Patents

Literature

45results about How to "Reduced power unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

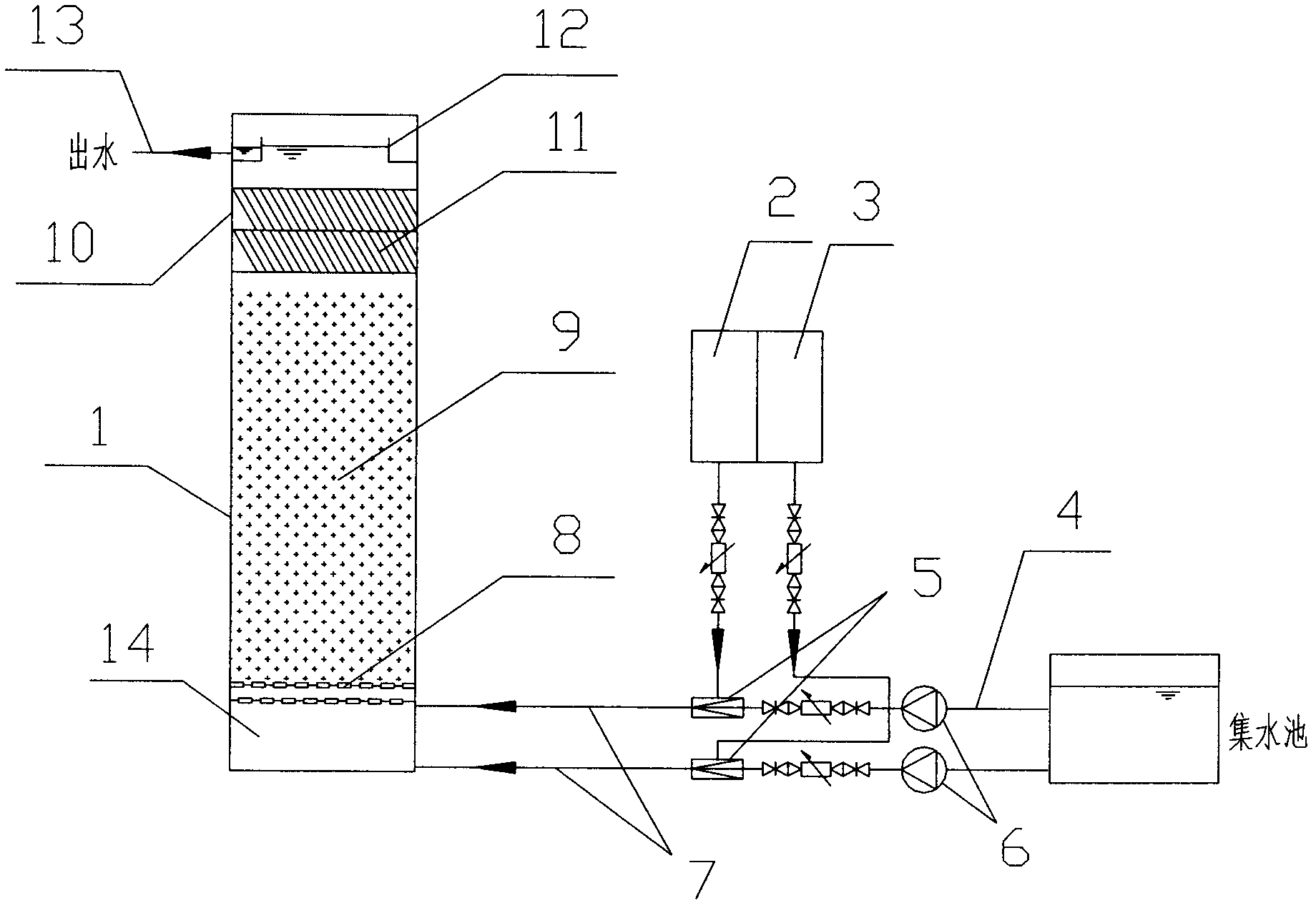

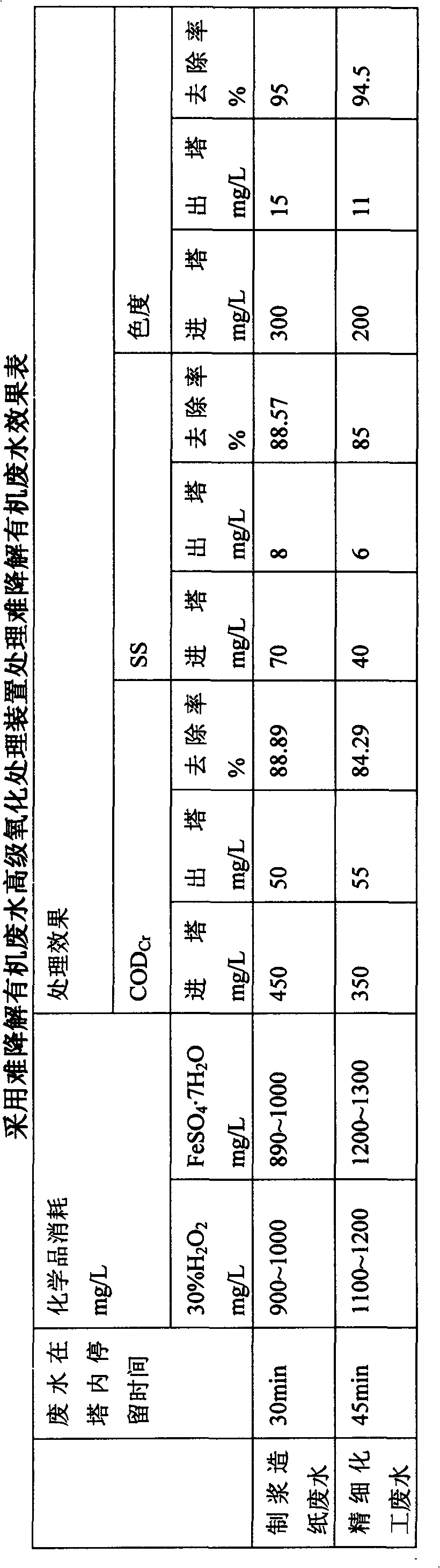

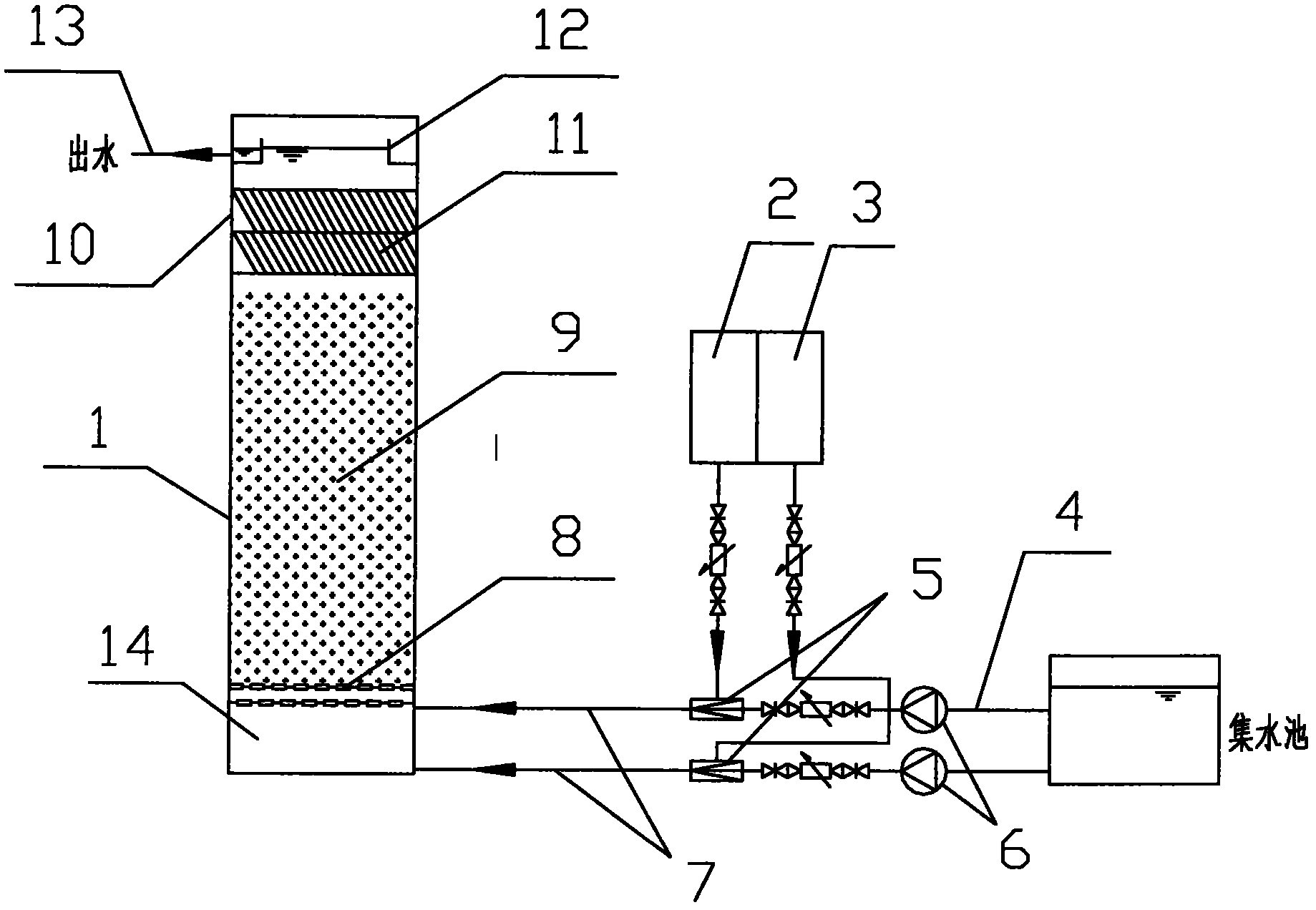

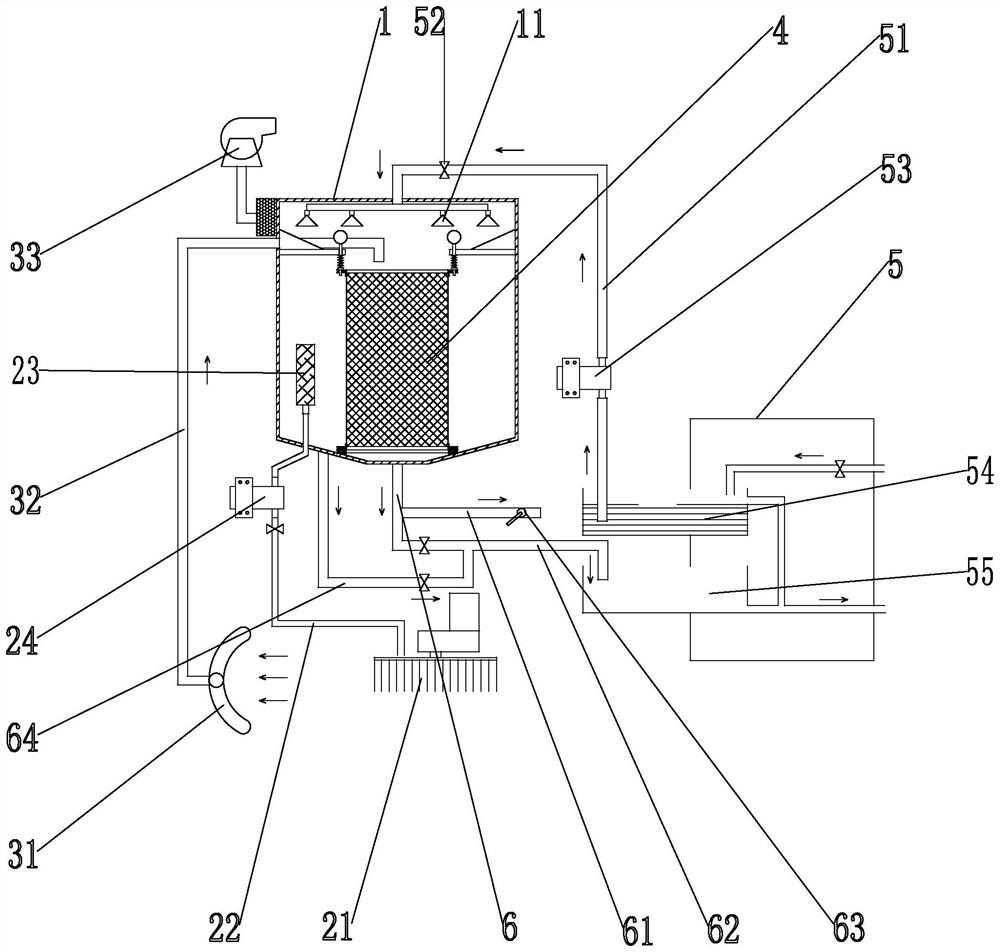

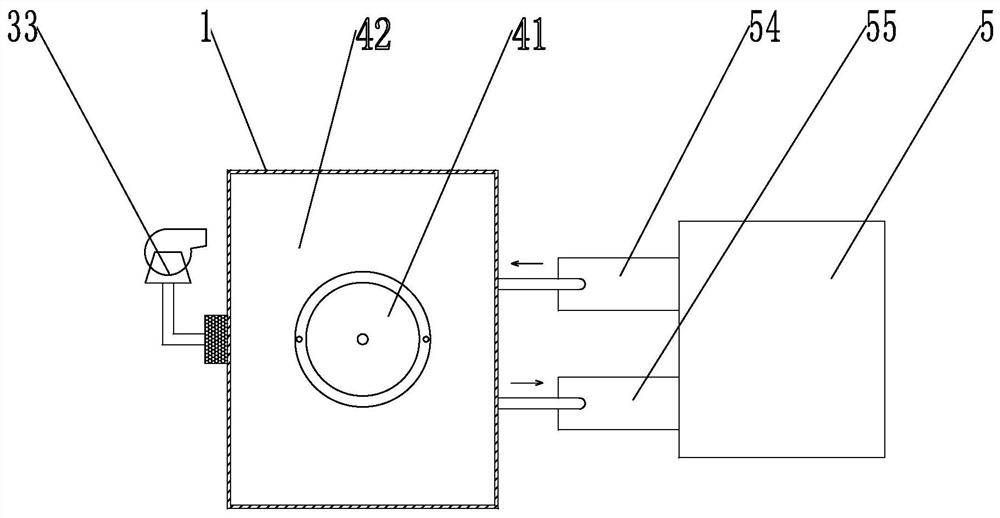

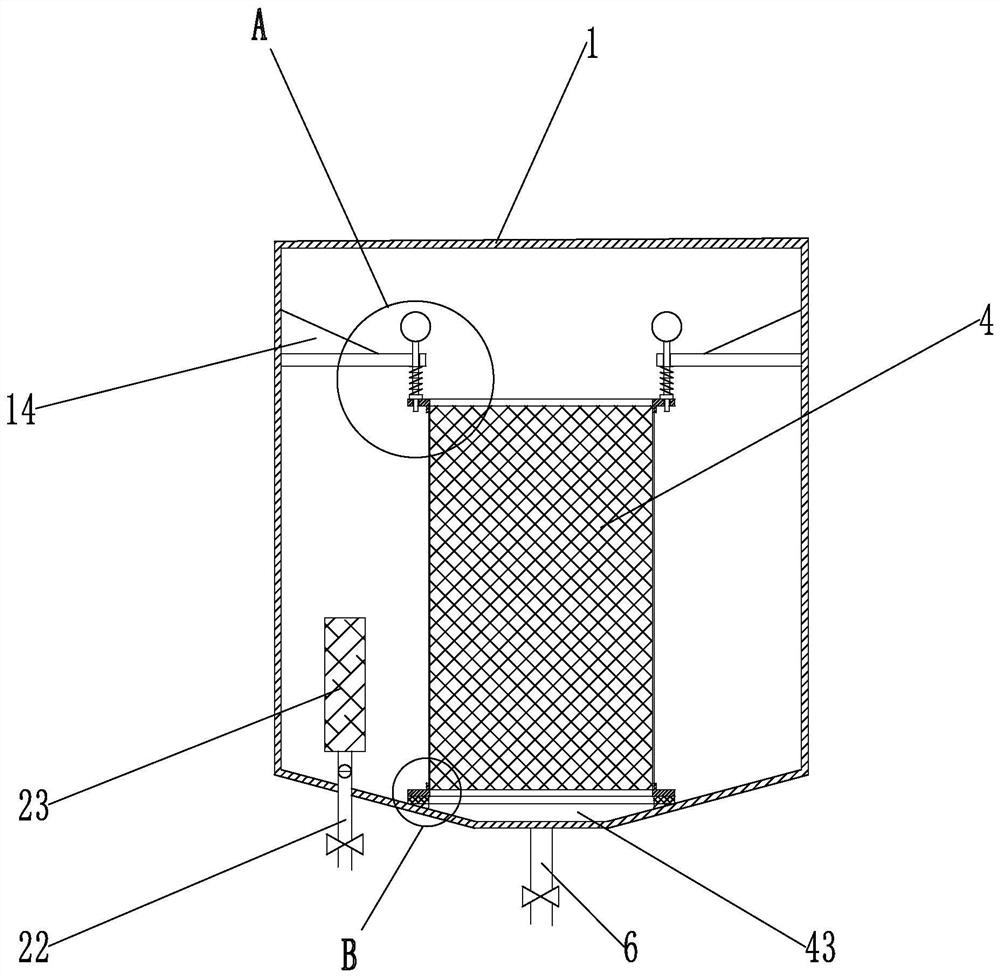

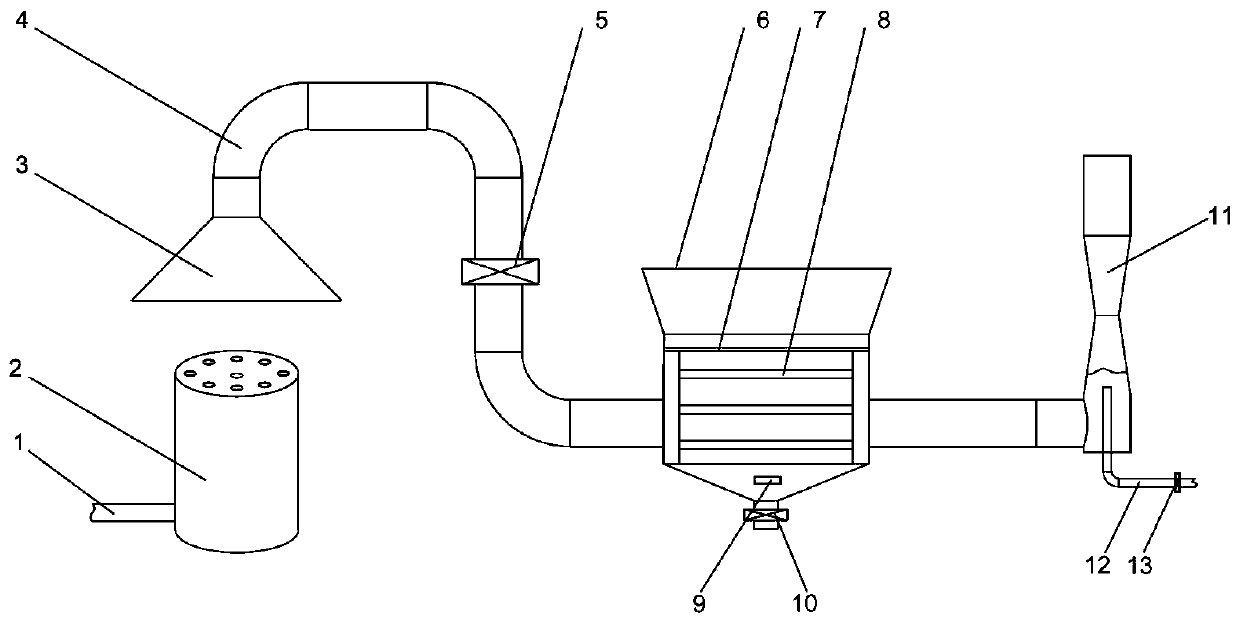

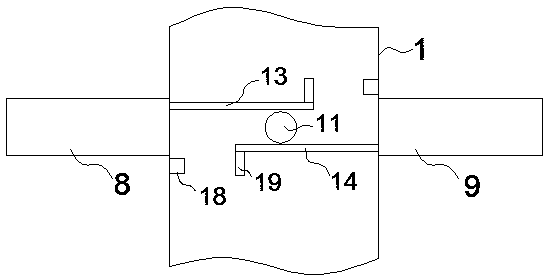

Advanced oxidation treatment device and advanced oxidation treatment process of refractory organic wastewater

InactiveCN102642911AReduced power unitWell mixedWater/sewage treatment by oxidationChemical oxygen demandRefractory

The invention aims at providing an advanced oxidation treatment device and an advanced oxidation treatment process of refractory organic wastewater, which are low in energy consumption, rapid in reaction speed, high in pollutant removal rate and low in operation cost. The device comprises a Fenton oxidizing tower, an oxidant feeding system and a catalyst feeding system, the Fenton oxidizing tower is a main device of the advanced oxidation treatment device, and the oxidant feeding system and the catalyst feeding system are respectively connected with multifunctional ejectors on two water inlet pipes of the Fenton oxidizing tower. The advanced oxidation treatment device and the advanced oxidation treatment process can treat refractory substances thoroughly, and chemical oxygen demand (COD) concentration of outlet water can reach below 50mg / L stably.

