Dual-hobbing-cutter screen net rapid side cutting forming device

A molding device and double-hob technology are applied to the online network, other household appliances, household appliances, etc., which can solve the problems of low production efficiency, high production cost, unfavorable environmental protection, etc., and achieve simple and reasonable structure, easy processing and manufacturing, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

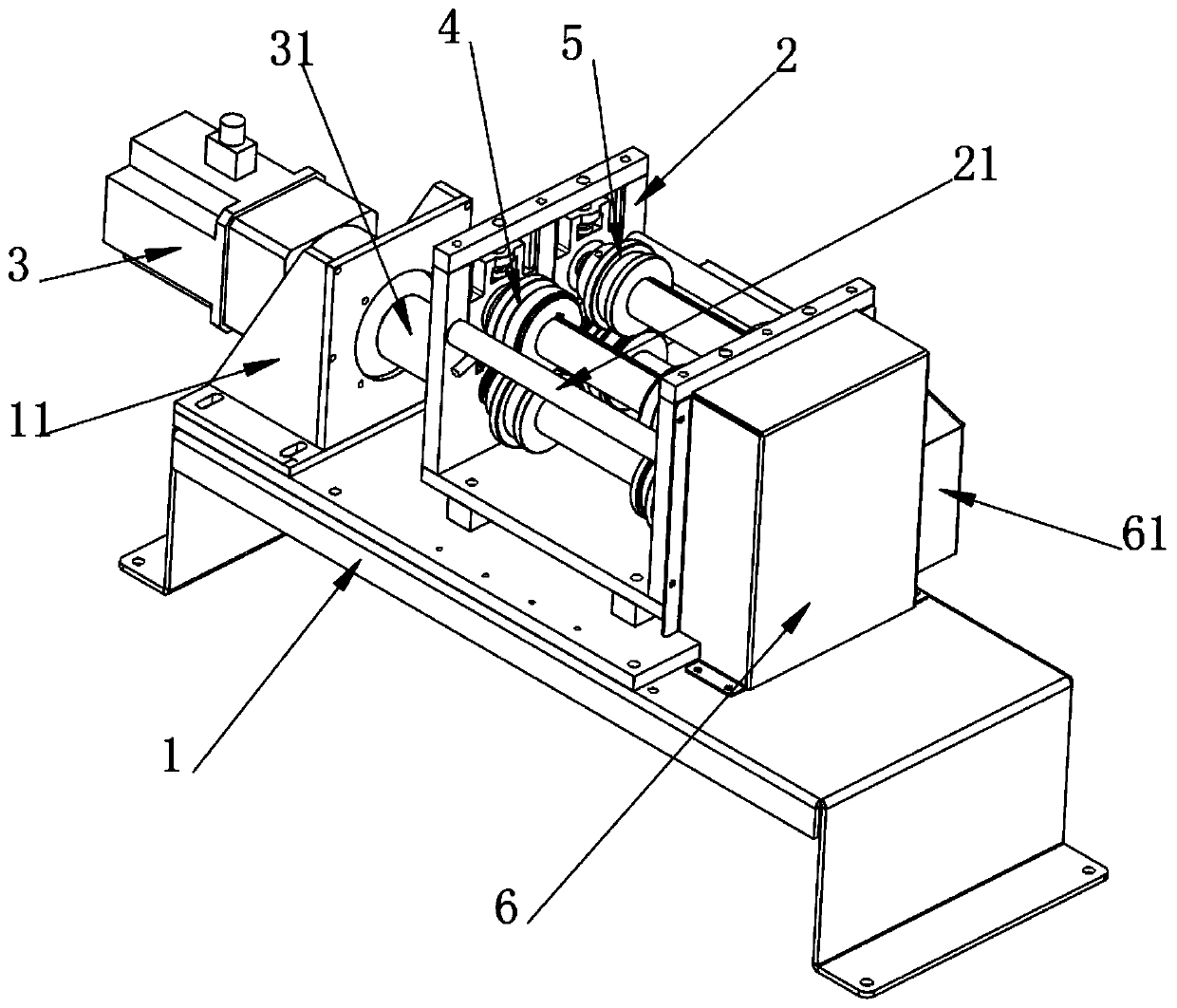

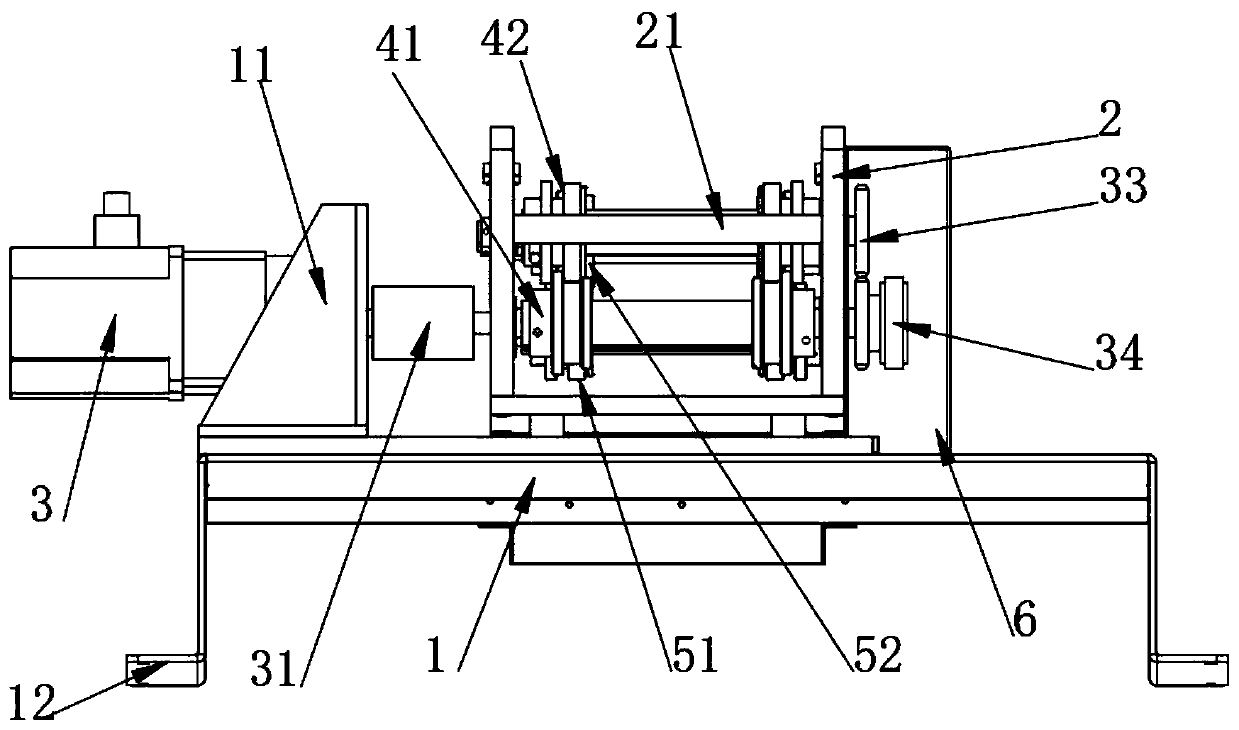

