Volatilization drying type printing method

A printing method and drying technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems that the substrate does not fully absorb ink, the particle protrusion affects the printing quality, etc., achieves ingenious structure, saves power devices, avoids The effect of raised particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The volatilization and drying type printing method comprises the following steps:

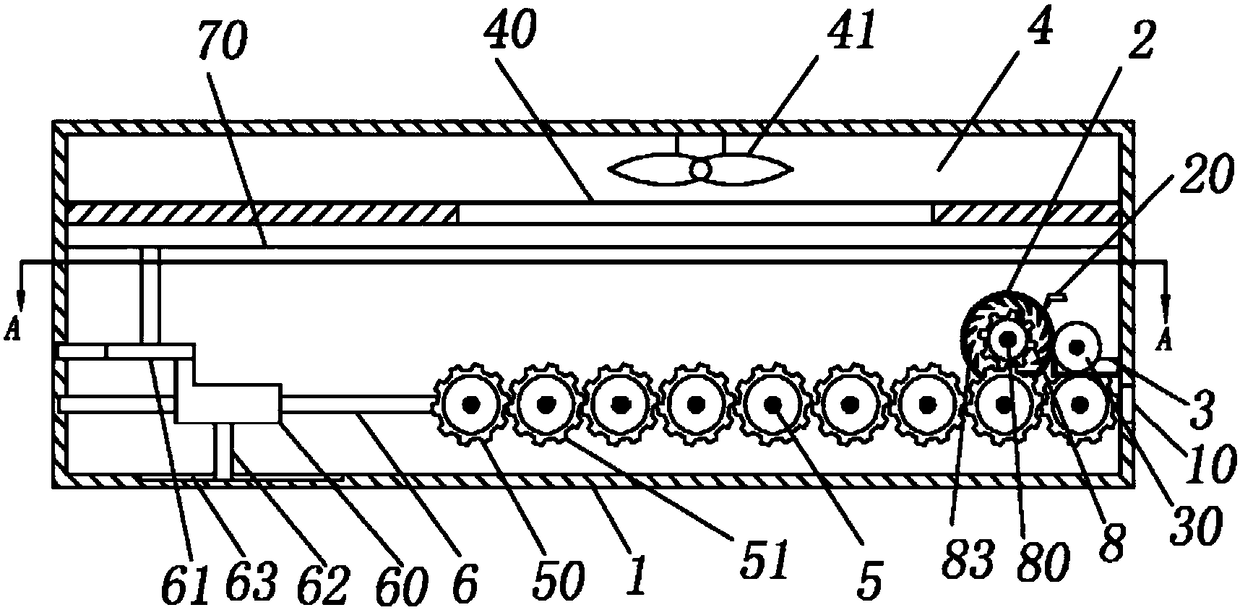

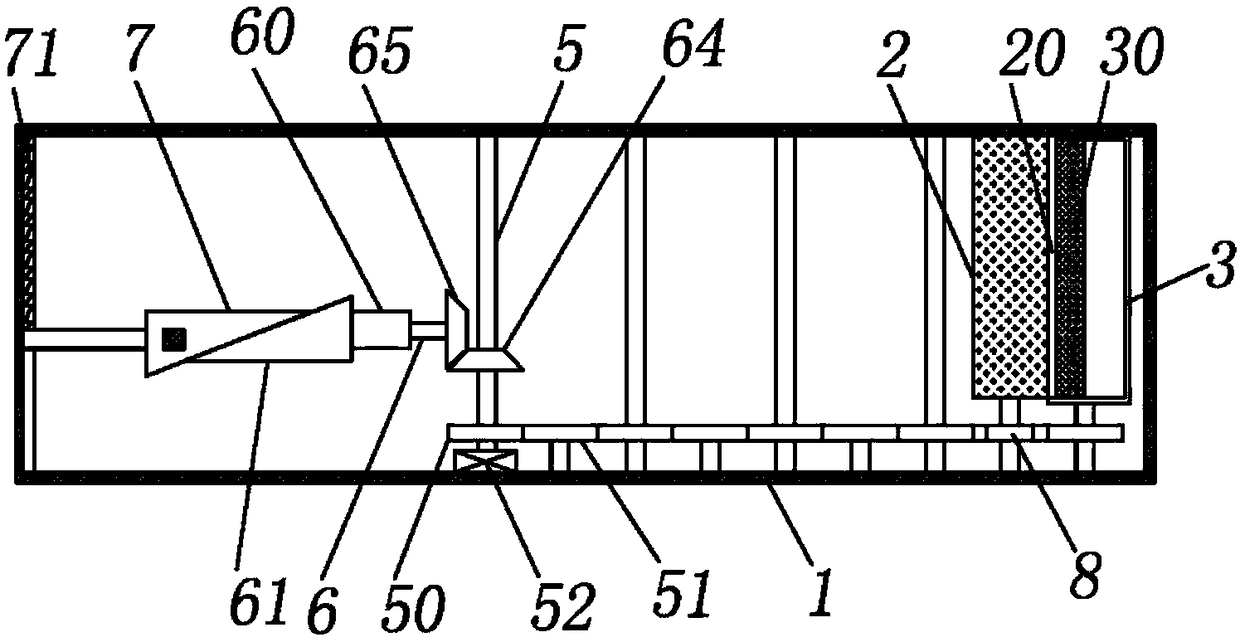

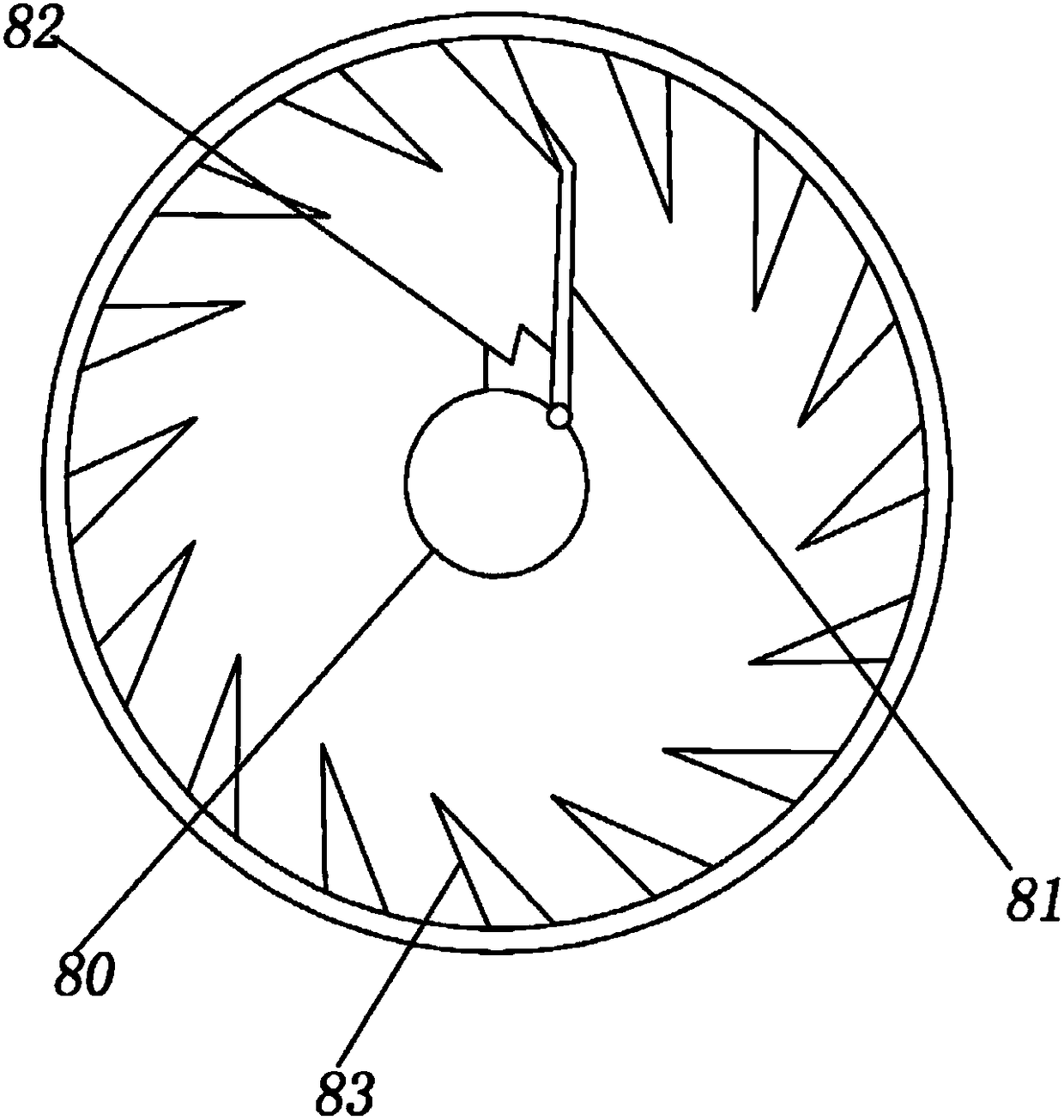

[0027] Step 1, printing preparation: prepare a frame 1, install a solvent spray box 4 in the frame 1, and pass solvent vapor isopropanol into the solvent spray box 4, and install some transfer rollers 5 below the solvent spray box 4 A translation mechanism that utilizes the rotation of the transmission roller 5 to carry out reciprocating translation is installed on one side of the transmission roller 5, and an inking mechanism that utilizes the rotation of the transmission roller 5 to perform intermittent ink coating is installed on the other side of the transmission roller 5. The inking mechanism includes The embossing cylinder 2 and the ink cartridge 3 are installed on the top of the conveying roller 5 and use a translation mechanism to intermittently open and close the covering mechanism of the solvent spray box 4 .

[0028] Specific as figure 1 As shown: the embossing cylinder 2 is ...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] Ink in step 3 comprises 20kg linking material by mass, 10kg pigment, 80kg organic solvent, 5kg manganese dry oil and 8kg menthol; Linkage comprises 15kg epoxy resin and 5kg polyester resin by mass;

[0040] In step 4, the drying temperature is 55°C;

[0041] The air-drying wind speed in the step 5 is 2.5m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com