Owner:山东绿泉环保科技股份有限公司

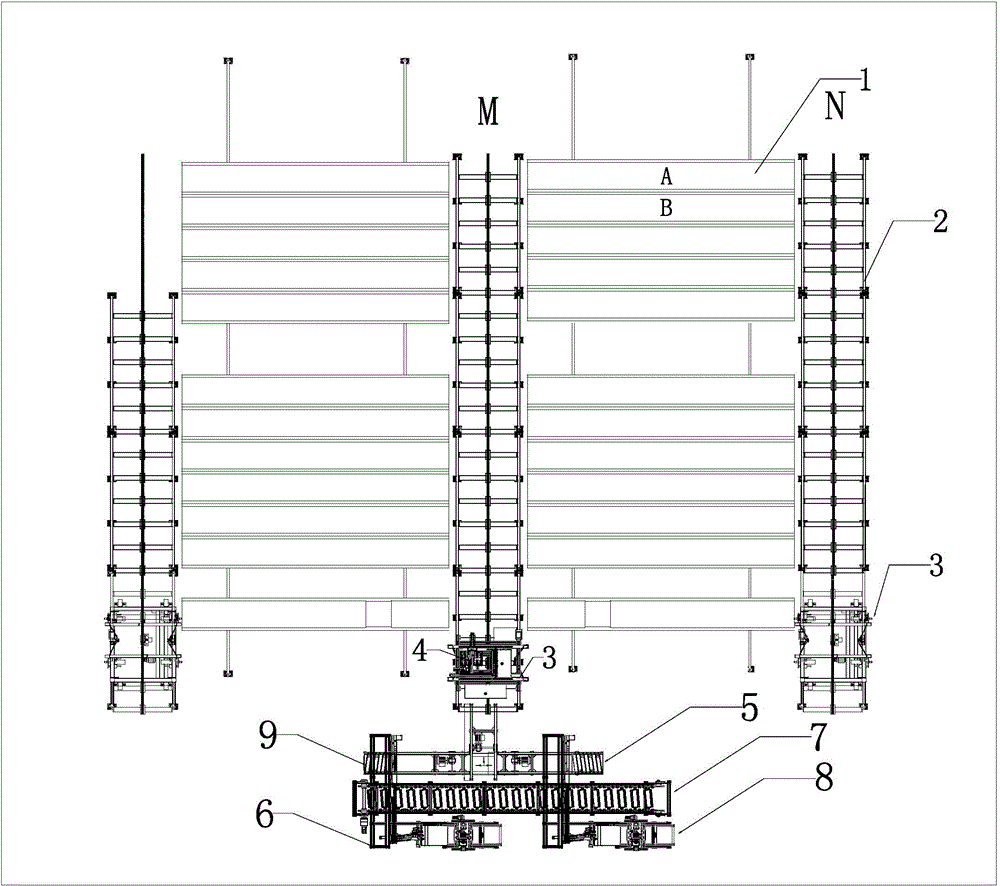

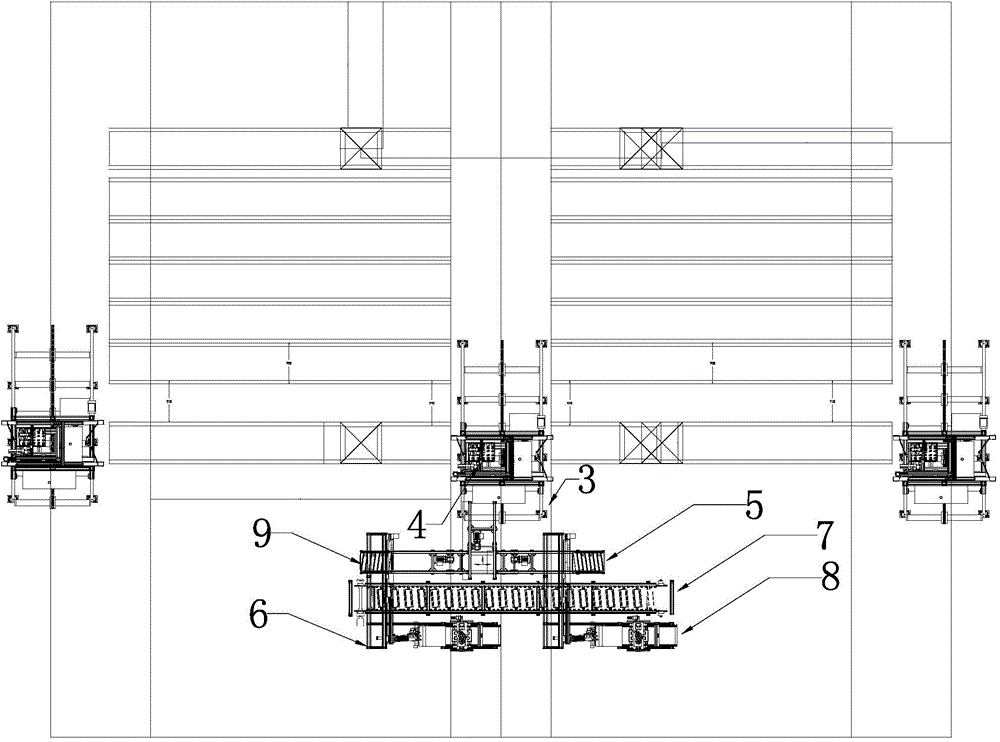

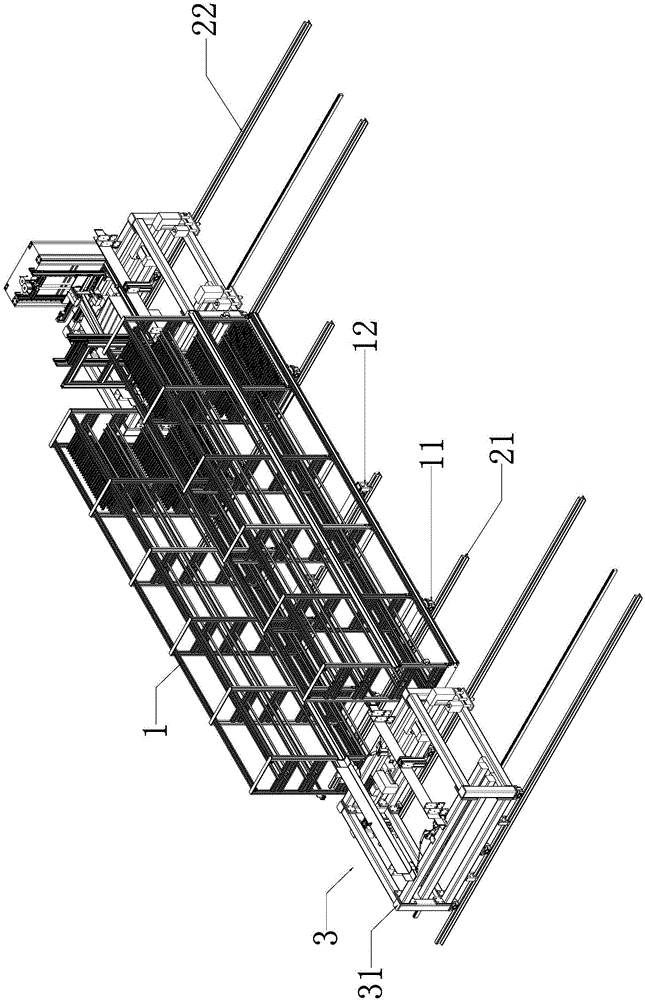

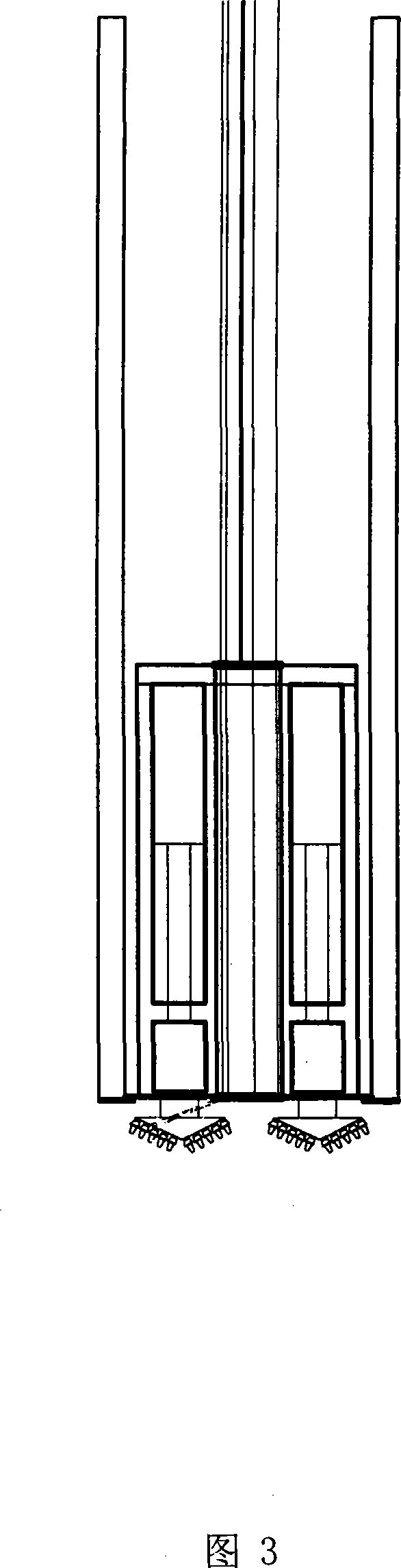

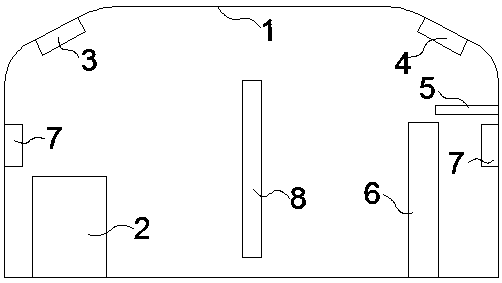

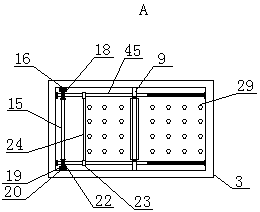

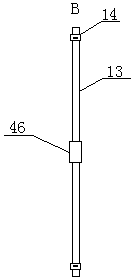

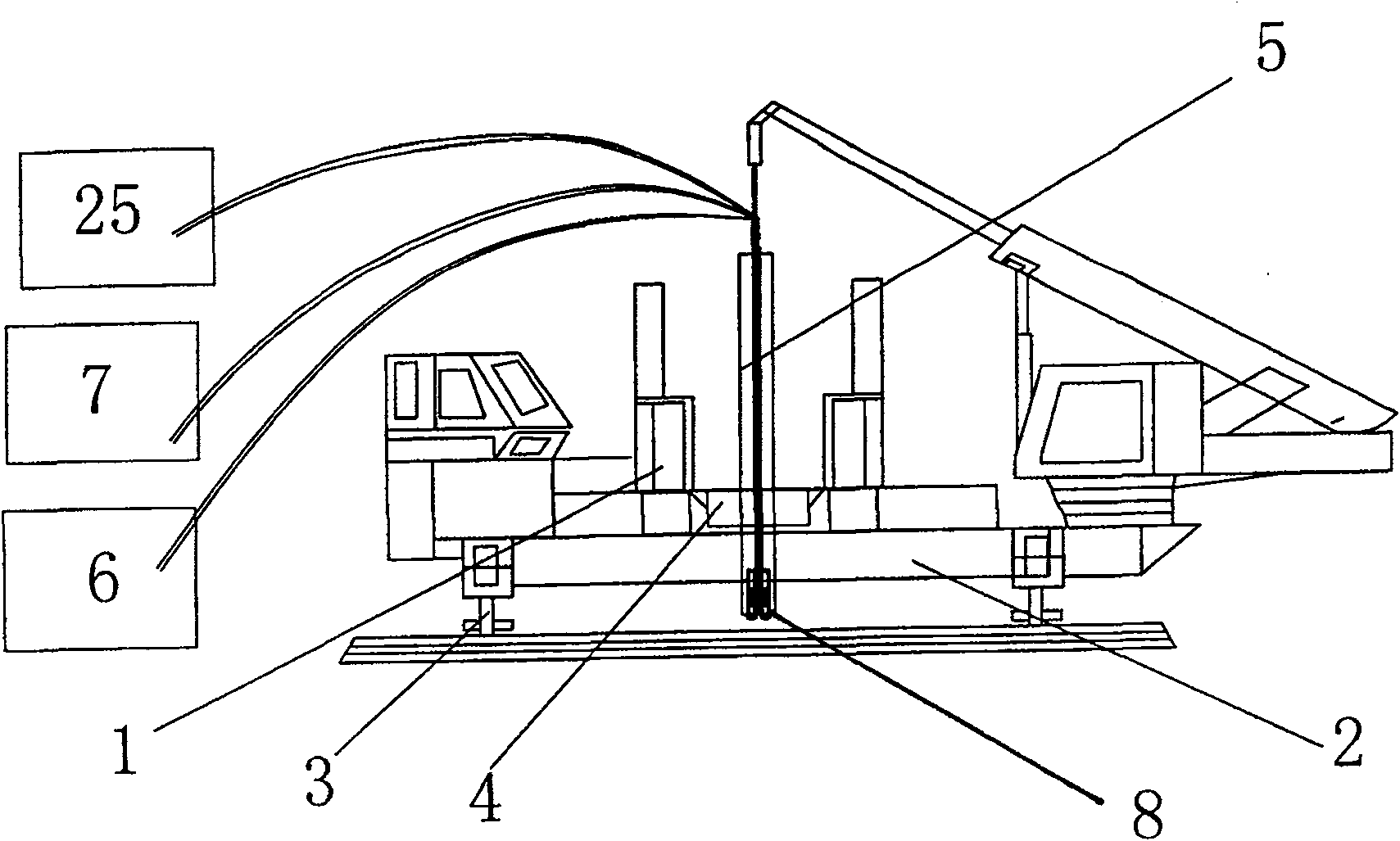

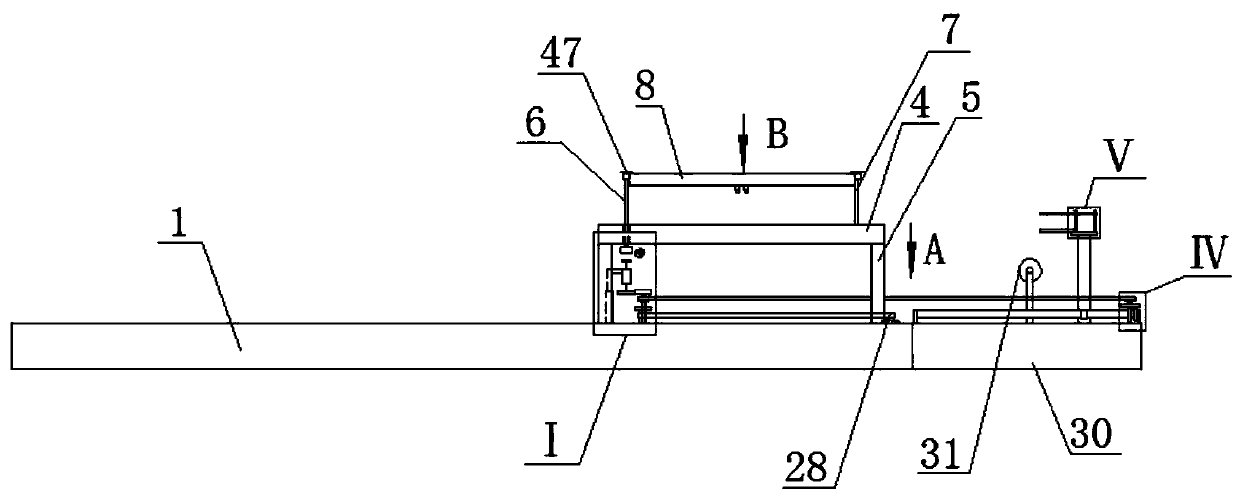

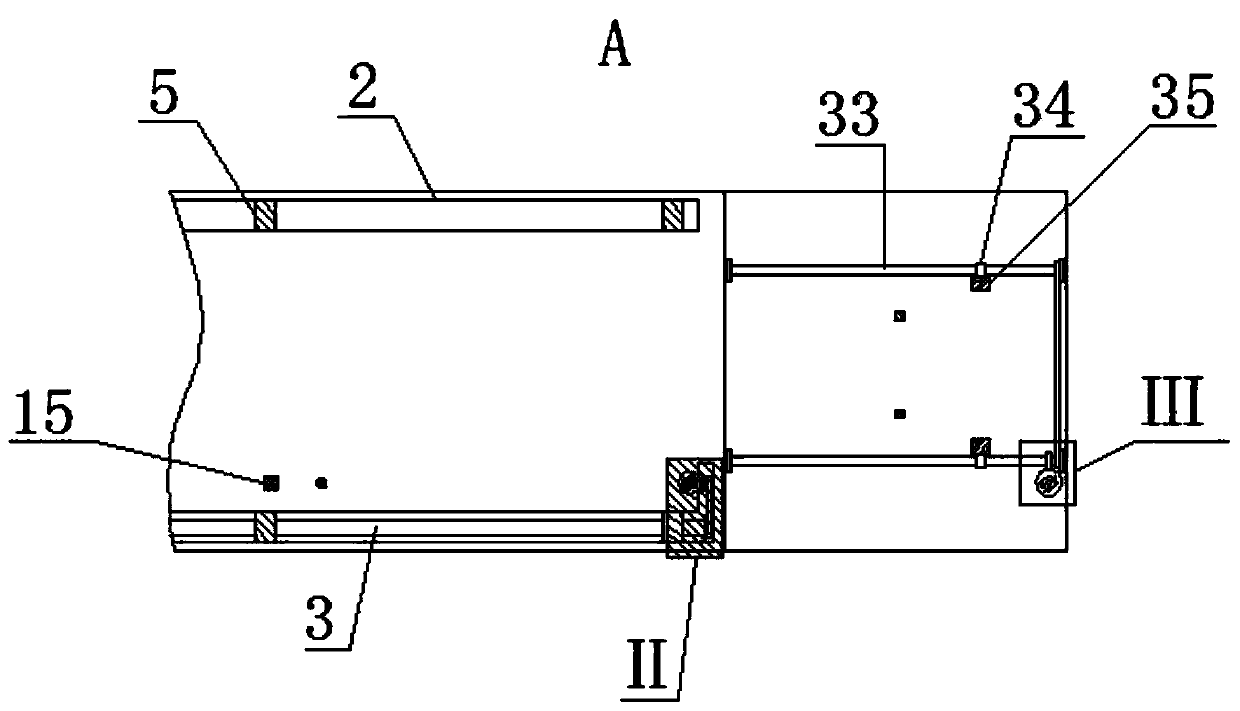

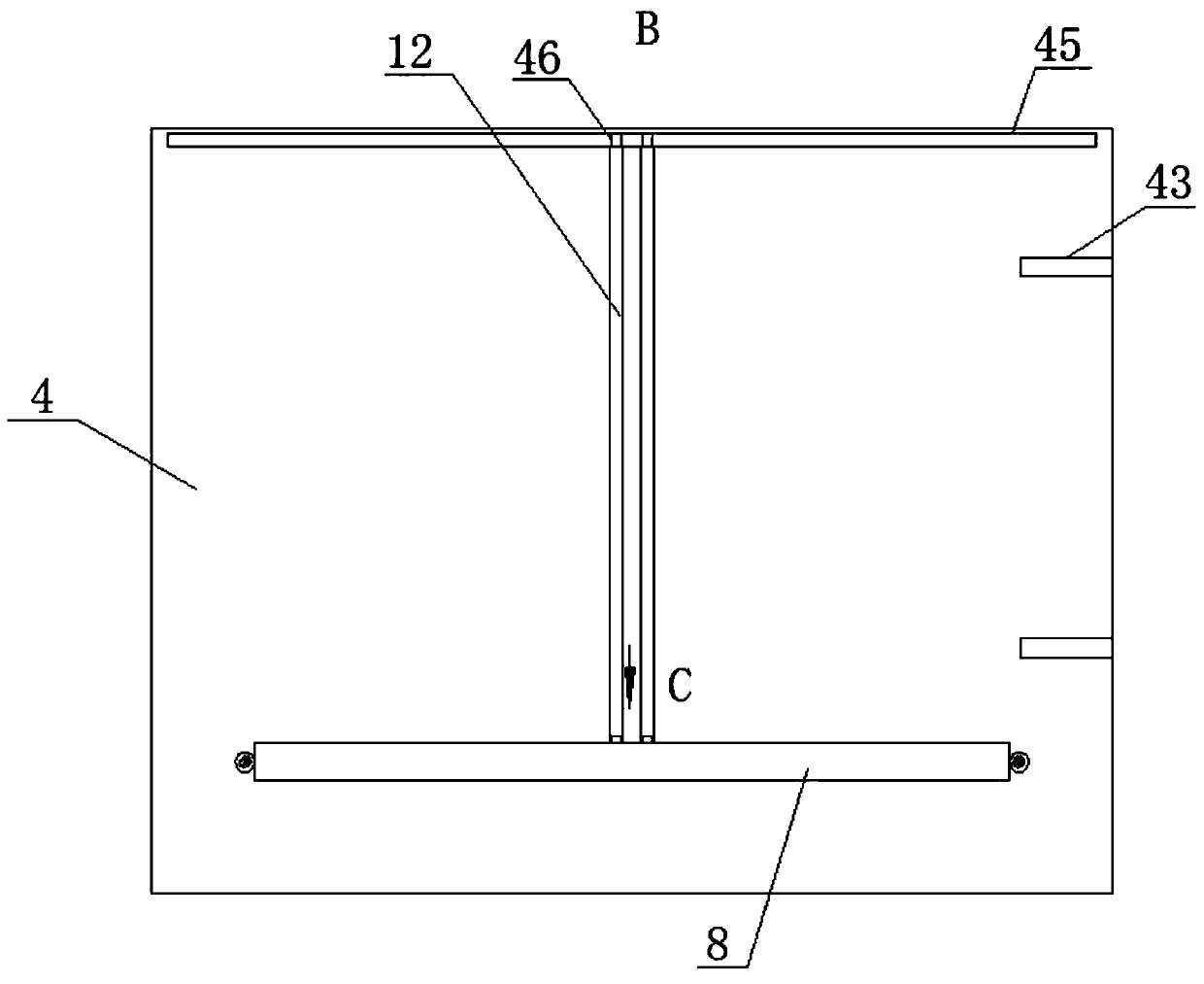

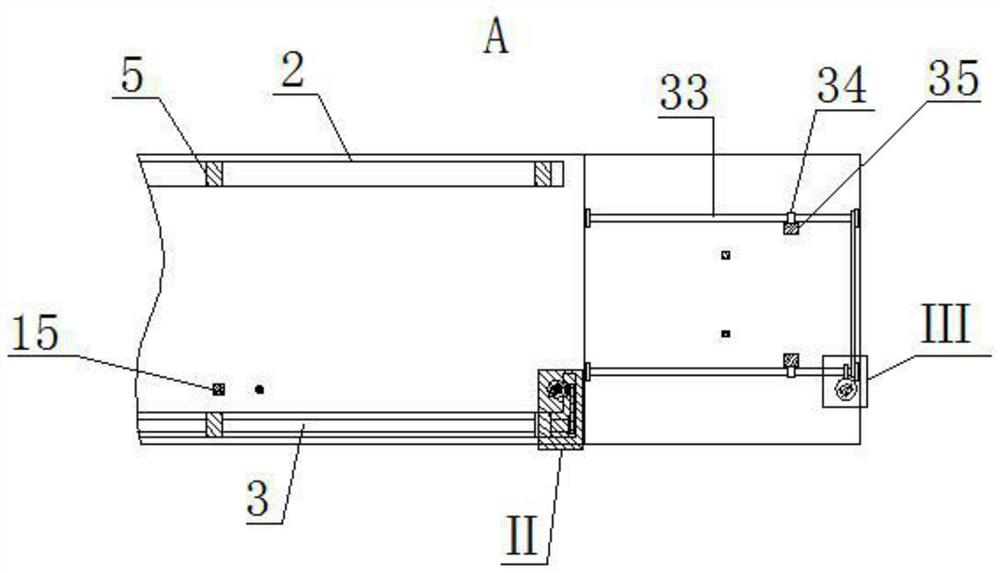

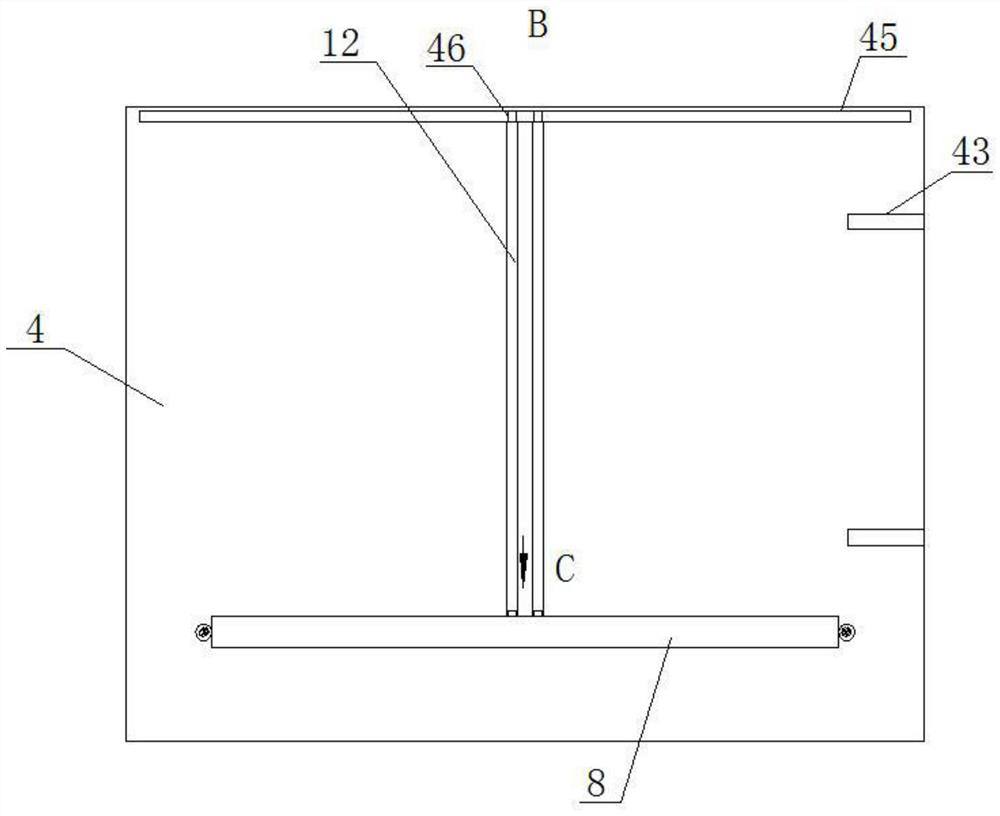

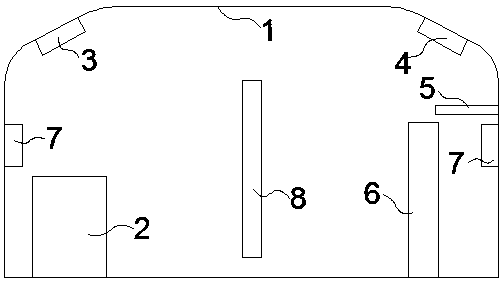

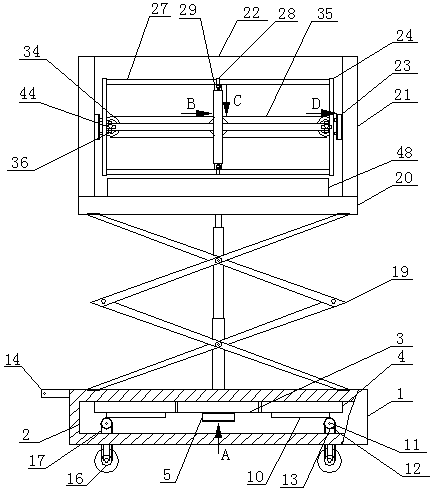

Full-automatic book management system with dense bookshelves

InactiveCN104444022AIncrease storage capacityReduced power unitStorage devicesEngineeringManipulator

The invention provides a full-automatic book management system with dense bookshelves. The full-automatic book management system with dense bookshelves comprises the bookshelves, bookshelf rails, laneway main carts, main cart rails and laneway auxiliary carts. Each laneway auxiliary cart is provided with a book fetching mechanical arm. The full-automatic book management system with the dense bookshelves is characterized in that the dense bookshelves are arranged on the bookshelf rails, and each laneway main cart is provided with a bookshelf opening mechanism. The bookshelves are opened through the bookshelf opening mechanisms on the laneway main carts, a drive device of the bookshelves can be effectively omitted, the bookshelves can be opened just by the laneway main carts, and borrowing and returning of books are completed at the same time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

