Ink printing equipment

A technology of ink printing and equipment, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of affecting printing quality and insufficient absorption of substrates, and achieve the effect of ingenious structure, power saving, and avoiding particle protrusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

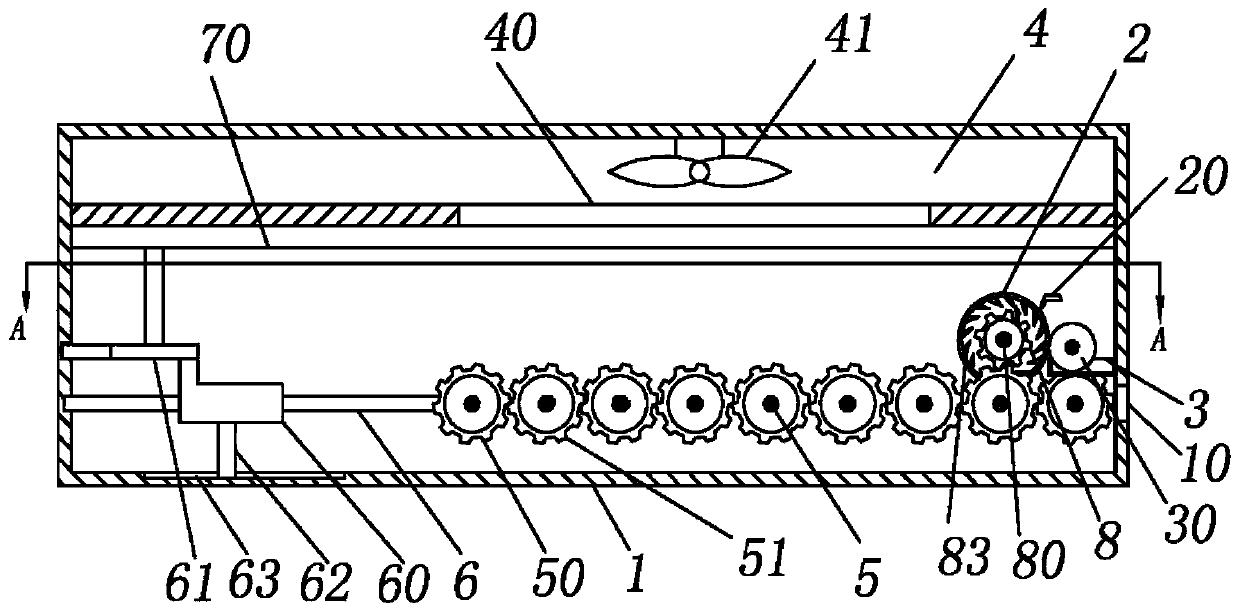

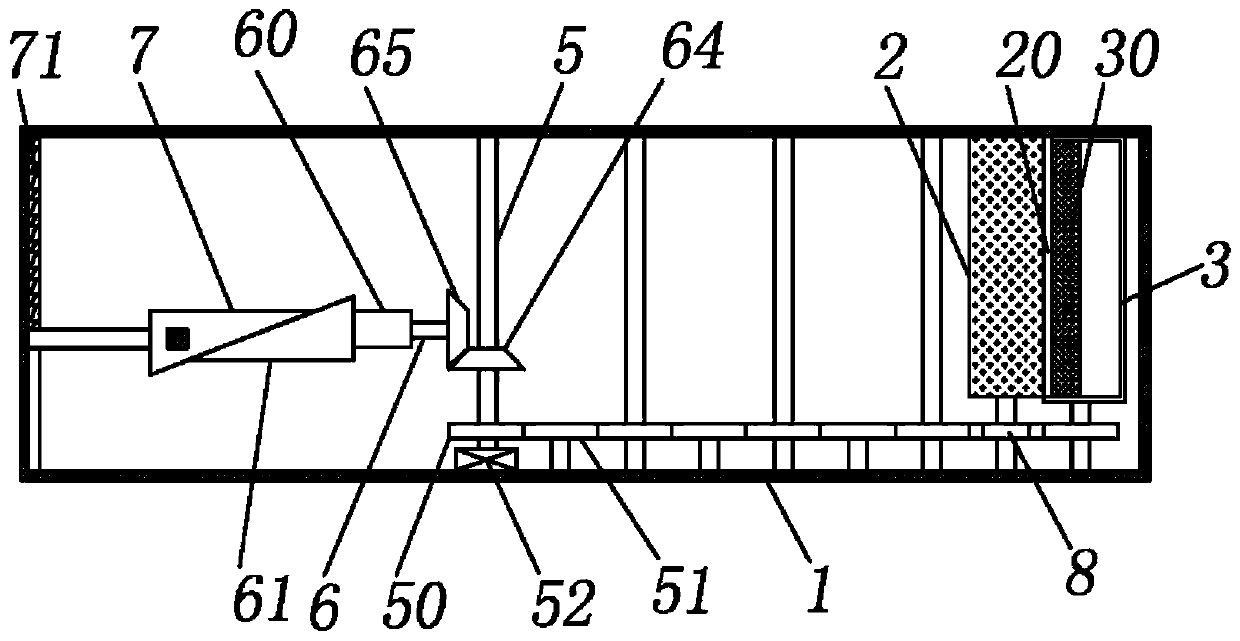

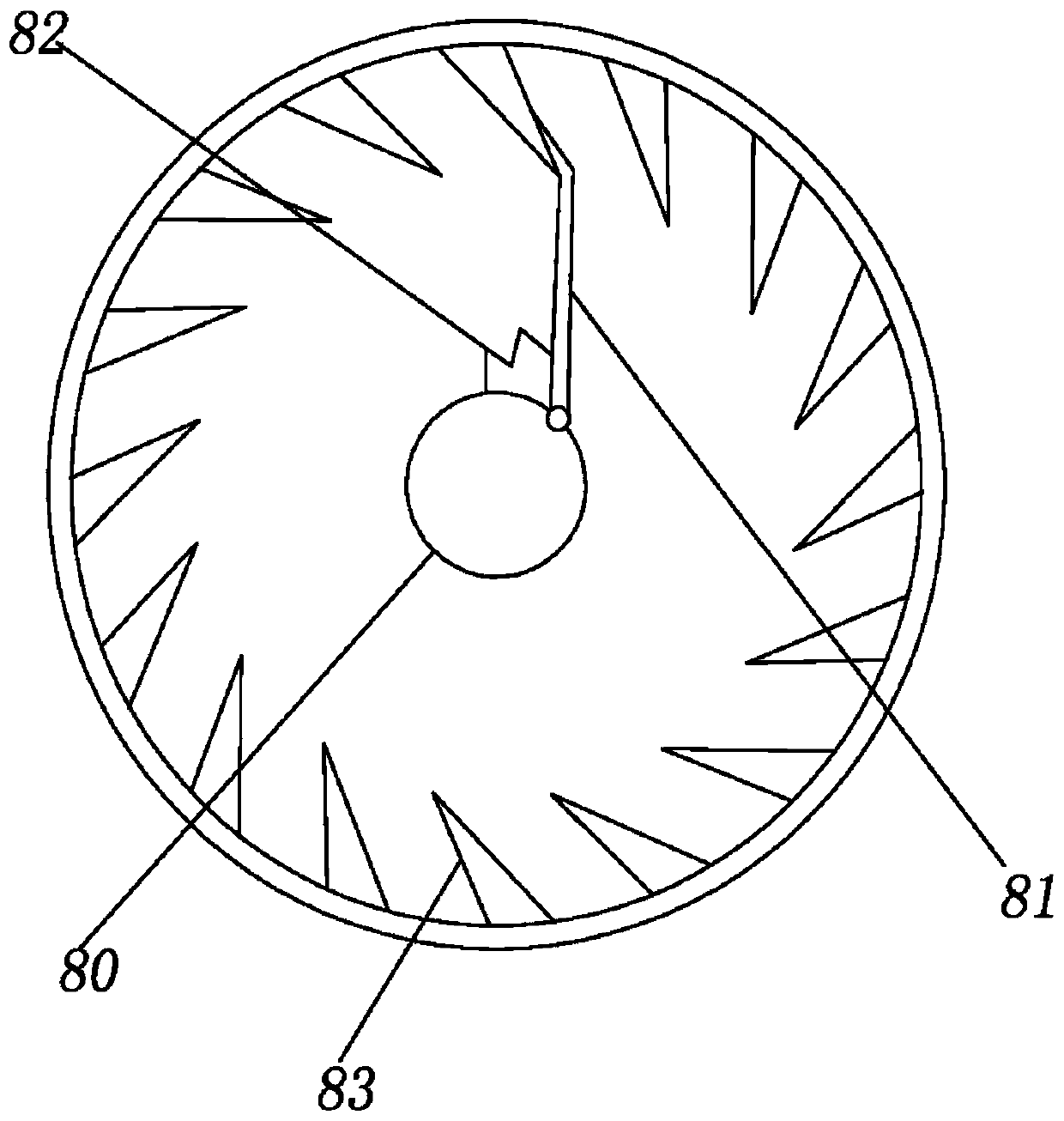

[0020] The reference signs in the accompanying drawings of the description include: frame 1, material inlet and outlet 10, impression cylinder 2, doctor blade 20, ink cartridge 3, ink absorption cylinder 30, solvent spray box 4, spray port 40, fan 41, transmission Roller 5, forward gear 50, reverse gear 51, motor 52, threaded rod 6, threaded cylinder 60, wedge 1 61, sliding shaft 62, chute 63, driving bevel gear 64, driven bevel gear 65, wedge Two 7, cover plate 70, stage clip 71, drum gear 8, rotating shaft 80, ratchet 81, extension spring 82, ratchet 83.

[0021] The embodiment is basically as figure 1 Shown: ink printing equipment, including a frame 1, which is equipped with an impression cylinder 2, an ink cartridge 3, a motor 52, a transmission mechanism, a translation mechanism, a capping mechanism and a solvent spray box 4.

[0022] The embossing cylinder 2 is hollow and ring-shaped, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com