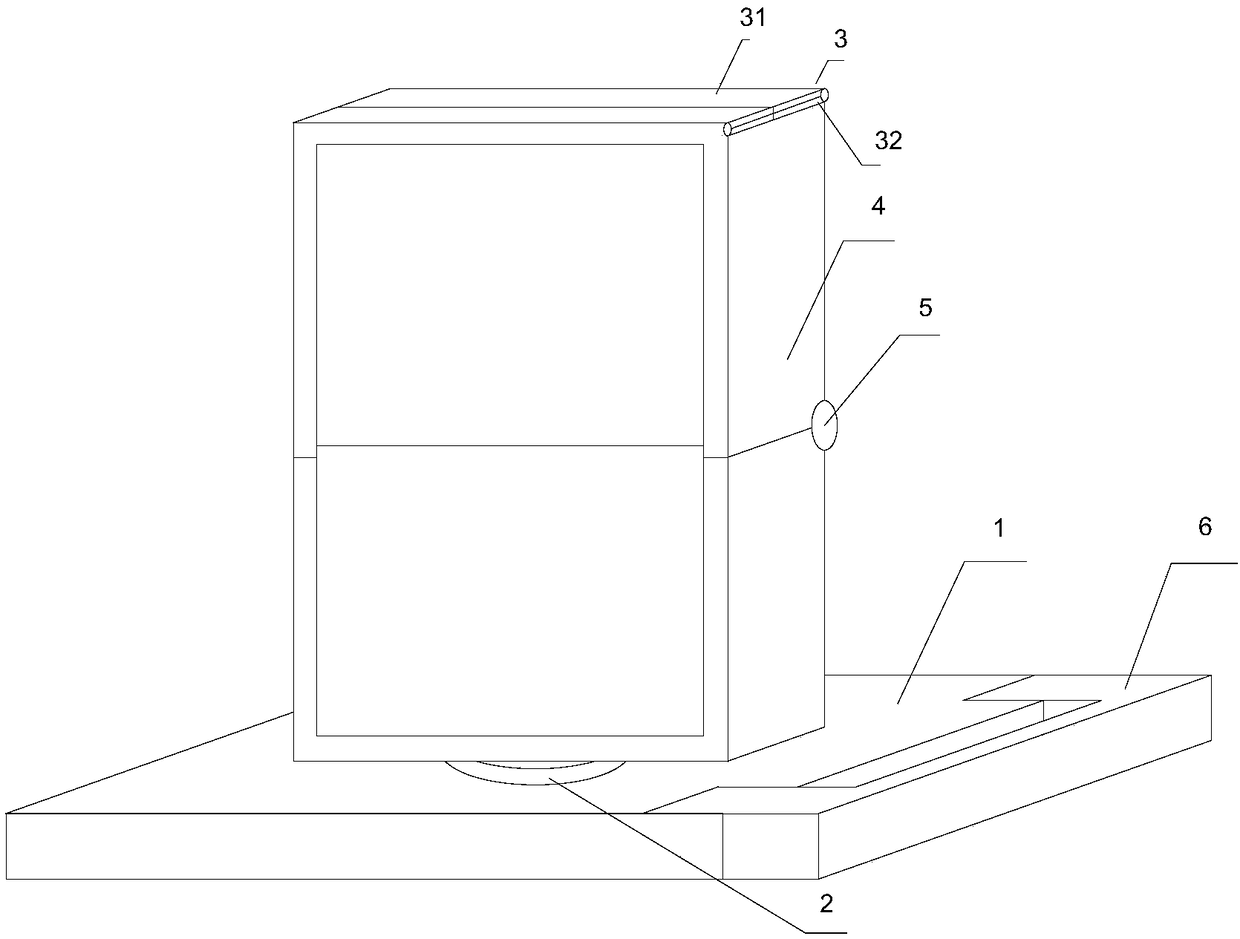

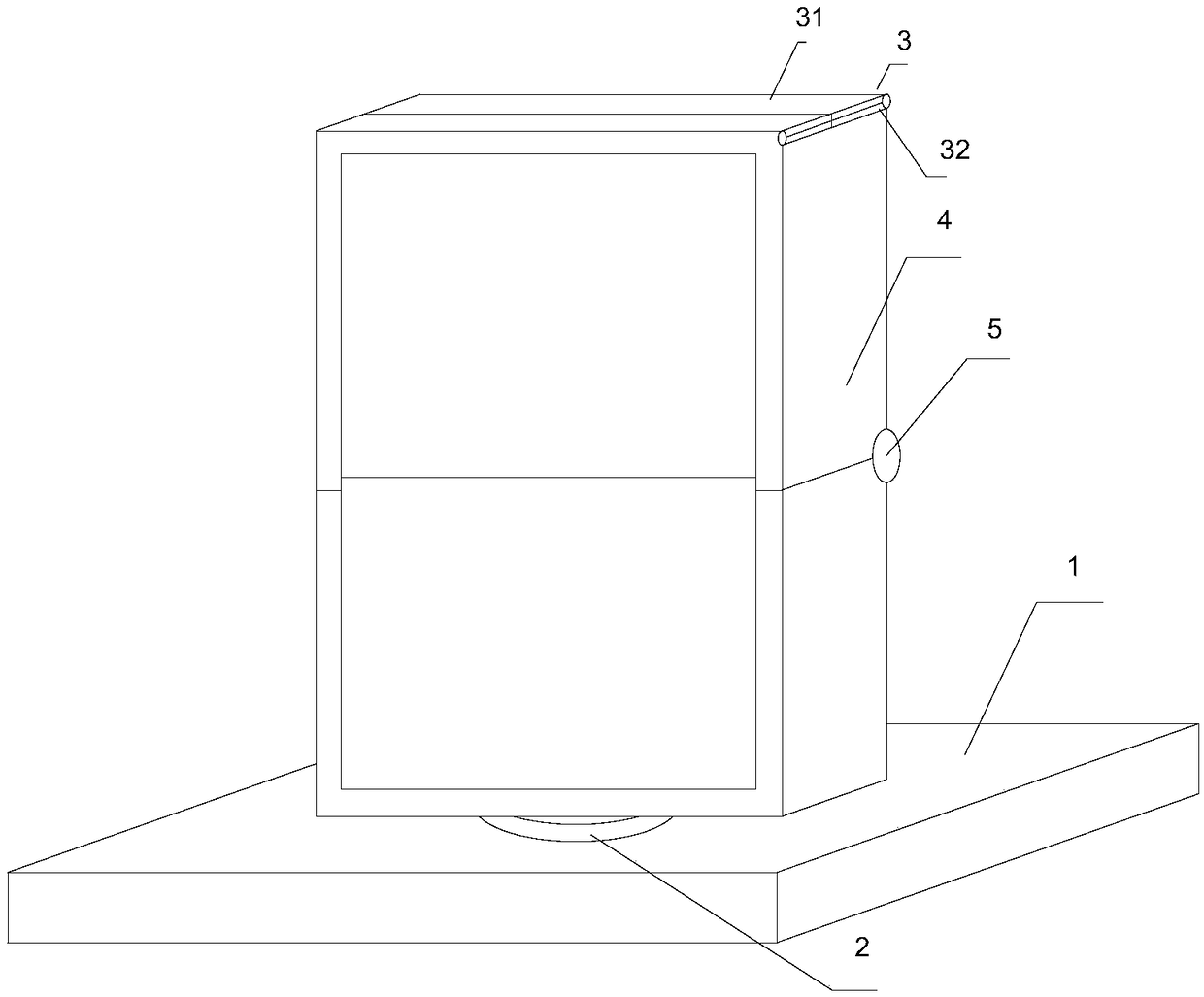

Efficient display rotating advertising board

The invention discloses an efficient display rotating advertising board. The advertising board is characterized in that pulleys are arranged below a base, a rotating bracket is arranged on a base, andan electronic advertising display board is arranged on the rotating bracket so as to be driven by the rotating bracket to rotate freely; an automatic rain shielding mechanism is arranged above the electronic advertising display board, and when raindrops are detected, the automatic rain shielding mechanism is opened to shield raindrops; the upper half portion of the electronic advertising displayboard and the lower half portion of the electronic advertising display board are connected through a rotating shaft, and the upper half portion of the electronic advertising display board can be rotated to the side face of the lower half portion of the electronic advertising display board through a rotating shaft; an operation handle is retracted into the base, one end of the operation handle canbe dragged out from the base, and the other end of the operation handle is fixed to the base. The advertising board overcomes the defect that an existing advertising board is fixed and cannot preventrain, and rotation of the advertising board and rain prevention are achieved.

Owner:安徽本质智能科技有限公司

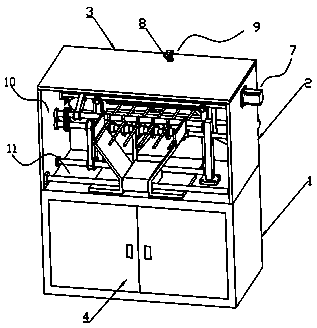

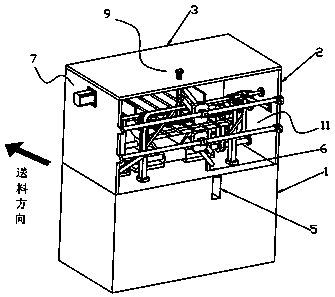

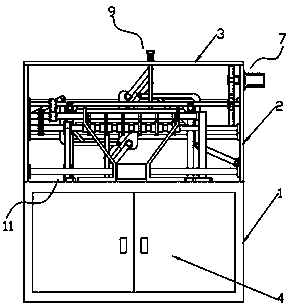

Carton component equipment

InactiveCN107914414ARealize automatic slidingImprove cleanlinessPaper-makingBox making operationsScrapClean environment

The invention discloses a carton component device, comprising a base and a support frame, the support frame is located above the base and is fixedly connected, a main support table, a cutting table and an I-shaped push plate are arranged above the base, the cutting table The platform and the I-shaped push plate are all located around the main supporting platform, and the ejector rod is arranged above the support frame, and the ejector rod is located inside the ejector rod placement groove on the surface of the support frame, and an air pump is arranged below the ejector rod, and the air pump The output end of the briquetting block is fixedly connected to the briquetting block, an L-shaped cutting knife is provided on the surface of the briquetting block, and a universal wheel is provided under the base. The present invention is novel in design, simple in structure, convenient in operation and high in production efficiency, thereby filling the vacancy in the market, meeting the demand of the market, obtaining more profits, and performing precise cutting and reasonable folding on the cardboard to be processed into cartons, and at the same time Realize the automatic sliding of the corner material after cutting, which is convenient for centralized processing after cleaning and keeps the environment tidy.

Owner:WUXI ZHONGHUAN PACKAGING

Anti-blocking municipal sewage treatment pipeline

PendingCN112479446AAvoid blockingPrevent outflowSpecific water treatment objectivesTreatment involving filtrationMunicipal sewageMechanical engineering

The invention discloses an anti-blocking municipal sewage treatment pipeline, which comprises a pipe body and an external power source, wherein the two ends of the pipe body are provided with a feeding end and a discharging end correspondingly, valves are installed at the feeding end and the discharging end correspondingly, a filter screen is fixedly connected to the inner wall of the pipe body, alimiting plate located on the outer side of the filter screen is further fixed to the inner wall of the pipe body, a floating plate is slidably arranged between the filter screen and the limiting plate, a telescopic spring is fixedly connected between the floating plate and the inner top wall of the pipe body, a pressing rod penetrating through the pipe body and extending out of the pipe body isfixedly connected to the upper side wall of the floating plate, and a mounting plate is fixedly connected to the outer wall of the pipe body. When the filter screen in the pipeline is blocked, hydrogen and oxygen are generated through electrolysis of water, the hydrogen and the oxygen are ignited through an electronic igniter, explosion is generated to impact the filter screen, impurities in meshes of the filter screen are flushed out, cleaning of the filter screen is achieved, and the situation that sewage treatment work is affected due to blockage of the filter screen is avoided.

Owner:彭广山

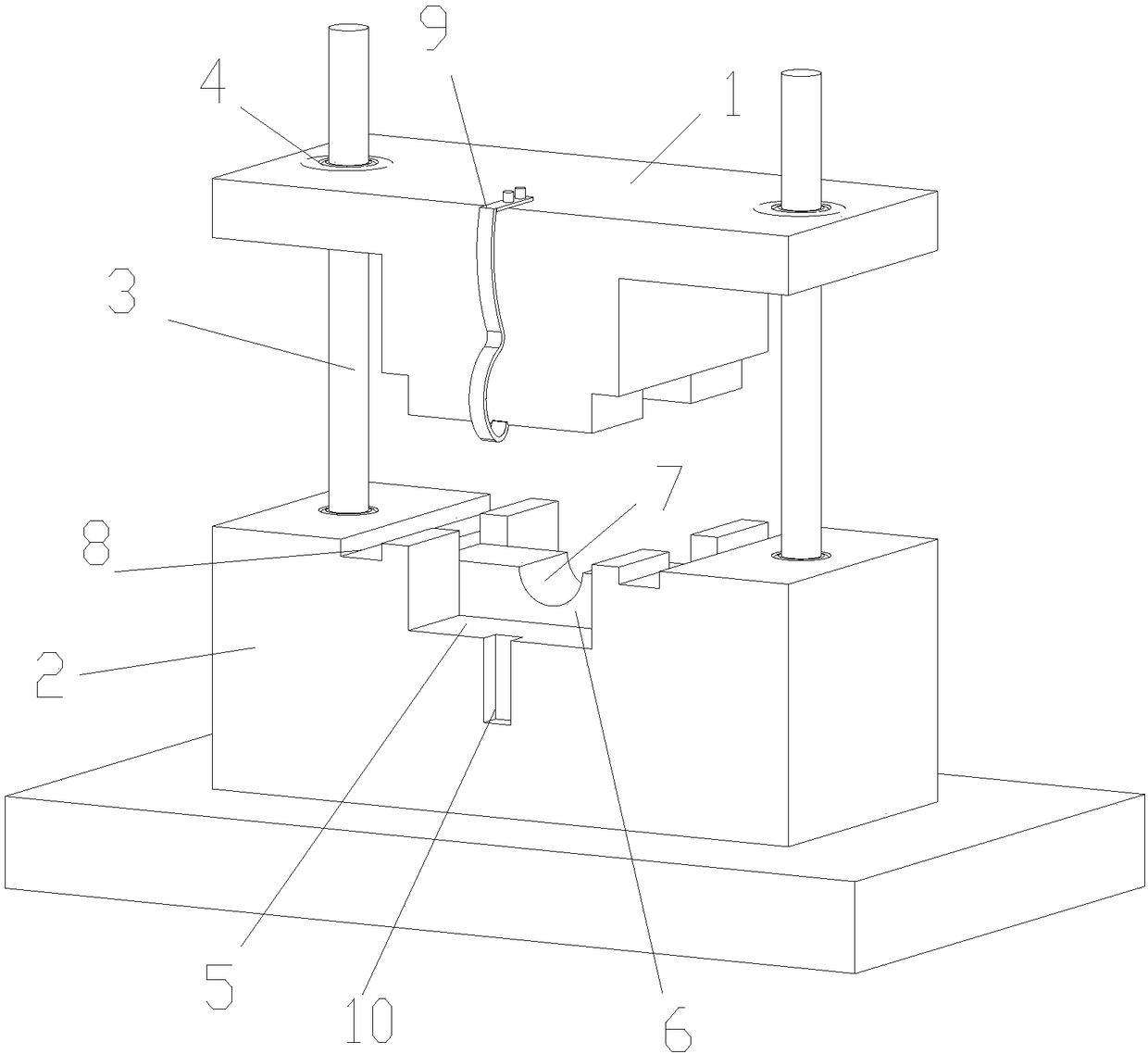

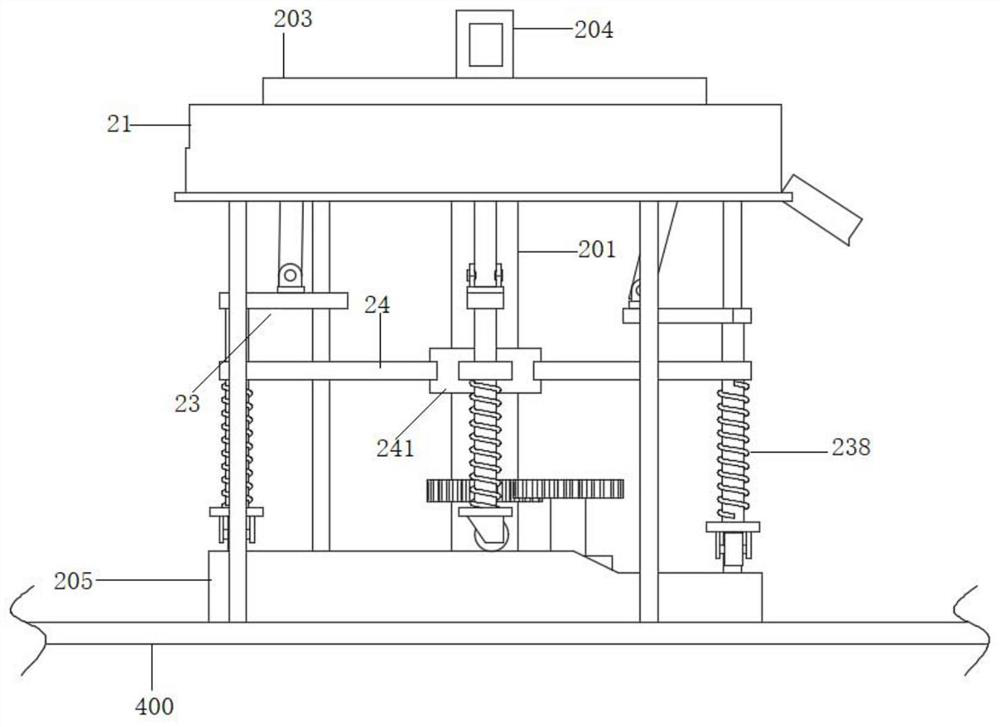

Stamping die with automatic material lifting function

InactiveCN108188279AReduce labor workloadIncrease productivityShaping toolsStripping-off devicesEngineeringHook plate

The invention discloses a stamping die with an automatic material lifting function. The stamping die comprises an upper die body, a lower die body and a guiding column. A mounting hole is formed in the lower die body and internally provided with a guiding column for lifting guiding of the upper die body, and a guiding sleeve matched with the guiding column is arranged on the upper die body. The upper die body is matched with the guiding column through the guiding sleeve, a machining area for stamping forming is arranged on the lower die body and penetrates in the width direction of the lower die body, and a protruding positioning block is arranged in the center of the machining area. A circular-arc-shaped positioning groove is formed in the positioning block, and grooves for positioning the upper die body are further formed in the end faces of the two sides in the length direction of the machining area. An arc-shaped hook plate for material lifting is further arranged on the upper diebody and fixed to the end face of one side of the upper die body, and the lower end of the arc-shaped hook plate is a hooking-up end. The hooking-up end is lower than the bottom face of the upper diebody, an arc-shaped area with the function of recovering deformation towards the die is arranged on the arc-shaped hook plate, and the hooking-up end is a circular arc upwards bending towards the die.A straight groove matched with the arc-shaped hook plate is formed in the side face of the lower die body and leads to the bottom face in the machining area.

