Rail robot inspection system for top of aluminum oxide decomposing tank or settling tank

A technology of orbital robots and inspection systems, which is applied to manipulators, manufacturing tools, etc., and can solve problems such as low inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

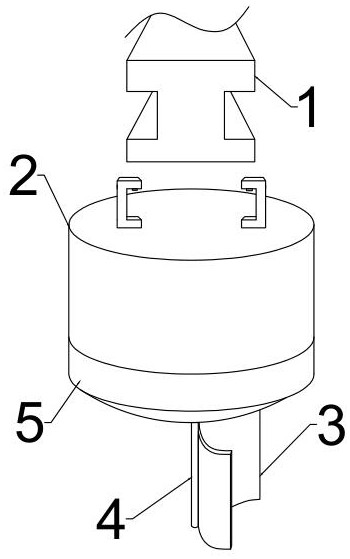

[0019] A rail robot inspection system for alumina decomposition tank or settlement tank top, including such as figure 1 The track 1 and the inspection robot 2 shown are erected on the top of the alumina decomposition tank or the settlement tank; the inspection robot is connected to the track, and inspects the alumina decomposition tank or the top of the settlement tank through the monitoring module, and is provided by the sail component power; in addition, it also includes a background server, which communicates wirelessly with the inspection robot and receives the obtained data.

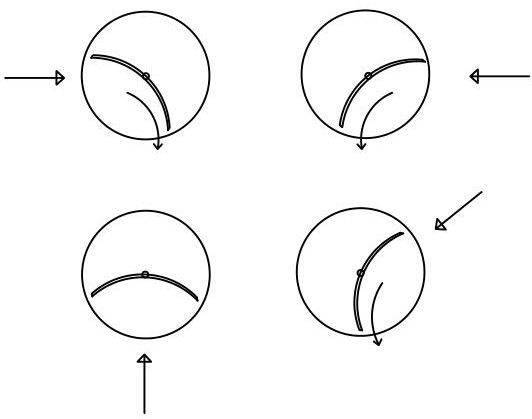

[0020] The inspection robot in this embodiment moves along the track and relies on the sail assembly for adjustment, making full use of the environmental characteristics of high-altitude operations. At the same time, because the track direction is fixed, the sail assembly does not need to consider the problem of lateral force balance, and the advantages of the sail assembly are maximized. Or rely on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com