Sliding-type display stand with automatic sensing function

An automatic sensing and sliding technology, applied in display hangers, display shelves, display tables, etc., can solve the problems of reduced transportation efficiency, inconvenient transportation, waste of manpower, etc., to improve stability and service life, reduce trouble, The effect of ensuring safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

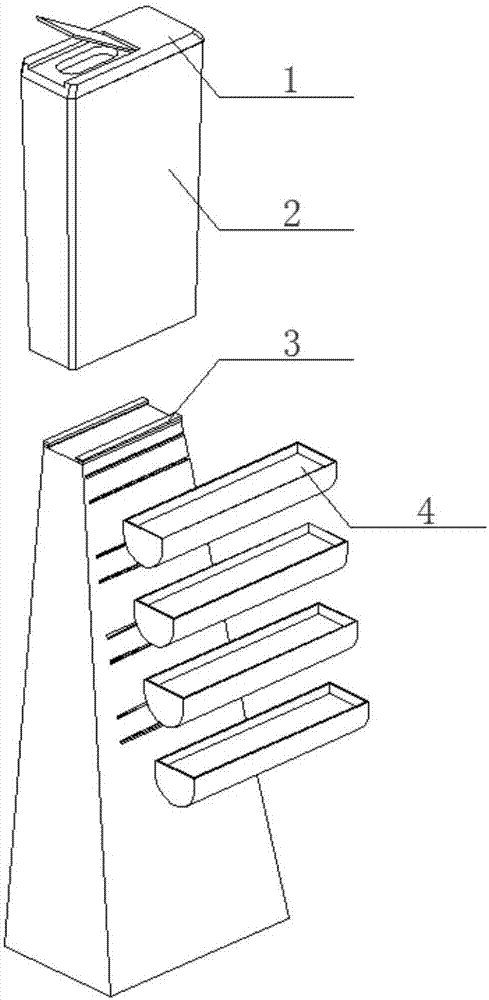

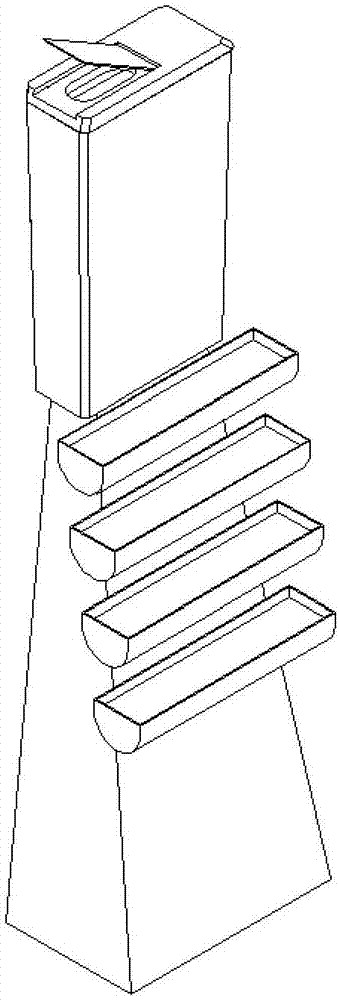

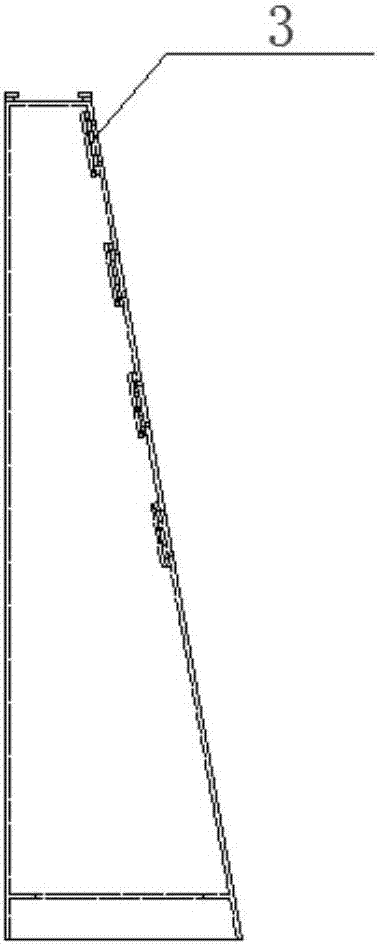

[0036] In order to solve the problem of poor fluidity and difficult transportation of existing display racks, this embodiment proposes a sliding display rack with automatic sensing function, including a display rack body, a display container and a display control terminal. The display control terminal and The display frame body is detachably connected, and the main surface of the display frame body is provided with multiple parallel display channels, which are connected to the display control terminal, and the display container is set on the display channel, and the two display channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com