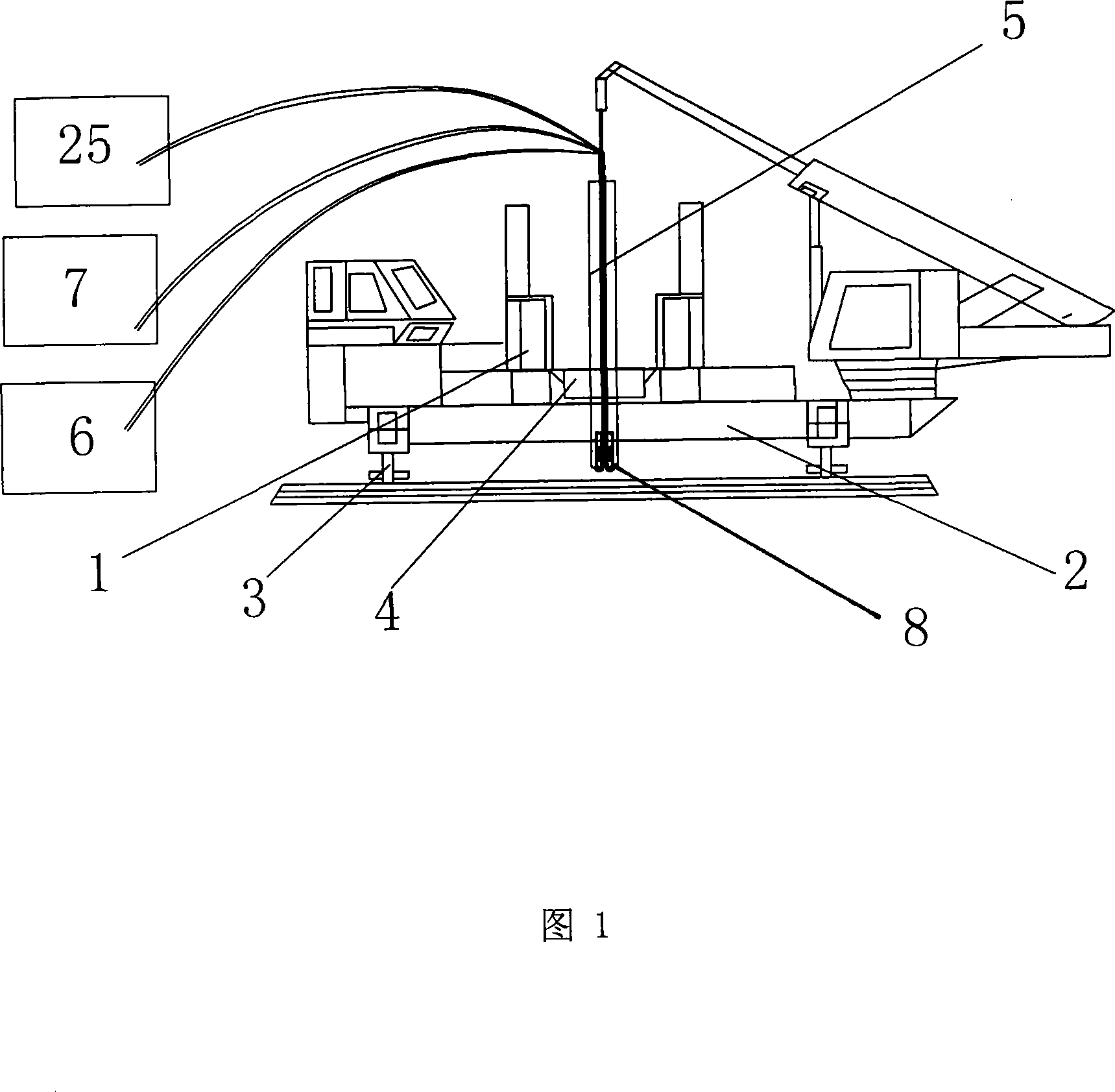

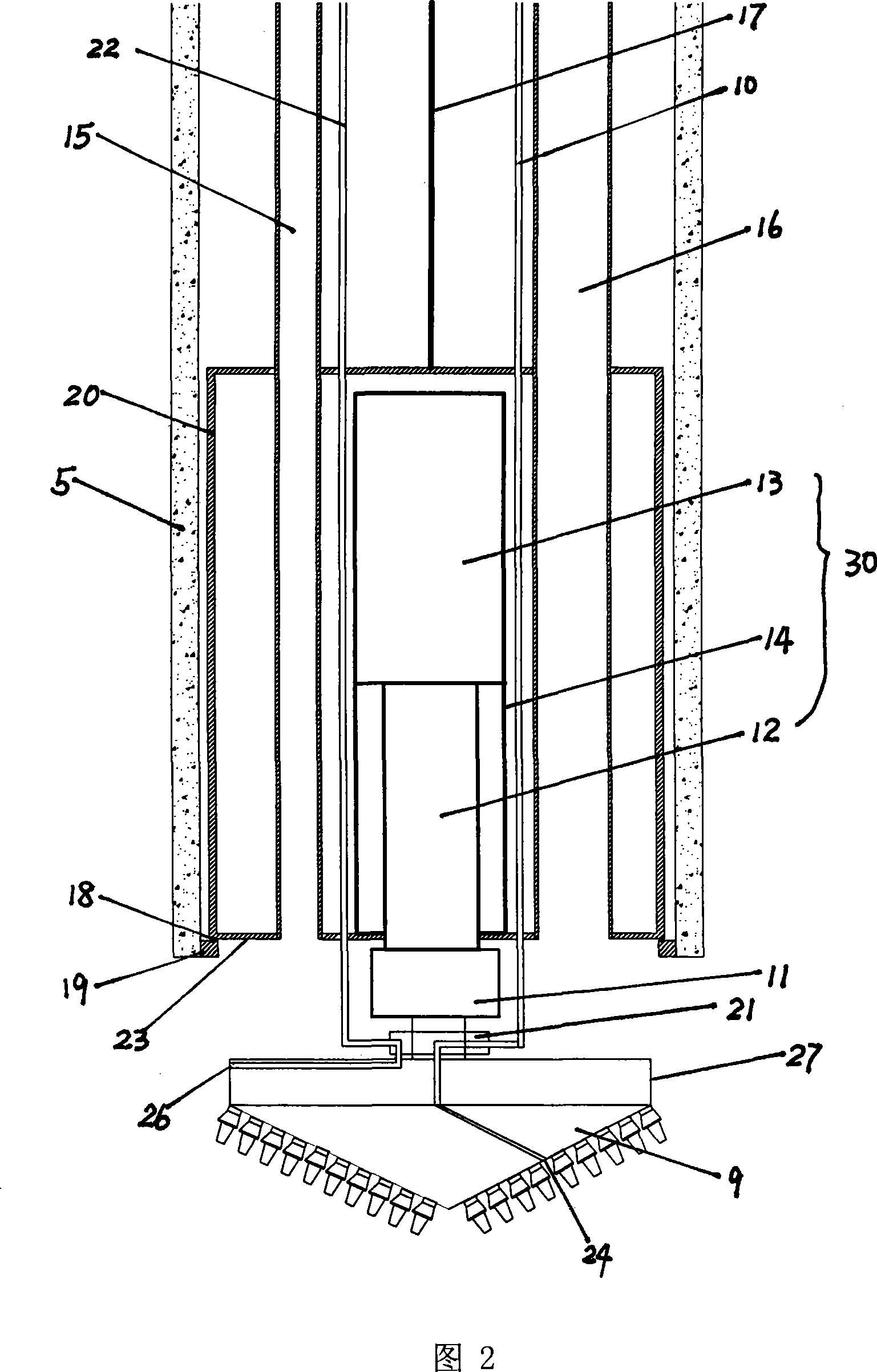

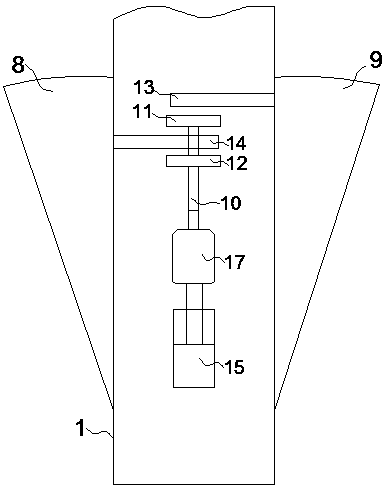

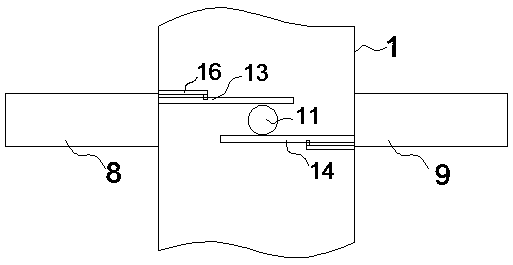

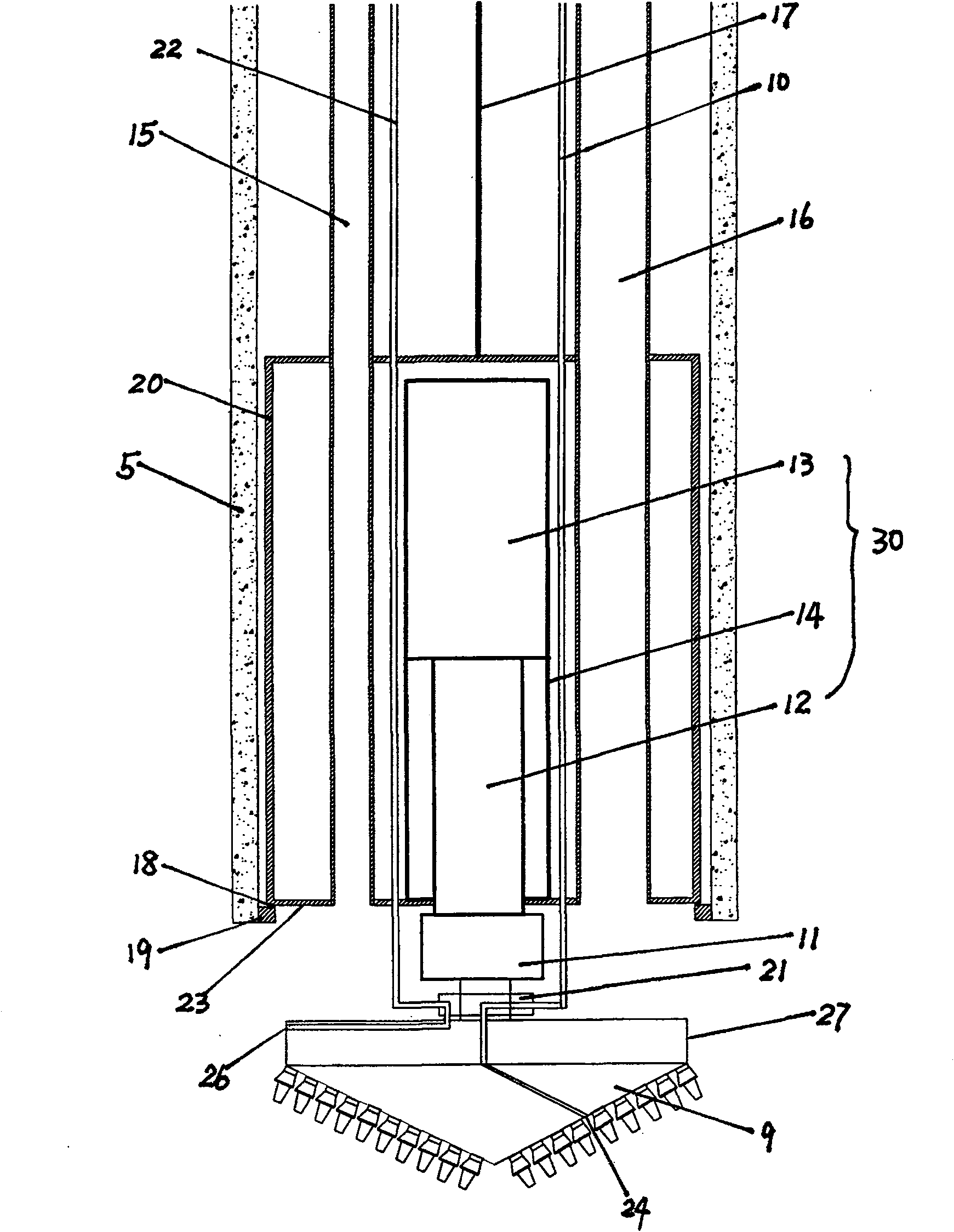

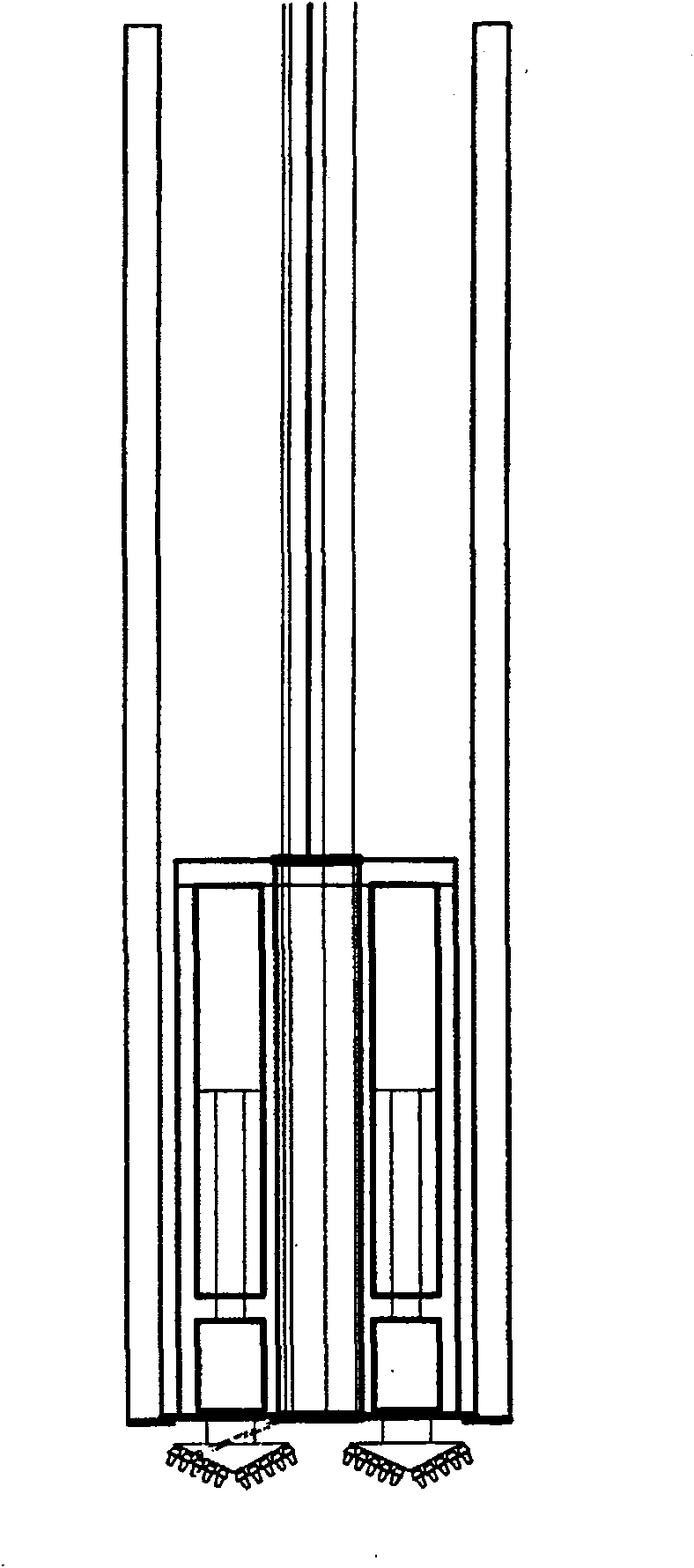

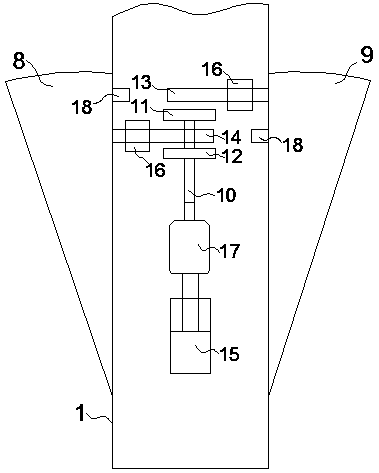

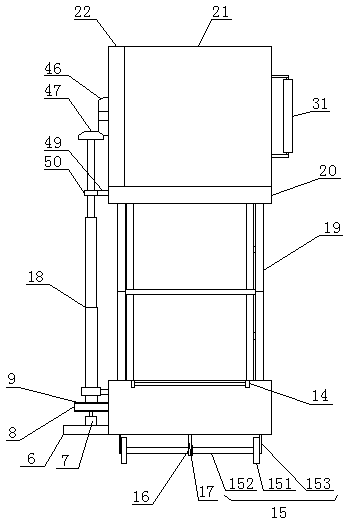

Construction machinery used for large diameter hollow pile and its construction method and use

InactiveCN101215836AReduce side frictionIncreased vertical bearing capacity of single pileBulkheads/pilesDrilling machines and methodsHigh pressureHigh load

The invention discloses a construction machine for hollow piles with large diameter and the construction method and usage, which comprises a drilling system, a pile pounding system, a drainage system which are integrated into one part. The pile forming method comprises: a high-spray drilling bit is arranged on a steel tube (a protection cylinder) or on the bottom of an inner hole of a pre-made tube pile for hole drilling and mud making; the mud is drained from a water joint or a drainage pipe; the protection cylinder or tube pile is pressed asynchronously or synchronously along with the drilling bit; during pile-sinking process, water mud is sprayed to the outer soil of the hole to solidify the surrounding soil of the pile and fill the gaps between the pile and surrounding soil of the pile; after the drilling bit reaches certain depth, the water mud is again sprayed to solidify surrounding soil of the pile; lifting the drilling bit; putting down reinforcement cage; casting concrete for piling. The invention is a construction method for foundation piles and drilling with large diameter, super long and high load, which especially provides convenient, labor-saving, rapid and economical equipment and method for marine pile driving.