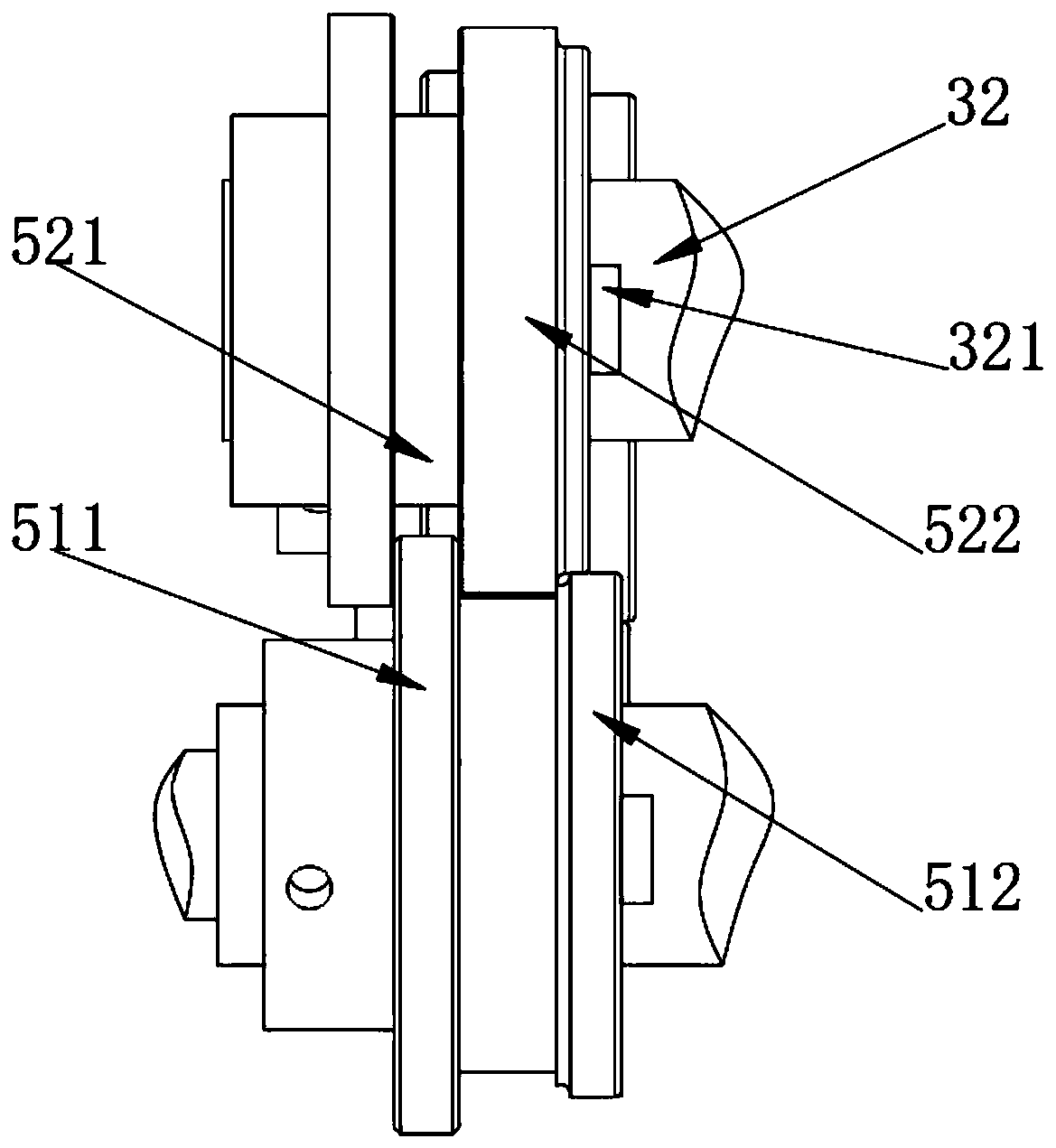

[0029] see Figure 1-3 , the present invention provides a technical solution: a double hob screen fast trimming forming device, including a base 1, a roller frame 2, a servo motor 3, a cutting wheel set 4, a correction wheel set 5 and a synchronous wheel guard 6 , the upper end surface of the base 1 is fixed with two roller frames 2 distributed in parallel, the servo motor 3 is located on one side of the roller frame 2, and the output end of the servo motor 3 is connected with four rollers 32, and the four rollers 32 Both are rotatably connected to the inner side of the roller frame 2, the cutting wheel group 4 is fixed on the two rollers 32 on the entrance side of the roller frame 2, and the correction wheel group 5 is fixed on the two rollers 32 on the exit side of the roller frame 2 .

[0030] In this embodiment, it is only necessary to drive the four rollers 32 to move through the servo motor 3, and to realize the simultaneous rotation of the four rollers 32 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com