Removal device and method after locking of precast pile in pile sinking process

A prefabricated pile and pile driving technology, which is used in sheet pile wall, soil protection, infrastructure engineering and other directions, can solve the problems such as the inability of the pile body to be driven again and the increase of the cohesive force, so as to reduce waste piles and waste pile disposal. The effect of increasing the lateral friction resistance and improving the bearing capacity of the pile foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments.

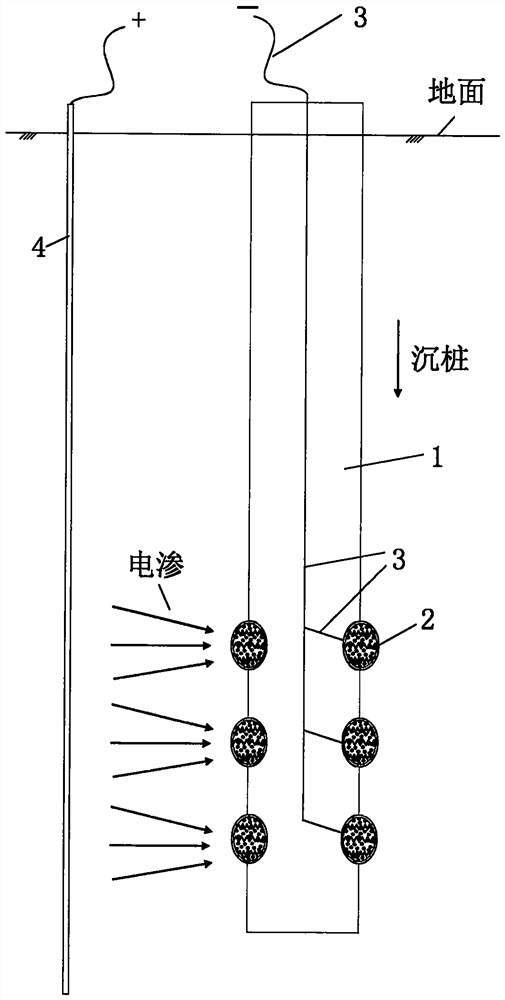

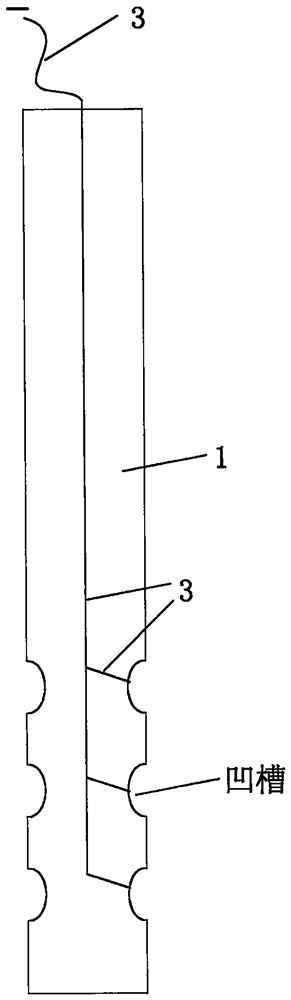

[0030] like figure 1 and figure 2 As shown in the figure, the device and method for getting rid of prefabricated piles after they are locked during the pile driving process, including prefabricated piles 1, sponge 2, wires 3, and steel plates 4;

[0031] When the prefabricated pile 1 is made, 2 to 5 annular grooves with a depth of 1 to 2 cm and a width of 6 to 8 cm are reserved at the lower end of the pile body; wires are embedded in the prefabricated pile 1 to allow the sponge body 2 to pass through. Wire 3 is connected to an external DC power supply, such as figure 2 shown;

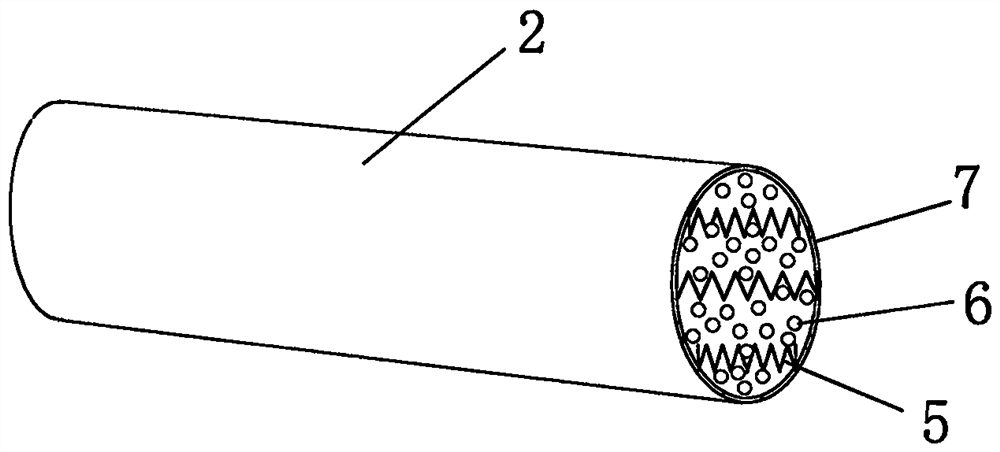

[0032] The inside of the sponge body 2 is filled with water-absorbing resin 6, the outside is wrapped by a fine wire mesh 7, and the middle is supported by a spring 5, which allows the sponge body to compress or expand and deform, such as: image 3 shown;

[0033] The sponge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com