Owner:雷玉华

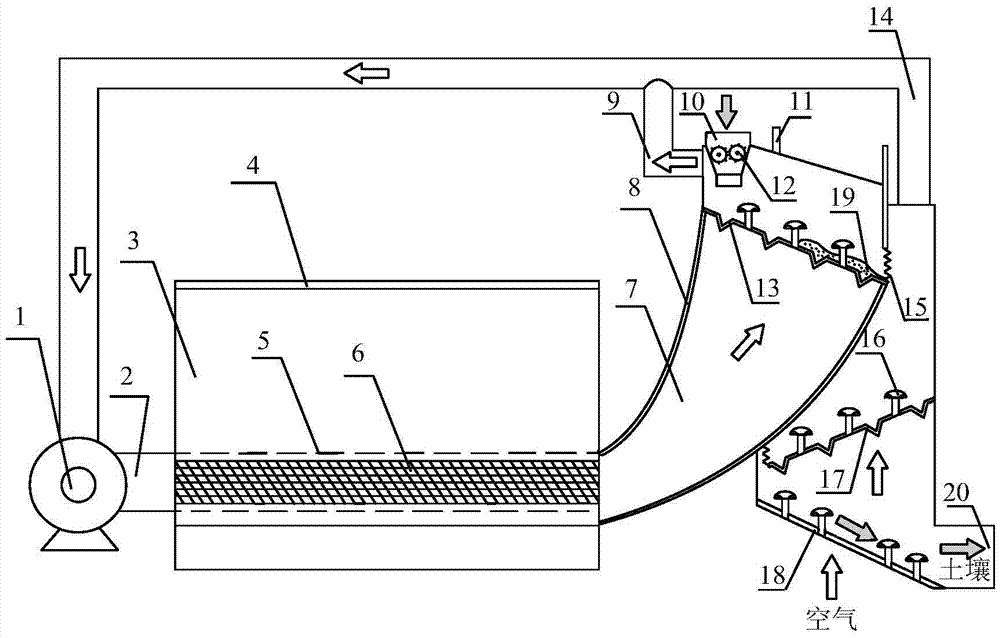

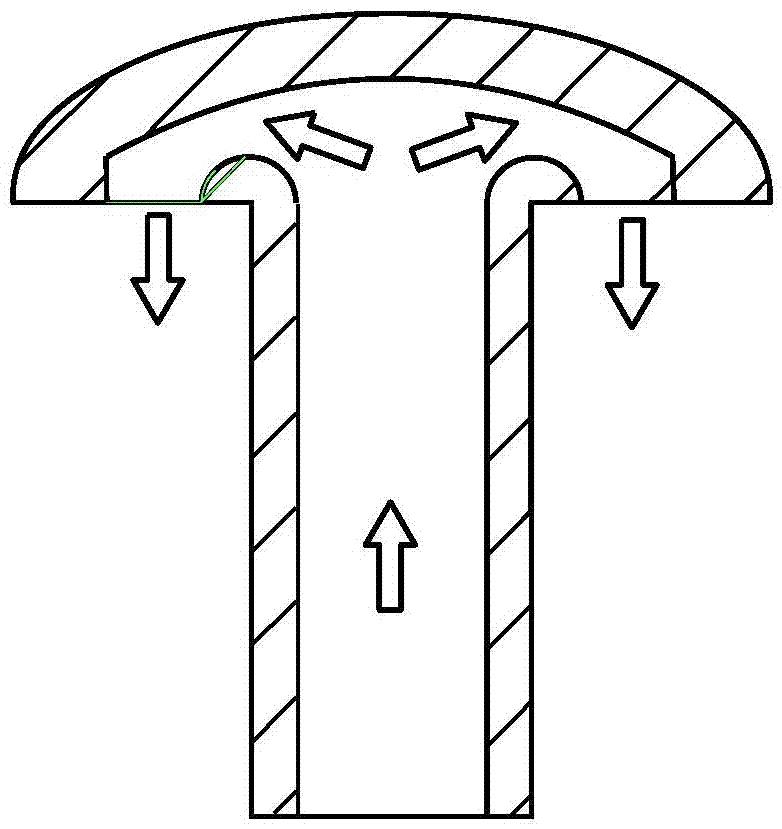

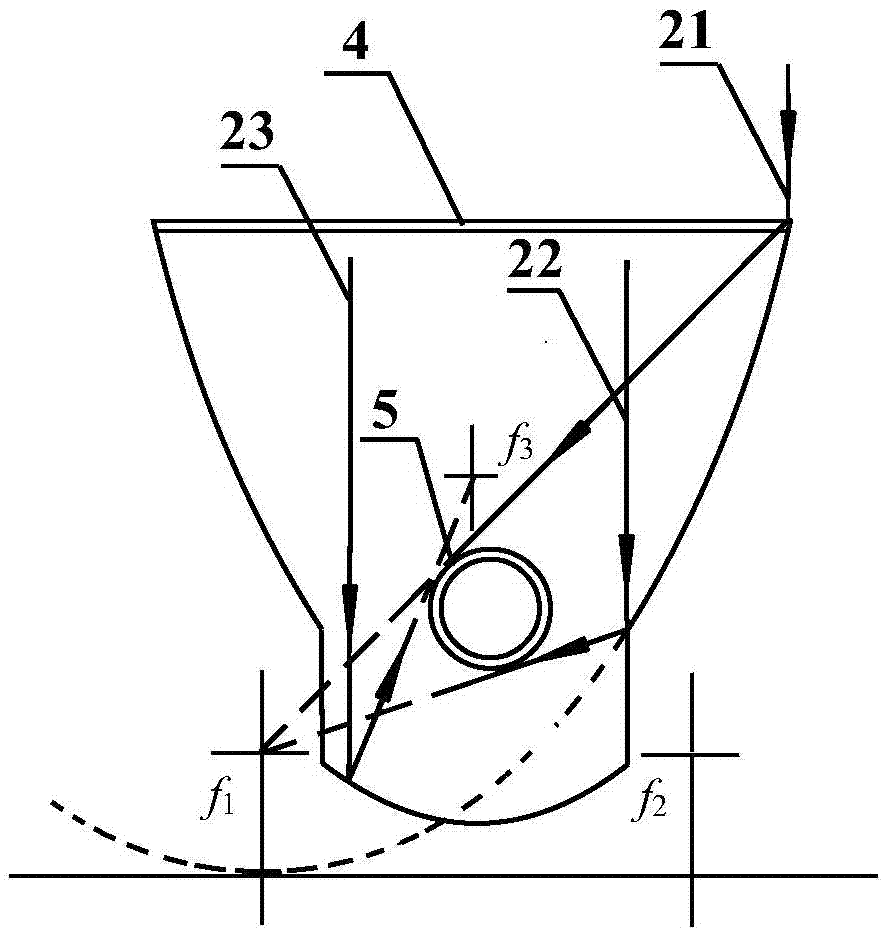

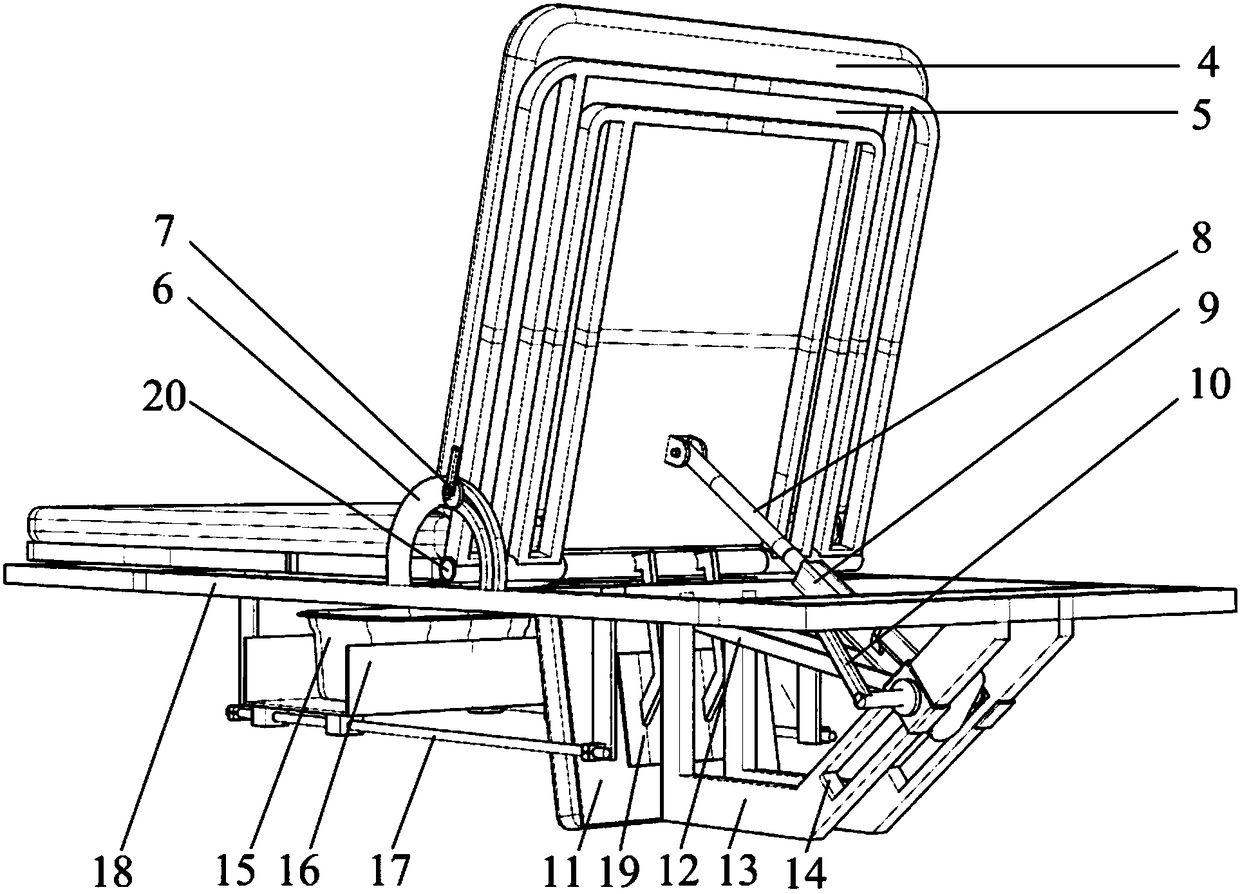

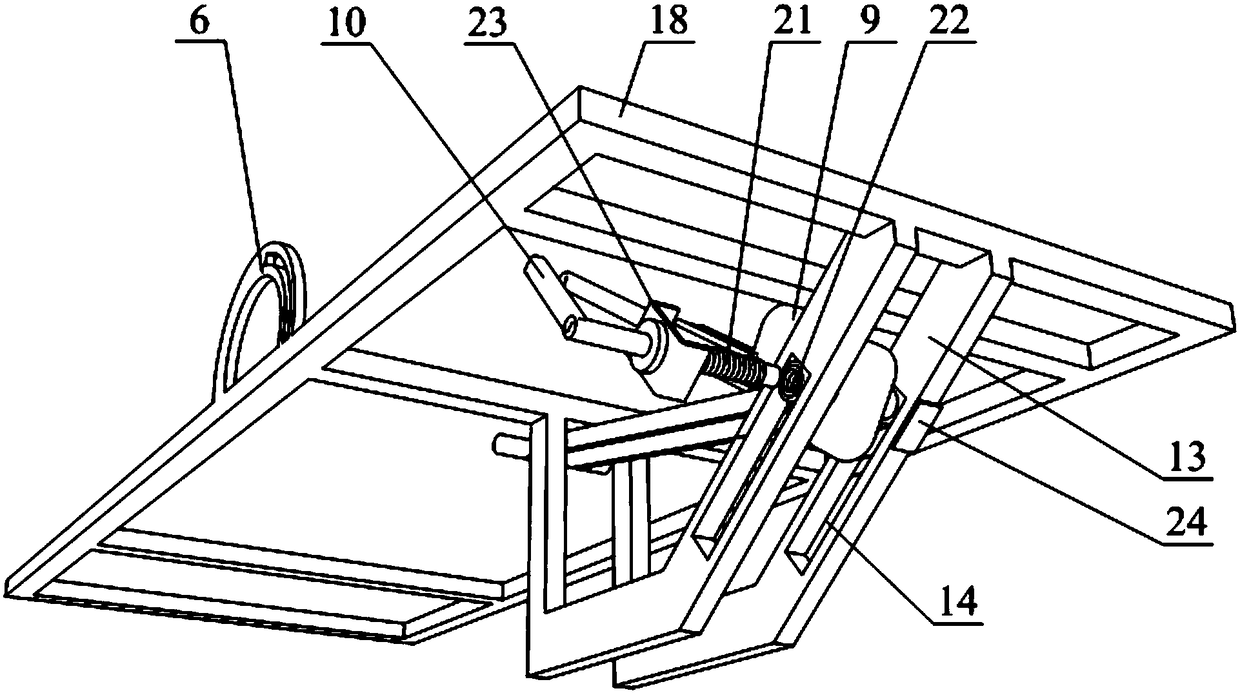

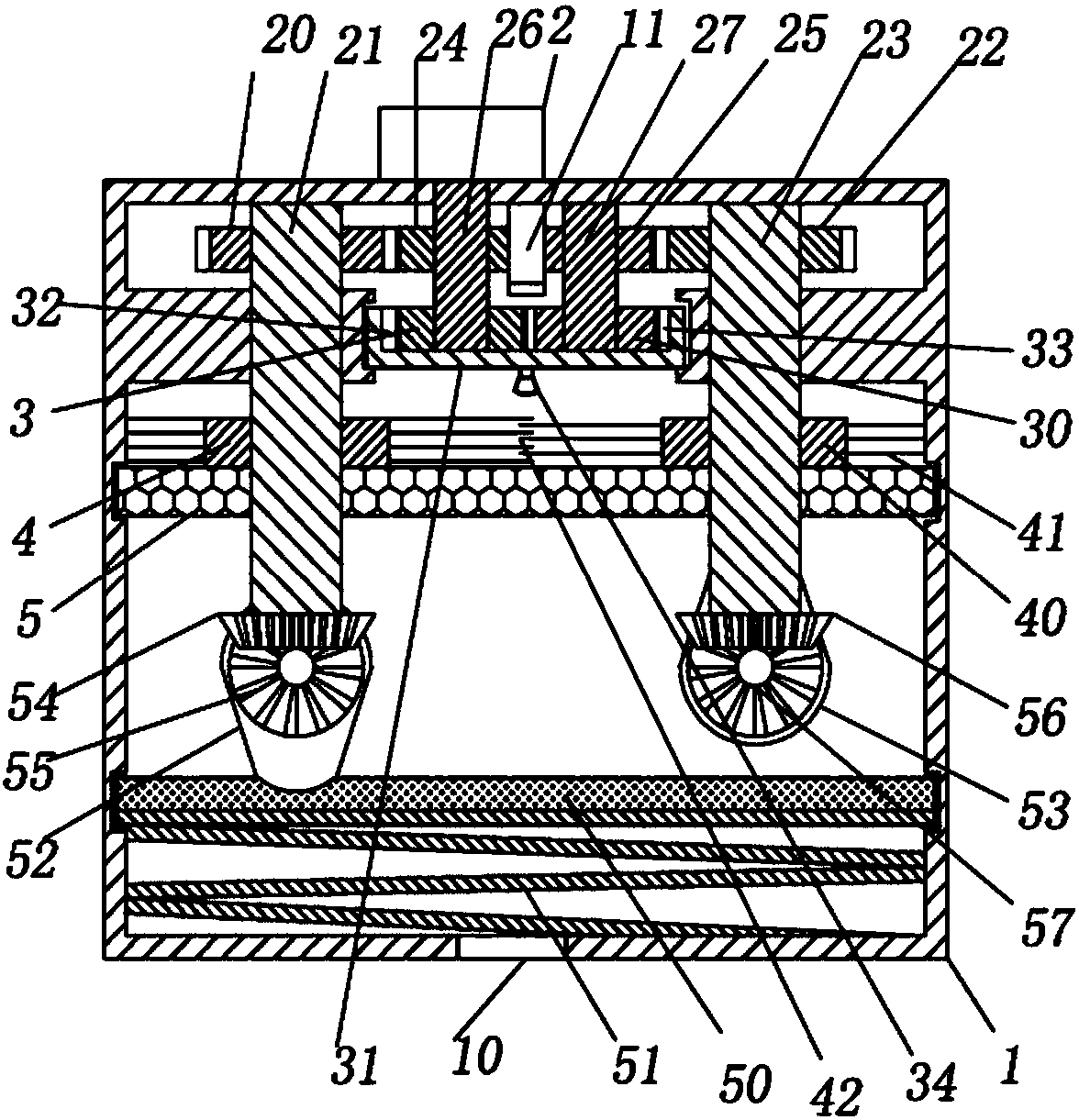

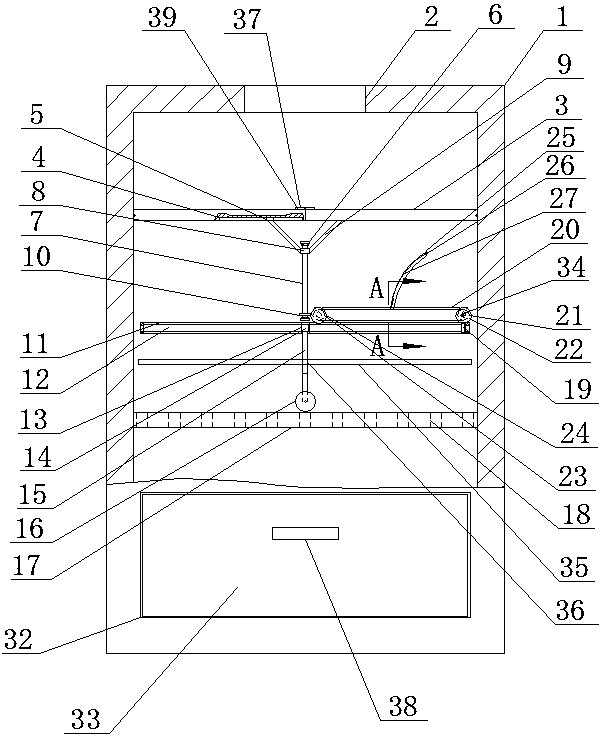

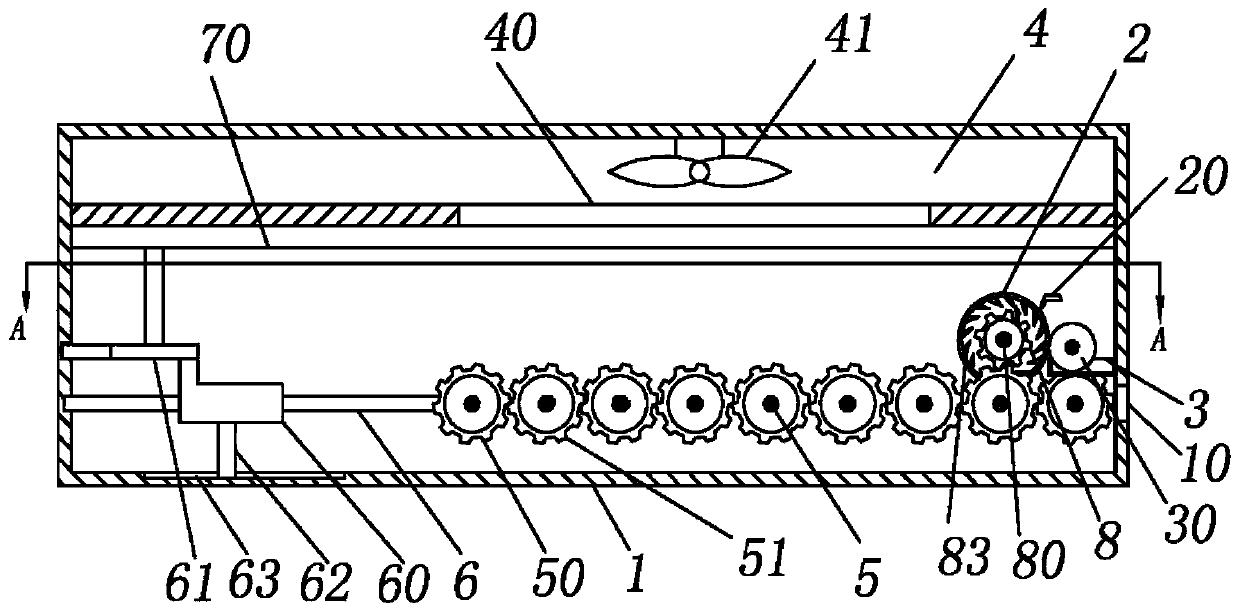

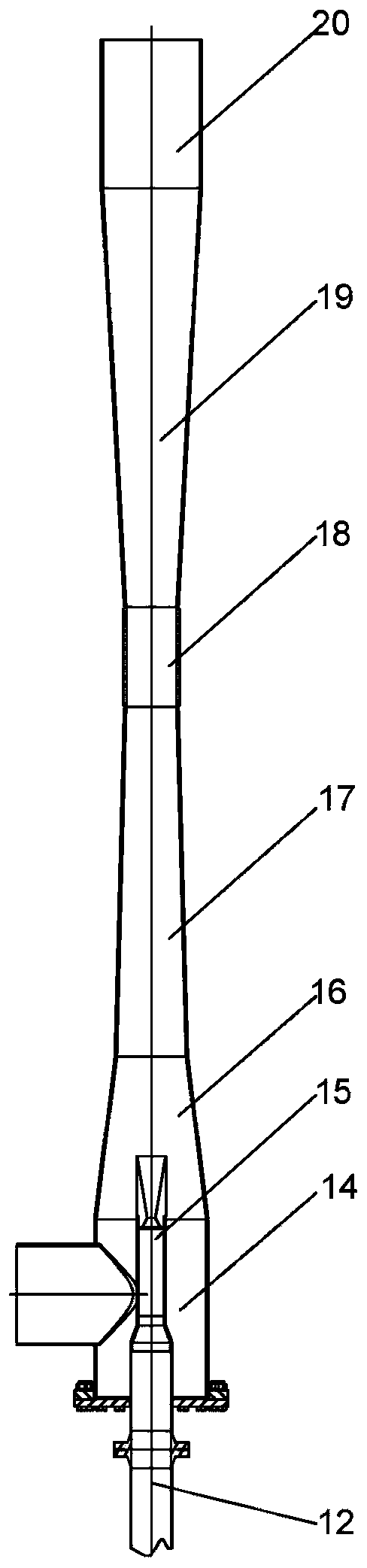

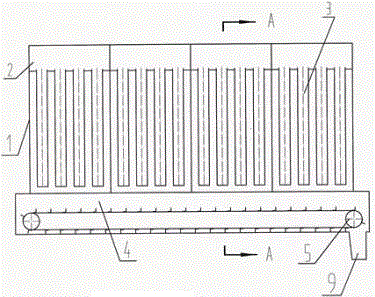

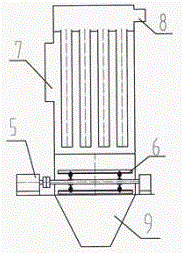

Light gathering and heat returning type soil disinfecting and repairing device

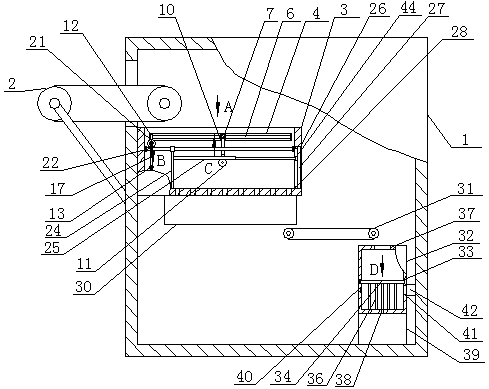

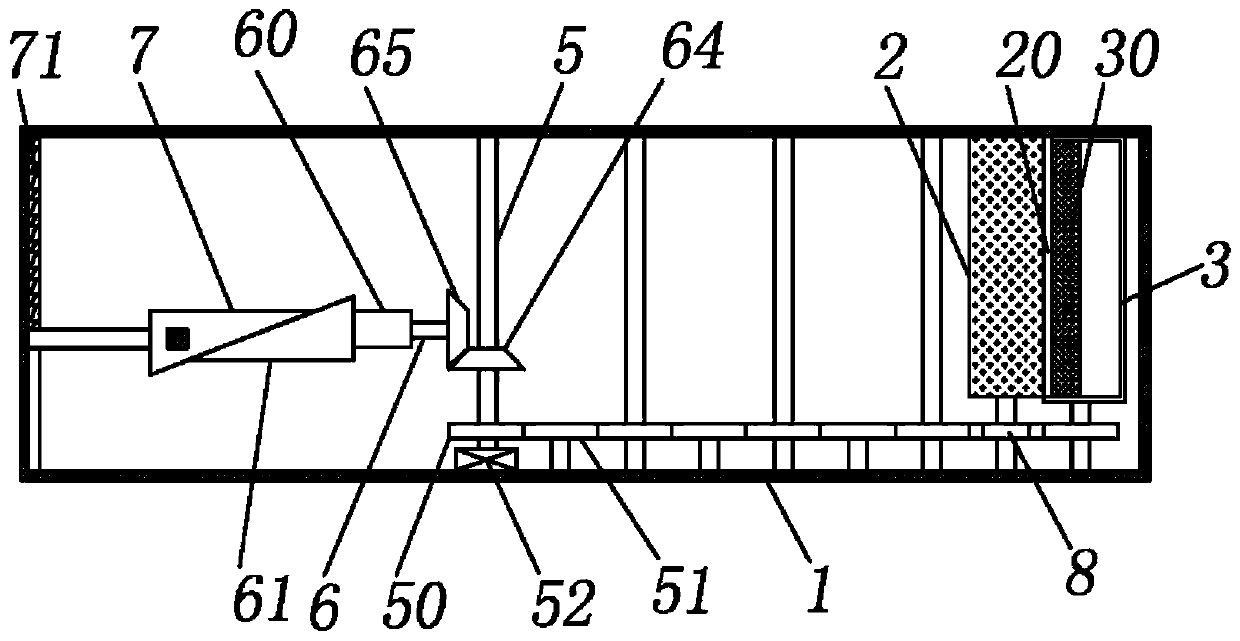

ActiveCN105432176AWon't clogRealize automatic slidingSoil lifting machinesRenewable energy machinesSoil treatmentGlass cover

The invention belongs to a solar application device, and particularly relates to a soil treatment device. A light gathering and heat returning type soil disinfecting and repairing device comprises an induced draft fan (1), an air outlet flue (2), a groove type multi-hook-face solar condenser (3), a glass cover plate (4), a double-layer glass vacuum pipe (5), a ventilation heat absorbing body (6), an insulating layer (8), a hot air cavity (7), a first-level metal heat exchange plate (13), a feeding hopper (10), a mushroom-shaped ventilation channel (16), a tail air backflow channel (9), an exhaust pipe (11), a natural vibration spring (15), a second-level metal heat exchange plate (17), a soil sliding conveying belt (18), a feeding air channel (14) and a discharging port (20). Soil is heated through high-temperature air heated through solar energy, then disinfecting and killing of injurious insects, pathogenic bacteria and weed seeds in the soil and separation of volatile organic compounds in the soil are carried out, the fossil energy does not need to be consumed, pollution to the soil is avoided, and food safety is effectively guaranteed.

Owner:INNER MONGOLIA UNIV OF TECH

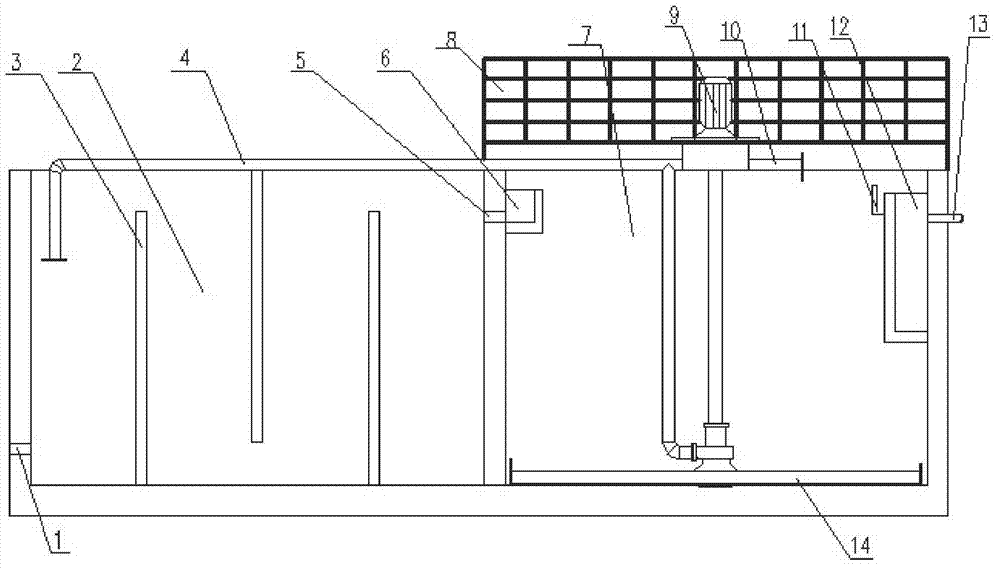

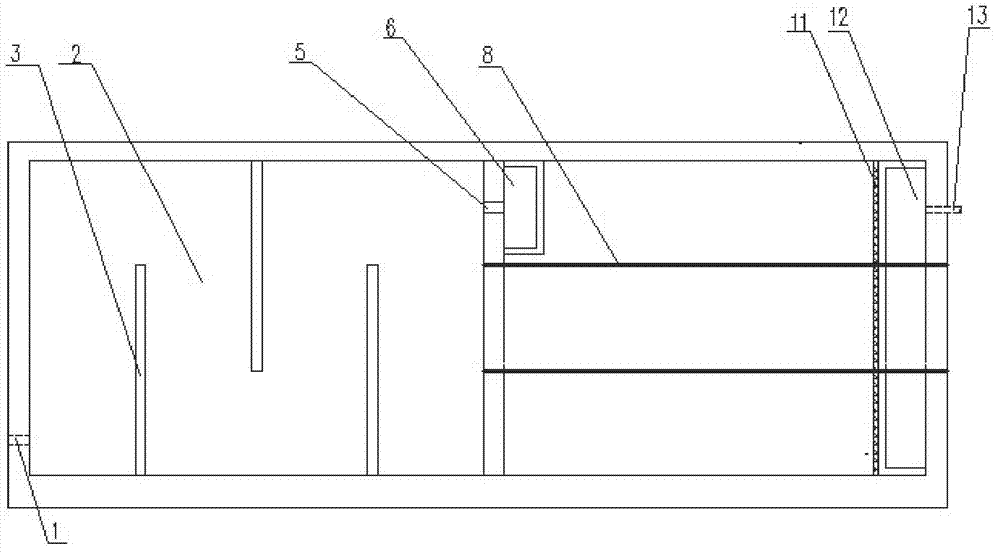

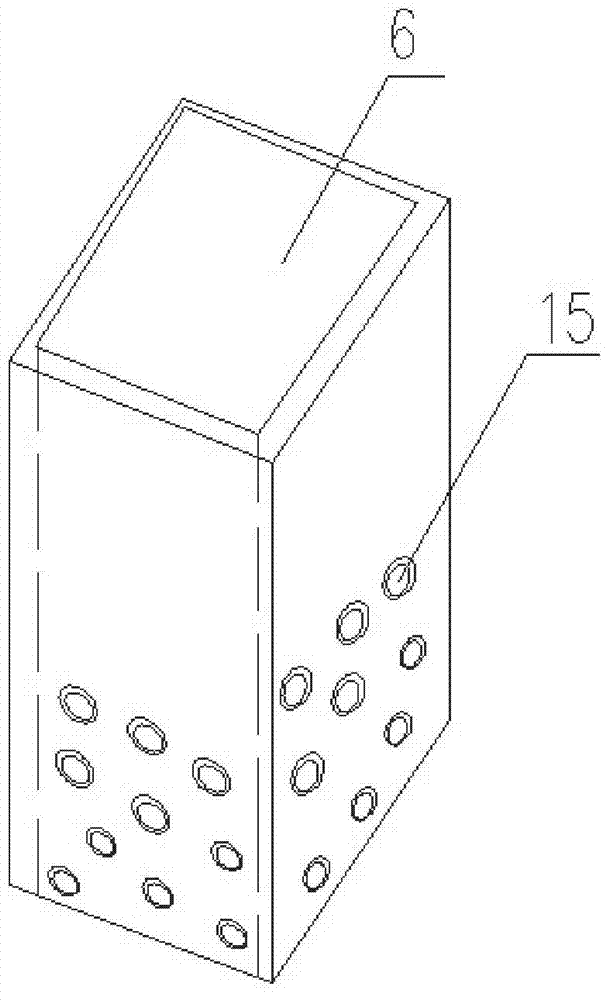

Waste water processing device for high-density flocculating clarification

ActiveCN102863063AReduced power unitReduce energy consumptionWater/sewage treatment by flocculation/precipitationFlocculationHigh density

The invention discloses a waste water processing device for high-density flocculating clarification, comprising a flocculation reaction device, a clarification concentration device and a sludge returning device; the clarification concentration device are connected in series after the flocculation reaction device; the sludge returning device is connected with the flocculation reaction device and the clarification concentration device. The device has the advantages of simple and compact structure, small floor space, low energy consumption, low operating cost and high sludge concentration, standard discharge of waste water, insensitivity of water inlet fluctuation and capability for bearing flow variation within a larger range.

