Tire assembly line tail end manipulator arranging and collecting device

A collection device and manipulator technology, applied in mechanical conveyors, conveyors, conveyor objects, etc., can solve the problems of low production efficiency and low degree of automation, and achieve the effect of improving production efficiency, high degree of automation, and saving power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

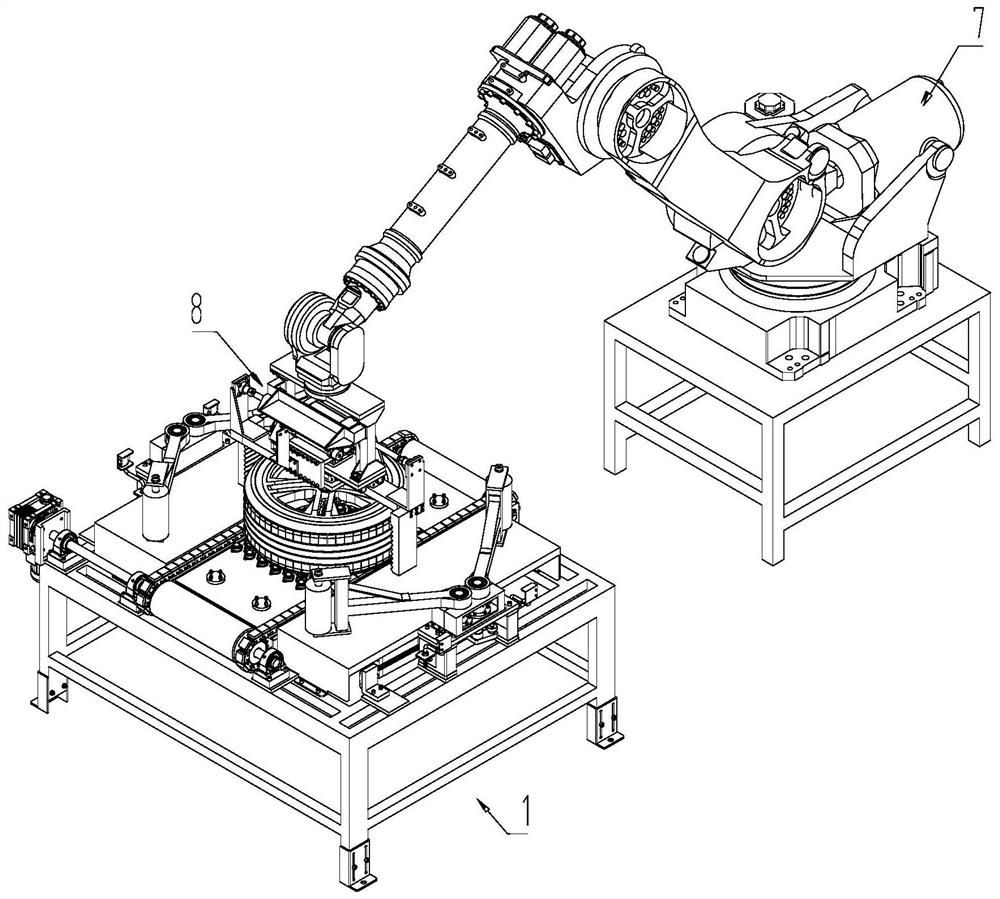

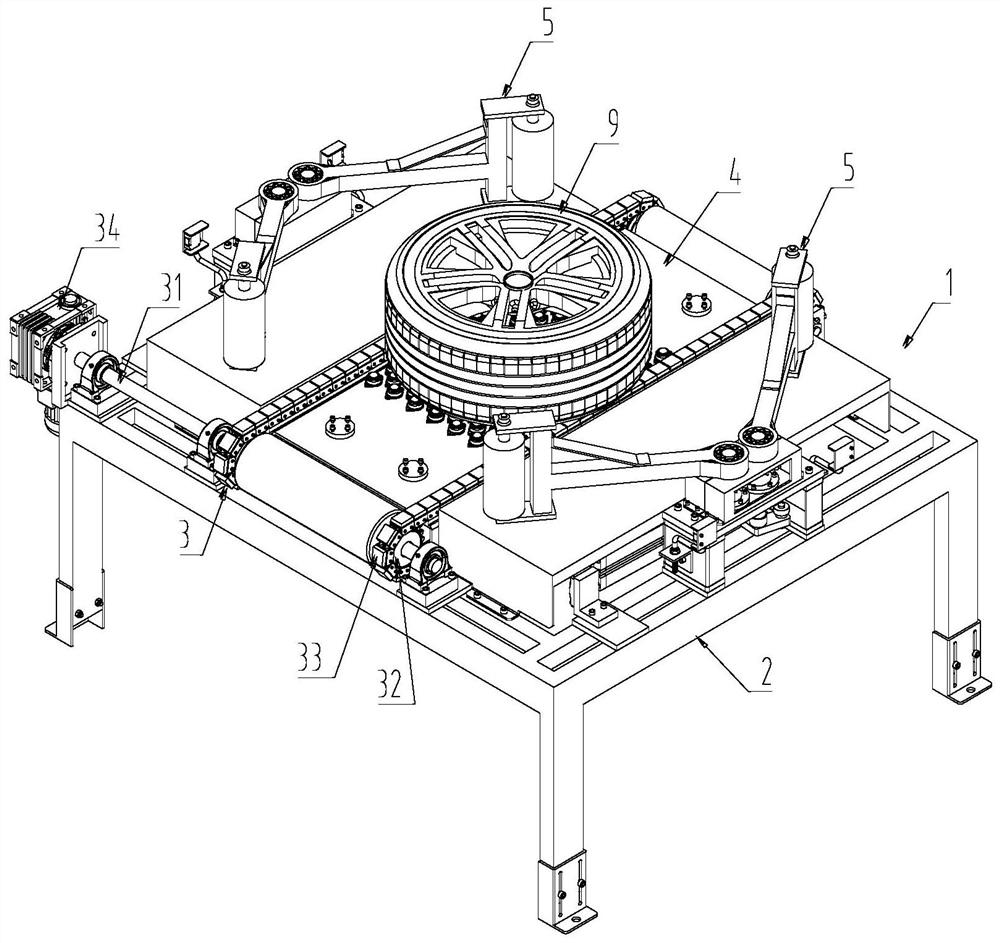

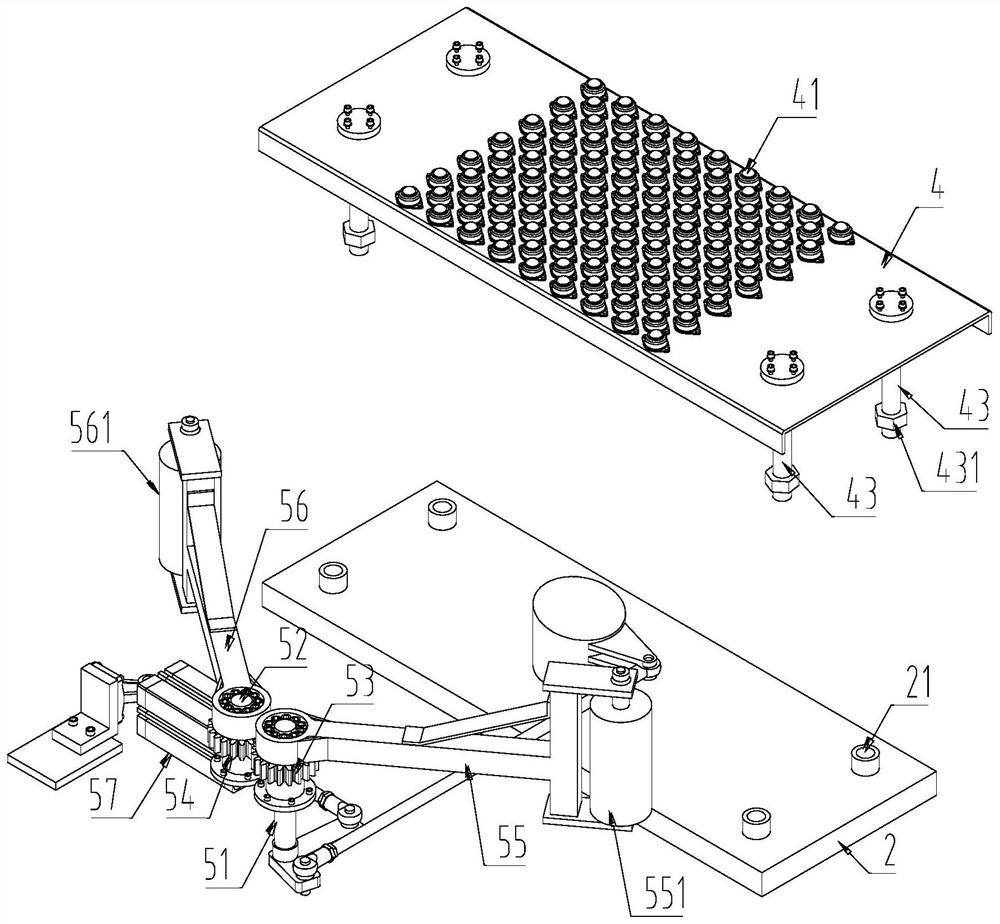

[0041] Embodiment: A sorting and collecting device for a manipulator at the end of a tire assembly line, such as figure 1 As shown, it includes a positioning workbench 1 and a manipulator 7. Such as figure 2 , image 3 , Figure 4 As shown, the positioning workbench 1 includes a support 2 , a conveying mechanism 3 disposed on the support 2 , a lifting platform 4 , and two positioning components 5 . The conveying mechanism 3 includes two conveying shafts 31 that are rotatably connected to the support 2, a conveying motor 34 that is installed on the support 2 to drive the conveying shaft 31 to rotate, four sprockets 32, two chains, and are fixed on the chain links of the chains. Two sprockets 32 are fixed on each conveying shaft 31. Each chain is sleeved on two sprockets 32 respectively. The conveying section 33 is made of plastic and is used for contacting with the wheel 9 . The lifting platform 4 is located between the two chains. A plurality of bull’s-eye ball bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com