Owner:SUZHOU RIPU MOLD CO LTD

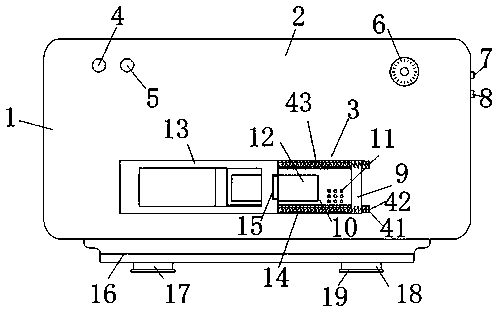

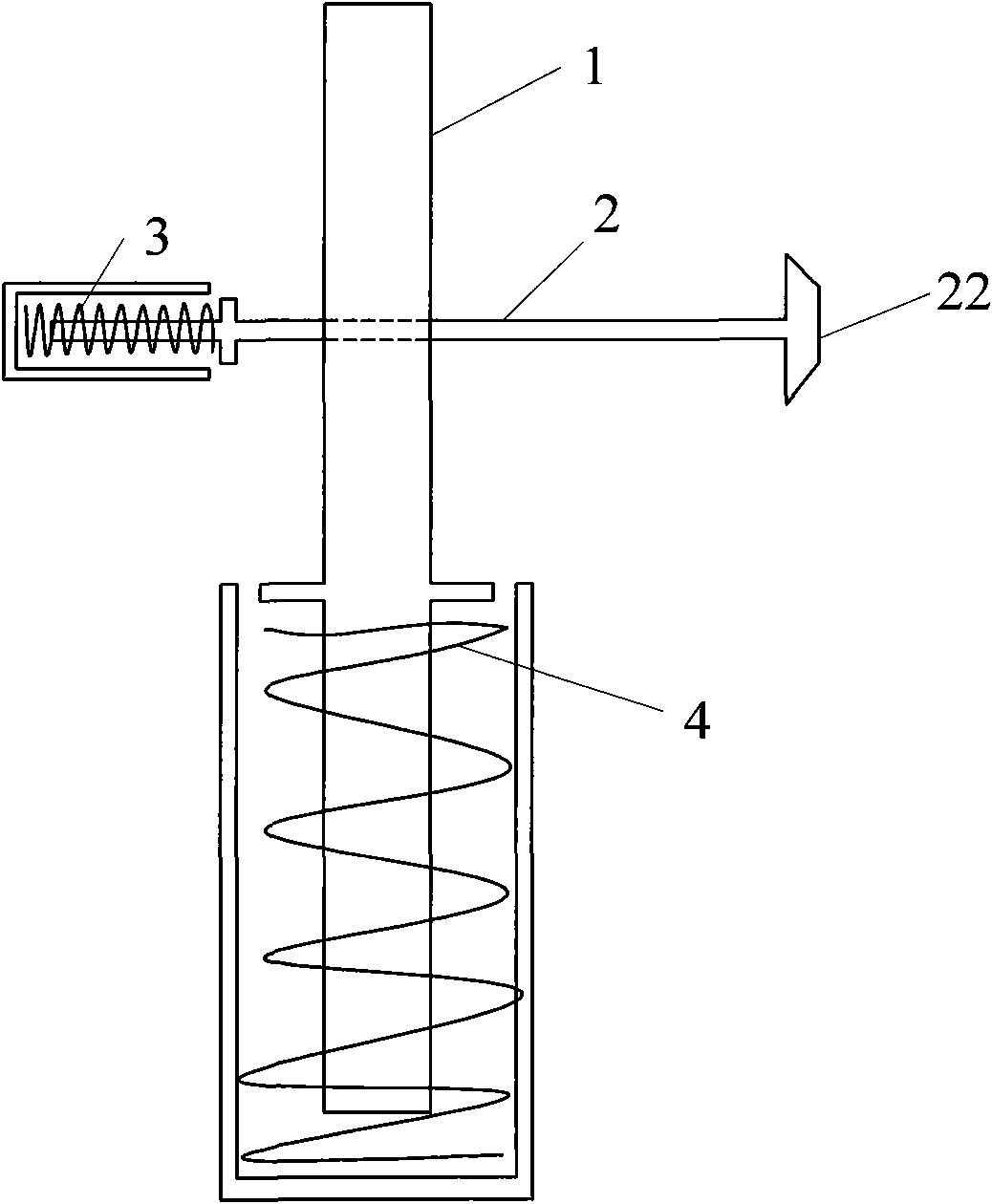

Water heater control system and method

InactiveCN109000376ADoes not affect the efficacy of the phenomenonRealize automatic slidingFluid heatersEngineeringElectromagnetic valve

The invention discloses a water heater control system. The water heater control system comprises a water heater body, and the water heater body comprises a water tank and a control device arranged inthe middle of the front end face of the water tank; a heating indicator light and a heat preservation indicator light are arranged on the upper left portion of the front end face of the water tank, awater level sensor and a temperature sensor are installed on the upper portion of the right end of the water tank, and a base is installed at the bottom of the water tank; a hot water outlet and a cold water inlet are symmetrically installed on the left side and the right side of the bottom of the base, and the hot water outlet and the cold water inlet are each provided with an electromagnetic valve; and the control device comprises a substrate fixedly connected with the water tank, an operation panel is arranged on the front end face of the substrate, control buttons and a display screen arearranged on the front end face of the operation panel, sliding grooves which extend left and right are symmetrically formed in the upper side and the lower side of the front end face of the substrate,and a protective cover capable of sliding left and right is arranged at the front end of the operation panel. According to the device, running is safe and stable, operation is convenient and fast, the aesthetics of a water heater can not be influenced, and the water heater is convenient to use.

Owner:天津七盛新能源科技有限公司

Special dust removing apparatus for ceramic production

InactiveCN108187426AEasy to moveRealize card position fixationUsing liquid separation agentSeparation devicesFiltrationSpray nozzle

The invention relates to the technical field of ceramic production, particularly to a special dust removing apparatus for ceramic production. The special dust removing apparatus comprises a box shell,wherein water boxes are respectively arranged on the left side surface and the right side surface of the box shell and at positions close to the top end, a water box connection pipe is connected between the two water boxes, and is connected to two spraying pipes, each spraying pipe is provided with a plurality of spraying nozzles, the box shell is hollow, and a first inclination plate is fixedlyarranged below the spraying pipe inside the hollow box shell. According to the present invention, the water box connection pipe is connected between the two water boxes on the box shell of the specialdust removing apparatus, the two sections of the connection soft pipes are arranged on the water box connection pipe, and each connection soft pipe is connected to the spraying pipe so as to achievethe movement between the spraying pipes, such that the surfaces of different sizes of the ceramic billets can be subjected to spraying an dust removing; and the filtration cavity and the precipitationcavity are arranged inside the box shell, such that the water mixed with dust can be filtered, and the filtered residue can be collected so as to provide strong practicability.

Owner:FOSHAN OUGE CERAMIC CO LTD

Cellphone with sliding cover

InactiveCN102469179ARealize automatic slidingEasy to openSupport structure mountingTelephone set constructionsEngineering

