Needle detecting device and detecting method

A technology of needle detection, detection and shooting, which is applied in the field of automatic intelligent needle detection devices, can solve problems such as single function, inability to realize automatic feeding, automatic material picking and automatic receiving, detection accuracy and detection efficiency that cannot meet expectations, etc., to achieve High detection accuracy, high-speed synchronous detection, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings.

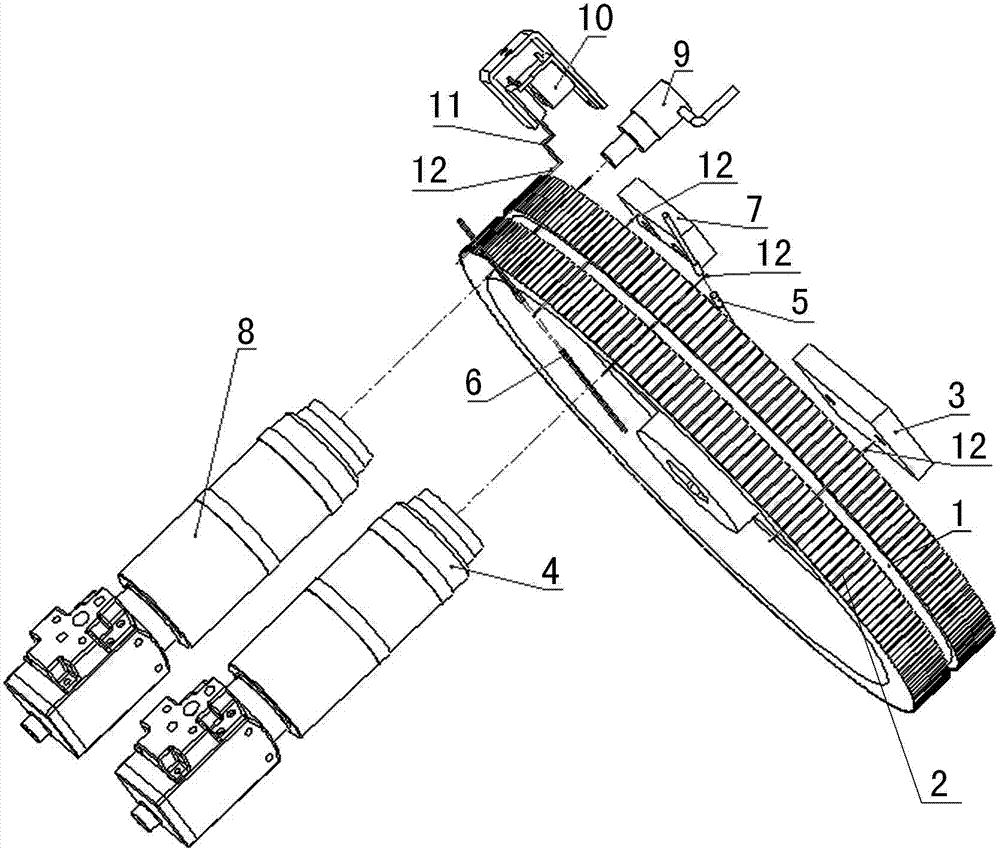

[0024] The present invention is a needle detection device, which is different from the prior art in that: the needle detection device is provided with a feeding turntable 1, and the outer surface of the feeding turntable 1 is axially equidistantly distributed with a number of needle grooves 2, and the feeding turntable 1 On the outer side, along the outer edge of the feeding turntable, there are successively provided a waste rejecting mechanism, a needle tube unclogging inspection mechanism, a needle tube total length inspection mechanism, a cutting edge detection mechanism, and a needle detection guide positioning block 3. The cutting edge detection mechanism is located on the feeding turntable 1 The edge detection camera unit 4 on one side of the edge and the fiber sensor 5 located on the other side of the edge of the feeding carousel 1 are composed. The detection beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com