Refractory material baking crystallizer casting powder drying device and method

A technology for mold slag and drying equipment, which is applied in drying, drying machine, and preliminary treatment for promoting the drying of solid materials, etc., can solve the problems of insufficient utilization, high production cost, and high energy consumption, and reduce power units , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

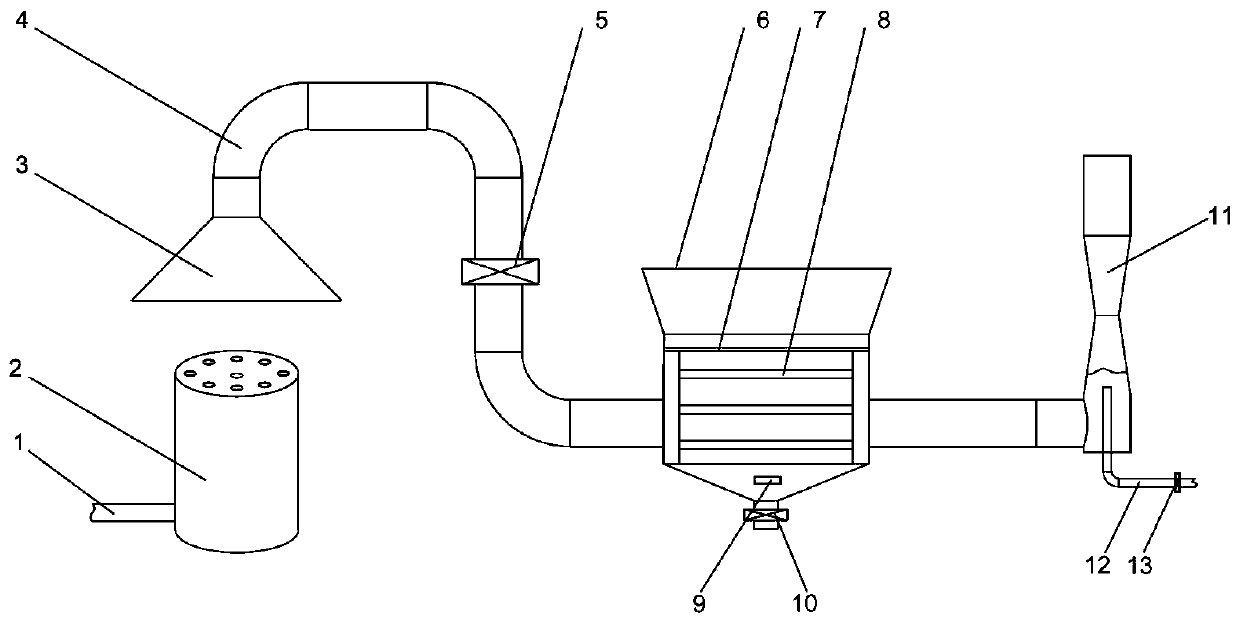

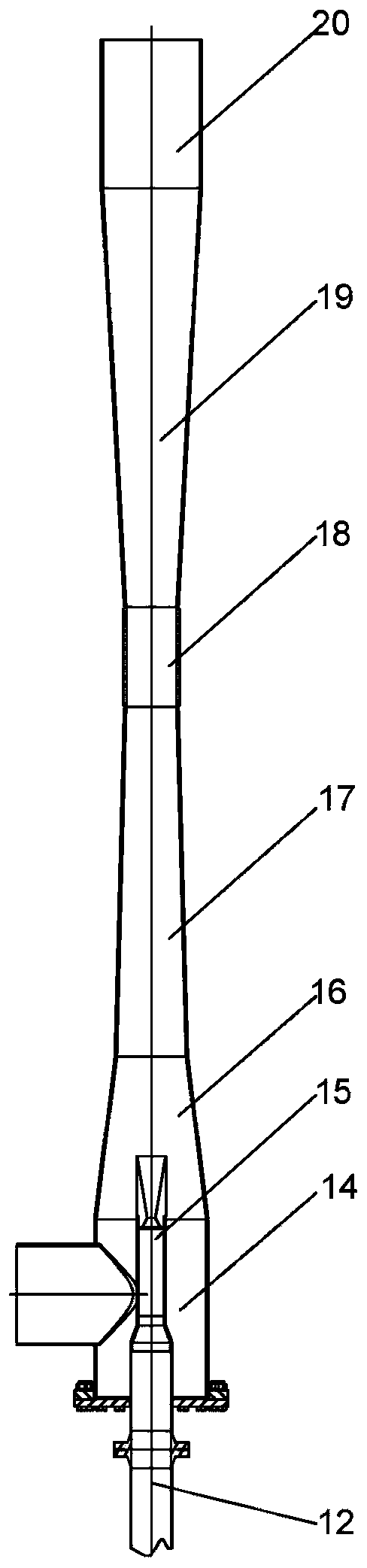

[0031] combine figure 1 , figure 2 As shown, the present invention provides a preferred embodiment of a mold flux drying equipment for refractory baking crystallizers, including a roaster 2, a gas collection device, a drying device, a venturi suction device 11, and the roaster 2 is used for For refractory baking, the gas collection device is used to collect the hot air from the roaster 2. The gas collection device includes an intermediate pipe 4 for transmitting hot air. The intermediate pipe 4 provides the drying heat source for the drying device. The venturi exhaust device 11 is used To provide the suction power of the gas collection device.

[0032] The drying proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com