Owner:SIMCOM WIRELESS SOLUTIONS SHANGHAI

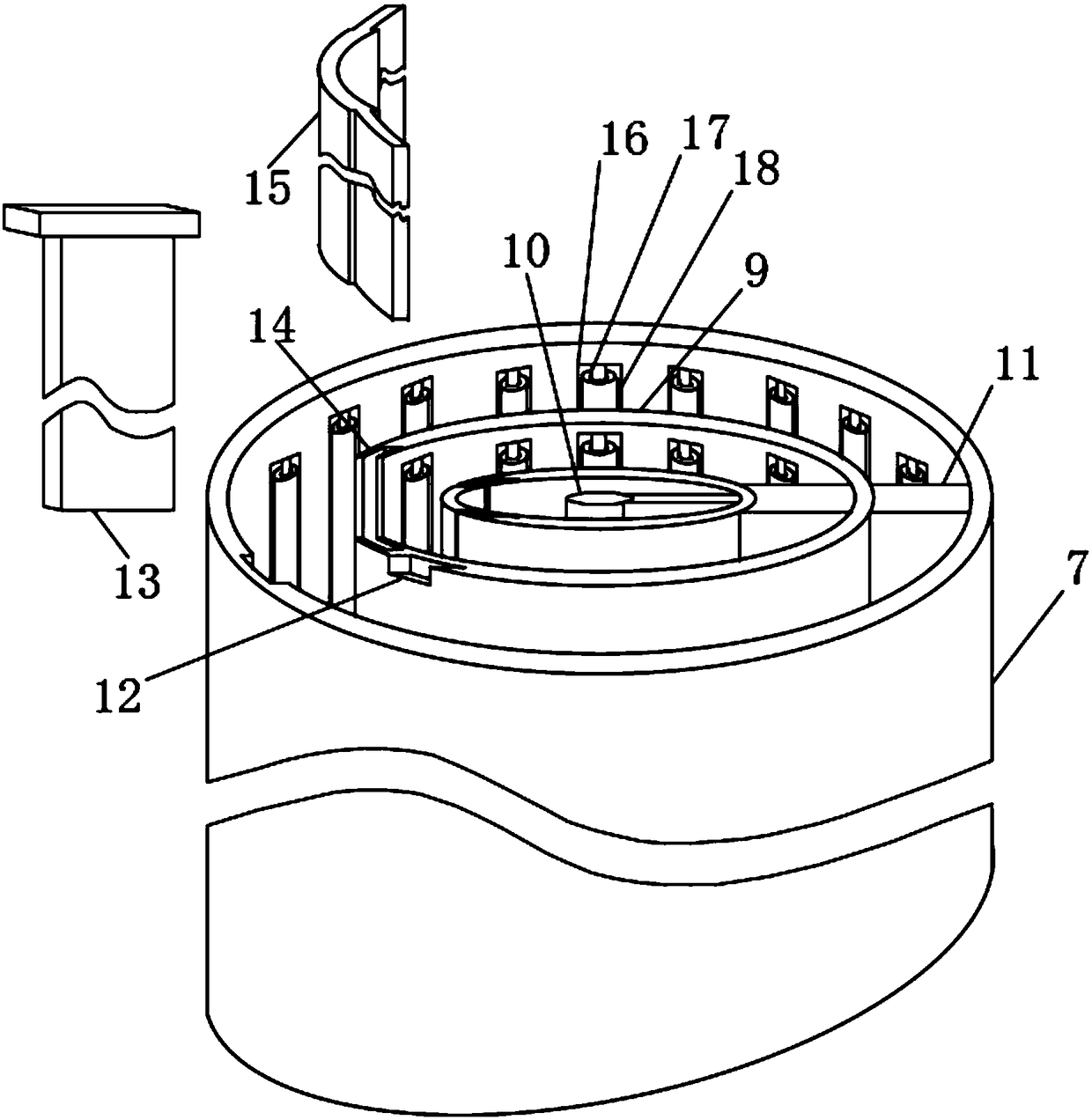

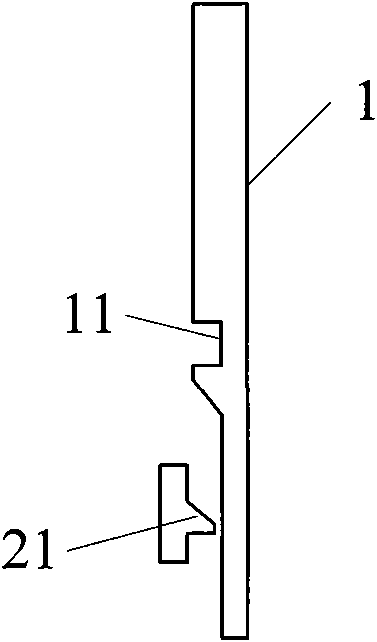

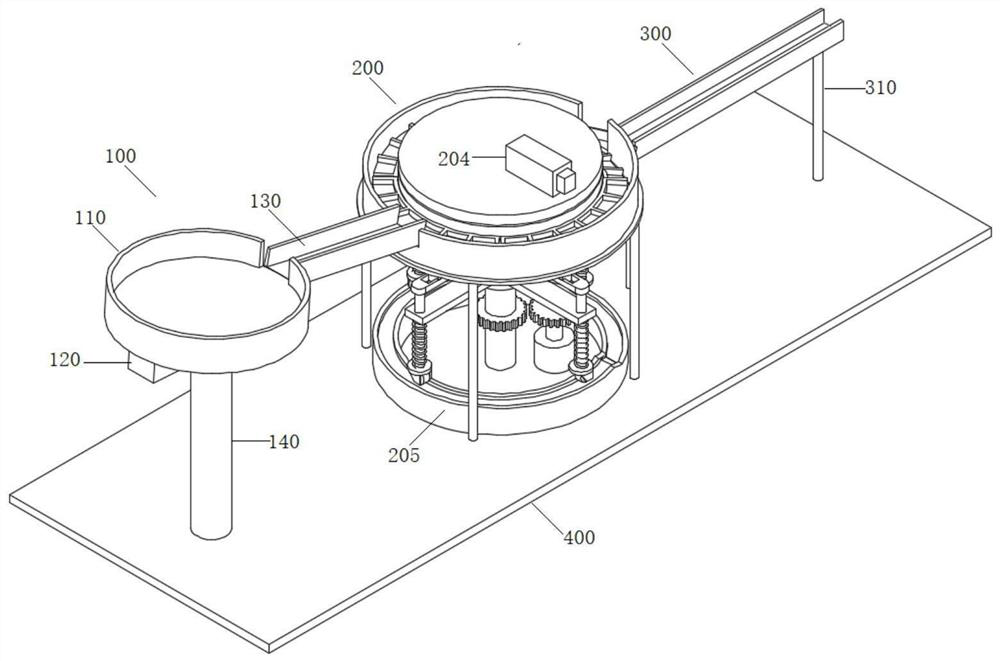

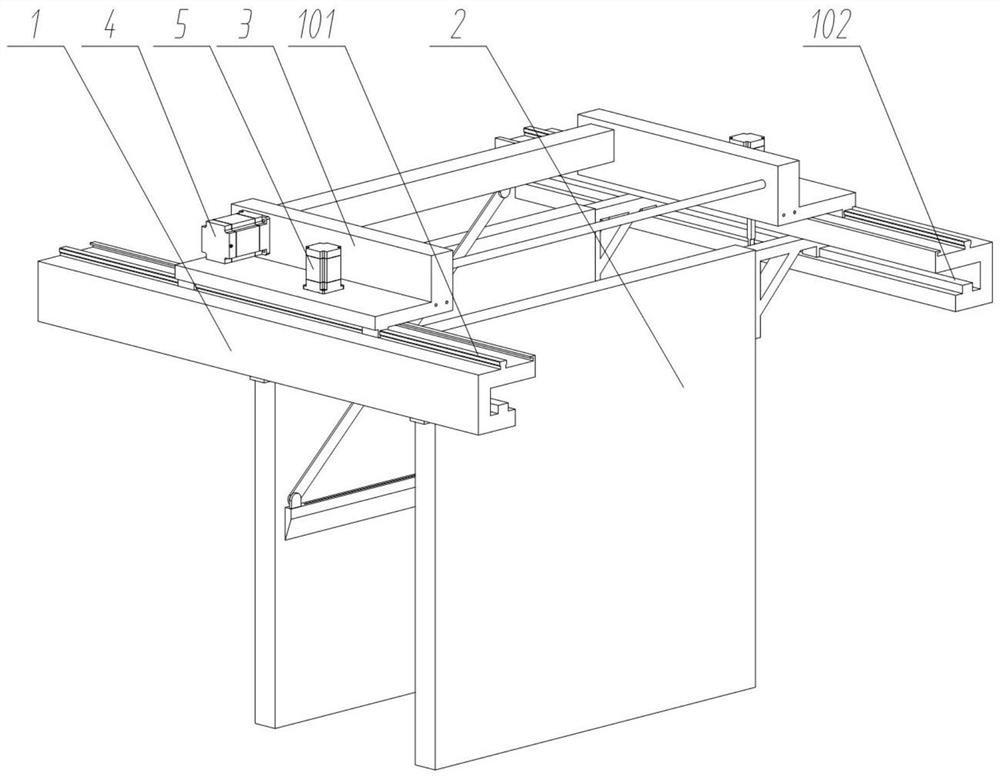

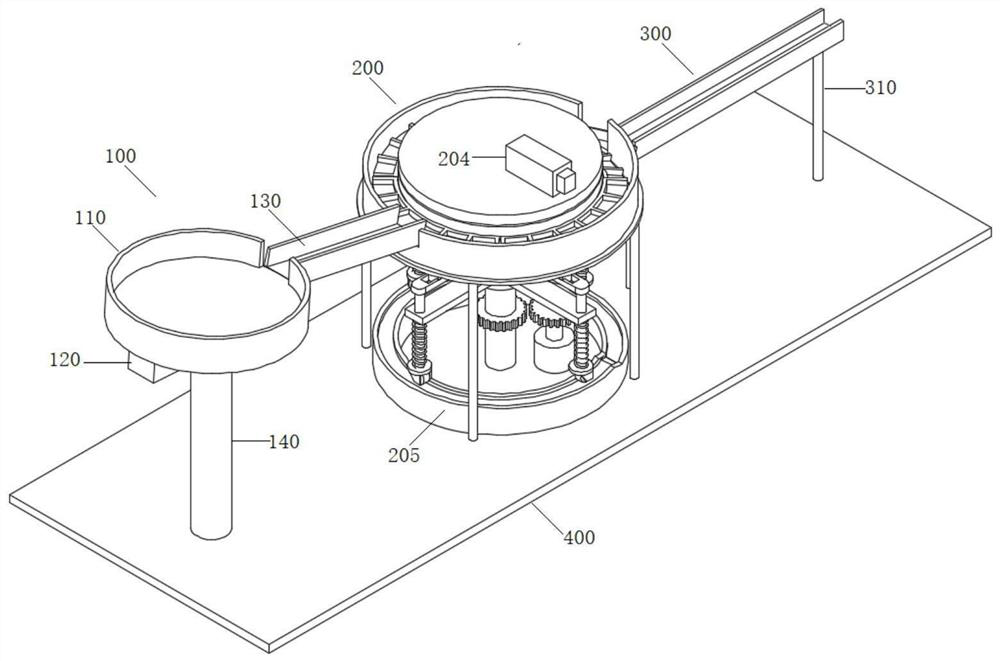

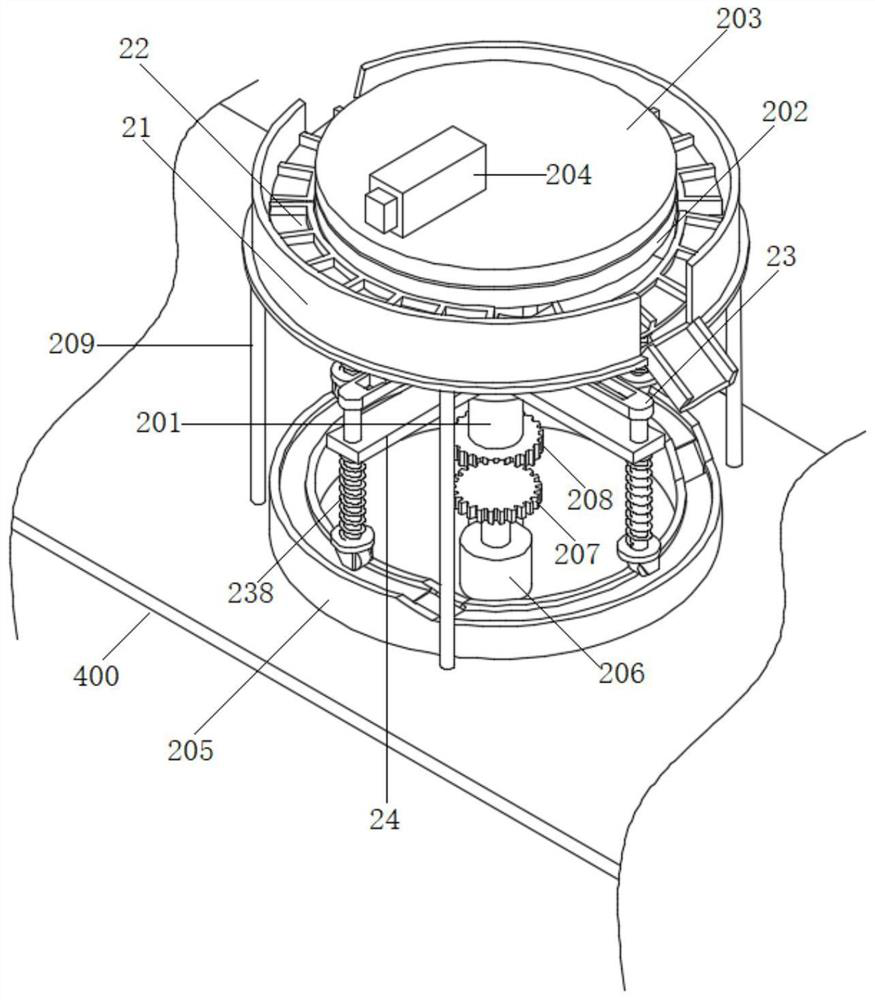

Automatic feeding and conveying mechanism based on medicine bottle printing

ActiveCN113428583AImprove printing efficiencyRealize automatic slidingTypewritersJigging conveyorsEngineeringPrinting press

The invention discloses an automatic feeding and conveying mechanism based on medicine bottle printing, and belongs to the technical field of medicine bottle processing. The automatic feeding and conveying mechanism based on medicine bottle printing comprises a base, and a vibrating device, a distributing device and a conveying device are fixedly connected to the base in sequence. The distributing device comprises a rotating shaft, a rotating disc is fixedly connected to the upper end of the rotating shaft, a fixing table is connected to the upper portion of the rotating disc, a printing mechanism is fixedly installed on the fixing table, a plurality of distributing plates are evenly and rotationally connected to the lower surface of the rotating disc in the radial direction, and lifting mechanisms are fixedly connected to the lower surfaces of the distributing plates. The distributing device further comprises an annular rail, and the lower end of the lifting mechanism is fixedly connected with a roller matched with the annular rail in a sliding mode. According to the automatic feeding and conveying mechanism based on medicine bottle printing, medicine bottles are conveyed into the distributing device in a vibrating mode through the vibrating device, a servo motor drives the rotating disc to rotate, the printing mechanism conducts code spraying and printing on the medicine bottles, finally the medicine bottles are transferred into the conveying device and conveyed to the next station through the conveying device, and therefore the overall efficiency of medicine bottle printing is improved.

Owner:安徽仁济印务有限公司

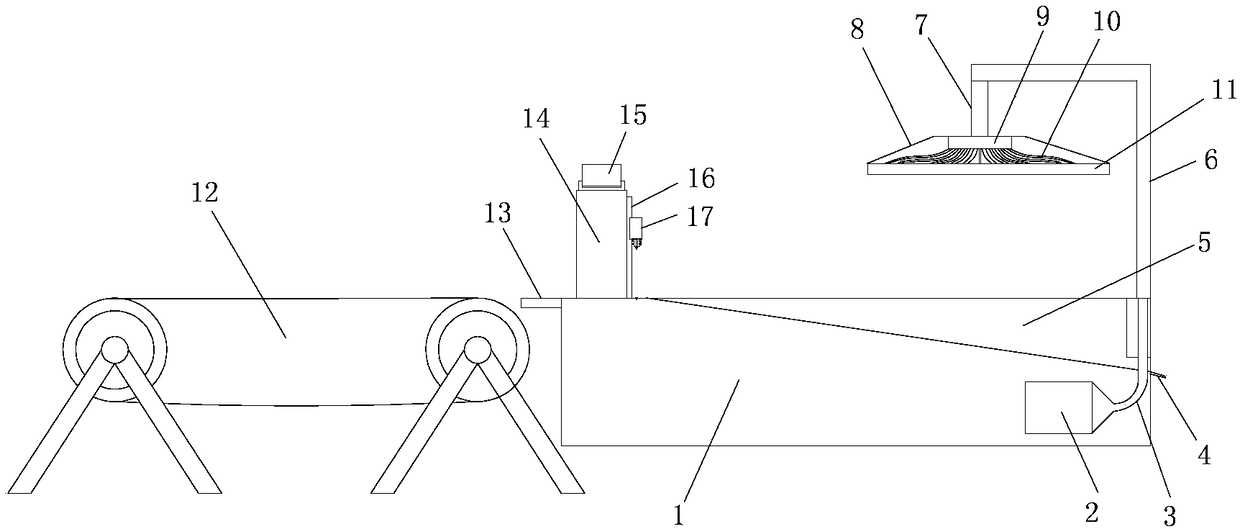

Backlight source die-cutting discharge automatic cutting device

InactiveCN109304745ARealize automatic transmissionRealize automatic slidingMetal working apparatusOptical ModuleConveyor belt

The invention discloses a backlight source die-cutting discharge automatic cutting device. The backlight source die-cutting discharge automatic cutting device comprises a workbench and a conveyor belt, wherein the conveyor belt is arranged at one end of the workbench. The backlight source die-cutting discharge automatic cutting device is characterized in that the workbench is of a cuboid structure, a supporting column is welded at the top of one end, close to the conveyor belt, of the workbench, the bottom of a connecting block is provided with a second sliding rail, the top of one clamping plate is welded on the second sliding rail, the top of the other clamping plate is in sliding connection with the second sliding rail, a cutting knife is fixed between the two clamping plates, the sideface of the workbench is fixedly provided with an air suction fan, the air suction end of the air suction fan is connected with a pipeline, an L-shaped supporting rod is welded to one side, away fromthe supporting column, of the workbench, a connecting rod is welded to the tail end of the L-shaped supporting rod, the lower end of the connecting rod is fixedly provided with an air suction disc, and the air suction disc is of a circular truncated cone-shaped structure. According to the backlight source die-cutting discharge automatic cutting device, through the design of the air suction disc, dust above the workbench can be absorbed, and the influence of the dust on an optical module of the workbench is prevented.

