Advanced oxidation treatment device and advanced oxidation treatment process of refractory organic wastewater

A treatment device and advanced oxidation technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of Fenton reagent transportation hazards, reduce equipment service life, increase equipment wear, etc., to save medicine consumption, reduce equipment wear, and save operation The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

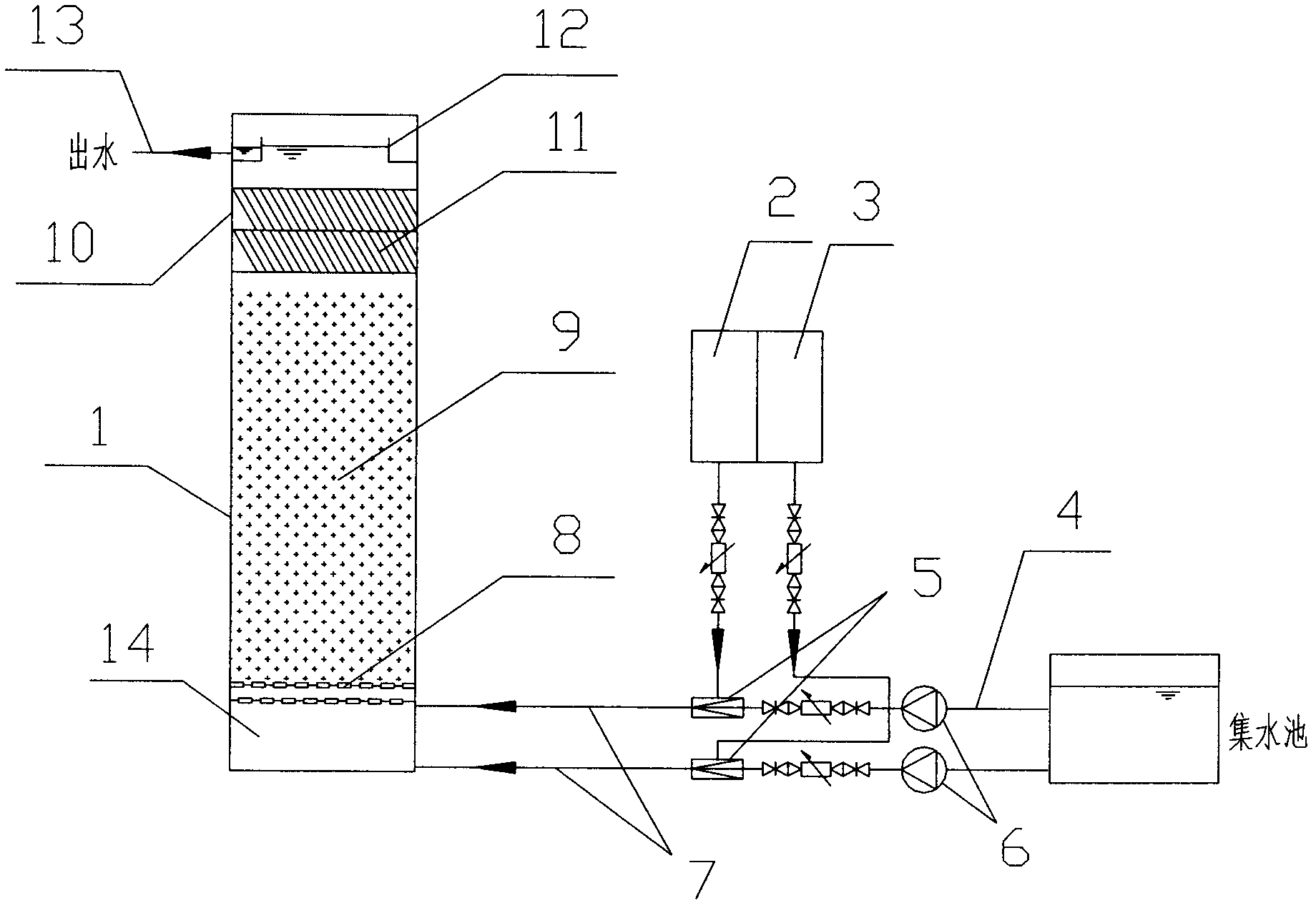

[0021] Example 1 An advanced oxidation device for treating refractory organic wastewater, the structure can refer to the attached figure 1 , mainly including Fenton oxidation tower 1, oxidant dosing system 2, and catalyst dosing system 3.

[0022] The Fenton oxidation tower 1 is the main device of the device, mainly including a water inlet system 4 , an inlet water mixing zone 14 , a water distribution system 8 , a fluidized bed reaction zone 9 and a water outlet system 10 . The water inlet system 4 is mainly composed of a water inlet pipe 7 , a multifunctional ejector 5 and a water inlet pump 6 . The multi-functional ejector 5 is arranged on the water inlet pipe 7, and the water inlet pipe 7 is connected with the bottom of the Fenton oxidation tower 1. The influent mixing zone 14 is located at the bottom of the Fenton oxidation tower 1; the water distribution system 8 is located in the upper part of the influent mixing zone 14 and consists of two layers of porous uniform wat...

Embodiment 2

[0027] Example 2 is an advanced oxidation device for treating refractory organic wastewater. The structure can refer to Example 1, but the difference from Example 1 is that the hole diameter of the porous uniform water distribution plate is 5mm. The particle size of quartz sand in the fluidized bed reaction zone is 3mm. The length of the inclined plate is 1000mm.

Embodiment 3

[0028] Example 3 is an advanced oxidation device for treating refractory organic wastewater. The structure can refer to Example 1, but the difference from Example 1 is that the hole diameter of the porous uniform water distribution plate is 2mm. The particle size of quartz sand in the fluidized bed reaction zone is 2 mm. The length of the inclined plate is 750mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com