Production equipment for electric meter

A technology for production equipment and electric meters, applied in cleaning methods using tools, cleaning methods using liquids, loose filter material filters, etc., can solve problems such as cumbersome operation, poor cleaning effect, waste of resources, etc., and achieve simplified operation The effect of less process and power devices and faster efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

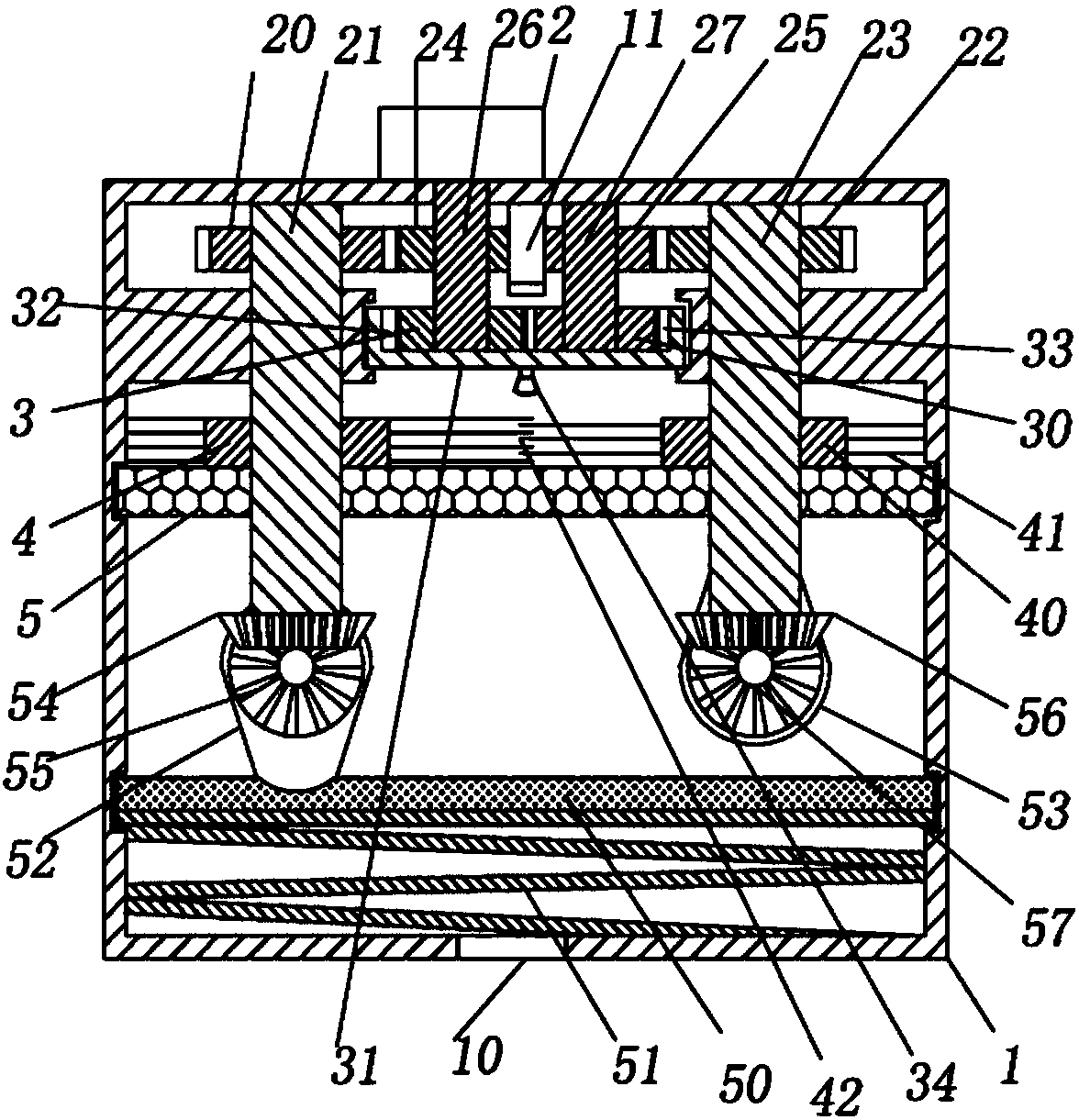

[0021] The reference signs in the accompanying drawings of the specification include: chassis 1, liquid outlet 10, alcohol nozzle 11; motor 2, left gear 20, left shaft 21, right gear 22, right shaft 23, central gear 1 24, central gear 2 25 , central shaft one 26, central shaft two 27; feeding gear one 3, feeding gear two 30, feeding plate 31, feeding rack one 32, feeding rack two 33, fixture 34; left turntable 4, right turntable 40, Cleaning soft brush 41, cleaning area 42; leaking plate 5, sponge layer 50, activated carbon filter layer 51, left cam 52, right cam 53, left bevel gear 1 54, left bevel gear 2 55, right bevel gear 1 56, right bevel Gears II: 57.

[0022] The embodiment is basically as attached figure 1 Shown: the production equipment of the electric meter, including the chassis 1, the transmission mechanism, the feeding mechanism, the cleaning mechanism and the filtering mechanism....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com