Owner:YANCHENG SANDING ELECTRONICS TECH CO LTD

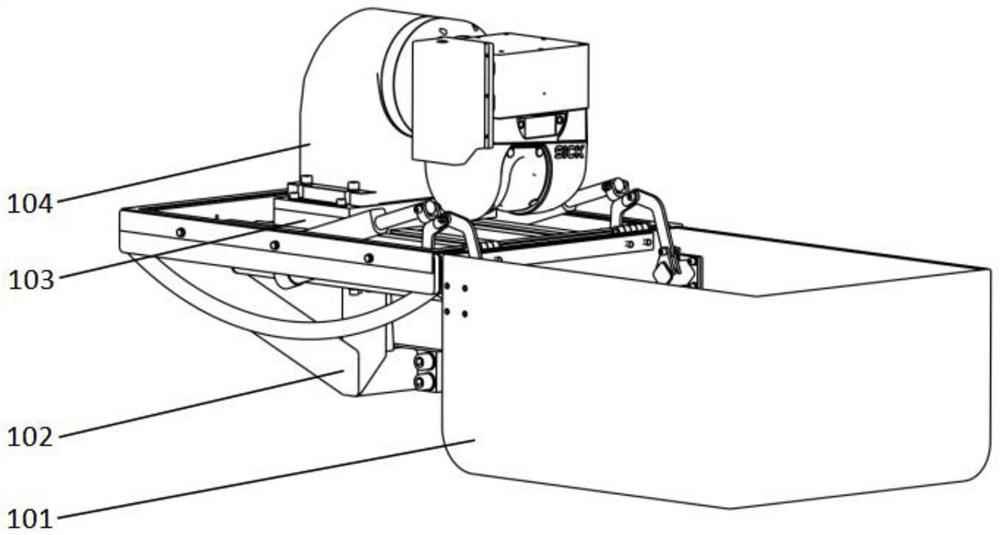

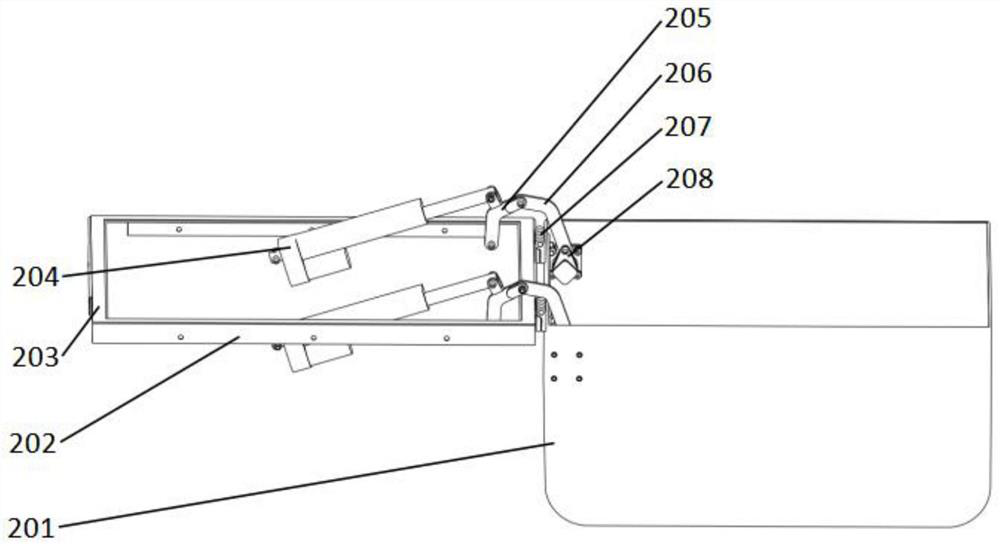

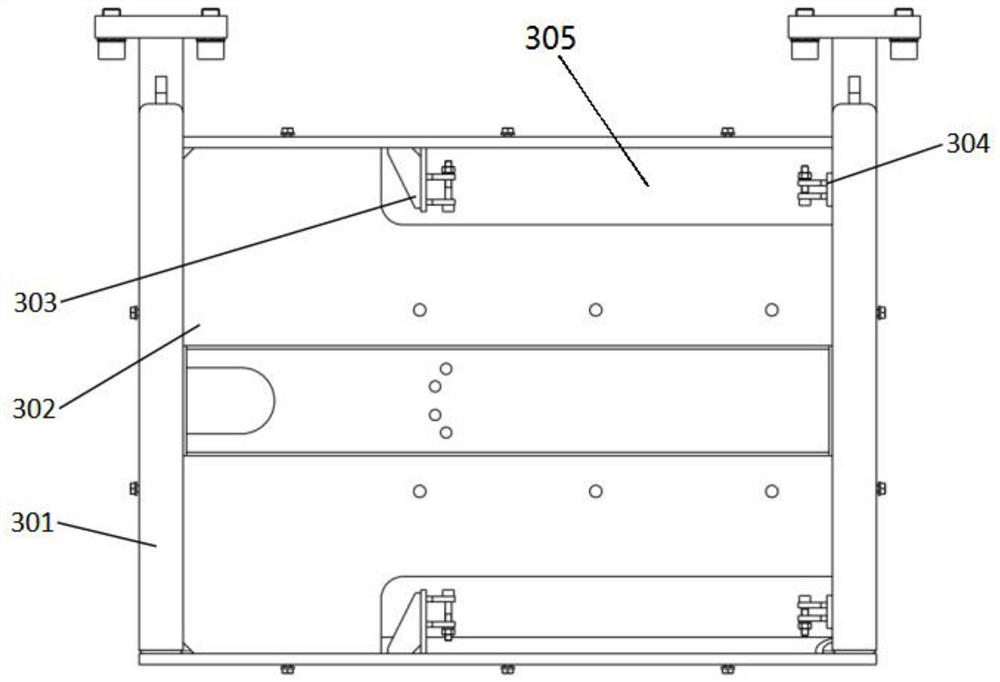

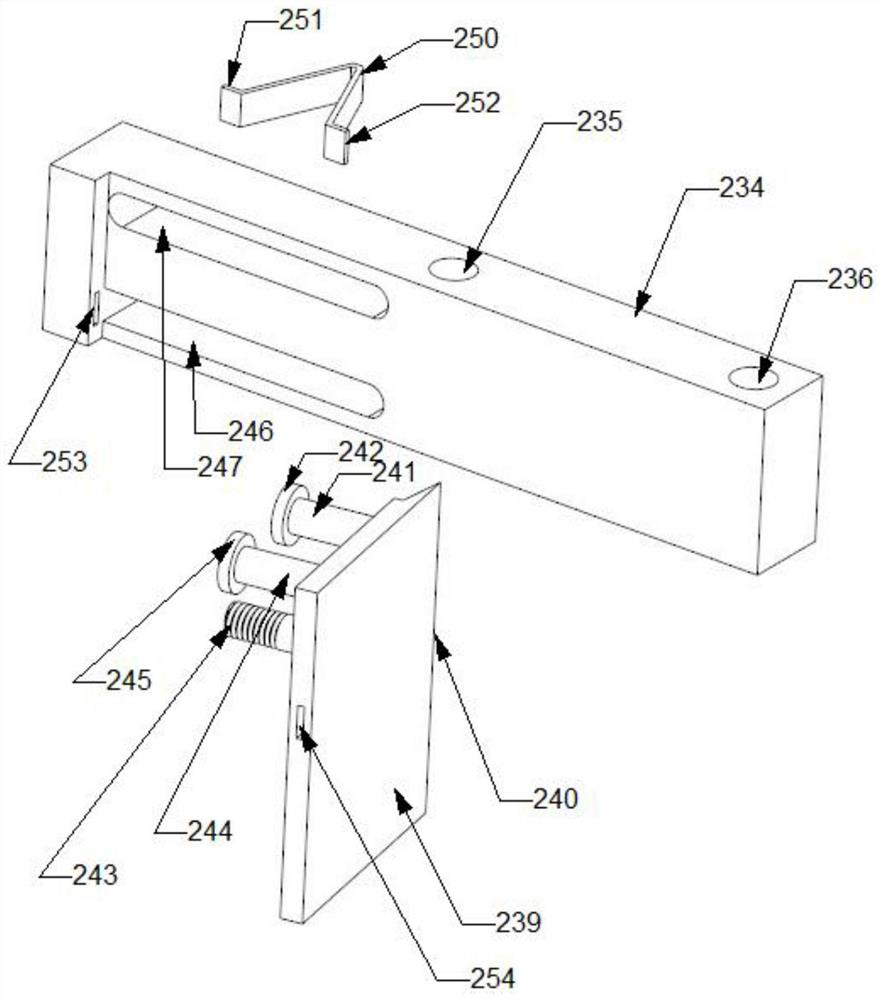

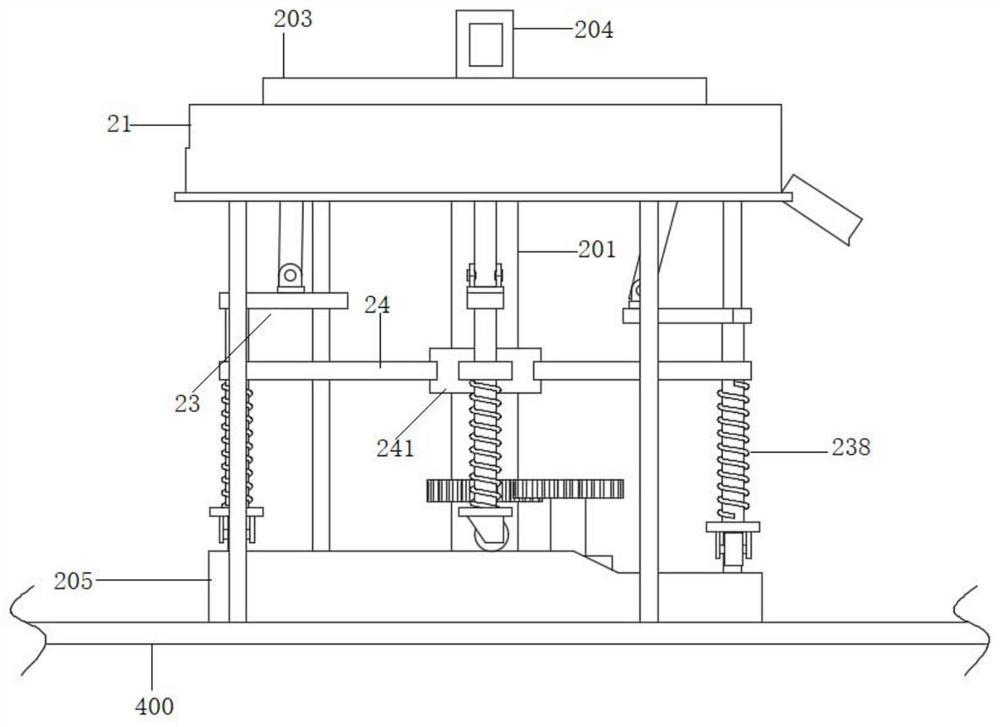

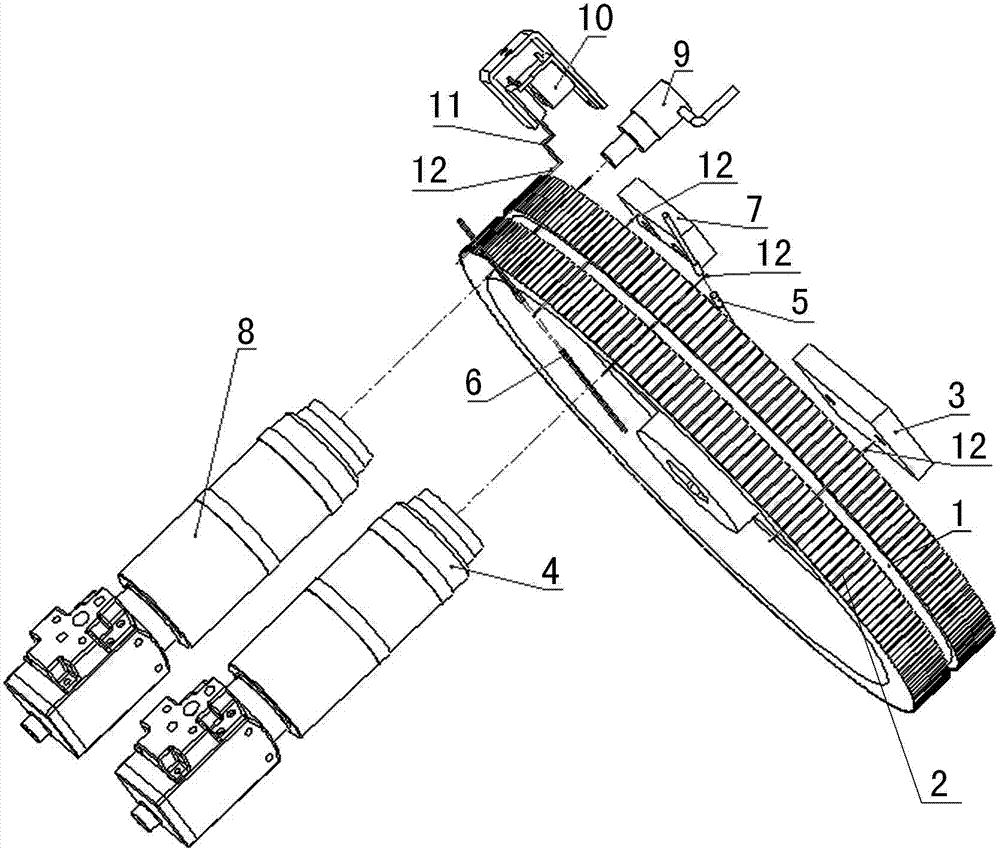

Movable scanner working device, concrete wet spraying machine and control method

PendingCN114856638ACompact structureImplement automatic expansionMining devicesUnderground chambersScannerStructural engineering

The invention provides a movable scanner working device. The movable scanner working device comprises a housing assembly, a support assembly, a driving assembly and a scanner. The scanner is arranged on the support assembly in a sliding mode through the driving assembly. The housing assembly is arranged on the support assembly and used for protecting the scanner, and the housing assembly comprises an open state and a closed state. According to the scanner working device, the protective cover is automatically opened and closed by turning over the driving part, the scanner is driven by the driving assembly to extend out of the vehicle body, automatic working of the working device can be achieved, and automatic positioning of a concrete wet spraying machine and tunnel contour scanning are achieved. The invention further provides the concrete wet spraying machine and a control method for automatic positioning and tunnel contour scanning of the concrete wet spraying machine.

Owner:CHINA RAILWAY CONSTR HEAVY IND

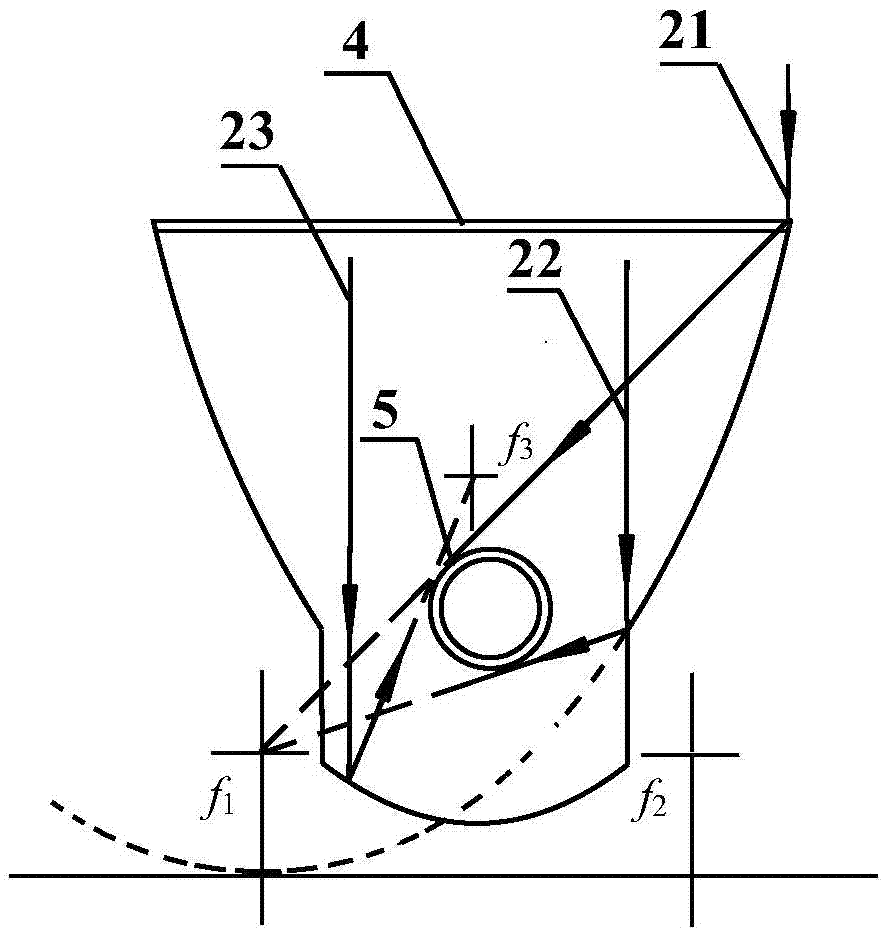

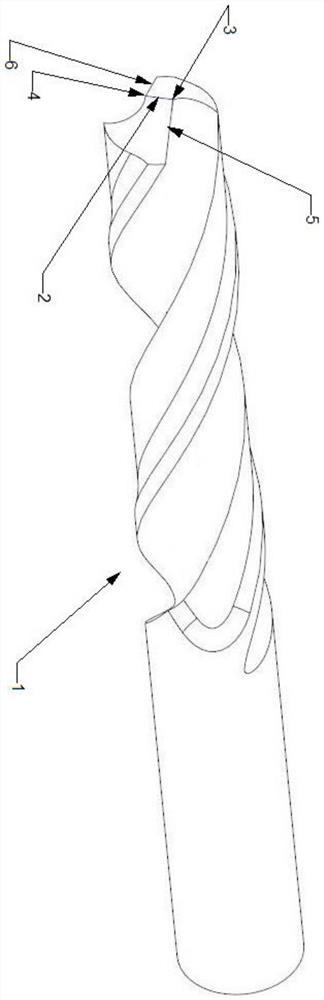

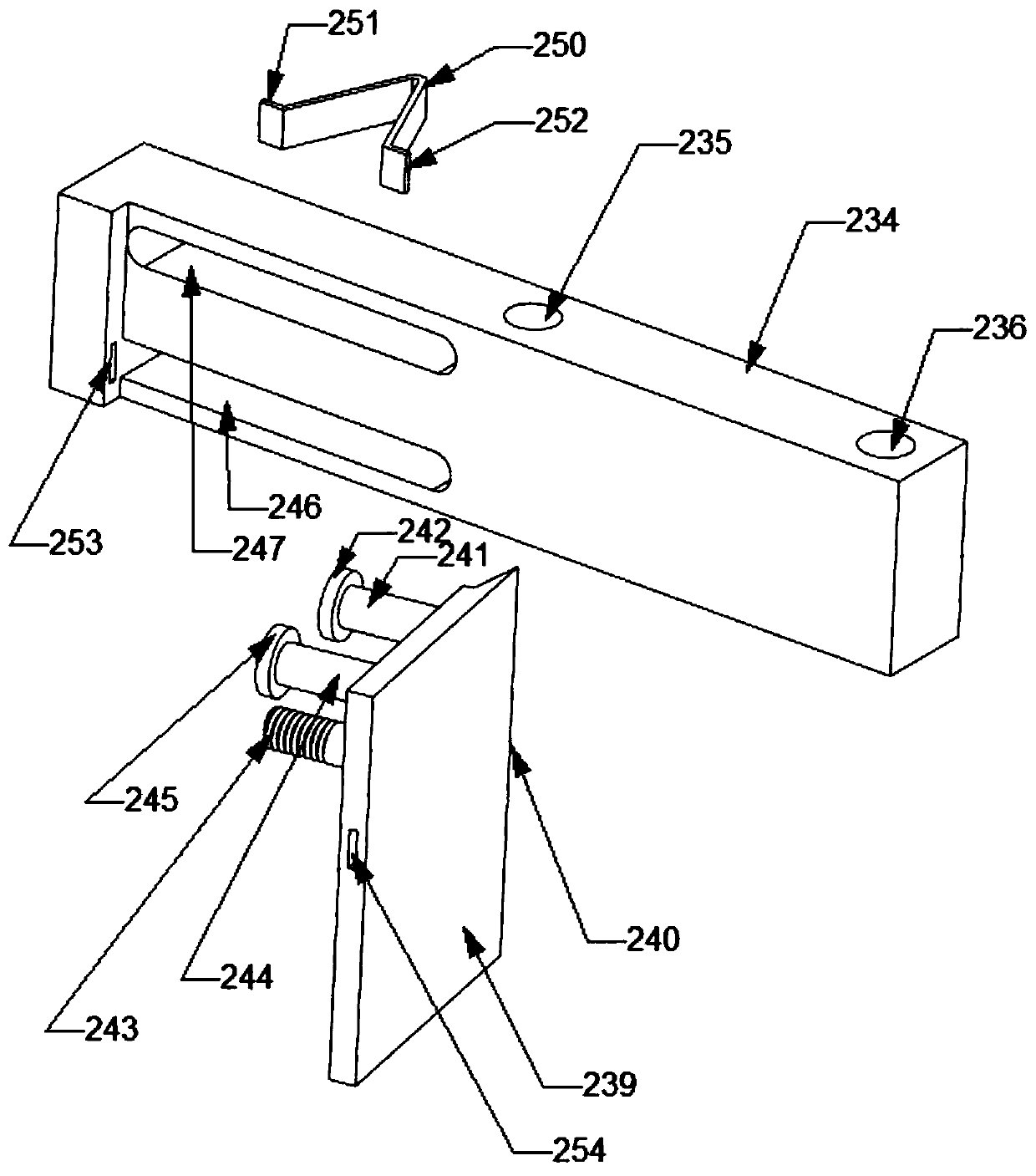

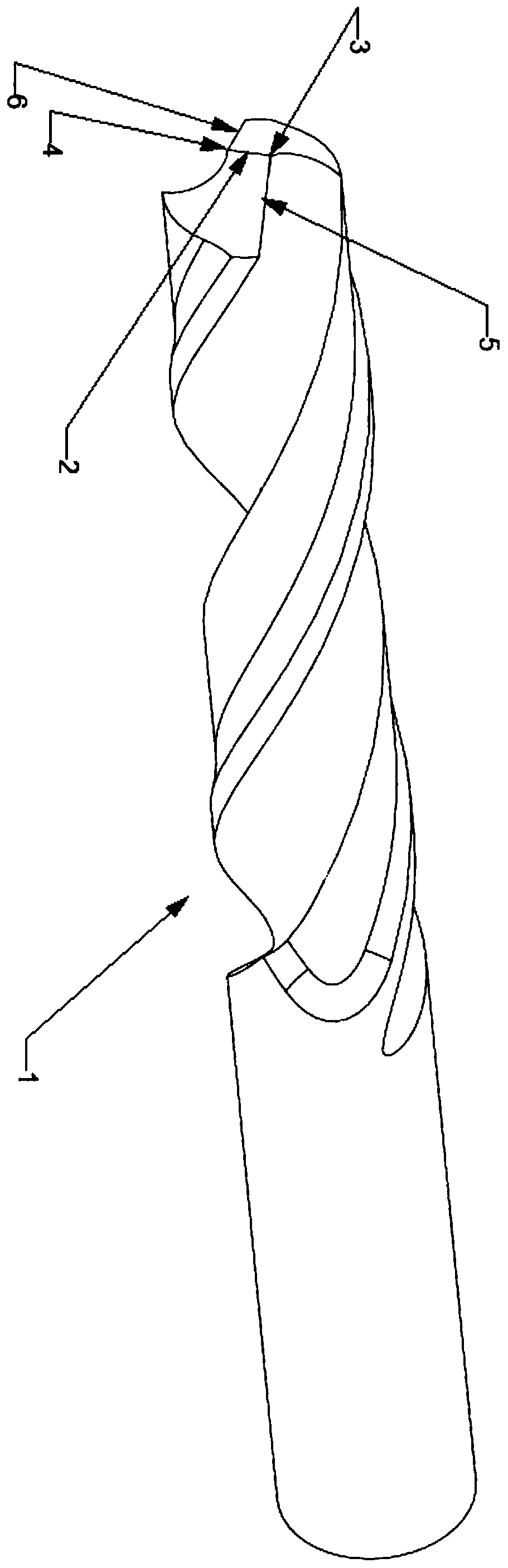

A semi-automatic twist drill detection device

ActiveCN111220046BEasy to detectNo need to worry about lengthAngles/taper measurementsSemi automaticSlide plate

The invention belongs to the technical field of machining testing tools and relates to a semi-automatic twist drill testing device. The main board of the semi-automatic twist drill detection device is fixed with a V-shaped groove for placing the tested twist drill. The front end of the main board has a front shaft, which is fixedly installed on the main board and is perpendicular to the upper surface of the main board. The top of the front shaft has a The front shaft cap has a sliding groove at the rear of the main board. The plane formed by the axis of the front rotating shaft and the center of the sliding groove is the central plane of the detection device, which is recorded as the central plane. The V-shaped groove is symmetrical to the central plane, and the sliding groove is also Symmetrical about the central plane. It can be observed whether the angle of the two main cutting edges is consistent with the preset angle, and the length of the tested twist drill is not limited. The invention is simple, convenient and universal in detecting the twist drill, without worrying about the length of the twist drill to be tested, and can realize automatic sliding of the slide plate.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Portable advertising board

InactiveCN109064891AProtection securityPrevent inflowPortable framesIdentification meansDisplay boardEngineering

The invention discloses a portable advertising board. The portable advertising board comprises a base, a rotating bracket, an automatic rain shielding mechanism and an electronic advertising display board; the rotating bracket is arranged on the base, and the electronic advertising display board is arranged on the rotating bracket and driven by the rotating bracket to freely rotate; the automaticrain shielding mechanism is arranged above the electronic advertising display board and unfolded to shield rainwater under the condition of sensing the rainwater. The portable advertising board solvesthe problem that advertising boards in the prior art are fixed to be motionless and cannot prevent rain, and achieves the functions of rotation and rain prevention.