Owner:广西绿晨环境工程有限公司

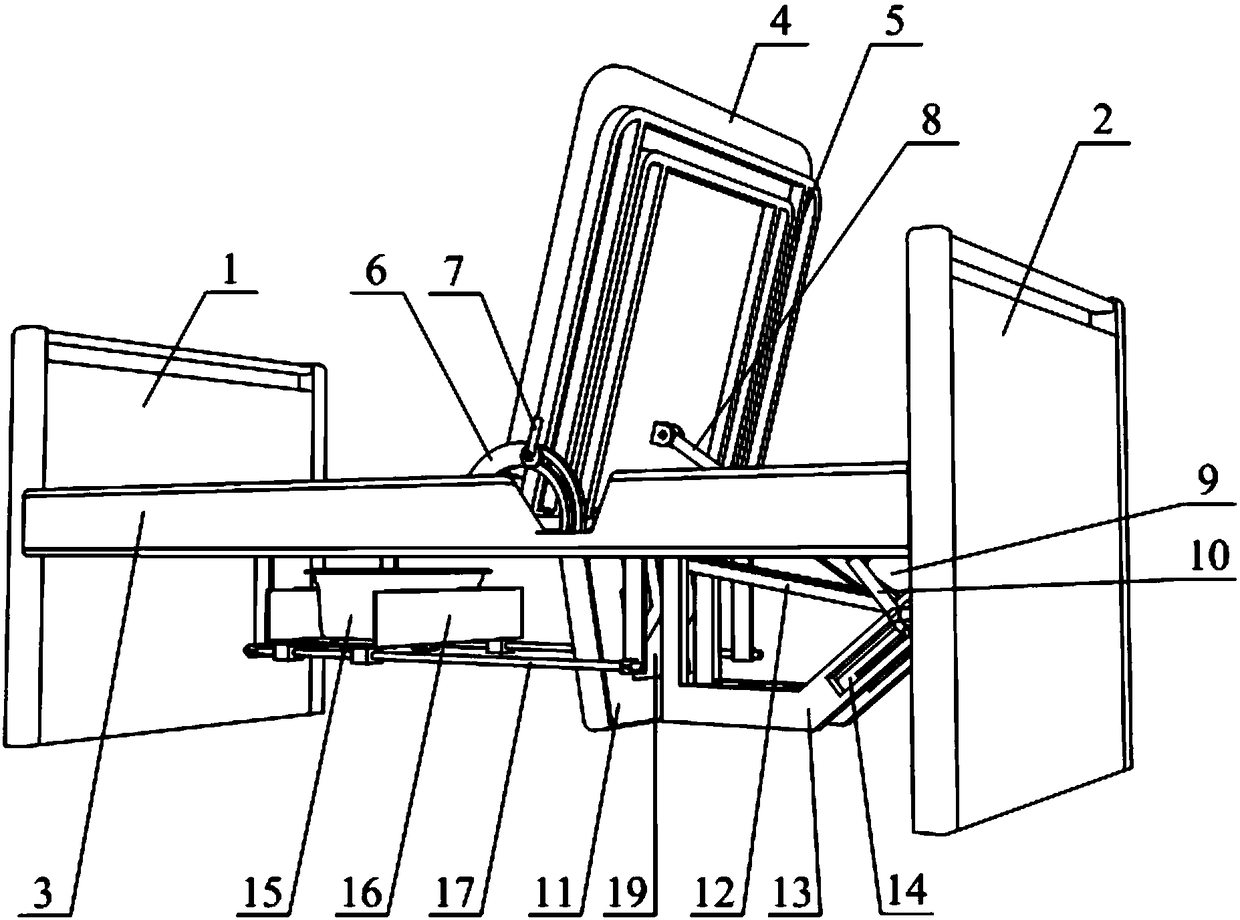

a nursing bed

Owner:GUANGDONG UNIV OF TECH

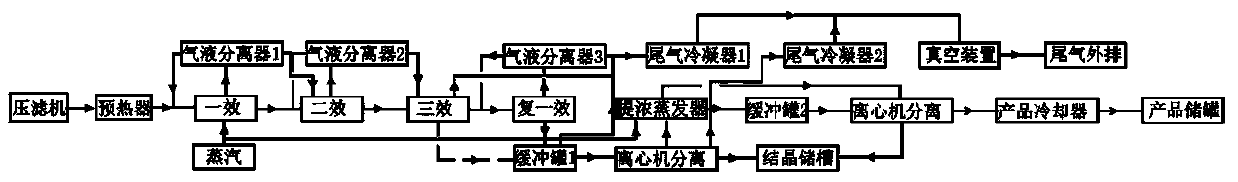

Treatment system for waste lead-acid storage battery electrolyte

PendingCN109888424AReduced power unitReduced steam consumptionWaste accumulators reclaimingWater/sewage treatment by heatingTriple effectChemistry

The invention discloses a treatment system for a waste lead-acid storage battery electrolyte. The system comprises a pressure filter for removing broken impurities and large particulate matters in theelectrolyte; the electrolyte is preheated through a preheater; the electrolyte enters triple-effect evaporation after being preheated by the preheater, and the concentration of an acid solution is increased to 50% from about 20% after the electrolyte is subjected to the triple-effect evaporation; the electrolyte enters a multiple-effect evaporator after being subjected to the triple-effect evaporation, and the concentration of the acid solution is increased to 70% from 50% after multiple-effect evaporation; after the electrolyte is subjected to the multiple-effect evaporation for increasing the concentration, a centrifugal machine performs centrifugal desalting; the treated electrolyte returns to a buffer tank again to carry out the next procedure of concentration increasing evaporation;acid becomes industrial sulfuric acid by increasing the acid concentration from 70+ / -2% after being treated with a concentration increasing evaporator; and crystal substances separated twice through the centrifugal machine are conveyed to a crystal substance storage tank. The boiling point of the sulfuric acid in a negative pressure state is reduced, so that the steam energy consumption can be reduced and the production cost can be reduced; and meanwhile, the sulfuric acid can become the industrial acid by increasing the concentration from 20-50% through the multiple-effect evaporation, so that the utilization value of the sulfuric acid is improved.

Owner:河北港安环保科技有限公司

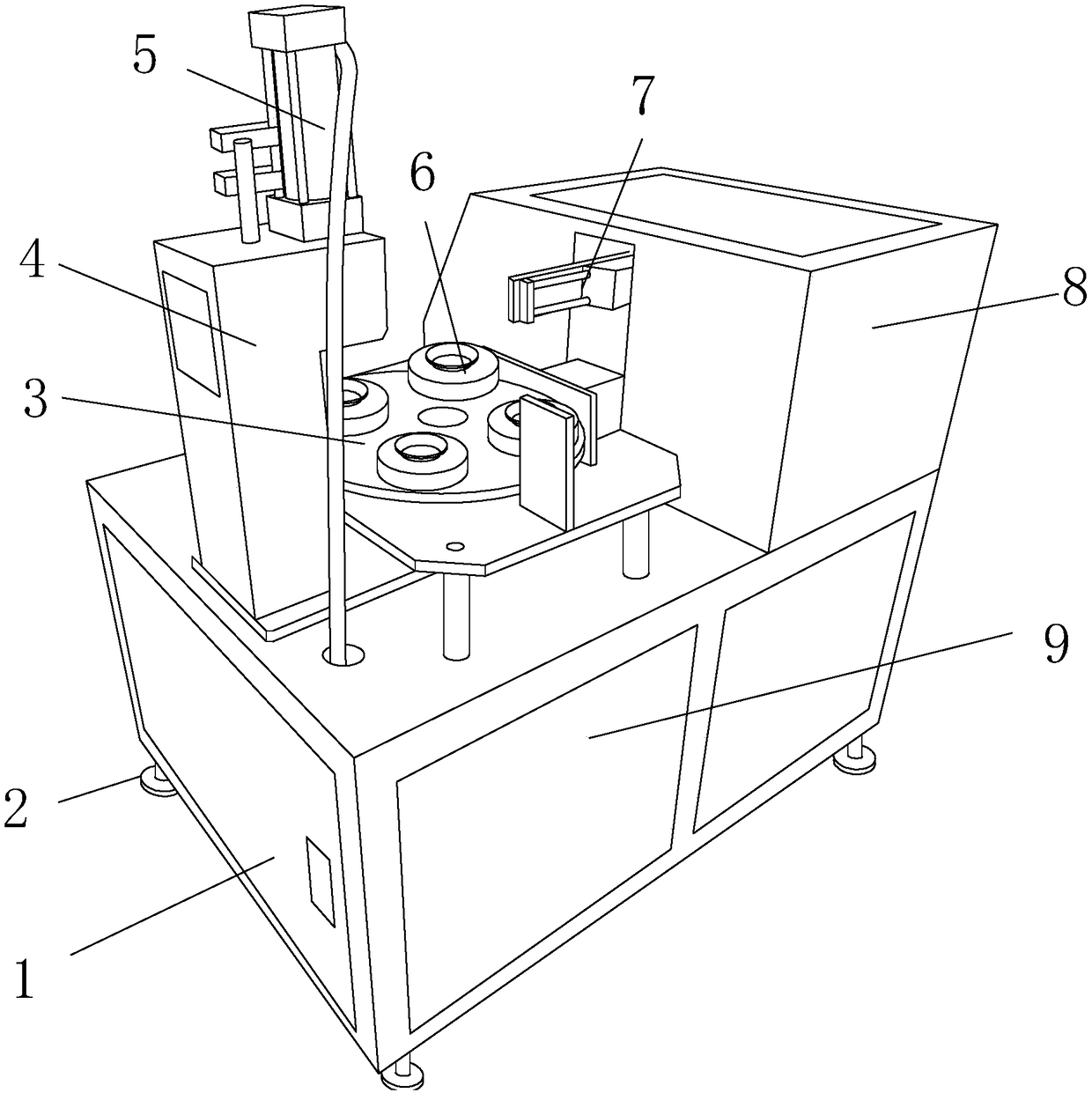

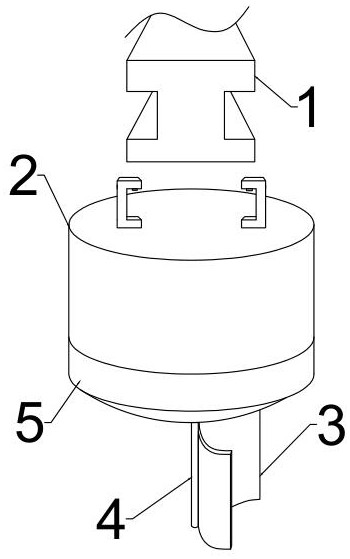

Turntable type plastic part sealing equipment

The invention discloses turntable type plastic part sealing equipment. The turntable type plastic part sealing equipment comprises a base, support legs, a turntable, a transmission box, a hydraulic cylinder, sealing and discharge devices, a loading manipulator, a material box and a collecting box; the support legs are mounted at four corners of the bottom of the base; one side of the top of the base is connected with the material box; the loading manipulator is mounted on the side surface of the material box; the turntable is mounted at the top of the base, and is arranged on the side surfaceof the material box; the sealing and discharge devices are uniformly distributed on the turntable; the collecting box is arranged below the sealing and discharge device, and is fixed in the base; theturntable is in transmission connection with the transmission box; and the transmission box is movably connected with the hydraulic cylinder arranged at the top. The turntable type plastic part sealing equipment performs alarm sealing on plastic parts by the sealing and discharge devices through gravity and falling force; a power device is saved; the plastic parts are sent away through a return device for discharge; and the sealing and discharge devices can synchronously perform sealing and discharge, so that procedures are reduced, the sealing efficiency is improved, and the practicability ishigh.

