Construction machinery used for large diameter hollow pile and its construction method and use

A technology of construction machinery and construction methods, which is applied to drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., and can solve the problem of driving prefabricated piles with pile diameter, limited pile length, limited load force, and slow hole forming speed, etc. problem, achieve the effect of overcoming the Achilles' heel and improving the end bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

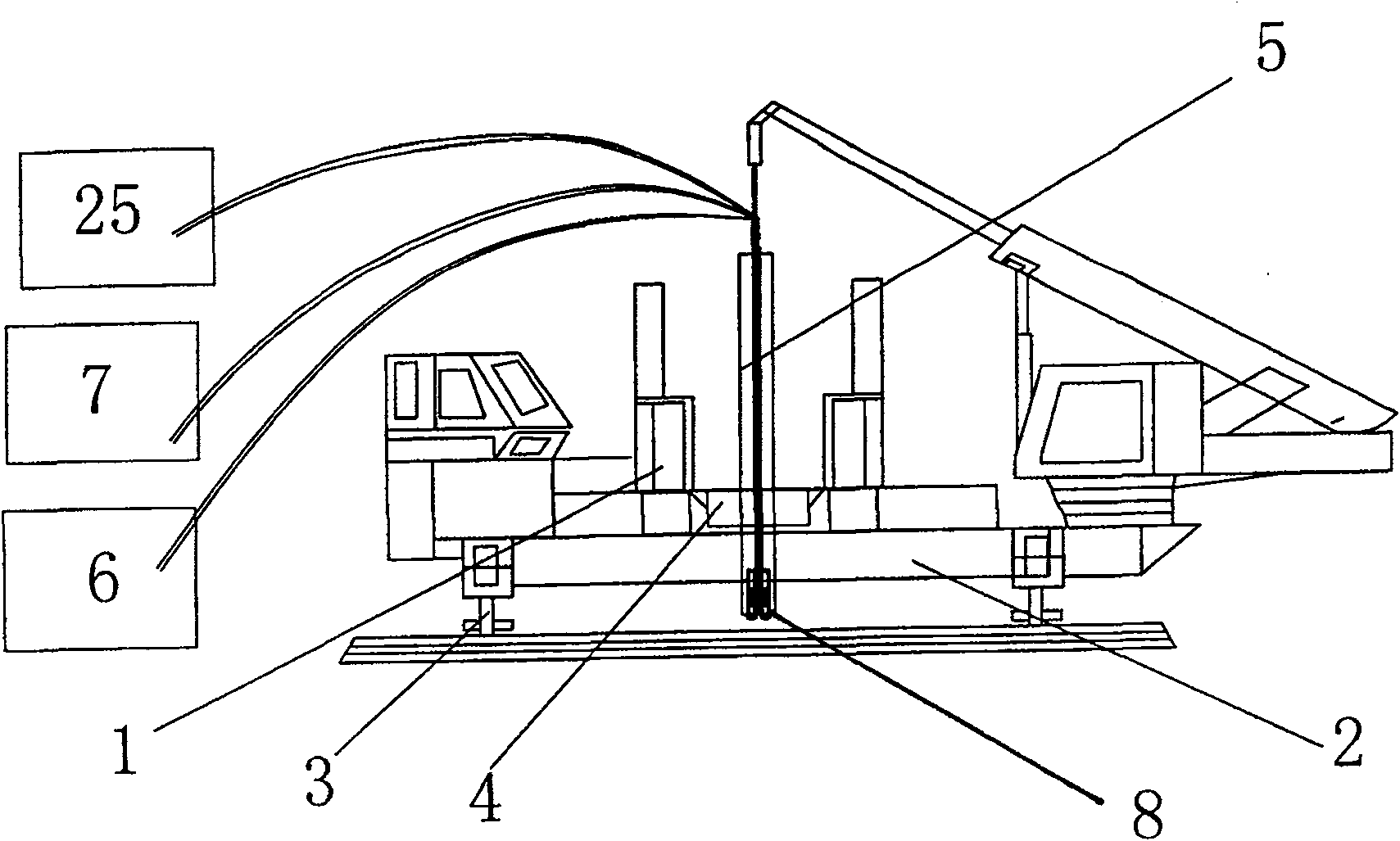