Owner:安徽本质智能科技有限公司

Semi-automatic twist drill detection device

ActiveCN111220046AEasy to detectNo need to worry about lengthAngles/taper measurementsSemi automaticEngineering

The invention belongs to the technical field of machining detection tools, and relates to a semi-automatic twist drill detection device. A V-shaped groove is fixed in a main board of the semi-automatic twist drill detection device, and is used for placing a detected twist drill. A front rotating shaft is disposed at the front end of the main board, and the front rotating shaft is fixedly mounted on the main board; a front rotating shaft cap is arranged at the top end of the front rotating shaft, a lower sliding groove is formed in the tail portion of the main board, a plane formed by the axisof the front rotating shaft and the center of the lower sliding groove is the center plane of the detection device and is recorded as the center plane; the V-shaped groove is symmetrical relative to the center plane, and the lower sliding groove is also symmetrical relative to the center plane. Whether the angles of the two main cutting edges accord with a preset angle or not can be observed, andthe length of the measured twist drill is not limited. According to the invention, the device can detect a twist drill simply and conveniently and is universal; the length of the detected twist drilldoes not need to be worried about, and automatic sliding of the sliding plate can be achieved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

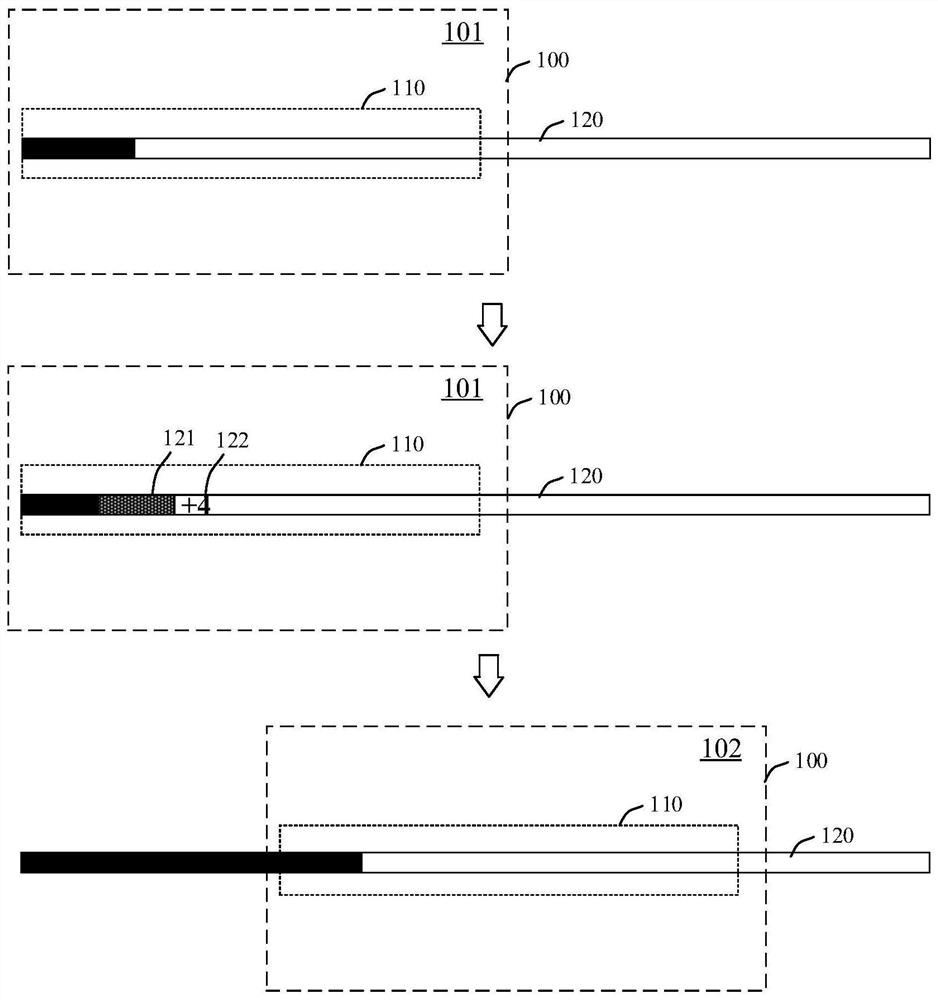

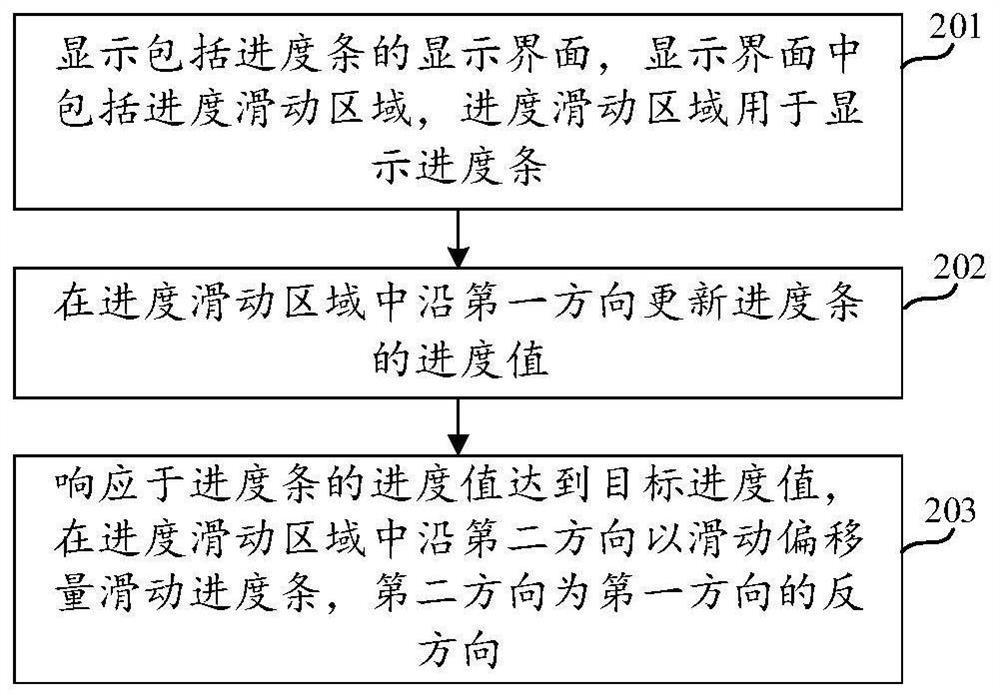

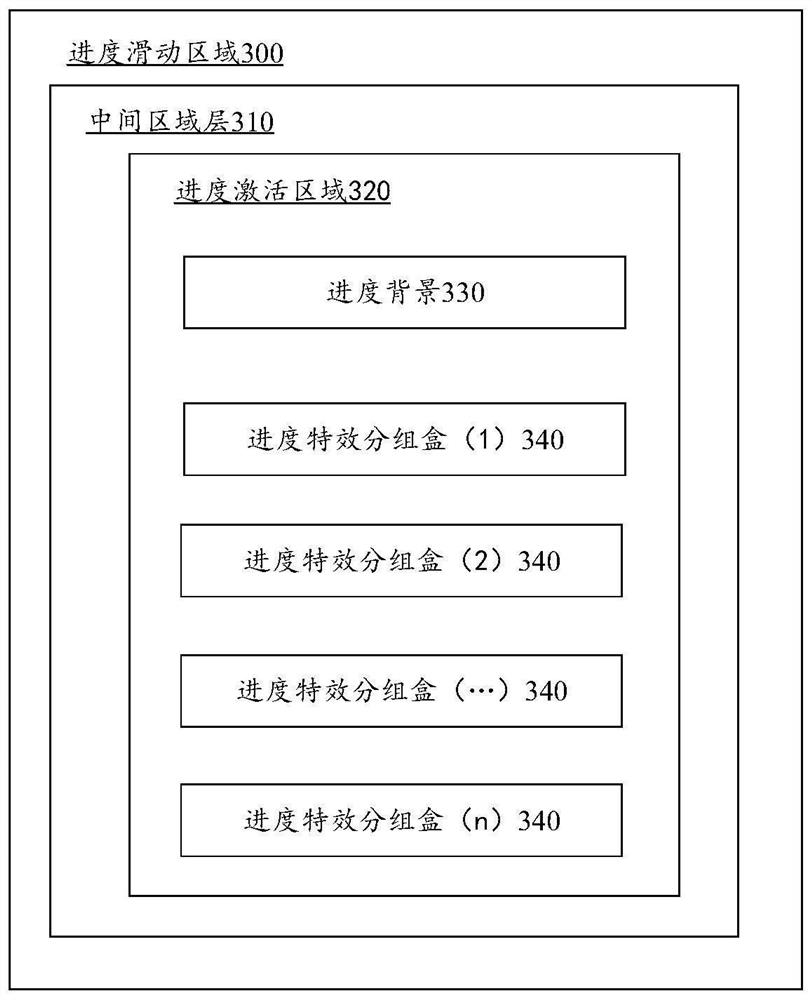

Progress bar control method, device, equipment and readable storage medium

ActiveCN111399736BRealize automatic slidingAvoid problems that reduce the efficiency of human-computer interactionExecution for user interfacesInput/output processes for data processingProgress barMechanical engineering

The present application discloses a progress bar control method, device, equipment and readable storage medium, and relates to the field of interface display. The method includes: displaying an interface including a progress bar, the display interface includes a progress sliding area, and the progress sliding area is The length in one direction is the first length, and the first length is smaller than the second length of the progress bar; the progress value of the progress bar is updated along the first direction in the progress sliding area; in response to the progress value of the progress bar reaching the target progress value, the In the progress sliding area, the progress bar is slid along the second direction with a sliding offset, and the second direction is opposite to the first direction. Update the progress value of the progress bar along the first direction, and when the progress value reaches the target progress value, that is, when the length of the progress bar exceeds the display width of the screen, slide the progress bar along the second direction with the sliding offset to realize the progress bar Automatic sliding, to avoid the problem that the user manually slides the progress bar and reduces the efficiency of human-computer interaction.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Sliding-type display stand with automatic sensing function

PendingCN107981627ARealization of automatic sensing functionLess hassleRacksShow shelvesComputer moduleComputer engineering