Owner:邱德平

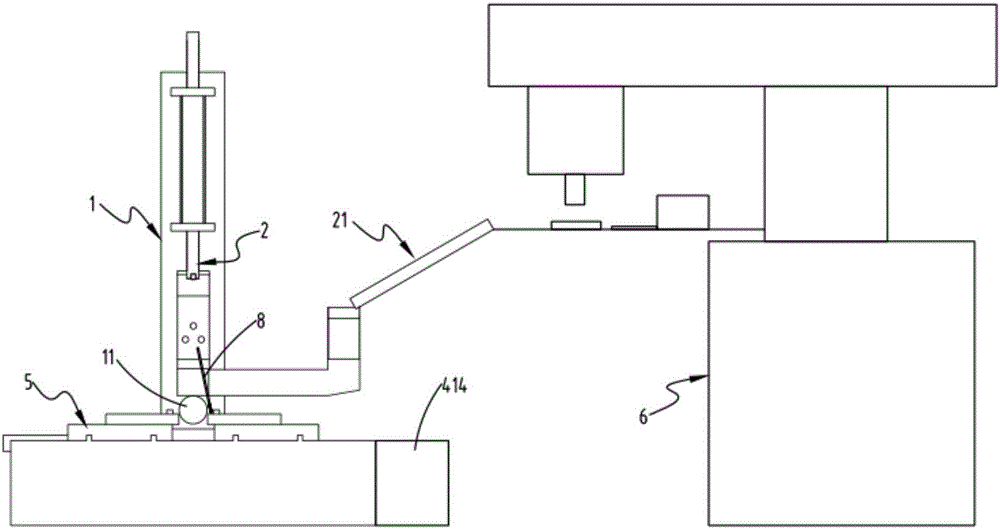

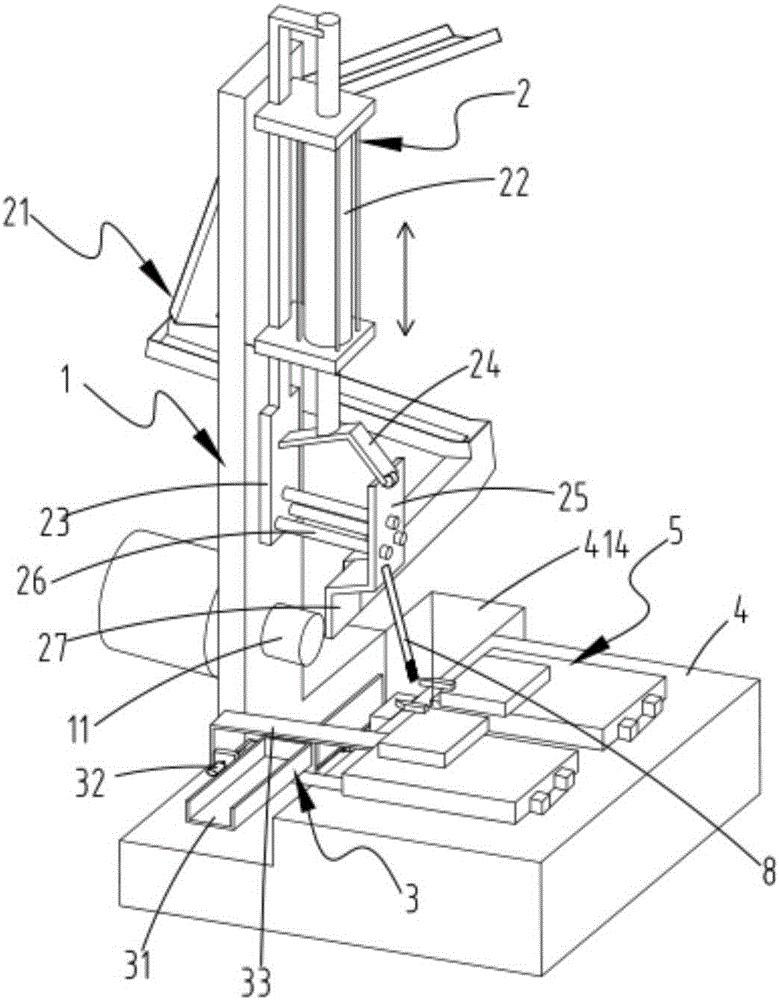

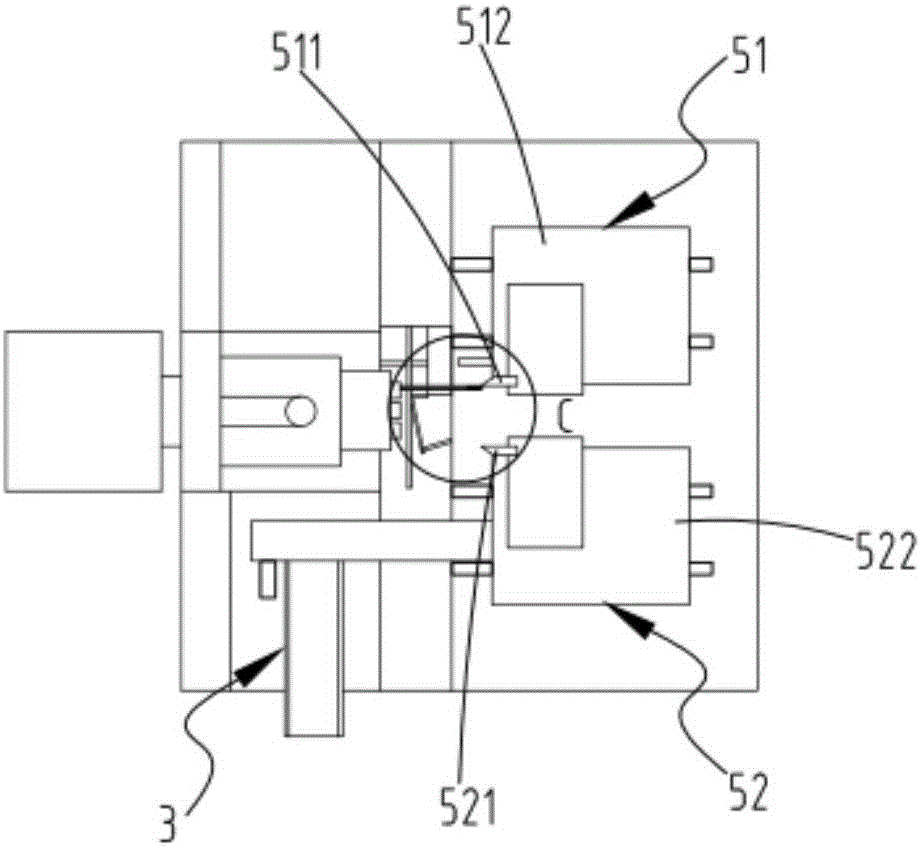

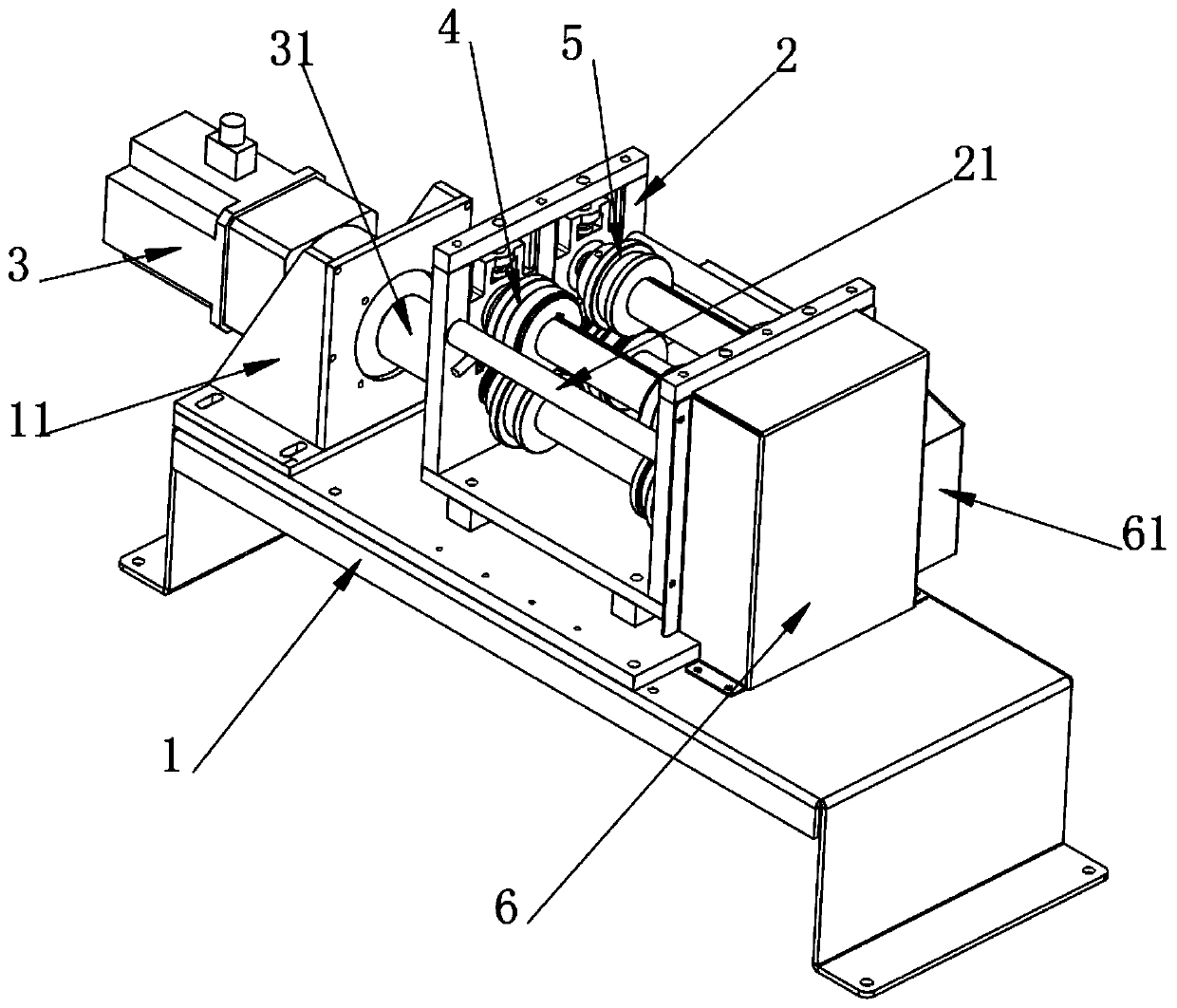

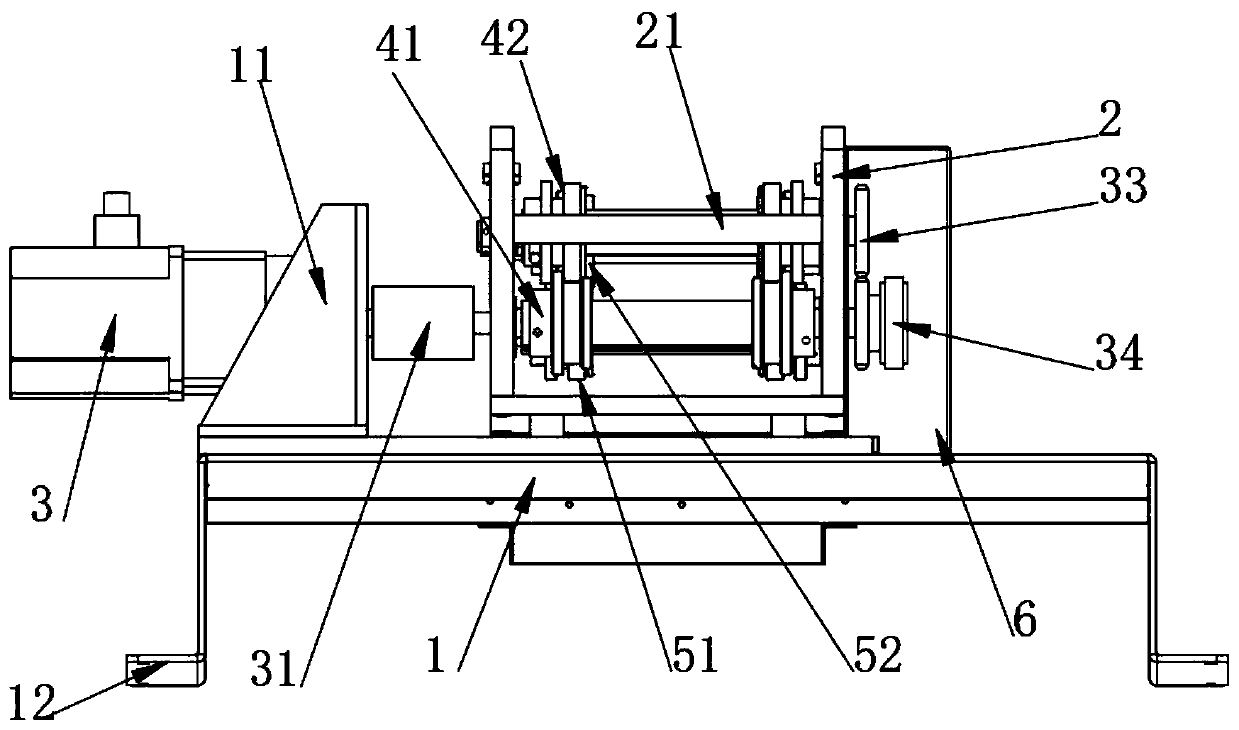

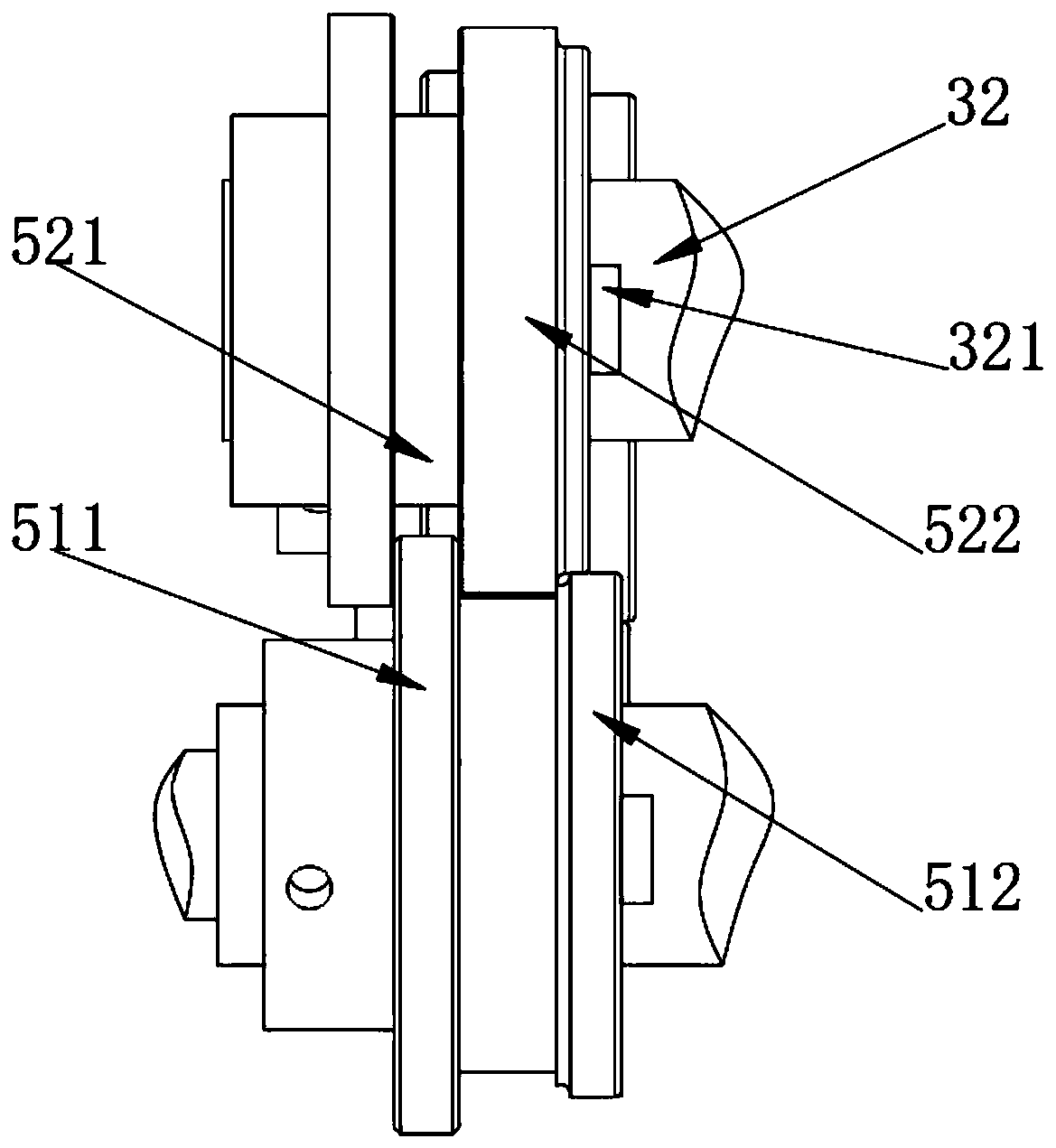

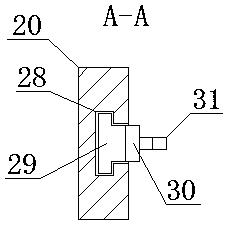

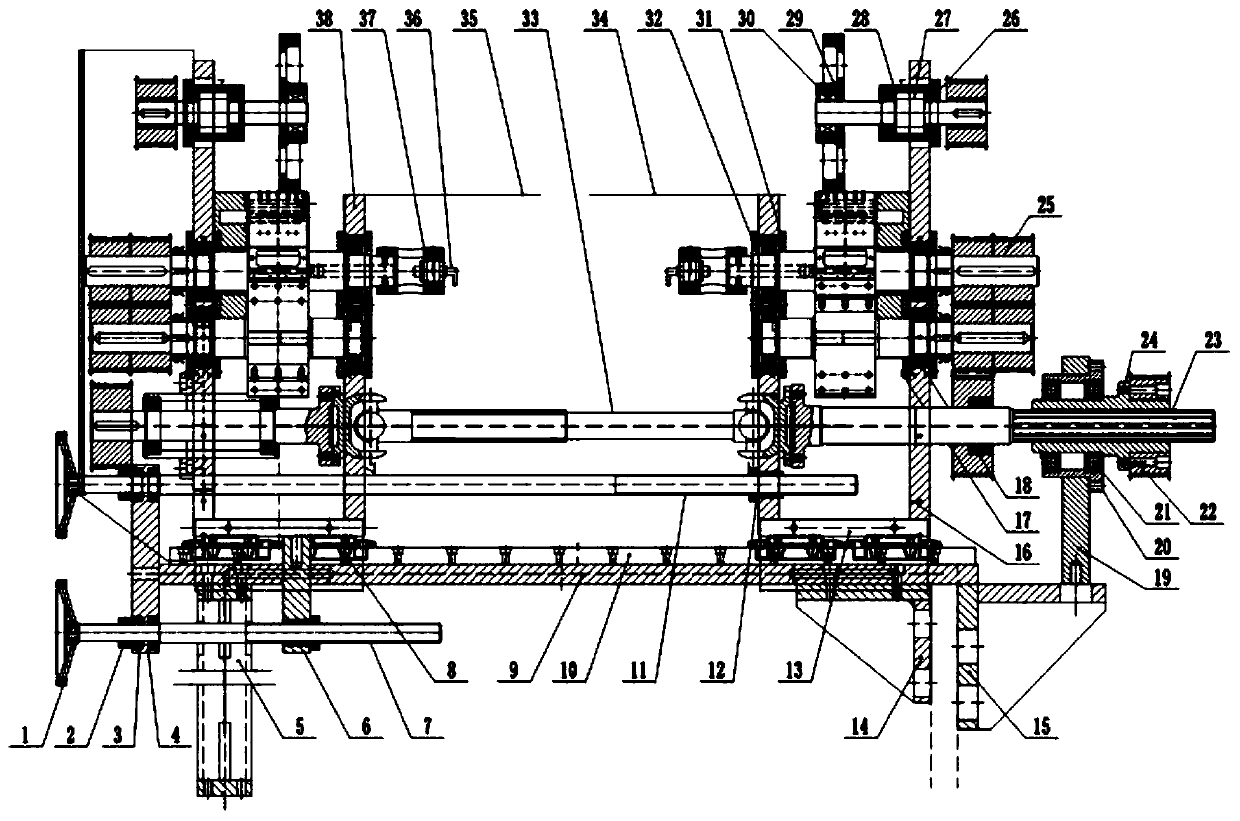

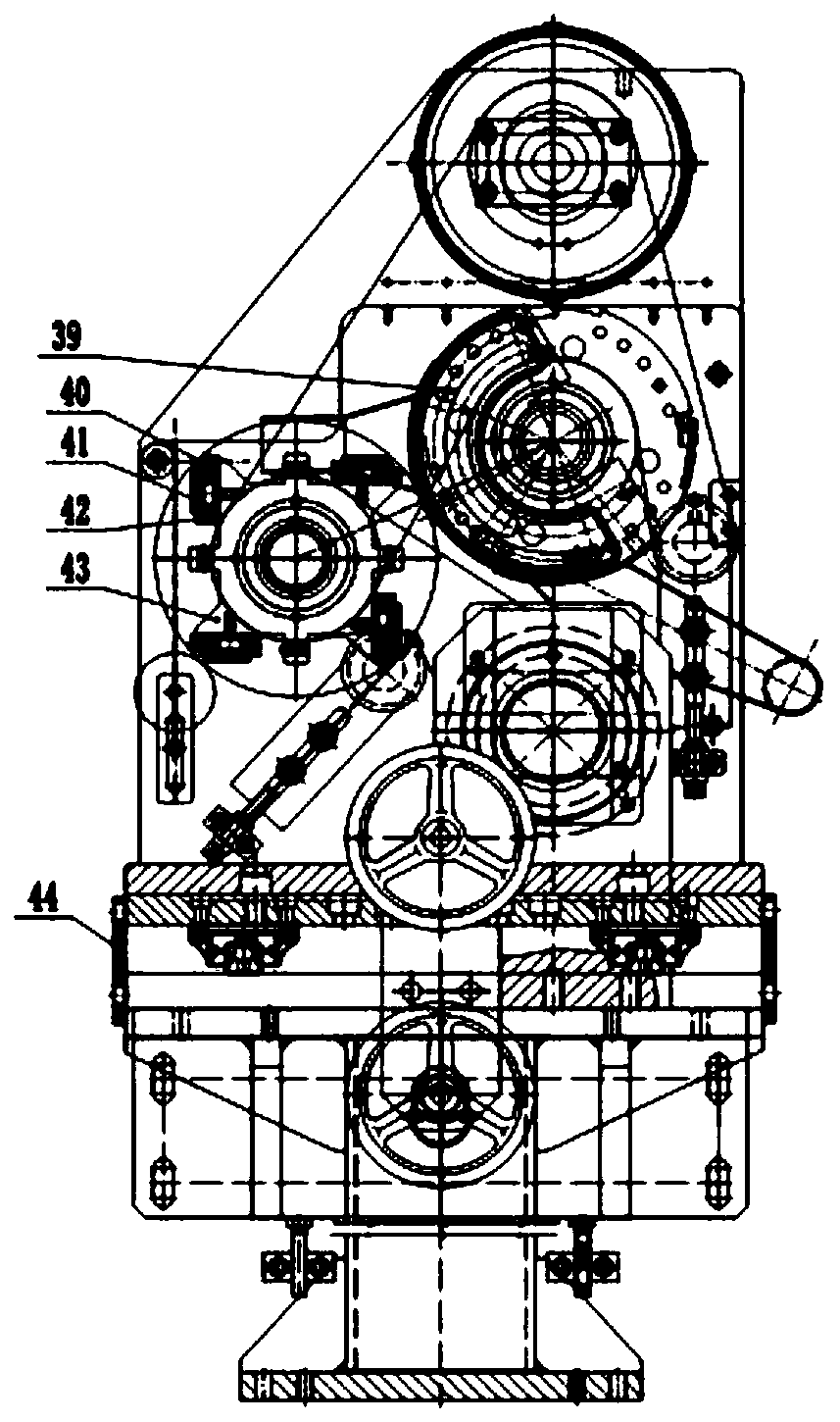

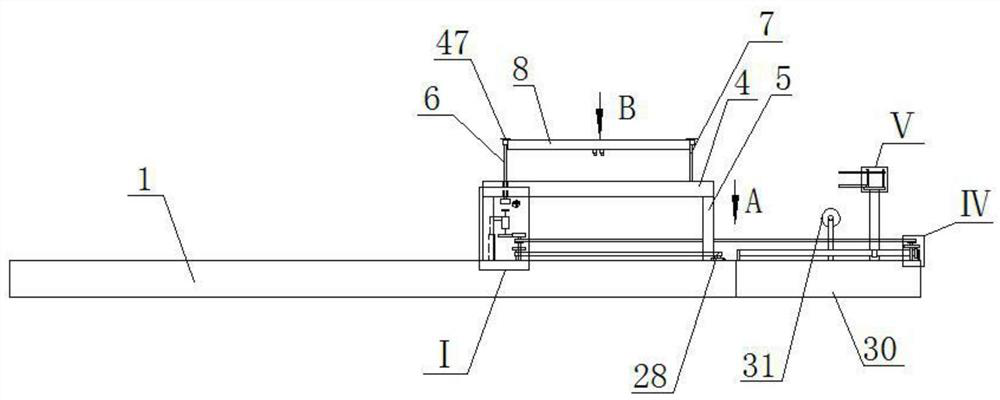

Machining device capable of improving feeding efficiency of clutch coil shell

InactiveCN106424761ACompact structureImprove feeding efficiencyTurning machinesMetal working apparatusPunchingSlide plate

The invention relates to a machining device capable of improving the feeding efficiency of a clutch coil shell. The device comprises a rack, a spindle, a feeding mechanism, a discharging mechanism and a turning device; the feeding mechanism comprises a feeding channel, a first drive air cylinder and a sliding plate; the other end of an L-shaped connecting rod is in sliding fit connection with a guide plate, a positioning push plate is arranged below the guide plate, one end of a feeding channel is communicated with the discharging end of a punching mechanism, the other end of the feeding channel is communicated with the positioning push plate, a waste output channel is formed in a work table, and the turning device comprises a first feeding module and a second feeding module; the feeding mechanism inclines downwards to be provided with a shifting rod, the feeding mechanism moves downwards, and the tail end of the shifting rod makes contact with the end of a first turning tool of the first feeding module; the feeding mechanism and the punching mechanism of the coil shell are integrated through the discharging channel, automatic, continuous and one-by-one order feeding of the coil shell is achieved, the feeding efficiency is improved, and the occupied space of the device is reduced.

Owner:浙江瑞虹机电股份有限公司

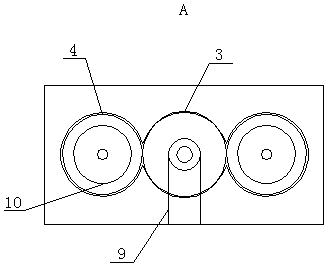

Dual-hobbing-cutter screen net rapid side cutting forming device

PendingCN109822016AAchieve weldingAutomate operationMetal-working apparatusWire networkHobbingEngineering

The invention belongs to the technical field of steel mesh production equipment, and particularly relates to a dual-hobbing-cutter screen net rapid side cutting forming device. The device comprises abase, roller frames, a servo motor, a cutting wheel set, a correction wheel set and a synchronous wheel protection cover; two roller frames which are distributed in parallel are fixed to the upper endface of the base, the servo motor is located on one sides of the roller frames, the output end of the servo motor is connected with four rollers, the four rollers are rotatably connected to the innersides of the roller frames, the manner that two hobbing cutters are combined is adopted, one hobbing cutter reversely cuts a screen net, meanwhile, one hobbing cutter is used for pressing removing ofburrs during reverse cutting and achieving forming, activation, cutting and forming are integrated, welding is achieved, mesh cutting and forming are automatically operated, the production efficiencyof the device is the sum of the efficiency of three to five persons, and in the production cost, no powder, oil contamination and the like exist.

Owner:常州新展智能装备有限公司

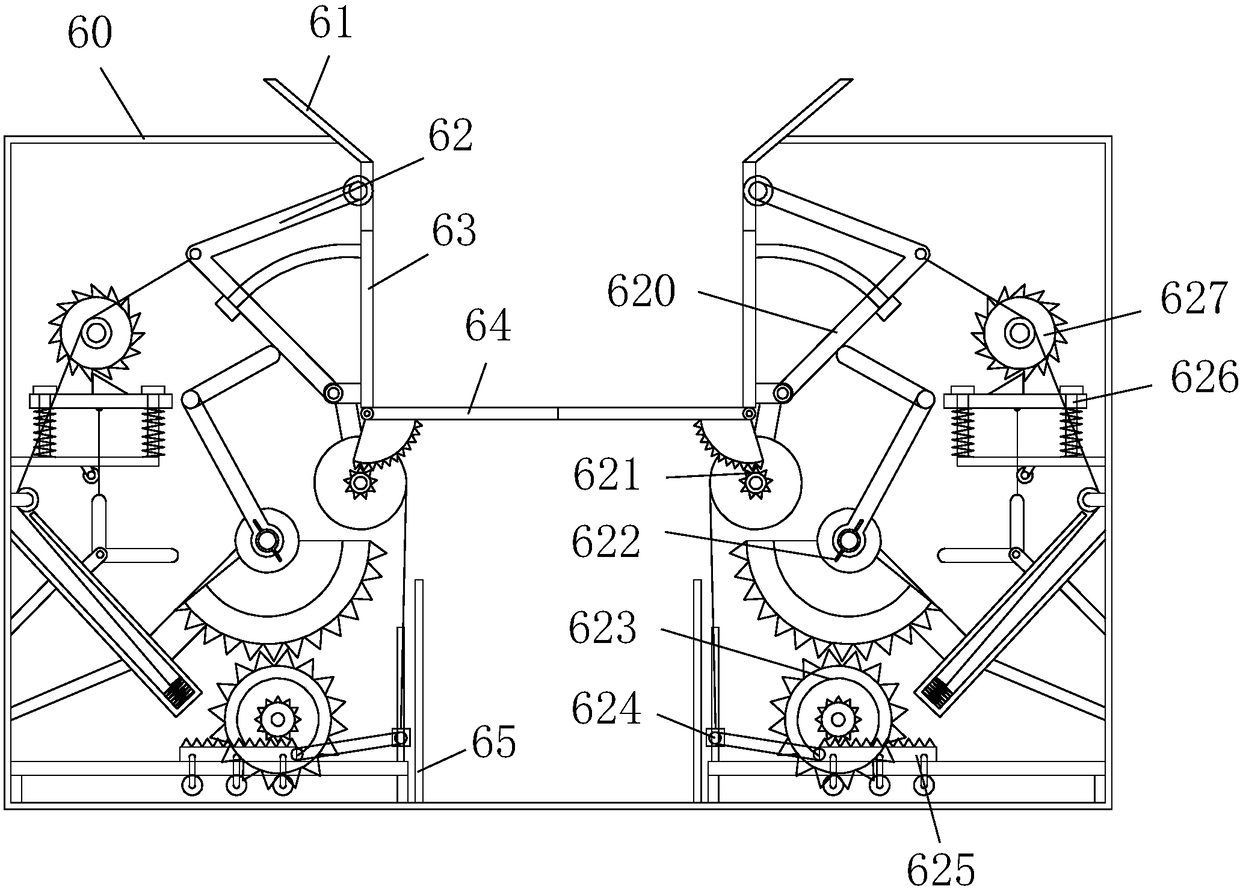

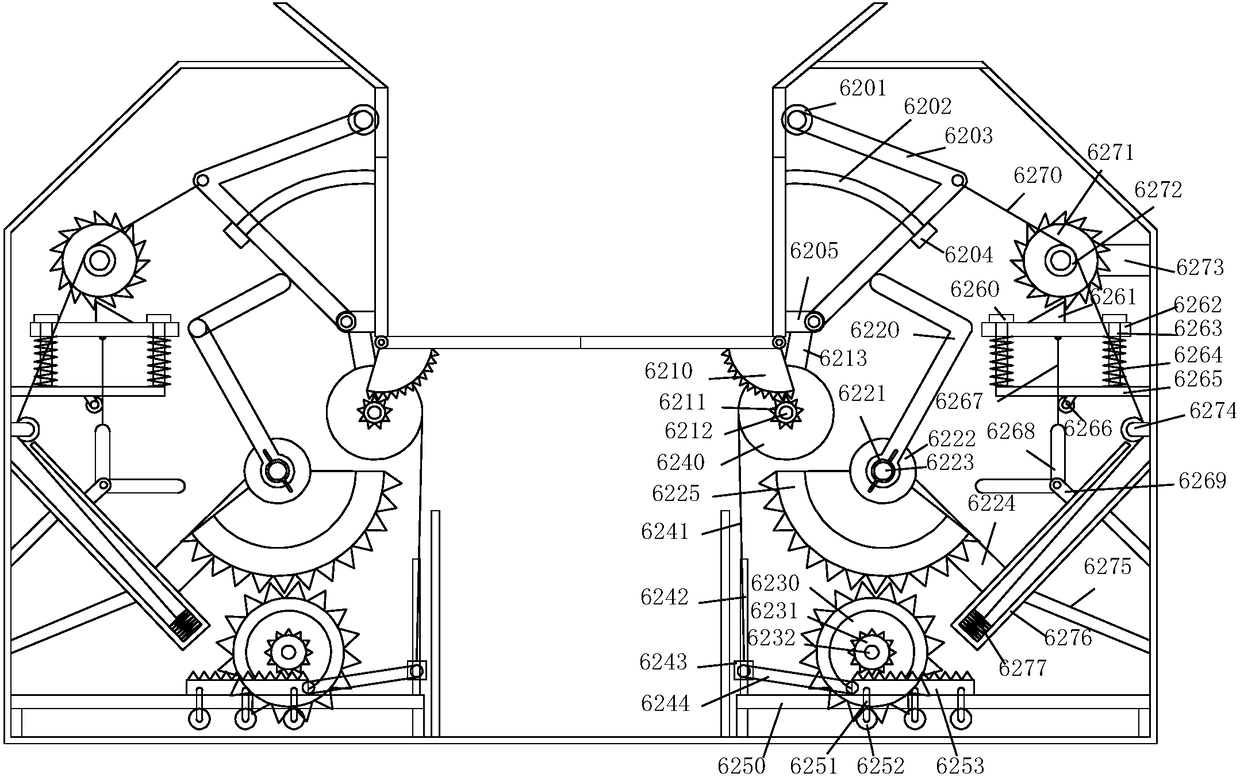

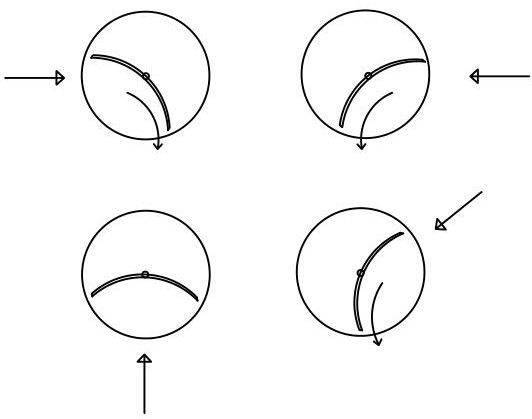

Convenient-to-maintain automatic ticket checker

InactiveCN108396683AStable structureImprove reliabilityTicket-issuing apparatusTraffic restrictionsCard readerComputer science

The invention discloses a convenient-to-maintain automatic ticket checker, which comprises a shell, a control unit, a get-in card reader, a get-out card reader, a single ticket collection device, a single ticket collection box, a direction indicating light, a first gate, a second gate, a transmission rod, a first gear, a second gear, a first rack, a second rack and a lifting power device. The get-in card reader and the get-out card reader are arranged at the top of a get-in side and the top of a get-out side of the shell respectively. The first gate and the second gate are hinged to two sidesof the shell, the first rack and the second rack are hinged to the first gate and the second gate respectively, guide mechanisms are arranged on the first rack and the second rack, a motor is connected to an output shaft of the lifting power device, the transmission rod is connected to the front end of an output shaft of the motor, and the first gear and the second gear are arranged on the top andthe upper portion of the transmission rod respectively. The convenient-to-maintain automatic ticket checker is simple in structure and high in reliability.

Owner:四川绿创环阅环保科技有限公司

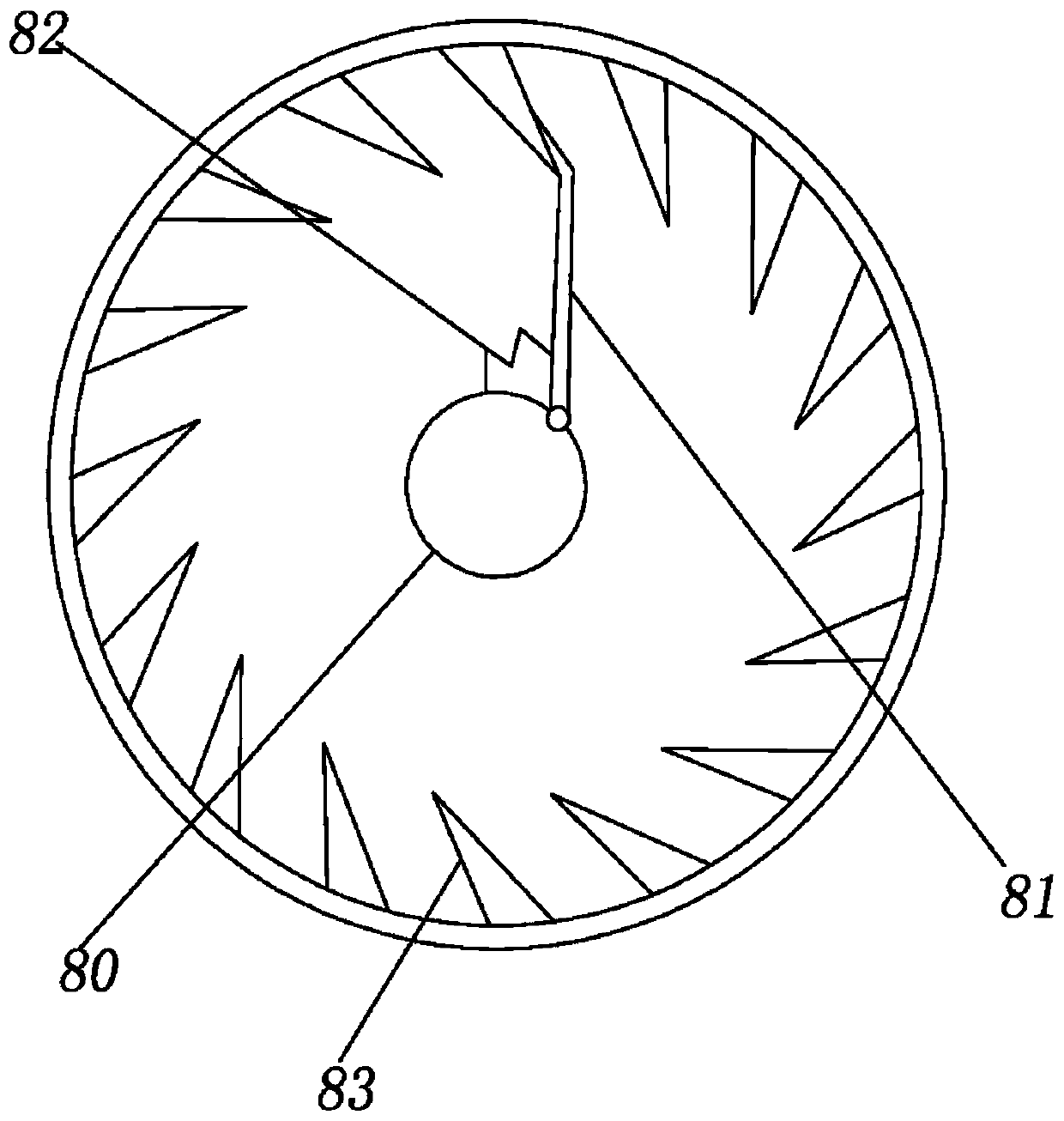

Efficient energy-saving environment-friendly aluminum ash separating and recycling device

ActiveCN108384951AImprove work efficiencyHigh recovery rateProcess efficiency improvementFront and back endsBelt conveyor

The invention relates to an efficient energy-saving environment-friendly aluminum ash separating and recycling device. The efficient energy-saving environment-friendly aluminum ash separating and recycling device comprises a box body and a first belt conveyor, wherein the first belt conveyor is located on one side of the box body, one roller of the first belt conveyor passes through the box body,the front and back ends of a rotary shaft of the roller are movably connected with the inner walls of the front and back ends of the box body respectively, the front and back ends of a rotary shaft ofthe other roller of the first belt conveyor are movably connected with the outer wall of one side of the box body respectively through oblique support rods, a treatment box with a top opening is fixedly installed on the inner wall of one side of the box body, the treatment box is located below the first belt conveyor, strip-shaped grooves are respectively formed in the inner walls of the front and back ends of the treatment box, the strip-shaped grooves are located in the upper part of the treatment box, and guide grooves are respectively formed in the inner walls of the upper and lower endsof each strip-shaped groove. According to the efficient energy-saving environment-friendly aluminum ash separating and recycling device, aluminum ash can be separated twice, and impurities in aluminumare gradually reduced, so that the purity of the recycled aluminum is increased, and the recovery rate is increased; aluminum in the aluminum ash can be continuously separated and recycled, so that the working efficiency is improved.