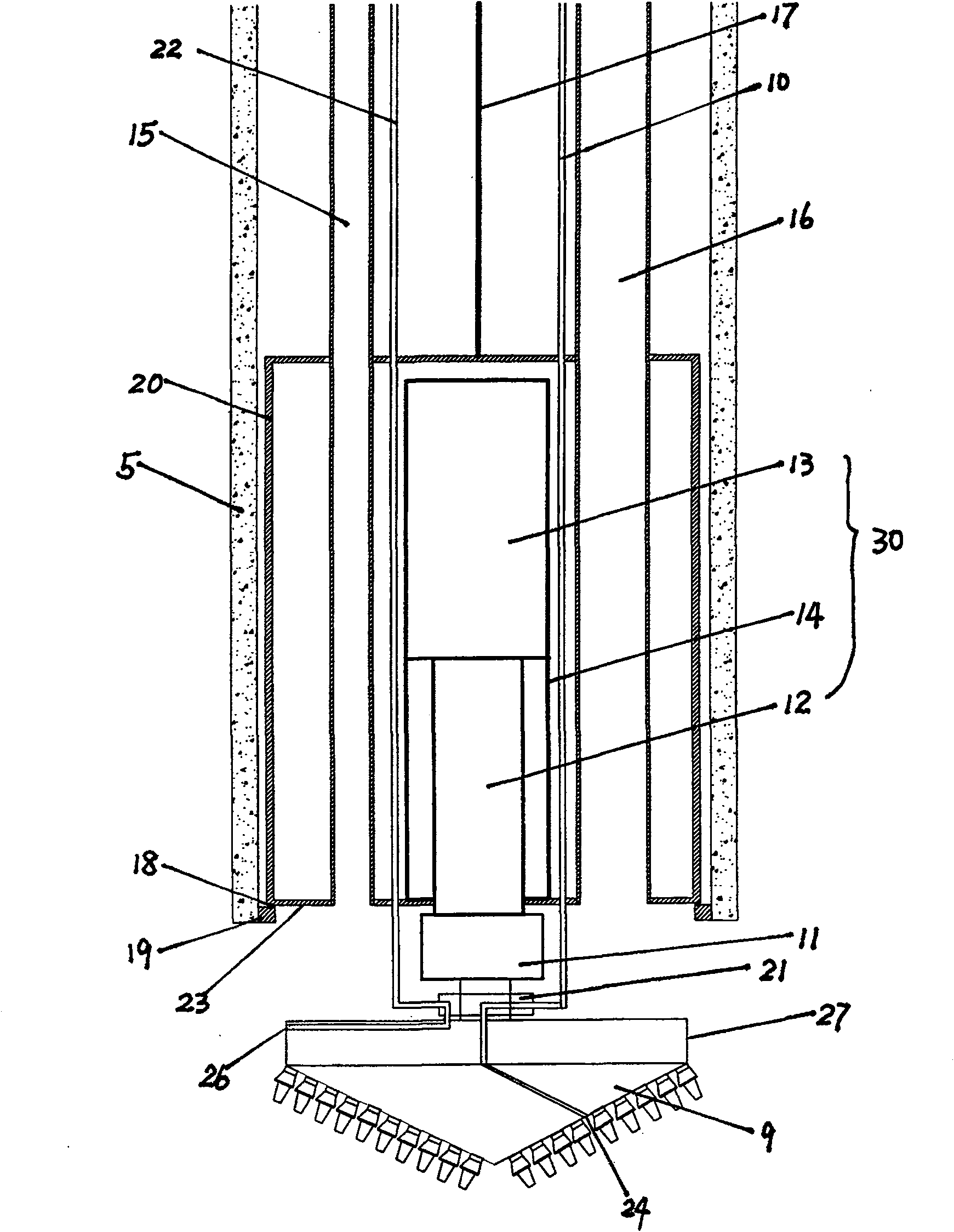

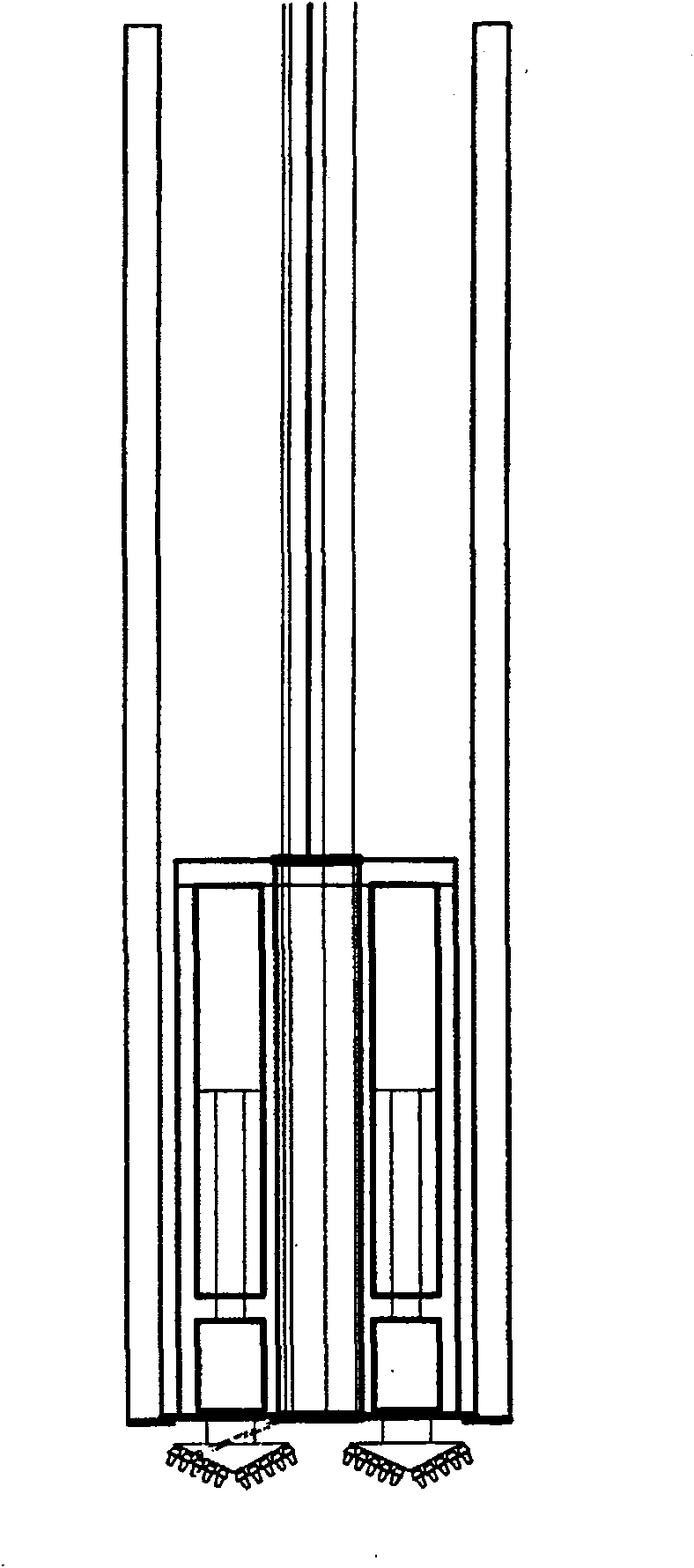

[0035] Below in conjunction with accompanying drawing, the specific implementation of equipment and working method of the present invention is described in detail:

[0036] Such as figure 1 , 2 As shown, the construction machinery for large-diameter hollow piles of the present invention includes a drilling system, an injection system, and a pile pressing system. The drilling system includes a drill bit 9 with a high-jet water injection device, and a drill power unit 11 , drill bit walking drilling device 30, a cylindrical retaining ring 27 integrally formed at the top of the drill bit and the drill bit; the pile pressing system includes a hoisting device 17, a pile driver moving device 3, and a pile pressing device; the drainage system Including high jet flow water injection device 6, concrete injection device 25 and slurry discharge pipe 15; fixed box 20 is fixed in the inner cavity of the drilling end of hollow pile 5, the upper end of fixed box 20 is connected with hoistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com