Owner:SHANGHAI GETELL DISPLAY PROD CO LTD

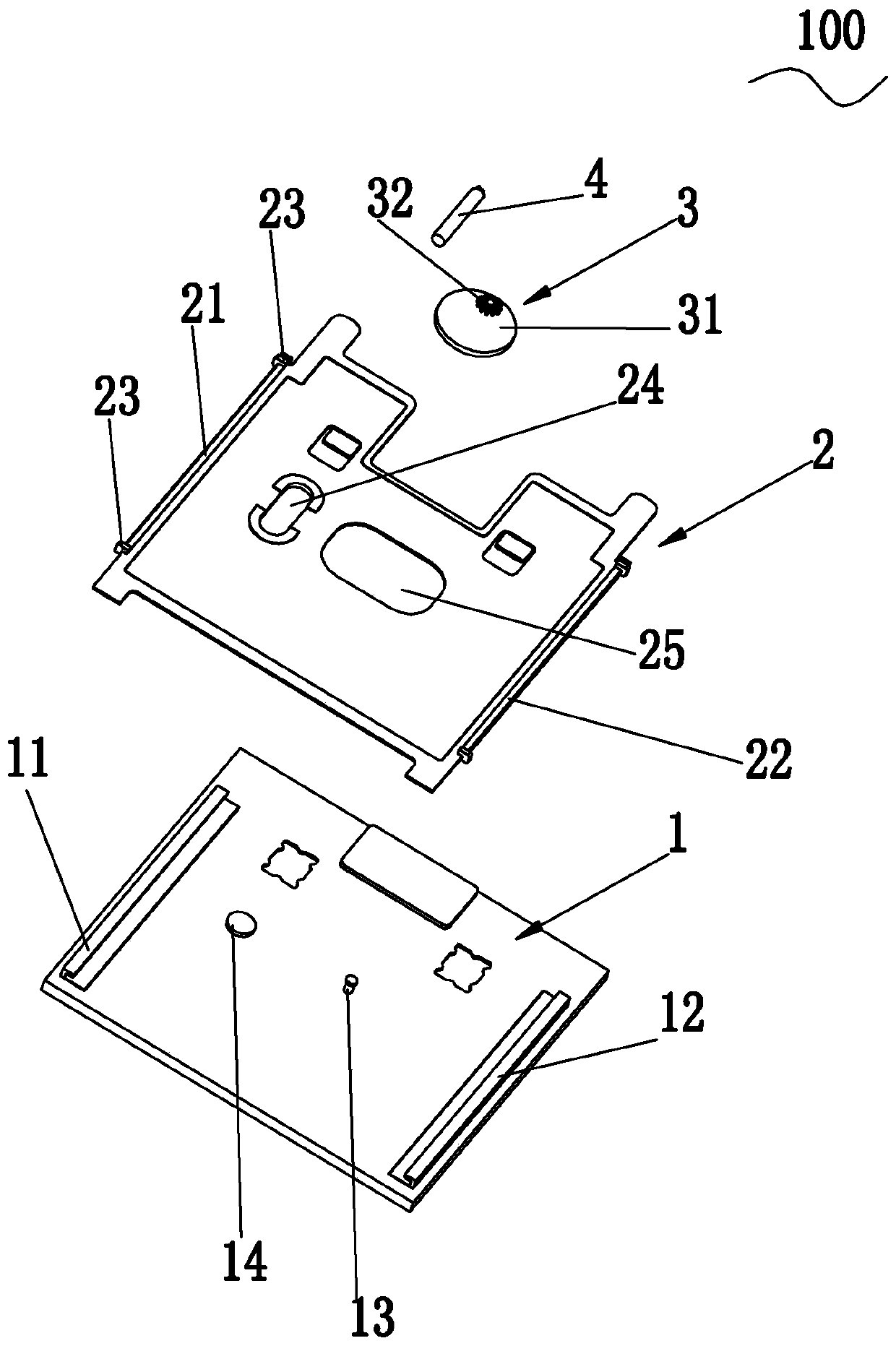

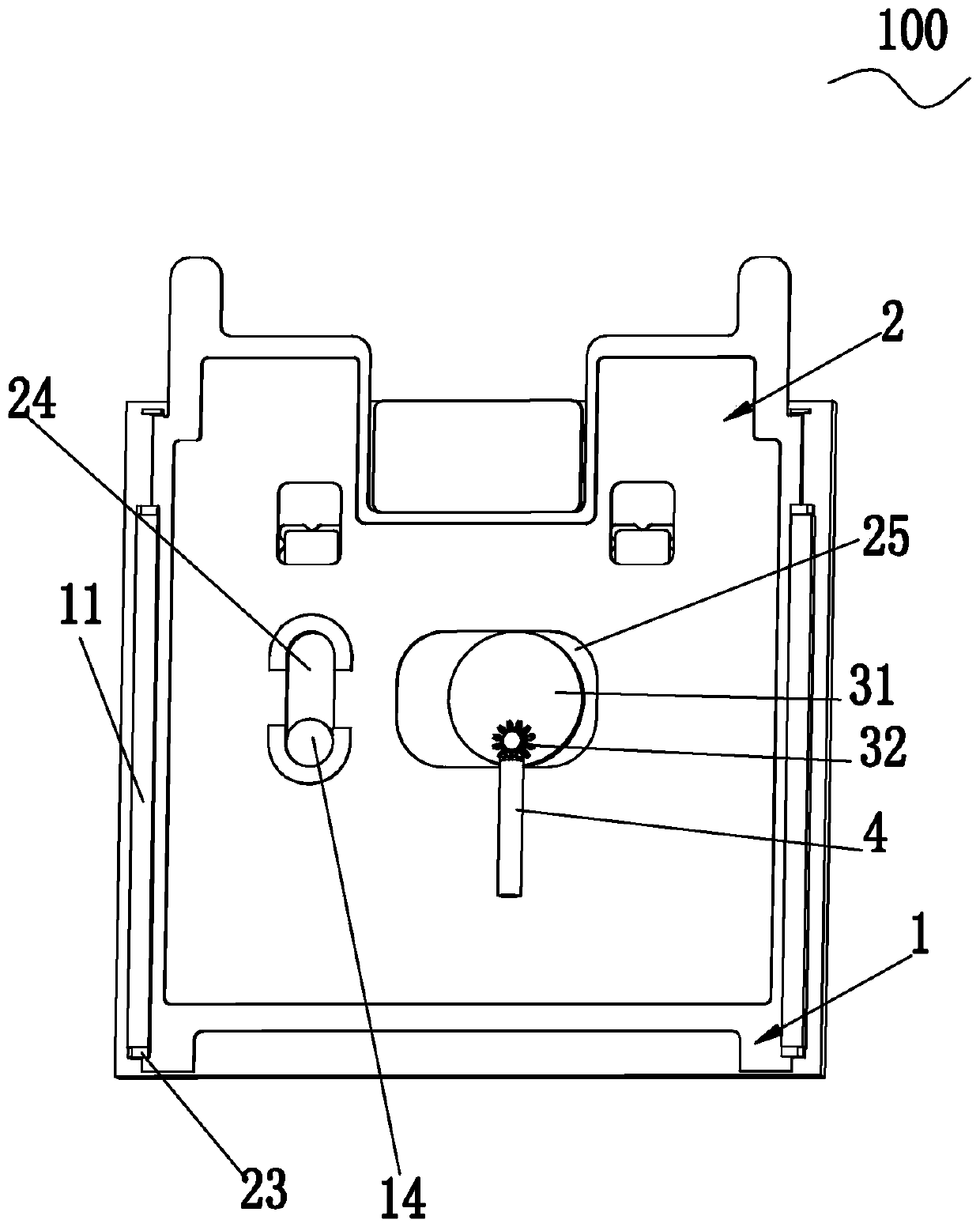

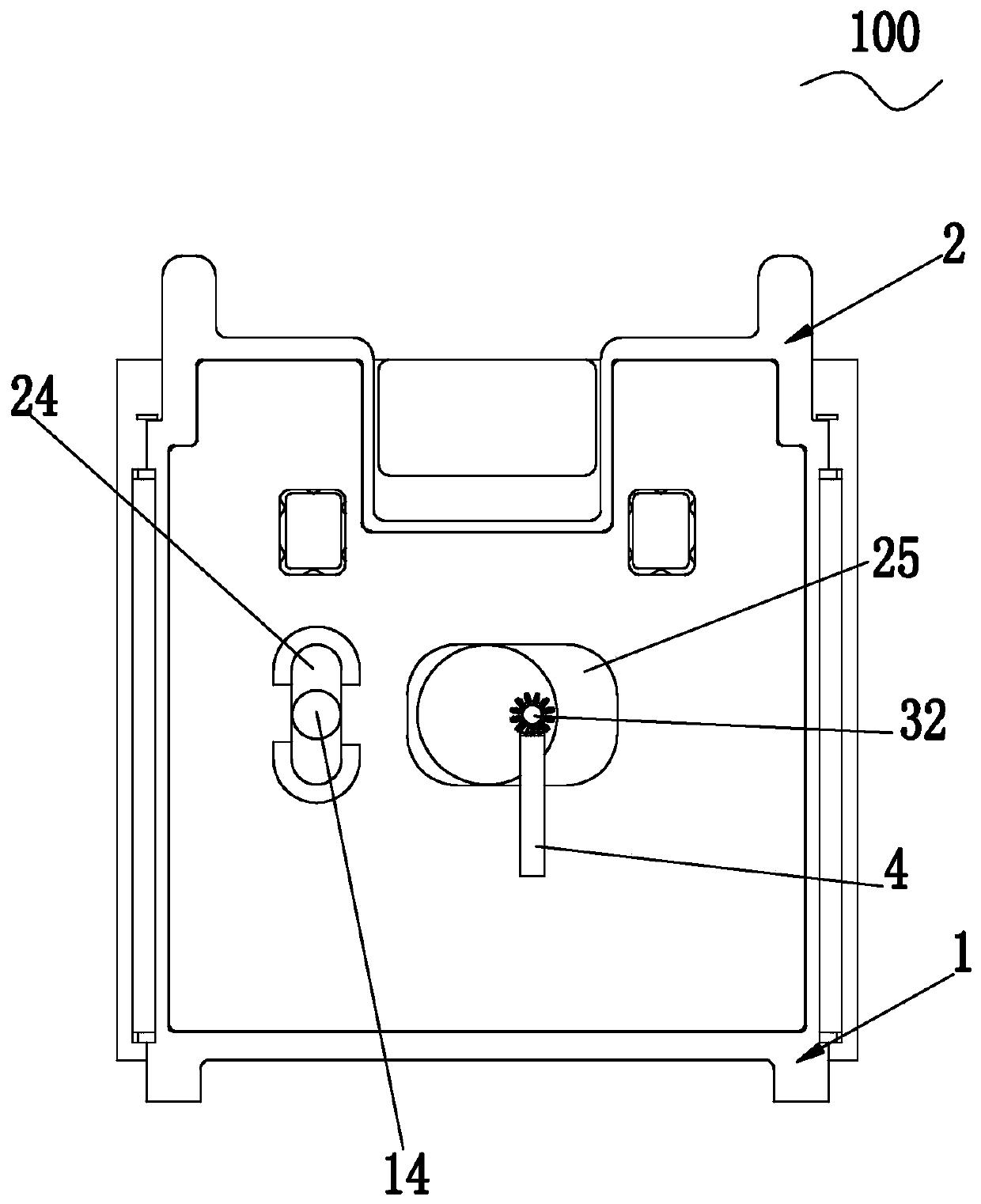

Slip cover assembly and electronic device applying slip cover assembly

PendingCN109889638AThe overall structure is simpleLow costGearingTelephone set constructionsMotor shaftElectronic equipment

The invention discloses a sliding cover assembly. The sliding cover assembly comprises a bottom plate; a sliding cover arranged on the bottom plate in a sliding manner; and a motor provided with a motor shaft for outputting rotary motion, and the slip cover assembly further comprises an eccentric device driven by the motor shaft. The eccentric device comprises an eccentric wheel rotationally arranged on the bottom plate, a containing cavity for containing the eccentric wheel is formed in the sliding cover, and the motor shaft drives the eccentric wheel to rotate eccentrically so as to drive the sliding cover to move in the longitudinal direction. The motor shaft is adopted to drive the eccentric wheel to eccentrically rotate so as to drive the sliding cover to move in the longitudinal direction to achieve automatic sliding of the sliding cover assembly, the overall structure is simple, and cost is low.

Owner:KUNSHAN JIAHUA ELECTRONICS

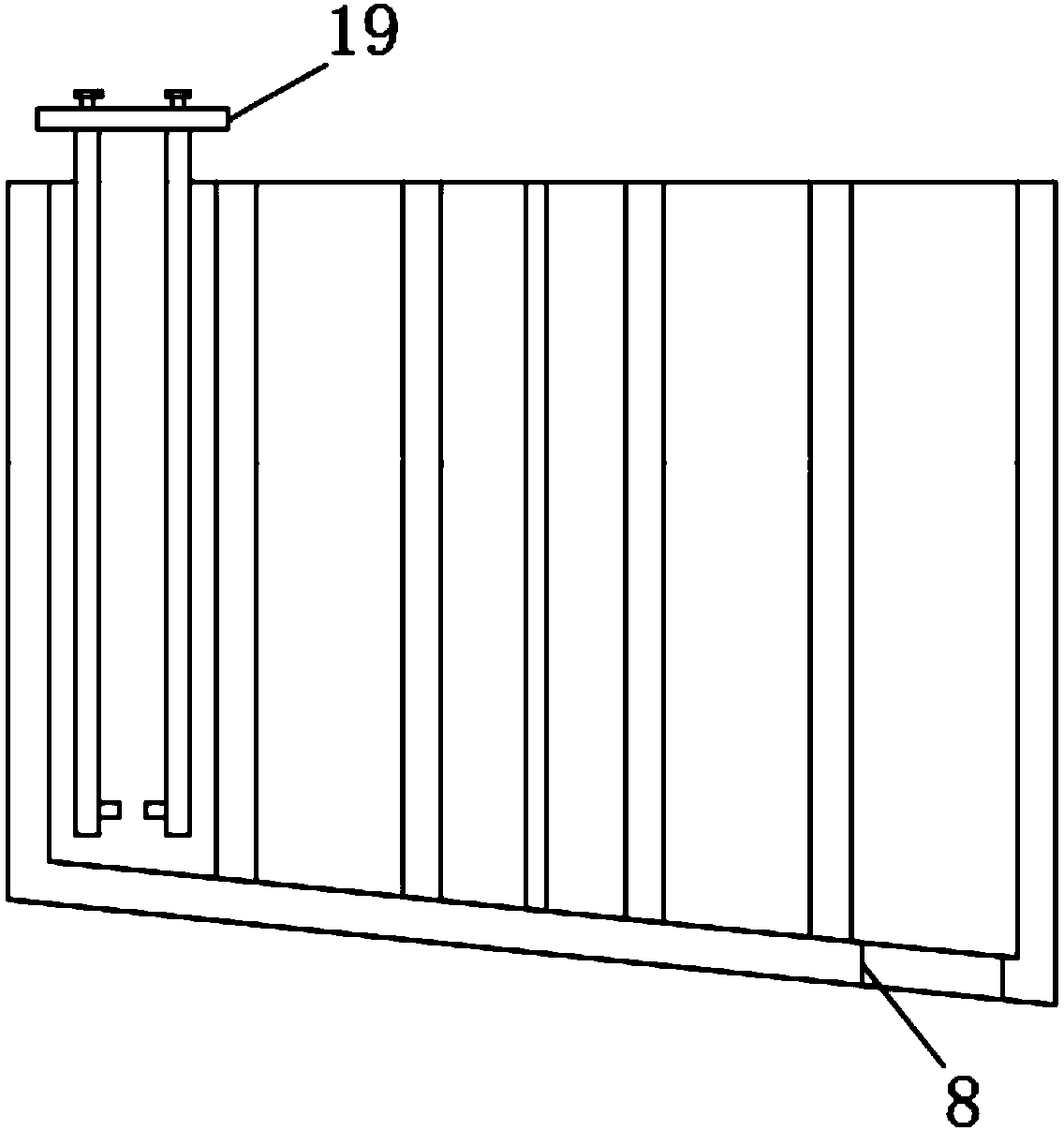

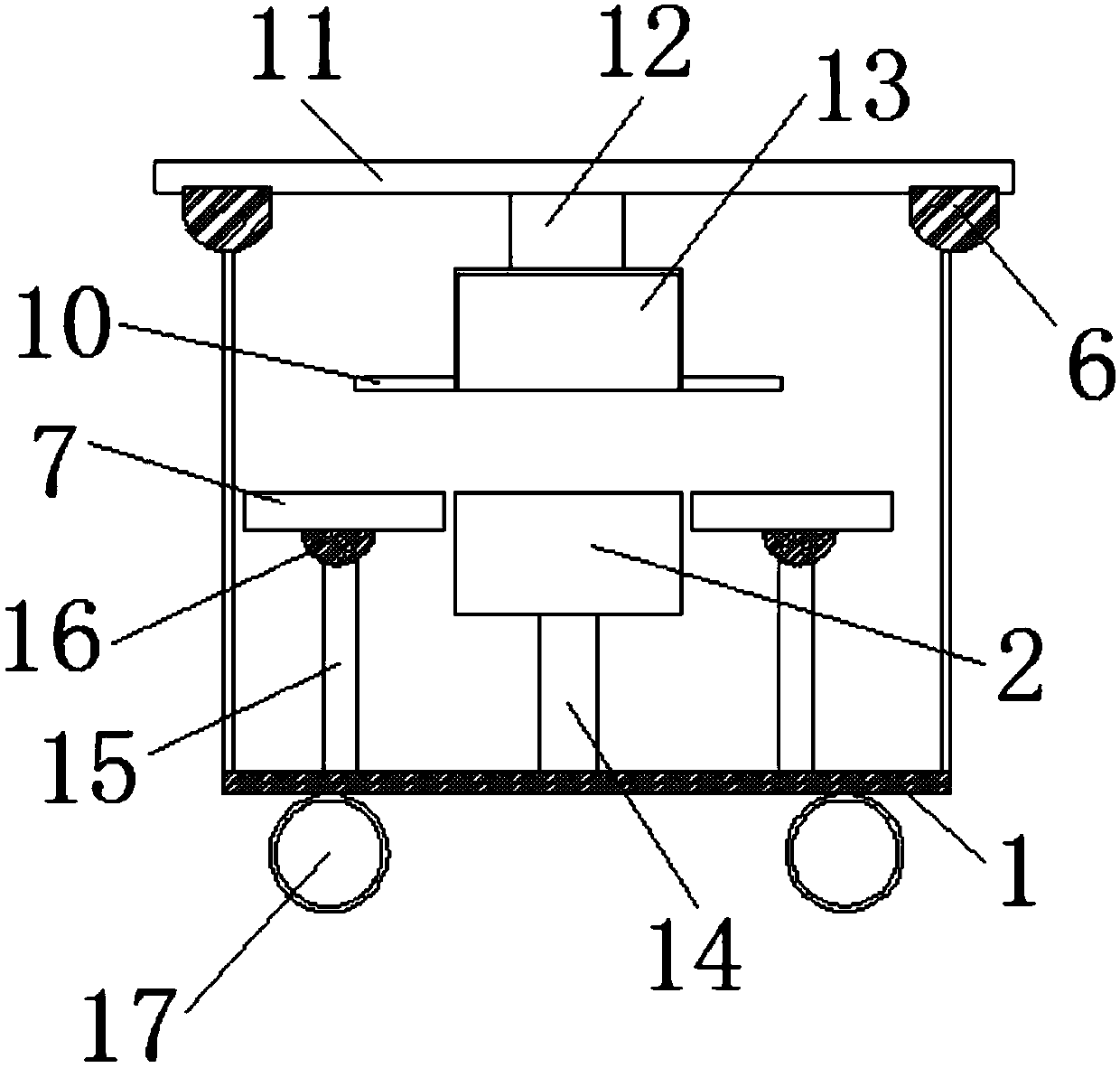

Rapid desilting device of plate-and-frame filter press for sewage treatment

InactiveCN111841094AAchieve slippageAchieve cleanupFiltration separationSewage treatmentFilter press

The invention discloses a rapid desilting device of a plate-and-frame filter press for sewage treatment, relates to the technical field of sewage treatment, and solves the problems that when an existing plate-and-frame filter press is used for cleaning filter residues, when the filter residues are adhered to a filter plate, the filter residues are difficult to fall off and need to be manually cleaned by workers, the cleaning speed is low, and the labor intensity of the workers is high. The device comprises a filter press main body. The top of the filter press main body is connected with a group of desilting devices in a sliding manner; the upper part of the filter press main body is connected with a filter plate in a sliding manner; the front portion and the rear portion of the top of thedesilting device are each fixedly connected with a group of advancing driving pieces; two groups of desilting support connecting rods are arranged at the lower part of the left side of the desilting device; and the bottoms of the two groups are jointly connected with a group of mud scraping plates. The rapid desilting device can replace the trouble of manual cleaning, can greatly improve the working efficiency and reduce the labor intensity of workers, and is simple in structure, low in manufacturing cost and suitable for popularization.

Owner:王树芝

An automatic feeding and conveying mechanism based on medicine bottle printing

ActiveCN113428583BImprove printing efficiencyRealize automatic slidingTypewritersJigging conveyorsEngineeringPrinting press

The invention discloses an automatic feeding and conveying mechanism based on medicine bottle printing, which belongs to the technical field of medicine bottle processing. The invention includes a base, on which a vibrating material device, a material distributing device and a conveying device are fixedly connected in sequence; There is a printing mechanism, and the lower surface of the turntable rotates evenly along its radial direction and is connected with a plurality of distribution plates, and the lower surface of the distribution plate is fixedly connected with a lifting mechanism; the material distribution device also includes a ring track, and the lower end of the lifting mechanism is fixedly connected with a ring The track cooperates with sliding rollers. In the present invention, the vibrating device vibrates the medicine bottle into the material distributing device, the servo motor drives the turntable to rotate, the printing mechanism sprays and prints the medicine bottle, and finally transfers the medicine bottle to the conveying device, and the conveying device transports it to the lower station, thus improving the overall efficiency of medicine bottle printing.