Owner:山东百斯特铝业科技有限公司

Production equipment for electric meter

InactiveCN108144882AEasy to operateEffective frictionCleaning using toolsLoose filtering material filtersAlcoholActivated carbon filtration

The invention belongs to the technical field of electronic product production, and specifically relates to production equipment for an electric meter. The production equipment comprises a case and analcohol spray head connected onto the case, and further comprises a transmission mechanism, a feeding mechanism, a cleaning mechanism and a filter mechanism, wherein a liquid discharge hole is formedin the bottom of the case; the transmission mechanism comprises a motor, a left gear, a left rotary shaft, a right gear, a right rotary shaft and a transition part used for transmitting power of the motor to the left gear and the right gear; the feeding mechanism comprises a clamp and a feeding part which slides along the case under action of the transition part; the cleaning mechanism comprises aleft rotary disc connected on the left rotary shaft and a right rotary disc connected on the right rotary shaft; and the filter mechanism comprises a water leaking plate, a sponge layer, an active carbon filter layer, a left cam which intermittently extrudes the sponge layer under action of the left rotary shaft and a right cam which intermittently extrudes the sponge layer under action of the right rotary shaft. According to the scheme adopted by the invention, alcohol is recycled while a PCB base plate is cleaned, so that an operating process is simplified, and the cleaning effect is improved.

Owner:重庆亨优机电设备有限公司

Metal material rapid grinding device for 3D printing

InactiveCN109128197AReduce the amount of driftReduce the amount of inhalationMetallic materialsSprocket

The invention discloses a metal material rapid grinding device for 3D printing. The metal material rapid grinding device comprises a box body, and a feed inlet is formed in the top end of the box body. Baffles are separately mounted on the inner walls of two sides of the box body in a hinged mode, and sliding grooves with T-shaped cross sections are separately formed in the front and rear ends ofthe bottom surface of each baffle. The sliding grooves are internally provided with sliding blocks with T-shaped cross sections in a matched mode, and fixing block groups are separately arranged on the inner walls of the front and rear ends of the box body, and the fixing block groups are located on the middle portion of the box body. Each of the fixing block groups is composed of upper and lowerfixing blocks, and a vertical first screw is movably mounted between the two fixing blocks in each of the fixing block groups through bearings. First nuts are arranged on the first screws in a matchedmode. The sliding grooves with the T-shaped cross sections are matched with the sliding blocks with the T-shaped cross sections to prevent the sliding blocks from moving out of the sliding grooves and enable the structure more stable. Two first chain wheels are connected by a connecting shaft, and then the two first chain wheels can be driven to synchronously rotate by a motor, so that a power device is eliminated and energy is saved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Cleaning robot

PendingCN112493939AWith self-cleaning functionReduced power unitCarpet cleanersFloor cleanersSewageMechanical engineering

The invention relates to the field of cleaning instruments, in particular to a cleaning robot. The robot comprises a water tank, a brush disc mechanism and a water suction mechanism, the brush disc mechanism comprises a brush disc and a water spraying pipe, an inlet of the water spraying pipe is communicated with the water tank, an outlet of the water spraying pipe is formed in the brush disc, andthe water suction mechanism comprises a water suction rake, a sewage suction pipe and a suction fan arranged on the water tank, an air inlet of the suction fan is communicated with the water tank; the water suction rake is connected with the water tank through a sewage suction pipe, the water tank is a single water tank, a filter cartridge is arranged in the water tank, two spaces are formed inside and outside the filter cartridge in the water tank, one space is used as a clear water area, the other space is used as a sewage area, the sewage suction pipe sucks sewage into the sewage area, andthe water spray pipe is communicated with the clear water area. Only one water tank needs to be designed to contain clean water and sewage at the same time, a power device for sewage to flow to the clean water is omitted, the structure is simplified, and cost is reduced.

Owner:ZHEJIANG GUOZI ROBOT TECH

Construction machinery used for large diameter hollow pile and its construction method and use

InactiveCN101215836BReduce side frictionIncreased vertical bearing capacity of single pileBulkheads/pilesDrilling machines and methodsCement slurryRebar

The invention discloses a construction machine for hollow piles with large diameter and the construction method and usage, which comprises a drilling system, a pile pounding system, a drainage system which are integrated into one part. The pile forming method comprises: a high-spray drilling bit is arranged on a steel tube (a protection cylinder) or on the bottom of an inner hole of a pre-made tube pile for hole drilling and mud making; the mud is drained from a water joint or a drainage pipe; the protection cylinder or tube pile is pressed asynchronously or synchronously along with the drilling bit; during pile-sinking process, water mud is sprayed to the outer soil of the hole to solidify the surrounding soil of the pile and fill the gaps between the pile and surrounding soil of the pile; after the drilling bit reaches certain depth, the water mud is again sprayed to solidify surrounding soil of the pile; lifting the drilling bit; putting down reinforcement cage; casting concrete for piling. The invention is a construction method for foundation piles and drilling with large diameter, super long and high load, which especially provides convenient, labor-saving, rapid and economical equipment and method for marine pile driving.

Owner:雷玉华

Cutting mechanism for left and right waist stickers

InactiveCN111419543AEasy to operateHigh adjustment accuracyAbsorbent padsBaby linensUniversal jointOptical axis

The present application provides a cutting mechanism for left and right waist stickers. The mechanism includes a supporting seat, a linear guide rail arranged on the supporting seat, two sets of waiststicker mechanisms slidably arranged on the linear guide rail, and a driving mechanism, inner and outer adjusting screw rods pivotally arranged on the supporting seat are threadedly connected with sliding frames of the inner waist sticking mechanism and the outer waist sticking mechanism, and the waist sticking mechanisms also include an adsorption transfer roller, a press silicone rubber wheel,cutter rollers, and a tension wheel component that move synchronously through a belt transmission mechanism; and the driving mechanism includes a length-adjustable universal joint fixedly connected between the two sliding frames, two ends of the length-adjustable universal joint are respectively provided with a transmission spline shaft and a transmission optical shaft, the transmission spline shaft and the transmission optical shaft respectively drive one corresponding cutter roller to move through the corresponding belt transmission mechanism, the transmission spline shaft is in fit connection with a transmission spline sleeve on the supporting seat, and the transmission spline sleeve is provided with a transmission input synchronous belt pulley. According to the mechanism provided by the present application, the distance between the left and right waist stickers can be convenient to adjust, and the processing accuracy is not affected after adjustment.

Owner:泉州市兴远机械制造有限公司

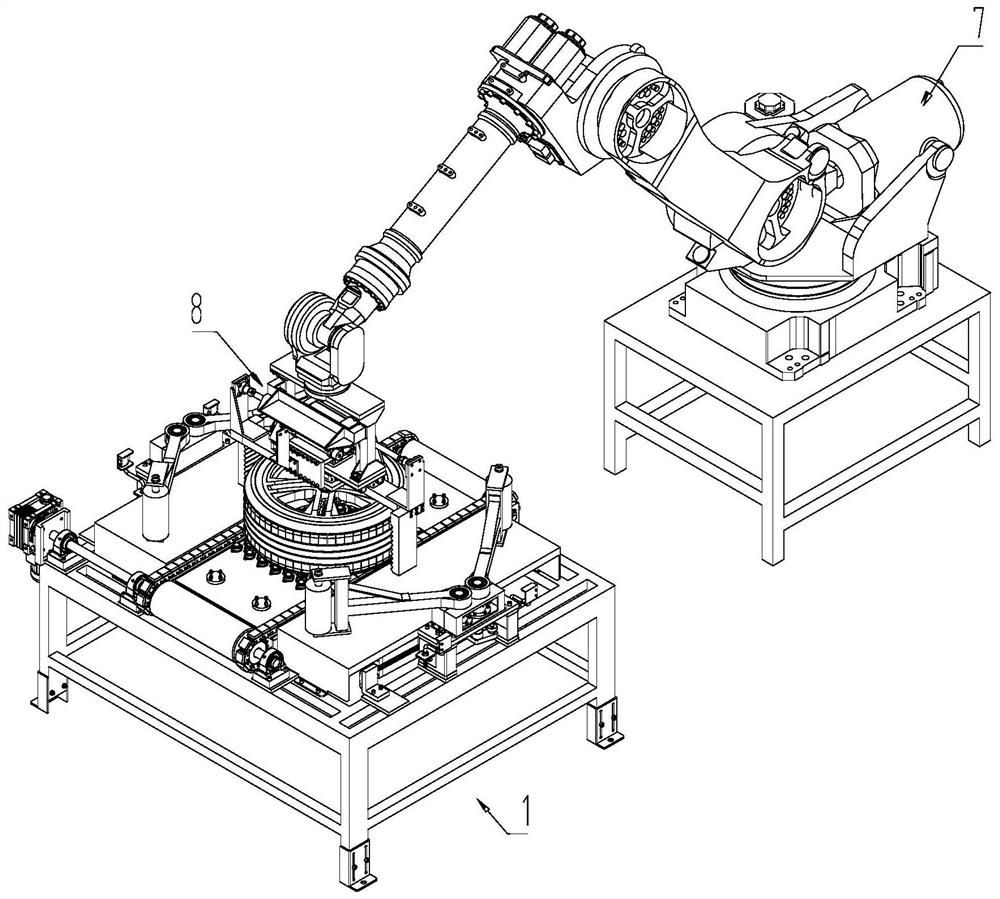

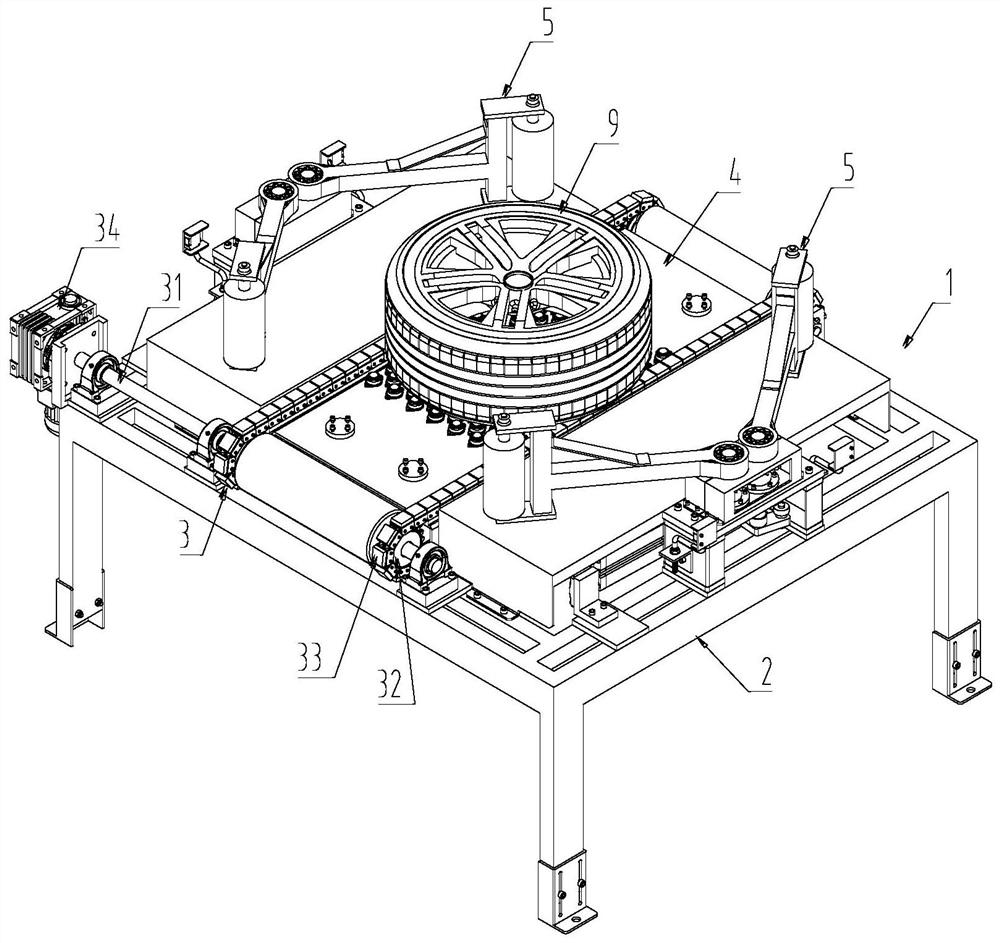

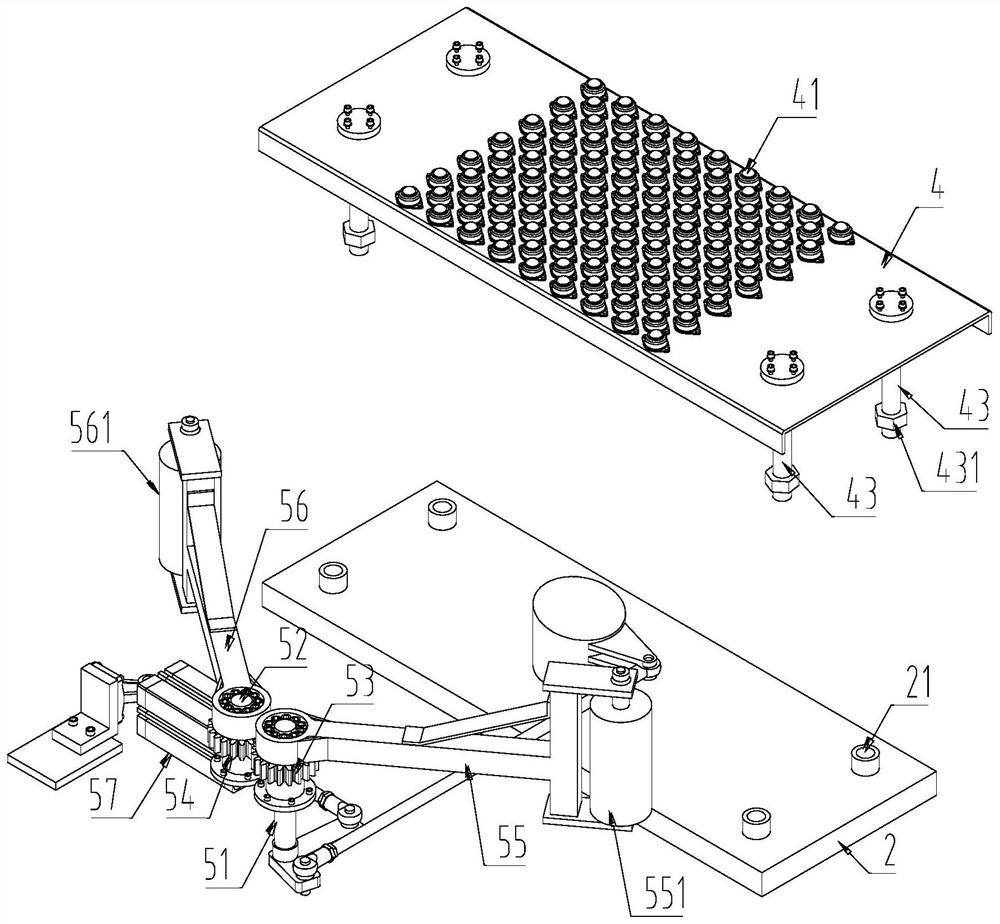

Tire assembly line tail end manipulator arranging and collecting device

ActiveCN113697483AReduce frictionEasy to transport after clippingConveyor partsMechanical conveyorsBall bearingAssembly line

The invention relates to the technical field of automobile part manufacturing, and discloses a tire assembly line tail end manipulator arranging and collecting device. The tire assembly line tail end manipulator arranging and collecting device comprises a positioning workbench and a manipulator, wherein the positioning workbench comprises a support, a conveying mechanism arranged on the support, a lifting platform and two positioning assemblies, a plurality of bull eye ball bearings are installed on the upper end face of the lifting platform, and the lifting platform can ascend and descend on the support so as to be higher than or lower than the conveying mechanism. The tire assembly line tail end manipulator arranging and collecting device has the following advantages and effects wheels are conveyed, supported, pushed and positioned through the positioning workbench, the positioned wheels are clamped and transferred through the manipulator, sorting and collecting of the wheels are completed, the automation degree is high, the production efficiency is improved, and the labor intensity of workers is low.

Owner:XIANNING VOCATIONAL TECHN COLLEGE

Sleeve buckle device with waste recovery function for garment processing

ActiveCN111493428AAchieve cleaning effectReduce consumptionClothes making applicancesEngineeringStructural engineering

The invention discloses a sleeve buckle device with a waste recovery function for garment processing. The device comprises a bottom plate, and two sliding grooves are formed in the top face of the bottom plate. A horizontal first screw rod is movably mounted between the inner walls of the two sides of the front sliding groove; a movable plate is arranged above the bottom plate in a matched mode, vertical supporting rods are fixedly installed at the four corners of the bottom face of the movable plate respectively, screw holes are formed in one sides of the bottom ends of the two supporting rods located in the front, the first screw can penetrate through the screw holes, and the bottom ends of the two supporting rods located in the front can be in contact fit with the inner wall of the bottom end of the sliding groove located in the front. According to the invention, cloth can be flatly laid on the moving plate by an operator, as pressing rod flattens the cloth, presses the two ends ofthe cloth and then conducts button sewing operation, after the button sewing operation is finished, the cloth is driven by the moving plate to return to one side of the bottom plate, in the process, an operator can check sleeve buttons on the cloth, defective products are removed, and the percent of pass is increased.

Owner:湖南新姿服饰有限公司

Ink printing equipment

InactiveCN108177423BAvoid particle bumpsImprove printing qualityInking apparatusRotary intaglio printing pressEngineeringSolvent

The invention belongs to the technical field of printing, and particularly relates to an ink printing device. The device comprises a rack, a pressing roller and an ink cartridge; the rack is further internally provided with a motor, a conveying mechanism, a transverse moving mechanism, a covering mechanism and a solvent spraying box; the conveying mechanism comprises multiple conveying rollers driven by the motor to rotate, the transverse moving mechanism comprises a thread rod driven by the conveying rollers to rotate, a thread cylinder in threaded connection with the thread rod, and a firstwedge block fixedly connected with the thread cylinder, the covering mechanism comprises a second wedge block in sliding connection with the rack anda cover plate fixedly connected with the second wedge block, a spraying opening covered by the cover plate is formed in the solvent spraying box, and is located above the conveying rollers, the pressing roller is driven by the conveying rollers to dointermittent rotation, and a feeding and discharging opening is formed in the side, close to the pressing roller, of the rack. Particle protrusions on the surface of a printing object can be effectively prevented, and the printing quality is improved.

Owner:重庆华康印务有限公司

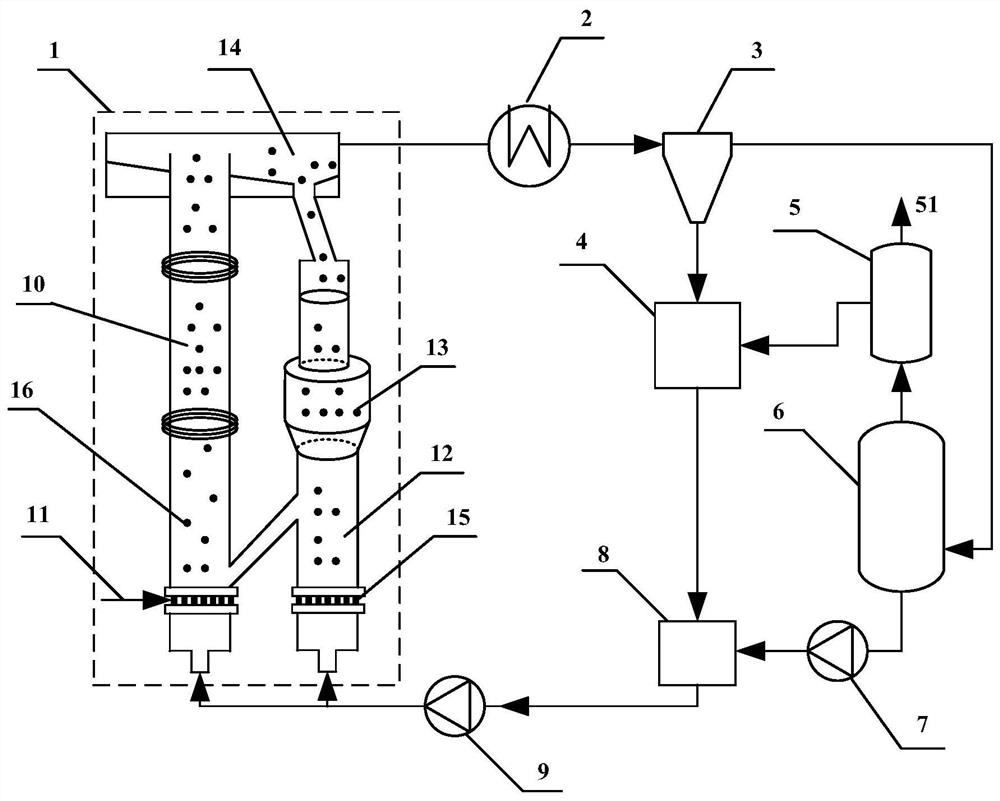

A circulating fluidized bed enhanced ammonia carbon capture device

ActiveCN110756011BImprove absorption efficiencyIncrease contact areaGas treatmentDispersed particle separationFlue gasFluidized bed

The invention discloses a circulating fluidized bed enhanced ammonia carbon capture device, comprising: a circulating fluidized bed, a crystallization separator, an ammonia water absorber, an ammonia-carbon separator, a desorber, a desorption solution pump, a mixed liquid storage tank, Lean liquid pump and other components. The concentrated ammonia water in the mixed liquid storage tank is connected to the gas-liquid distributor of the circulating fluidized bed through the lean liquid pump. After the flue gas and the ammonia water are fully contacted in the circulating fluidized bed, the rich liquid is separated by the solid-liquid separator and cooled by the cooler. It is connected to the crystal separator; the liquid outlet at the lower part of the crystal separator is connected to the ammonia water absorber, which is used to absorb the liquid ammonia desorbed and separated by the desorber and the carbon ammonia separator to regenerate the ammonia water absorbent; the outlet of the ammonia water absorber is connected to the mixed liquid storage tank , while the liquid outlet of the desorber is also connected to the mixed liquid storage tank. The circulating fluidized bed enhanced ammonia capture device of the present invention utilizes a circulating fluidized bed to strengthen the absorption of carbon dioxide and improve the absorption efficiency.

Owner:NINGBO UNIV

A buckle device for garment processing with waste recycling function

ActiveCN111493428BAchieve cleaning effectReduce consumptionClothes making applicancesWaste materialIndustrial engineering

A buckle device for garment processing with the function of recycling waste materials, comprising a bottom plate, two chute troughs are provided on the top surface of the bottom plate, and a horizontal first screw rod is movably installed between the inner walls on both sides of the chute in front, and the top of the bottom plate is equipped with The mobile plate, the four corners of the bottom surface of the mobile plate are respectively fixedly installed with vertical support rods, and screw holes are provided on the bottom side of the two support rods in the front, the first screw rod can pass through the screw holes, and the two support rods in the front are provided with screw holes. The bottom end can contact and cooperate with the bottom end inner wall of the chute positioned ahead. Through the present invention, after the operator lays the cloth on the moving plate, the pressing bar will smooth the cloth and press the two ends of the cloth, and then perform the buttoning operation, and after the buttoning operation is completed, the cloth is moving Driven by the board, it returns to one side of the bottom board. During this process, the operator can check the buckles on the fabric, remove defective products, and improve the pass rate.