Owner:安徽仁济印务有限公司

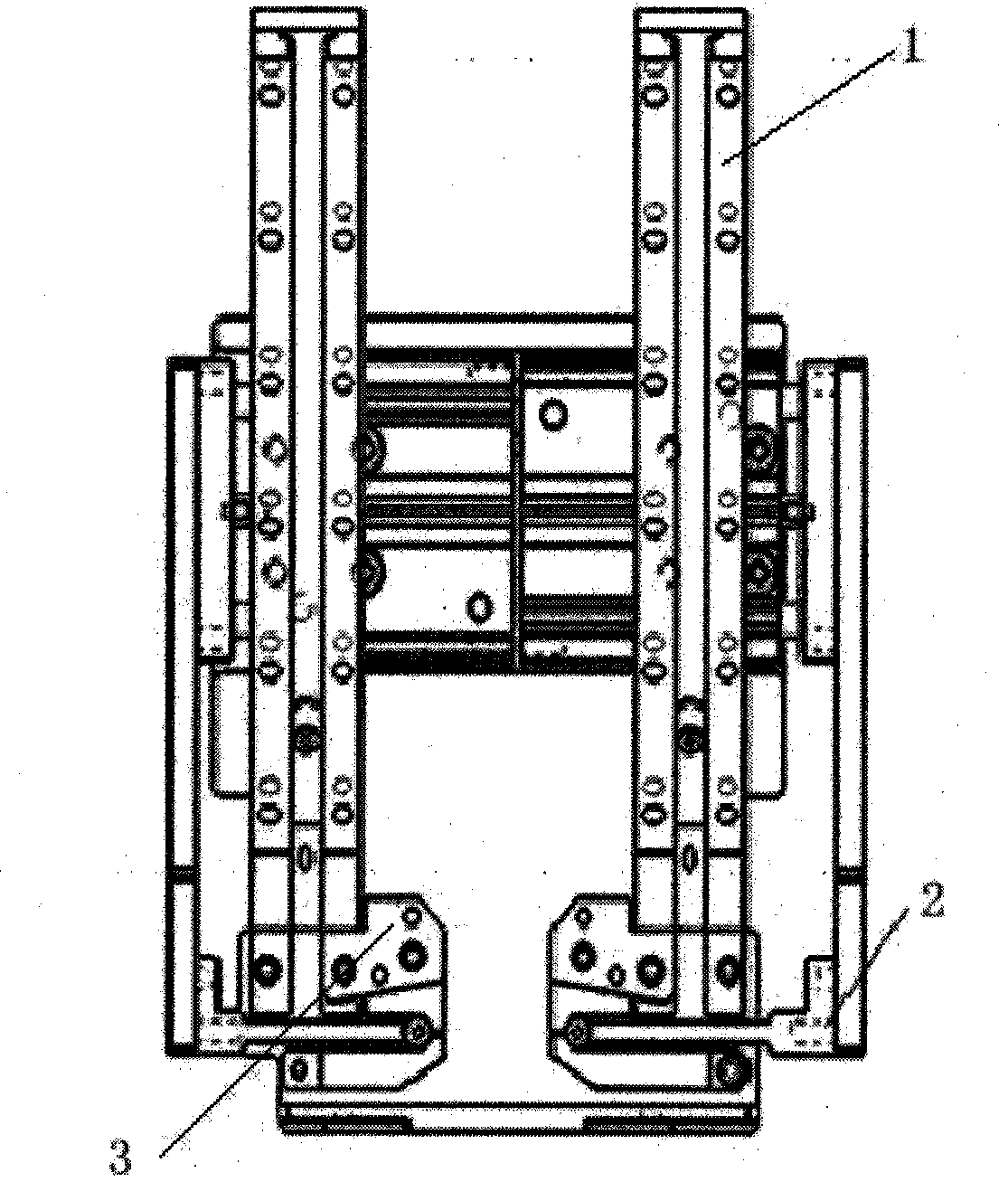

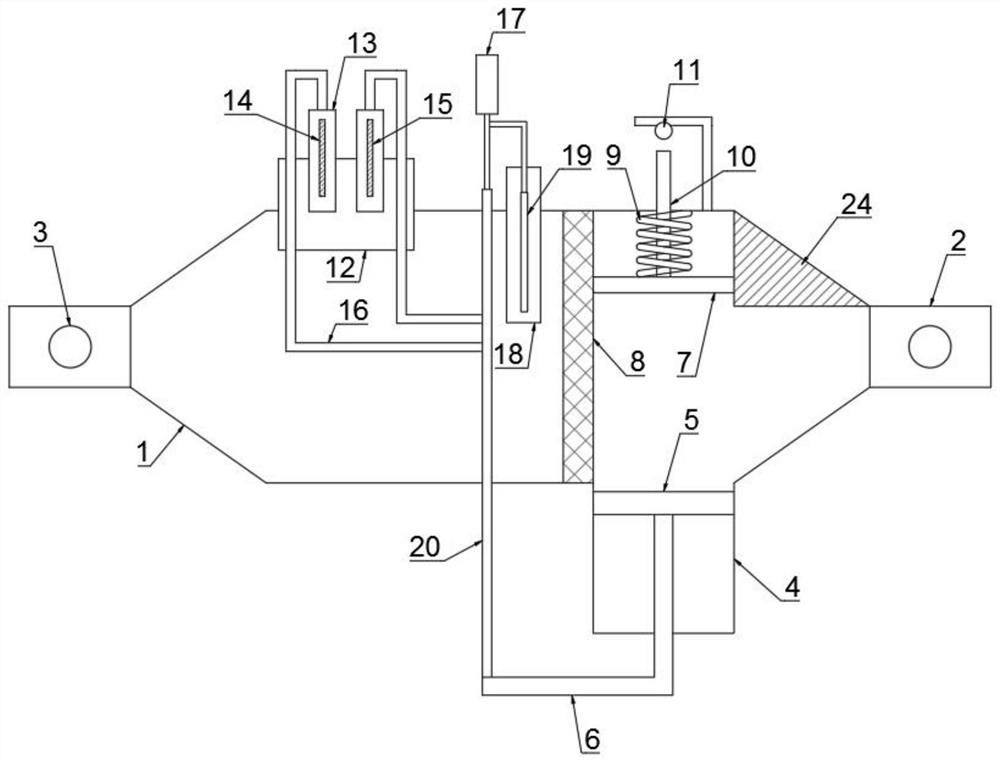

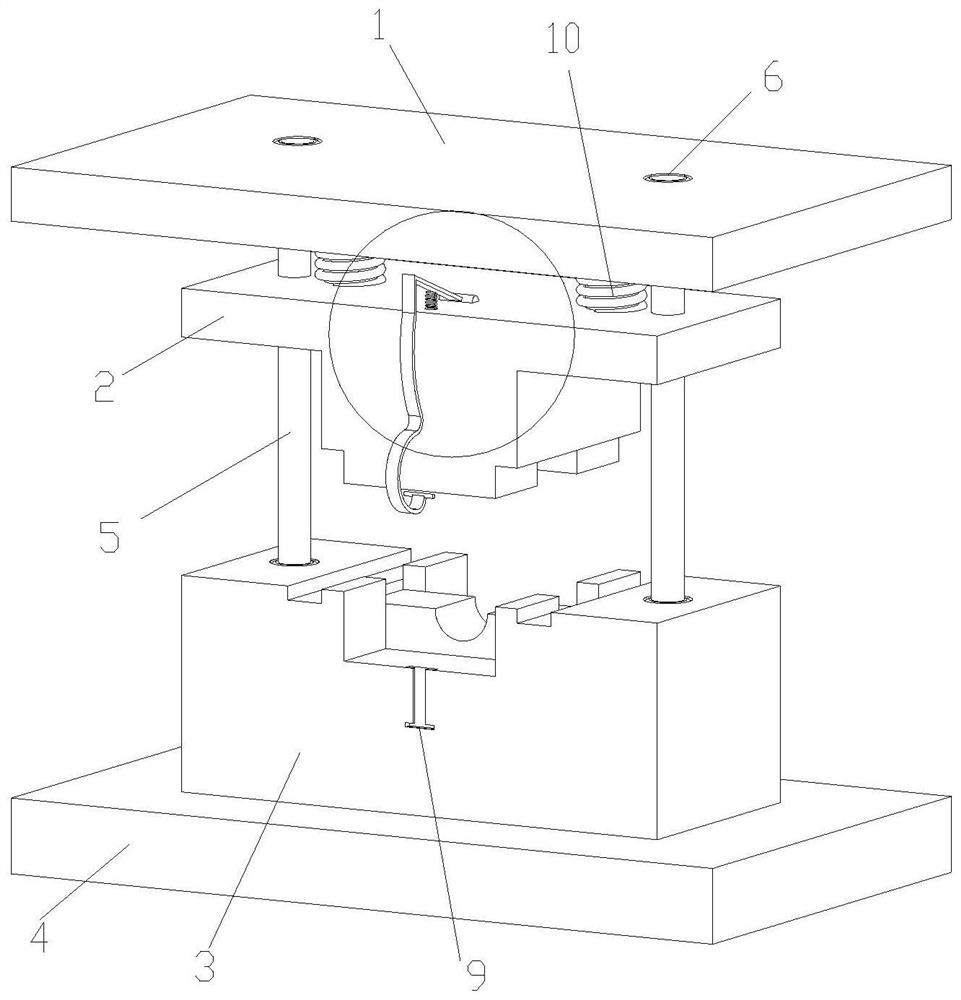

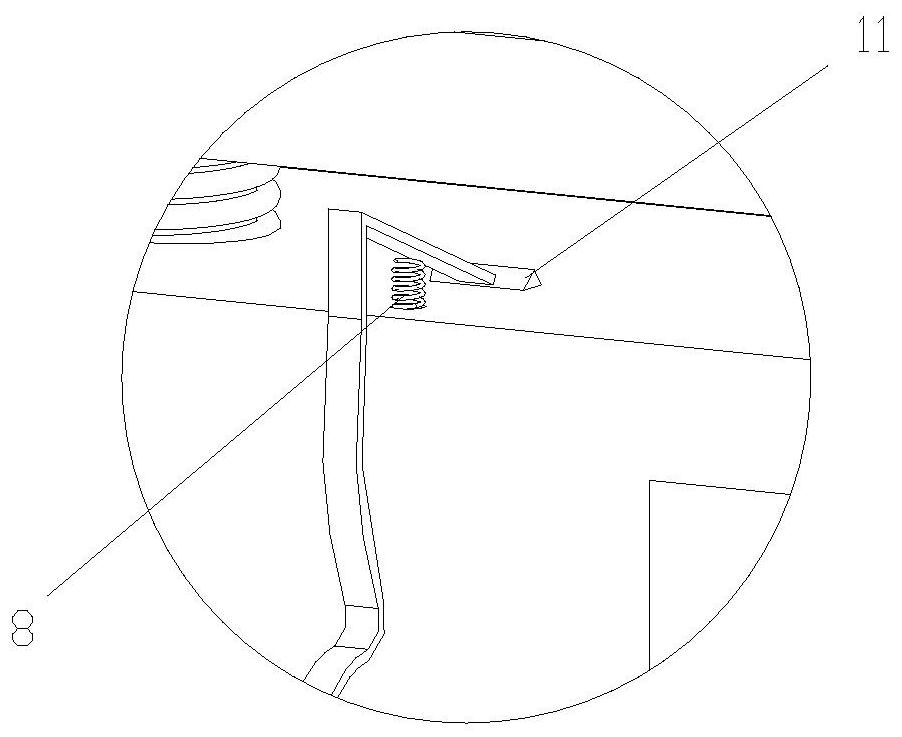

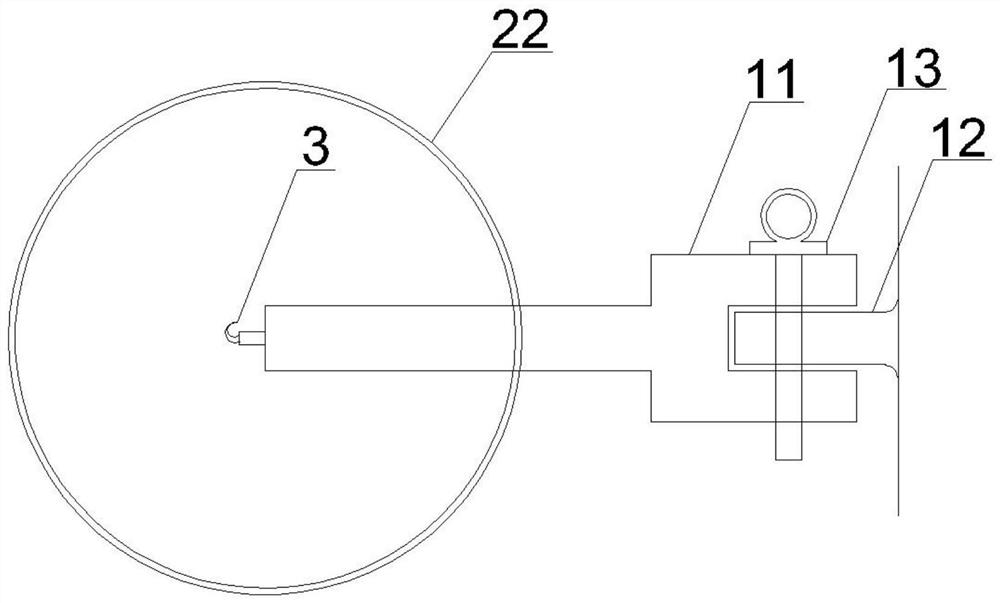

A kind of automatic lifting type stamping die

ActiveCN108393399BRealize automatic slidingTo achieve the purpose of automatic strippingShaping toolsEjection devicesStampingStructural engineering

The invention discloses an automatic lifting type stamping die which comprises a top plate, an upper die, a lower die, a bottom plate and an arc hook plate. The lower die is fixed to the bottom plate,the upper die is connected with the top plate, a supporting spring is arranged between the upper die and the top plate, the upper die is further provided with the arc hook plate for lifting, the archook plate is provided with an arc area which is restored in the die direction, the upper end of the arc hook plate is fixed to the top face of the upper die though a rotating shaft, a telescopic spring is arranged between the upper end of the arc hook plate and the top face of the upper die, the telescopic spring supports the upper end of the arc hook plate to enable the lower end of the arc hookplate to produce no pressure, the lower end of the arc hook plate is a hooking end, the hooking end is lower than the bottom face of the upper die, the hooking end is a circular arc bent upwards in the die direction, the end of the hooking end is provided with a columnar rubber head, the side face of the lower die is provided with an I-shaped groove matched with the arc hook plate, the I-shaped groove extends to the bottom face inside a machining area, and the rubber head is clamped into the I-shaped groove and slides out of the opening of the I-shaped groove from the bottom face inside the machining area.

Owner:SUZHOU RIPU MOLD CO LTD

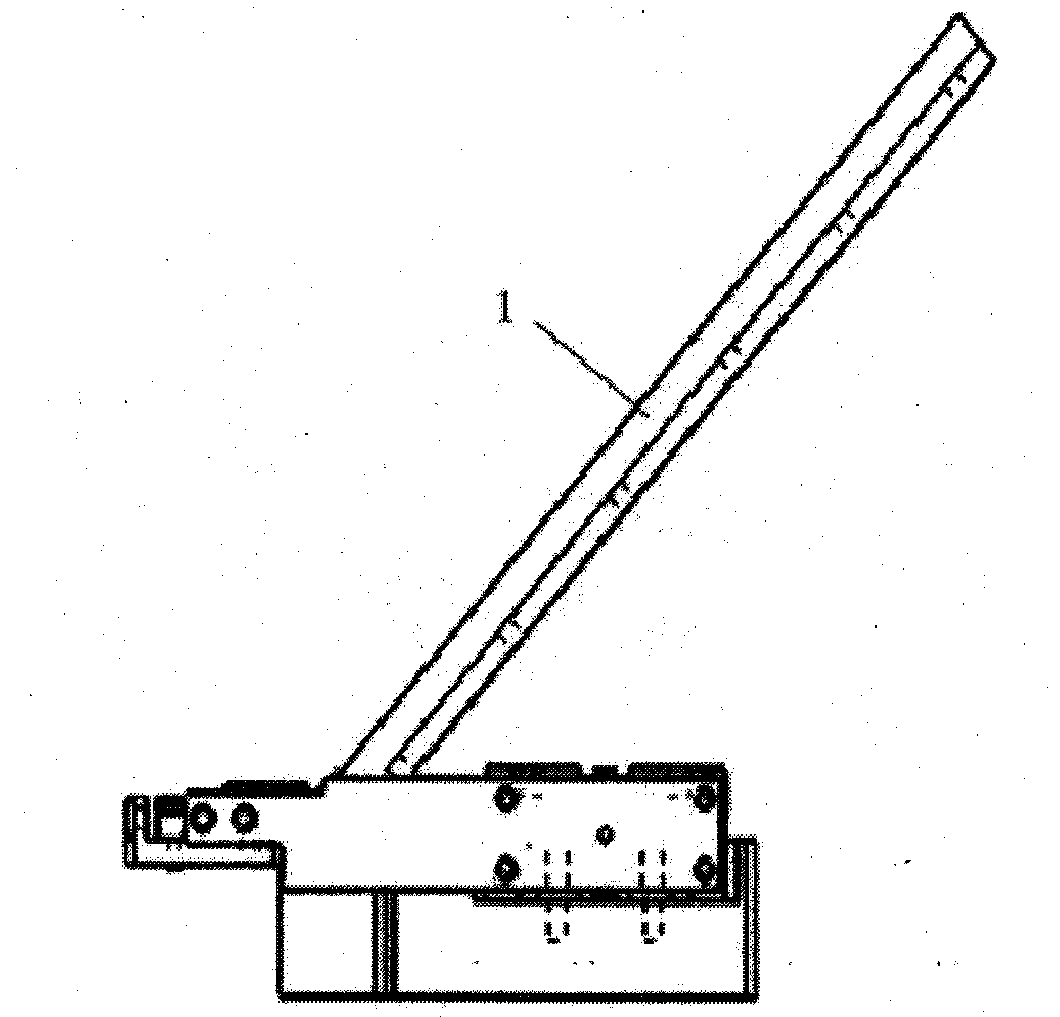

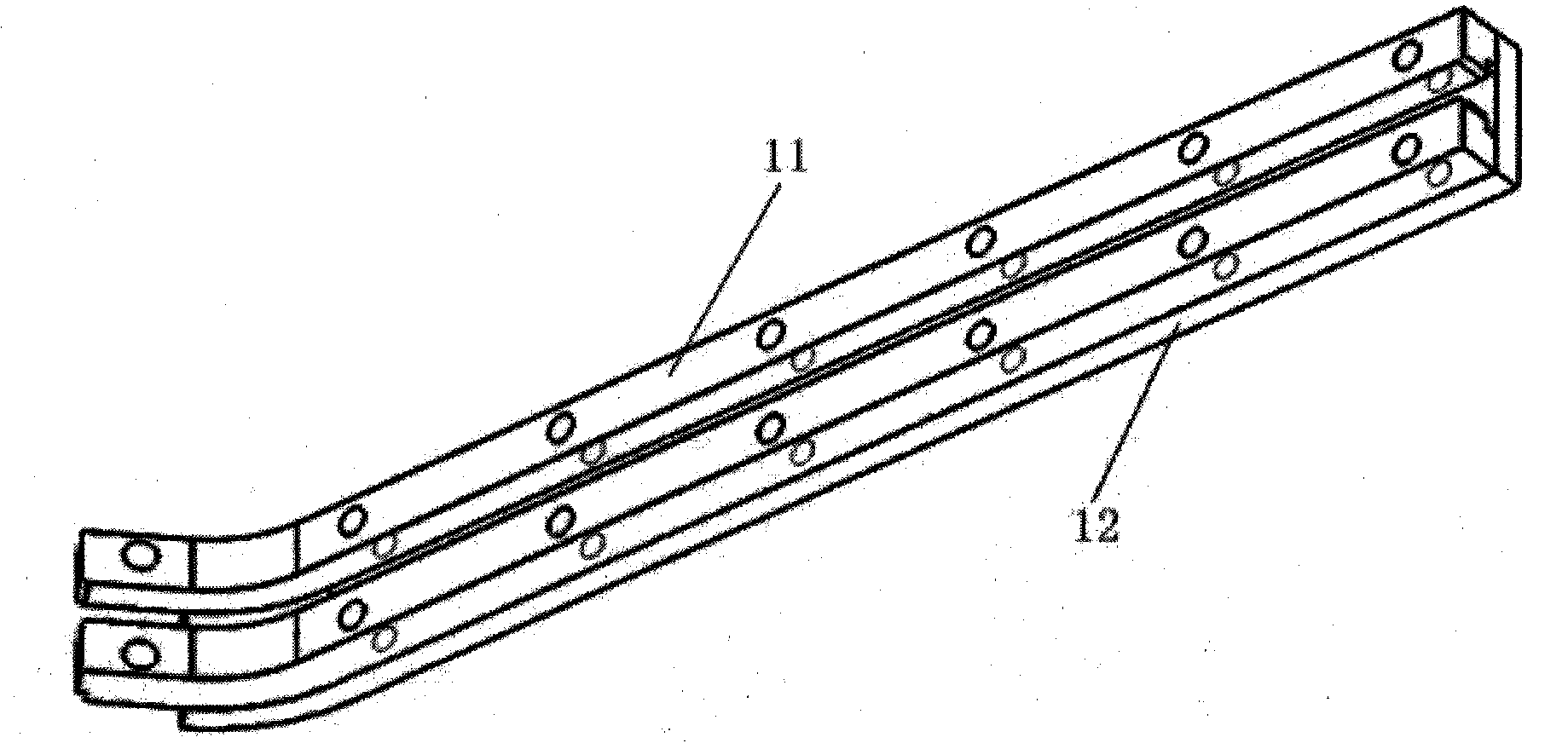

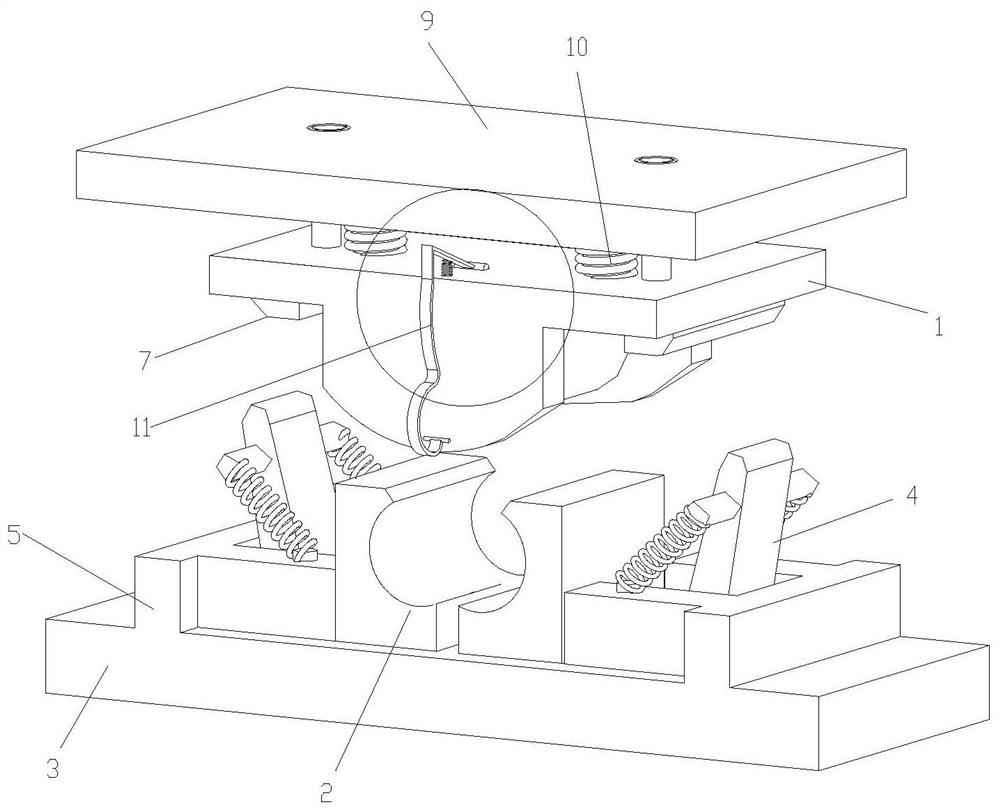

A mold structure for processing bent pipe

ActiveCN108393377BReduce fit errorRealize automatic slidingEjection devicesMechanical engineeringHook plate

The invention discloses a die structure for machining a bent pipe. The die structure comprises a bending die, two clamping dies and a bottom plate. The two clamping dies are provided with a semicircular forming area and installed on the bottom plate and move in the opposite directions and the same direction. Each clamping die is connected with a triangular turnover block, wherein the turnover block is provided with a fixed end, a turnover end and a push-pull end, the fixed end is fixed to the bottom plate through the effect of a rotating shaft, an included angle not smaller than 90 degrees isarranged between the turnover end and the push-pull end, and the push-pull end is connected with the clamping die. The bending die comprises a forming portion, and is further provided with protrusionsacing on the turnover ends. The bending die descends to enable the protrusions to press the turnover ends and push the turnover ends towards the outer side. The push-pull ends will turn over around the rotating shaft on the fixed ends, and push the clamping dies to move. The bottom plate is further provided with a spring for resetting the turnover ends, the spring acts between the turnover ends and the bottom plate, the bending die is further provided with an arc hook plate for lifting, and the arc hook plate is provide with an arc area restored in the forming area direction.

Owner:SUZHOU RIPU MOLD CO LTD

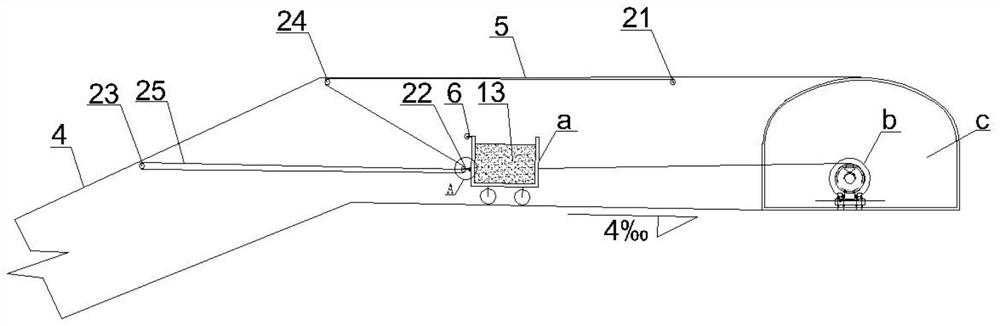

Tramcar system capable of being used for underground mine inclined shaft and mine unloading platform humping

PendingCN113581227ARealize automatic slidingImprove work efficiencyEarth drilling and miningUnderground transportArchitectural engineeringBlock and tackle

The invention discloses a tramcar system capable of being used for underground mine inclined shaft and mine unloading platform humping, which comprises a tramcar, a winch connected with one end of the tramcar, a traction mechanism and a trailer plate, one end of the trailer plate is connected with the tramcar, and the other end of the trailer plate is connected with the traction mechanism. The traction mechanism is provided with a motor rope winding and unwinding component and a pulley assembly, and the tramcar is driven by the motor rope winding and unwinding component through the pulley assembly to be capable of humping on the mine unloading platform. The whole-process advancing and humping of the tramcar on the inclined shaft and the mine unloading platform can be realized. The problem that in the prior art, a tramcar needs to be pushed manually on an ore unloading platform to cause safety or cannot be pushed manually is solved.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Concentrated light recovery type soil disinfection and restoration device

ActiveCN105432176BWon't clogRealize automatic slidingSoil lifting machinesRenewable energy machinesGlass coverSoil treatment

Owner:INNER MONGOLIA UNIV OF TECH

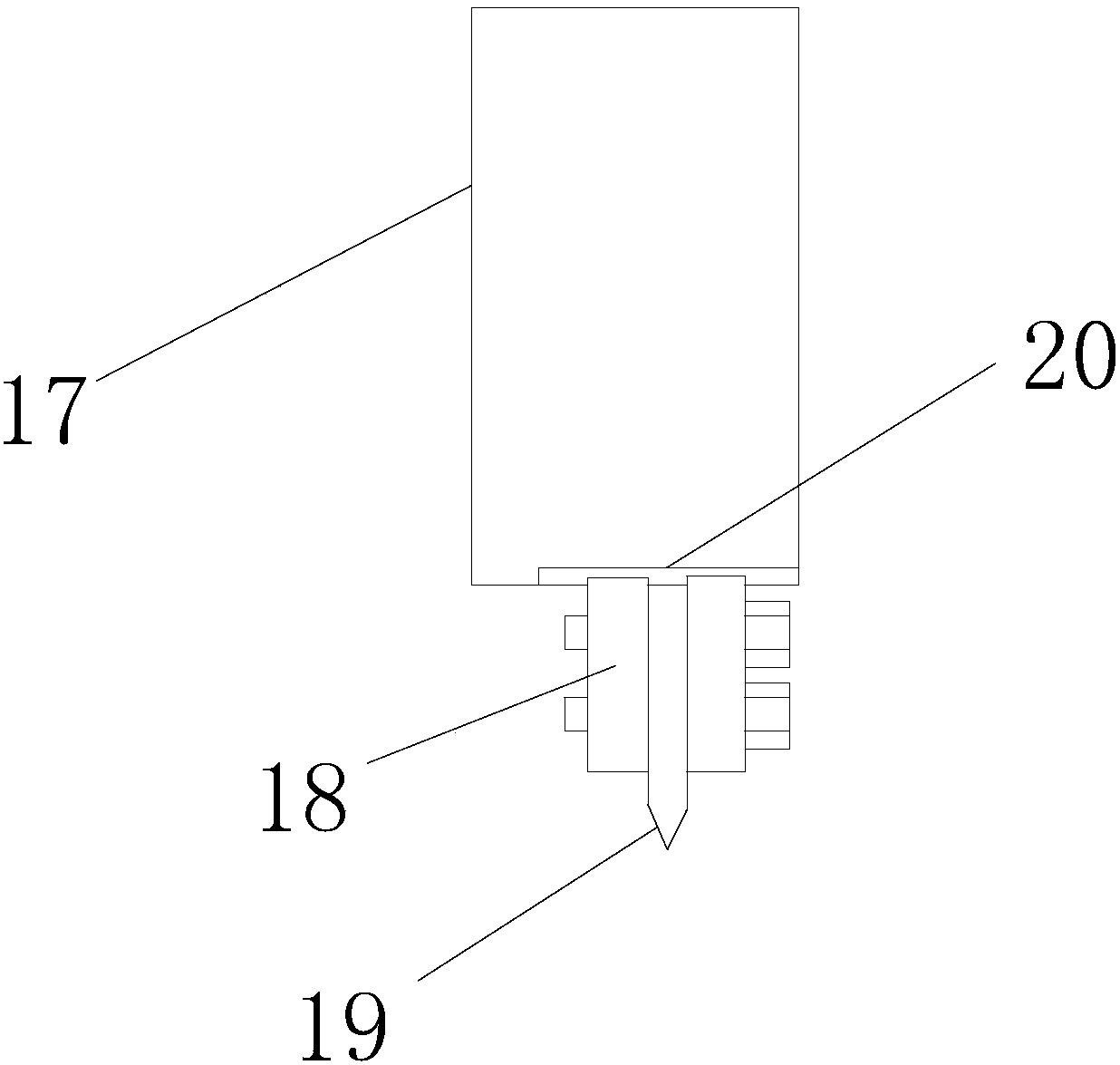

Needle detecting device and detecting method

ActiveCN104324889ARealize automatic slidingHigh degree of automationSortingBlunt traumaBiomedical engineering

The invention discloses a needle detecting device; a waste elimination mechanism, a needle tube through-blocking detecting mechanism, a needle tube total length inspection mechanism, an edge inspection mechanism and a needle detecting and guiding positioning block are respectively and sequentially arranged on the outer side of a feeding turntable along the outer edge of the feeding turntable; the needle detecting device can realize full automatic detection function, the main inspection items include inspecting whether needle tube cutting edge parts have blunt trauma and burr, whether the needle tube is blocked and bent, whether the needle tube total length is oversize and the like, the needle detecting device can automatically feed a needle, automatically eliminate a needle, automatically draw back a needle, and is high in degree of automation, by the use of a high performance fiber optic sensor, high speed synchronous detection, data storage and data feedback can be realized, the whole device is reasonable in design, efficient in integration, high in detection precision, and stable in working state, has good practicability, can further improve the work efficiency, and avoids false detection and missing detection in detection links.

Owner:BERPU MEDICAL TECH CO LTD

Wiring harness cut-off device

ActiveCN110947874AGuaranteed openRealize automatic slidingIndustrial equipmentStructural engineering

The invention discloses a wiring harness cut-off device, and relates to the technical field of industrial equipment. The wiring harness cut-off device comprises a workbench, side plates and a top plate, wherein the workbench is of a cavity structure, and the opening of the cavity is hinged with two sliding doors which are symmetrically arranged; a PLC is mounted inside the workbench; an avoiding slot is formed in the side end, away from the sliding doors, of the workbench; a through hole I which extends to the avoiding slot is formed in the upper end of the workbench; the two side plates are symmetrically fixed at the upper end of the workbench; and a power mechanism used for providing power is mounted on one side plate. According to the wiring harness cut-off device disclosed by the invention, the cut-off mechanism can be arranged to guarantee equal-length wire splitting of a wiring harness, so that follow-up production processes are smoothly performed; and a discharge mechanism can be arranged for sliding a cut-off wiring hardness product onto a conveyor belt between two carrying plates, and the cut-off wiring hardness product is finally fed into a corresponding carrying box to accomplish automatic unloading.

Owner:WUHU QIAOYUN & YOUXING ELECTRICAL IND CO LTD

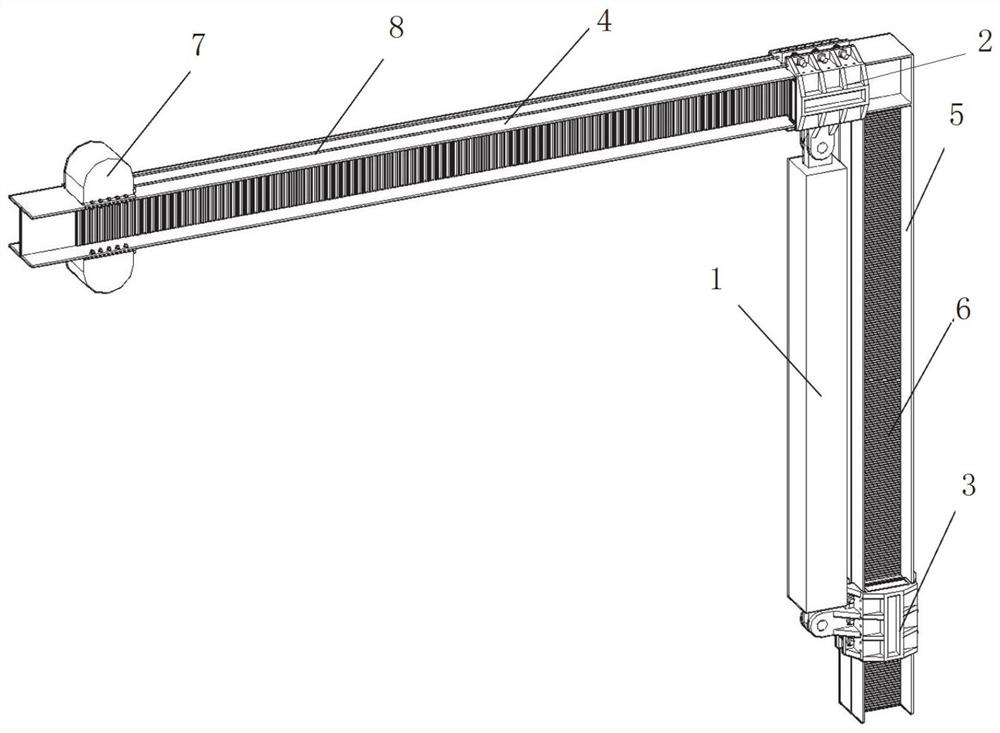

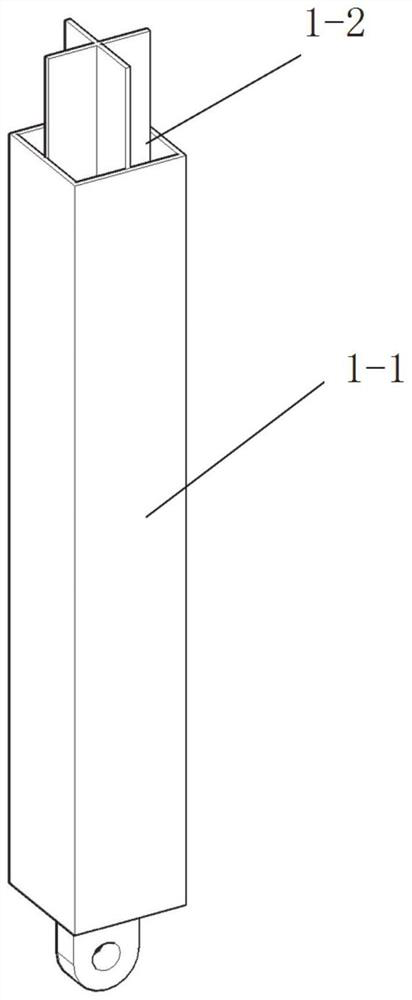

Steel structure anti-buckling support reinforcement device and building

ActiveCN112663811BEasy to operateEasy to install and disassembleProtective buildings/sheltersShock proofingArchitectural engineeringCivil engineering

Owner:NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com