Owner:湖南新姿服饰有限公司

Refractory material baking crystallizer casting powder drying device and method

InactiveCN109798733AReduced power unitReduce energy consumptionDrying gas arrangementsDrying machines with local agitationHeat conductingMetallurgy

The invention relates to the technical field of metallurgical continuous casting, in particular to a refractory material baking crystallizer casting powder drying device and method. The refractory material baking crystallizer casting powder drying device comprises a gas collection device, a drying device and a venturi pumping device; the gas collection device is used for collecting hot gas of a baker and comprises an intermediate pipeline for conveying the hot air, and the intermediate pipeline provides a heat source for drying for the drying device; and the venturi pumping device is used forproviding pumping power of the gas collection device. The refractory material baking crystallizer casting powder drying method comprises the steps: the gas collection device collects a hot fluid, andthe hot fluid flows into a heat conducting pipe of the drying device; casting powder enters a drying chamber, and the heat fluid carried by the heat conducting pipe and the casting powder are subjected to heat exchange; and the hot fluid flows into the venturi pumping device under the pumping effect of the venturi pumping device. According to the refractory material baking crystallizer casting powder drying device and method, refractory material baking waste heat is fully utilized, energy consumption is reduced, and the equipment structure is simplified.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Rail robot inspection system for top of aluminum oxide decomposing tank or settling tank

PendingCN112720530AReduced power unitMake full use of resourcesManipulatorControl theoryMechanical engineering

The invention discloses a rail robot inspection system for the top of an aluminum oxide decomposing tank or a settling tank. The rail robot inspection system comprises a rail, an inspection robot and a background server, wherein the rail is erected at the top of the aluminum oxide decomposing tank or the settling tank; the inspection robot is connected with the rail, inspects the top of the aluminum oxide decomposing tank or the settling tank through a monitoring module, and is powered by a sail assembly or a battery assembly; and the background server is in wireless communication with the inspection robot and receives obtained data. The rail robot inspection system for the top of the aluminum oxide decomposing tank or the settling tank has the substantive effects that the labor intensity of manual inspection can be reduced, the production safety coefficient can be effectively improved through robot inspection, potential faults can be found in time, and the risk occurrence probability of an inspection area is reduced; and meanwhile, the characteristics of the high-altitude environment are fully utilized, wind power driving is utilized, energy consumption is reduced, and the structure is simplified.

Owner:中铝智能科技发展有限公司

Reliable rail transit ticket checking device

InactiveCN108416849AStable structureImprove reliabilityTicket-issuing apparatusStops deviceEngineering

The invention discloses a reliable rail transit ticket checking device, comprising a casing, a control unit, an inbound card reader, an outbound card reader, a single ticket collecting device, a single ticket collecting box, a direction indicator light, a first gate, a second gate, a transmission rod, a first gear, a second gear, a first rack, a second rack and a lifting power device. The inboundcard reader and the outbound card reader are disposed on the inbound-side top and the outbound-side top of the casing respectively. The first gate and the second gate are hinged to both sides of the casing. The first gate is hinged to the first rack. The second gate is hinged to the second rack. The first rack and the second rack are provided with stopping devices. A motor is connected to the output shaft of the lifting power device. The transmission rod is connected to the front end of the output shaft of the motor. The first gear is arranged on the top of the transmission rod. The second gear is arranged on the upper part of the transmission rod. The reliable rail transit ticket checking device has simple structure and high device reliability.

Owner:四川绿创环阅环保科技有限公司

Wall quick painting device

Owner:MINJIANG UNIV

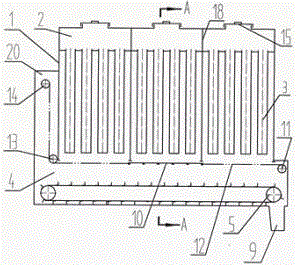

Large-size bag type dust collector without conical dust collection hopper

InactiveCN106492557ALower the altitudeReduced power unitDispersed particle filtrationEngineeringLarge size

The invention discloses a large-size bag type dust collector without a conical dust collection hopper. The large-size bag type dust collector is a large-size dust collector which consists of a plurality of box bodies arranged in parallel; the conical dust collection hopper is canceled; a container being about 1m in height is designed below middle box bodies, wherein the bottom of the container is sealed, and the container is connected with the middle box bodies; the length of the container is greater than the overall length of the large-size dust collector; the width of the container is equal to that of the dust collector; a scraper conveying machine is arranged in the container; an air inlet is formed in each middle box body; an air outlet is formed in each upper box body; and an ash discharge hole is formed in the head of the scraper conveying machine. By adopting the large-size bag type dust collector, the height of the dust collector is effectively reduced, a part of steel is saved, the space can be saved, and power devices for multiple ash discharge holes can be saved as only one ash discharge hole needs ash discharge power.

Owner:天津杰能道然环保科技有限公司

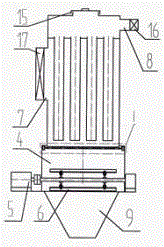

Offline overhaul bag type dust remover without cone-shaped ash deposition hopper

InactiveCN106492558ALower the altitudeReduced power unitDispersed particle filtrationMembrane filtersEngineeringPulley

The invention discloses an offline overhaul bag type dust remover without a cone-shaped ash deposition hopper. The off-line overhaul bag type dust remover is characterized in that a container with a height of about 1 m is designed under middle box bodies, a scraper conveyer is put in the container, and an air inlet is formed in each of the middle box bodies; an ash discharge opening is formed at a machine head of the scraper conveyer; a shutter door horizontally placed in the container is designed in a position, closely attached onto the middle box bodies, at the bottoms of the middle box bodies, and when the shutter door is positioned under a room, a lower opening of the room is just blocked; a track is arranged on each of the two sides of the shutter door; a side room communicated with the container and specially used for allowing the shutter door to be placed in is arranged outside one end surface of the middle box body; one end of the shutter door is connected with a main reel by a pull rope, and the other end is connected with an auxiliary reel in the side room by the pull rope through a guide pulley; the offline overhaul bag type dust remover is free from the cone-shaped ash deposition hopper and can be subjected to offline overhaul. The offline overhaul bag type dust remover has the benefits that the height of the dust remover is effectively reduced, and part of steel products is saved; a less space is occupied; only one ash discharge power for one ash discharge opening exists, so that a plurality of sets of power devices for a plurality of ash discharge openings are saved.

Owner:天津杰能道然环保科技有限公司

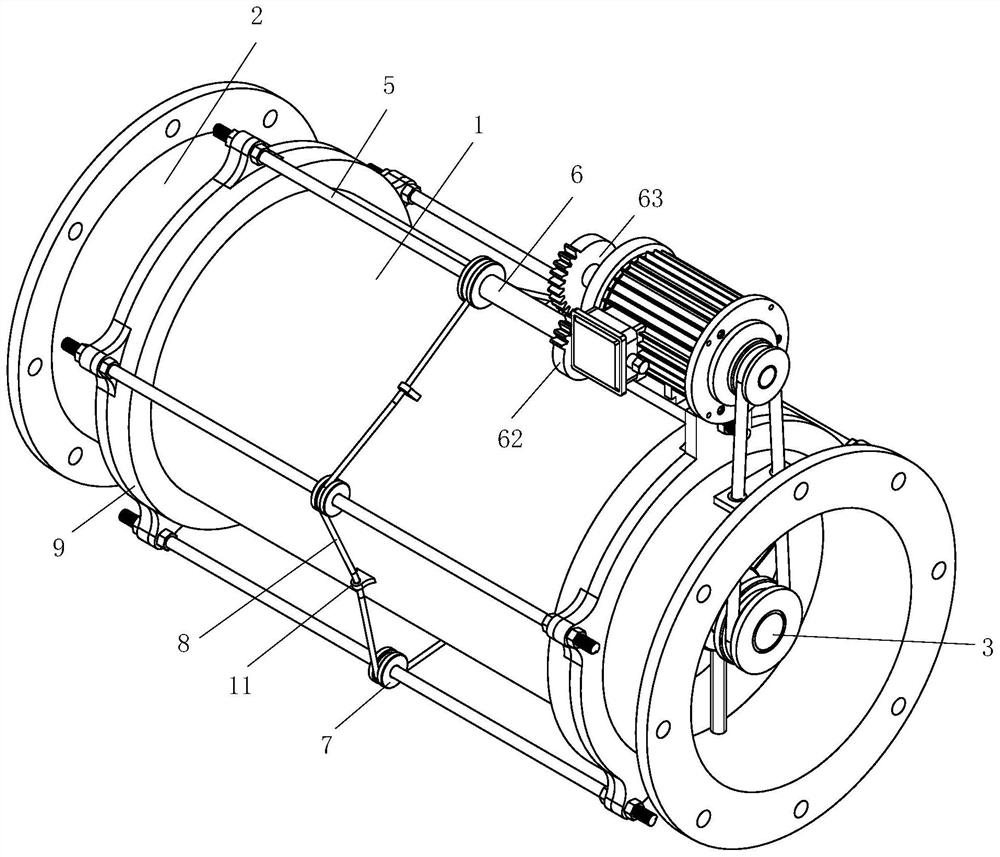

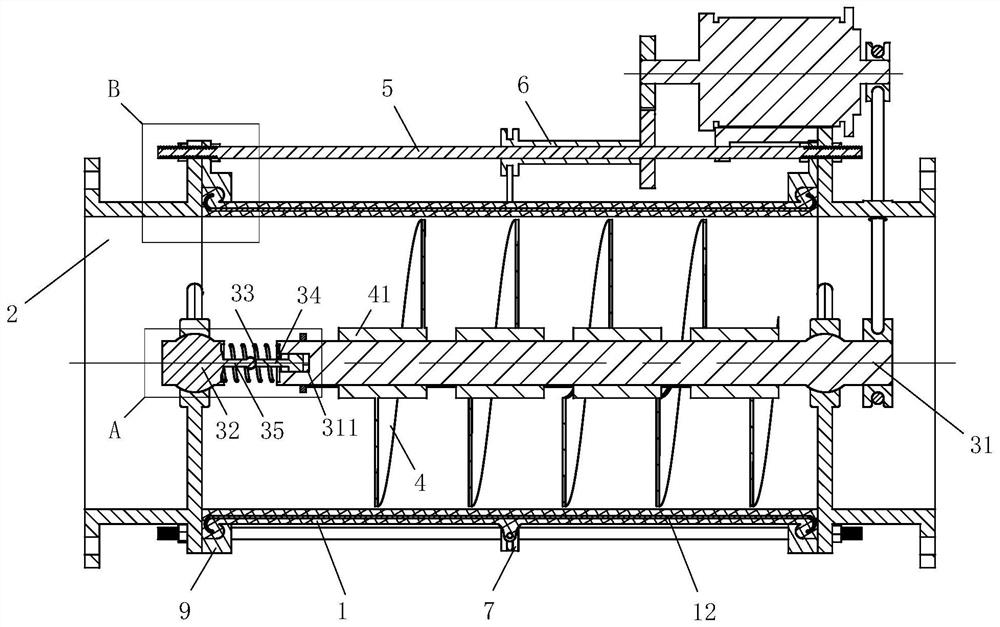

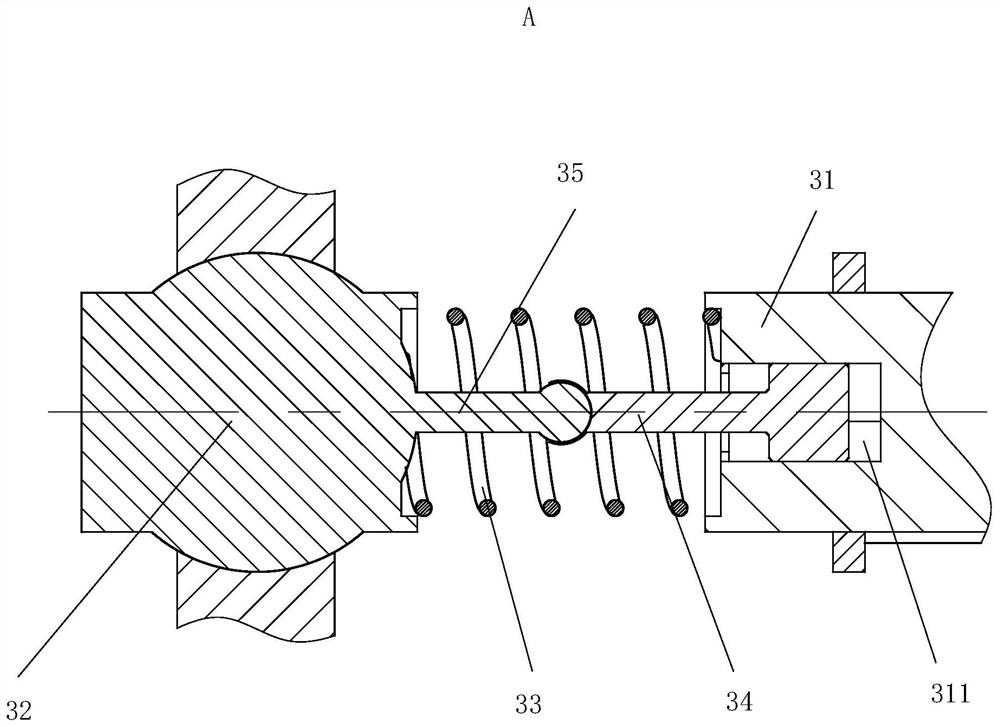

Self-unblocking sewage pump based on flexible pump body

ActiveCN113323883ABig spaceExtended maintenance periodSpecific fluid pumpsPump componentsElectric machinerySewage

The invention belongs to the technical field of sewage pumps, and particularly relates to a self-unblocking sewage pump based on a flexible pump body. The self-unblocking sewage pump comprises a rubber cylinder body, a support ring, a rotating part, a spiral plate, a motor and a belt. According to the sewage pump, the motor is started to drive the rotating part to rotate, and the rotating part drives the spiral plate to rotate in the rubber cylinder body, so that the sewage pump achieves the function of pumping sewage; and the cylinder body of the sewage pump is made of rubber, when sundries block the space between the spiral plate and the rubber cylinder body, the spiral plate rotates to enable the sundries to extrude the rubber cylinder body, and the rubber cylinder body is elastically deformed, so that the space of the rubber cylinder body is expanded, the sundries are prevented from being stuck between the spiral plate and a rubber pipe body and are conveniently taken away by the spiral plate, the sewage pump realizes the function of automatically cleaning blocked sundries, the sewage pump is prevented from being stuck, the maintenance period of the sewage pump is prolonged, and the service life of the sewage pump is prolonged.

Owner:太谷县旭阳机械有限公司

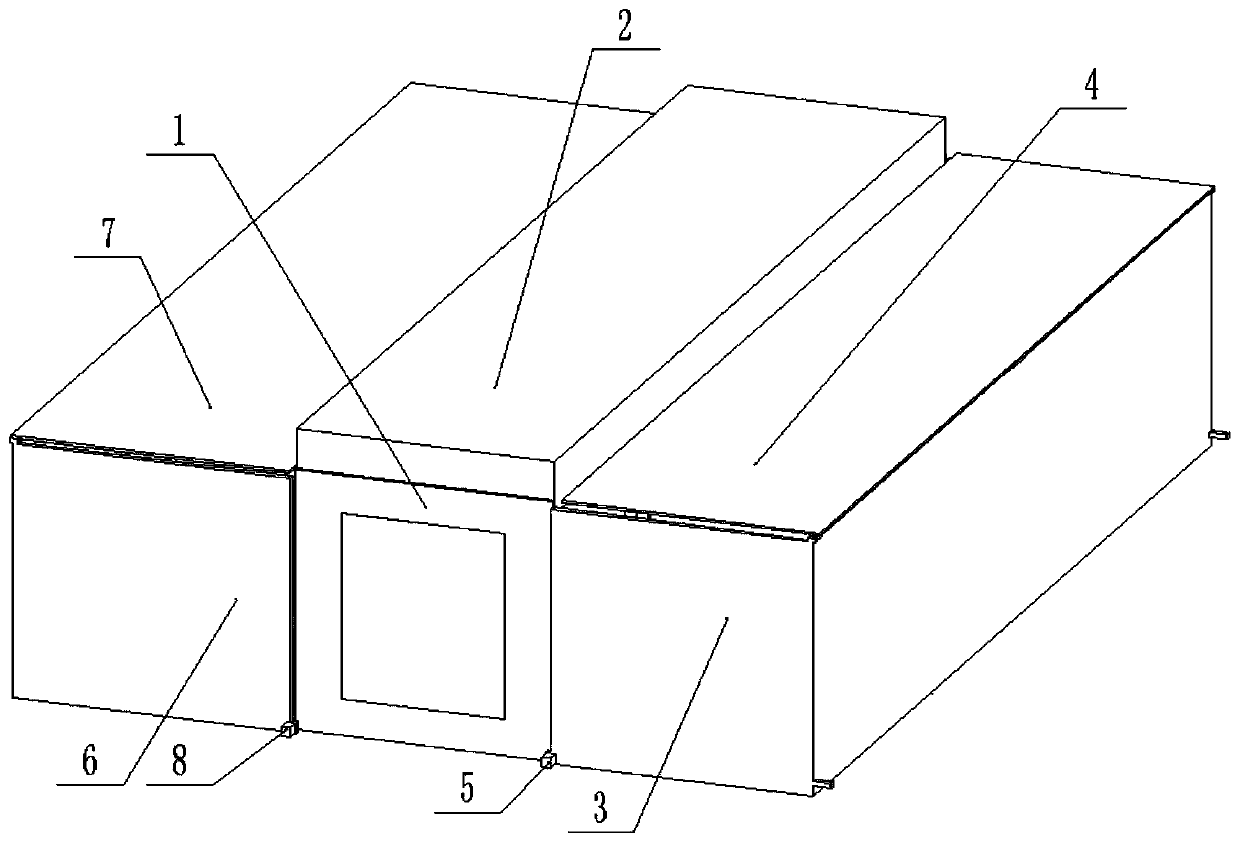

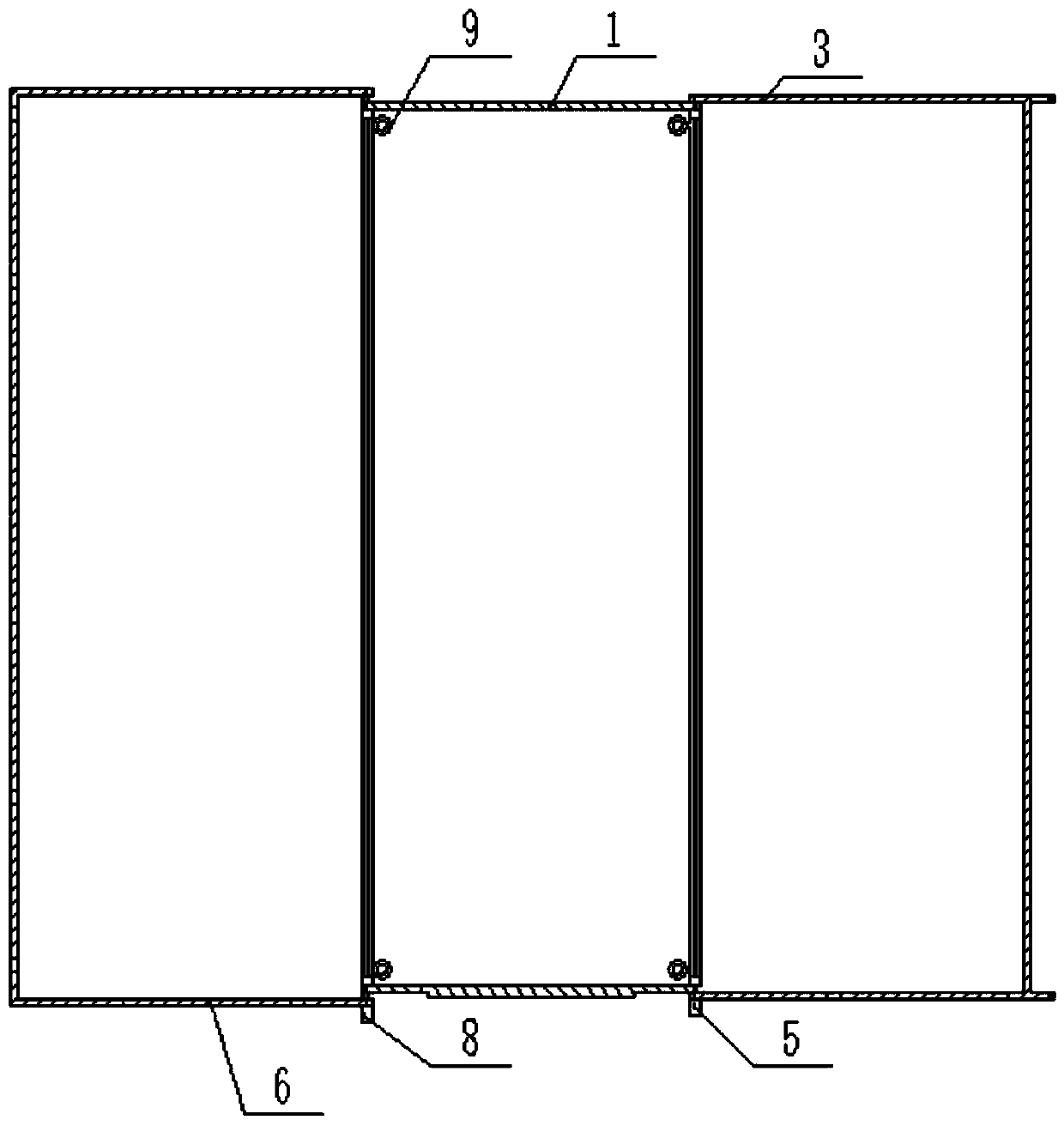

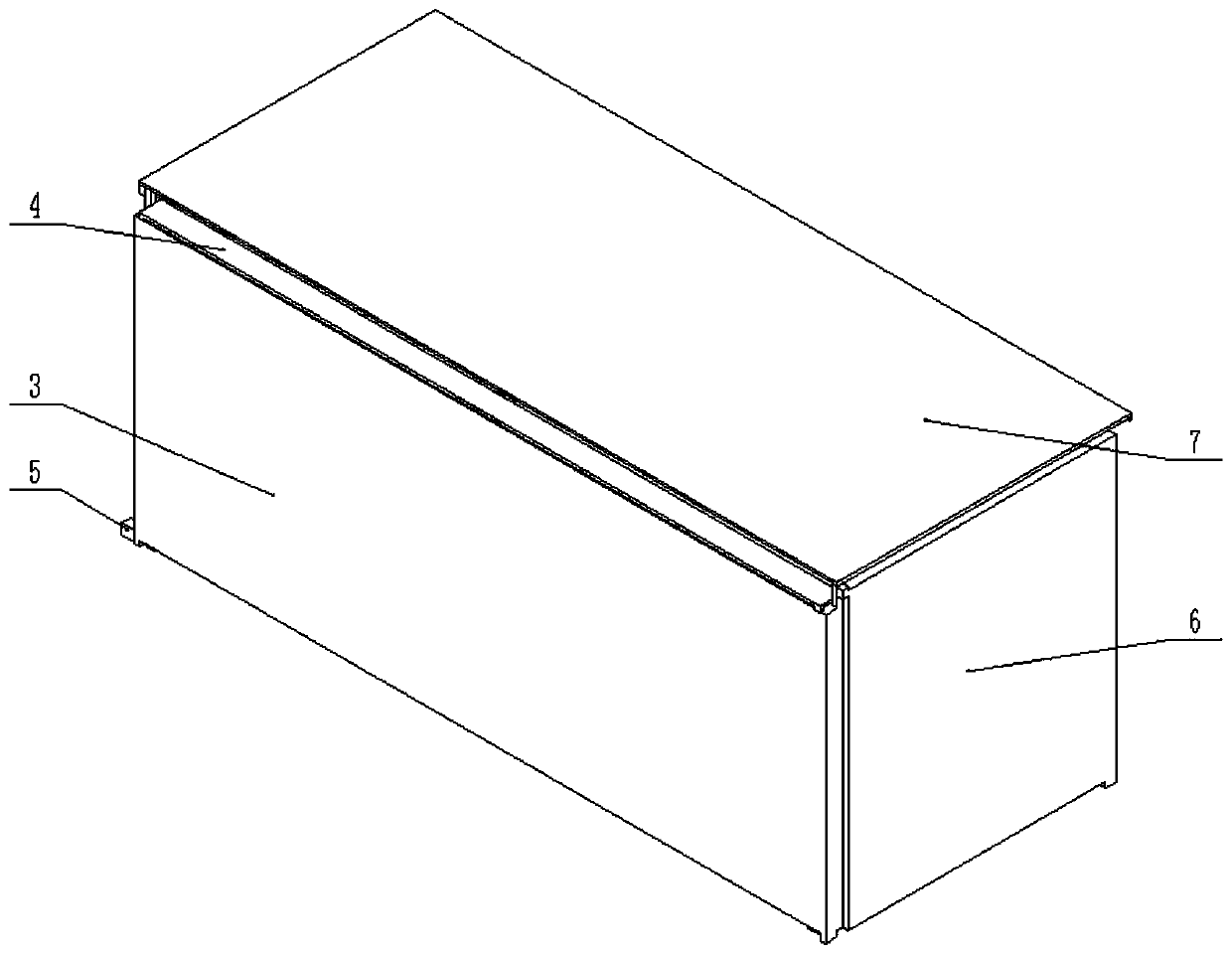

Extension square cabin

InactiveCN110145032ASmall operating forceReduced power unitSpecial buildingBuilding constructionsEngineering

Owner:济南萨博特种汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com